Perfluoropolyether type lubricating grease of composite thickening agent and preparation method of perfluoropolyether type lubricating grease

A technology of perfluoropolyether and perfluoropolyether oil, which is applied in lubricating compositions, petroleum industry, etc., can solve the problems of low volatility, complex process, and needs to be further improved, and achieve excellent anti-friction performance and simple preparation method Ease of handling and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

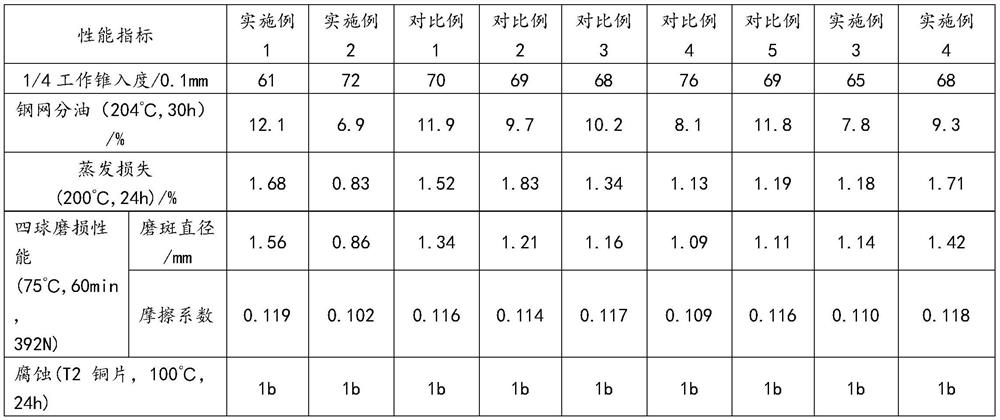

Examples

Embodiment 1

[0049] (1) Put 20g of bentonite additive and 650g of perfluoropolyether oil in a mixer, start stirring for 1h, and the stirring speed is 1000r / min, and the obtained mixture is ultrasonicated in a water bath ultrasonicator, the ultrasonic temperature is 70°C, and the ultrasonic time is 1h, to obtain a homogeneous mixture;

[0050](2) Place 220g of chlorotrifluoroethylene-polyethylene copolymer (particle size 20μm) and 110g tetrafluoroethylene-hexafluoropropylene copolymer (particle size 0.06μm) in another stirrer, start stirring for 0.5h, and stir The speed is 1000r / min, mixed to form a composite thickener;

[0051] (3) Add the compound thickener obtained in (2) to the mixture obtained in step (1) and continue to stir for 1 hour at room temperature at a stirring speed of 1000r / min. Stir to obtain a homogeneous mixture and ultrasonicate it in a water bath ultrasonicator at a temperature of 50°C , Ultrasonic 1h.

[0052] (4) Place the mixture after ultrasonication in a three-ro...

Embodiment 2

[0054] (1) Put 30g of silicon dioxide additive and 700g of perfluoropolyether oil in a mixer, start stirring for 2 hours, the stirring speed is 1500r / min, the obtained mixture is ultrasonicated in a water bath ultrasonicator, the ultrasonic temperature is 70°C, ultrasonic Time is 2h, obtains homogeneous mixture;

[0055] (2) Place 180g polytetrafluoroethylene (particle size 1μm) and 90g tetrafluoroethylene-hexafluoropropylene copolymer (particle size 0.05μm) in another stirrer, start stirring for 1h, and the stirring speed is 1500r / min, Mix to form a compound thickener;

[0056] (3) Add the compound thickener obtained in (2) to the mixture obtained in step (1) and continue to stir for 2 hours at room temperature at a stirring speed of 1500r / min. Stir to obtain a homogeneous mixture and ultrasonicate in a water bath ultrasonicator at a temperature of 50°C , ultrasonic 2h.

[0057] (4) Place the mixture after ultrasonication in a three-roll mill and grind it repeatedly 4 times...

Embodiment 3

[0082] (1) Put 20g of silicon dioxide additive and 600g of perfluoropolyether oil in a mixer, start stirring for 1.5h, the stirring speed is 1000r / min, the obtained mixture is ultrasonicated in a water bath ultrasonicator, the ultrasonic temperature is 70°C, Ultrasonic time is 2h to obtain a homogeneous mixture;

[0083] (2) Put 253g polytetrafluoroethylene (particle size 1μm) and 127g tetrafluoroethylene-hexafluoropropylene copolymer (particle size 0.05μm) in another stirrer, start stirring for 1.5h, and the stirring speed is 1000r / min , mixed to form a composite thickener;

[0084] (3) Add the compound thickener obtained in (2) to the mixture obtained in step (1) and continue to stir for 1.5h. The stirring speed at room temperature is 1000r / min. Stir to obtain a homogeneous mixture and ultrasonicate it in a water bath ultrasonicator. The ultrasonic temperature is 70 ℃, ultrasonic for 1h.

[0085] (4) Place the mixture after ultrasonication in a three-roll mill and grind it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com