Preparation method of mechanically fertilized controlled-release fertilizer special for winter wheat

A technology of controlled-release fertilizer and special machine, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of brittleness, poor particle uniformity, poor toughness and anti-friction ability, etc., and achieve the effect of improving surface characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

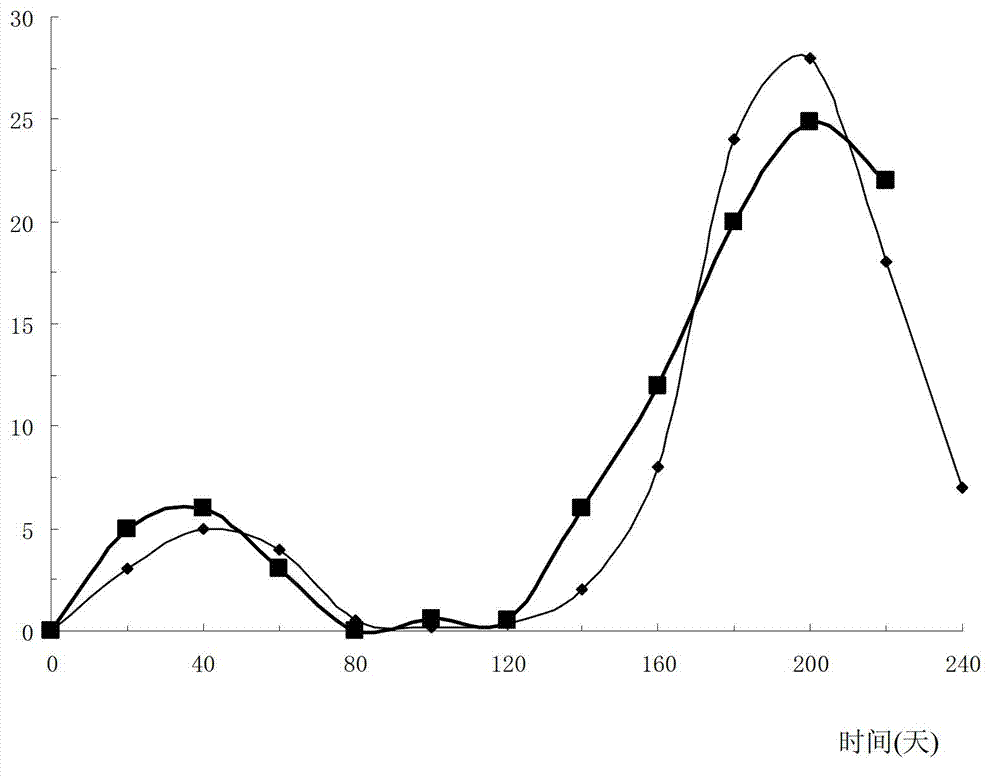

Image

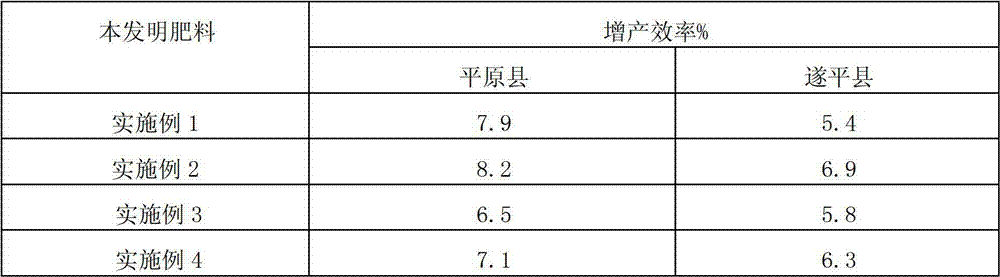

Examples

Embodiment Construction

[0011] The preparation method of winter wheat special-purpose machine-applied controlled-release fertilizer, the steps are as follows:

[0012] (1) Preparation of core fertilizer

[0013] Take urea, monoammonium phosphate, potassium chloride and zinc sulfate according to the mass ratio 1: (0.5~0.8): (0.2~0.45): (0.015~0.025), mix them evenly, and make granules according to the prior art high tower granulation The compound fertilizer is sieved, and the granular fertilizer with a particle size of 2-4 mm is selected as the core fertilizer for future use.

[0014] (2) Preparation of bottom urea-coated fertilizer

[0015] Preheat the core fertilizer in step (1) to 40°C to 50°C in the drum, and spray the molten urea solution at 125°C on the continuously rotating core fertilizer particles in the drum to form a urea film. The mass accounts for 4~7wt% of the mass of the core fertilizer to obtain a urea-coated fertilizer;

[0016] (3) Preparation of outer membrane coating agent

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com