Anchor cable seat

An anchor cable seat, anchor cable technology, applied in the direction of anchoring processing/binding, ship parts, transportation and packaging, etc., can solve the problems of low anchor cable gravity, hull damage, small manual operation range, etc., and achieve fast cable guiding speed , The effect of strong anti-friction ability and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is further described below in conjunction with accompanying drawing:

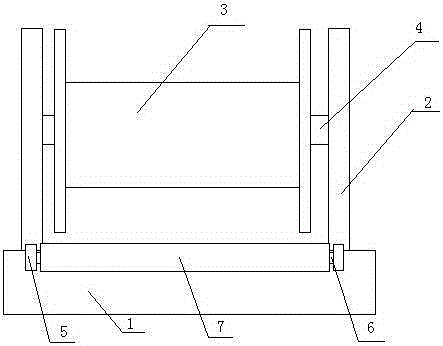

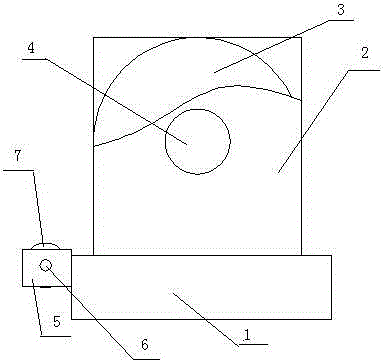

[0012] As shown in the accompanying drawings, an anchor cable seat is composed of an anchor cable base 1, an anchor cable support 2 and an anchor cable roll 3. The left and right sides of the anchor cable base 1 are respectively provided with anchor cable supports. 2. There is an anchor cable roll 3 between the left anchor cable support 2 and the right anchor cable support 2, and the anchor cable roll 3 is connected to the hydraulic cylinder through the drive shaft 4. It is characterized in that the left anchor cable support 2 The anchor cable base 1 between the anchor cable bracket 2 on the right side is provided with a cable roller consisting of a support bracket 5, a cross arm 6 and a casing 7, and the support bracket 5 is located on the anchor cable bracket 2 On the anchor cable base 1 between them, the two ends of the cross arm 6 are respectively connected with the left sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com