Acrylic ester powdered resin having self-cleaning property and synthesizing method thereof

A powder resin and acrylate technology, applied in powder coatings, coatings, etc., can solve problems such as anti-friction, high and low temperature resistance, and self-cleaning defects, and achieve a wide range of high and low temperature applicability, excellent weather resistance, and good abrasion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

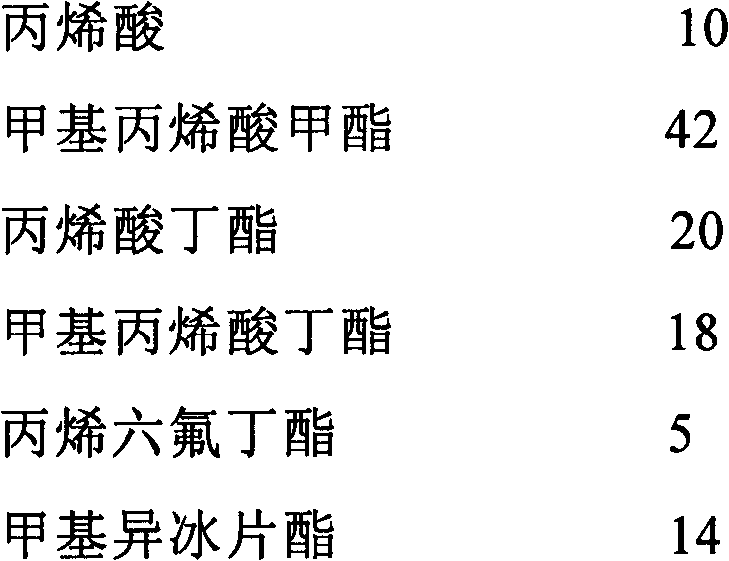

[0041] Prepare materials by weight:

[0042]

[0043]

[0044] Put 100 parts of ethanol into the reactor with condensation back, mix the monomers evenly and add them to the dropping device, and add 1.8 parts of initiator to the dropping device with 20 parts of ethanol solvent. Heat the ethanol in the reactor to 72°C, feed nitrogen gas, start to drop the monomer solution and initiator solution, control the flow rate, control the monomer solution within 3-3.5h to complete the dropwise addition, and control the initiator solution at 4-4.5 After the dropwise addition of h, the reaction was incubated at 75° C. for one hour. The obtained resin solution is vacuum degassed to recover the solvent, cooled and pulverized to obtain powdered resin.

Embodiment 2

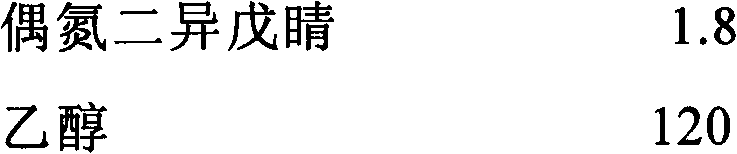

[0046] Prepare materials by weight:

[0047]

[0048] Put 120 parts of ethanol into the reactor with condensation back, mix the monomers evenly and add them to the dropping device, and add 1.6 parts of initiator to the dropping device with 30 parts of ethanol solvent. Heat the ethanol in the reactor to 60-65°C, feed nitrogen gas, start to drop the monomer solution and initiator solution, control the flow rate, control the monomer solution within 3-3.5h to complete the dropwise addition, and control the initiator solution at 4 ~4.5h after the dropwise addition, keep the reaction at 62°C for one hour. The obtained resin solution is vacuum degassed to recover the solvent, cooled and pulverized to obtain powdered resin.

[0049] The specific synthesis process refers to Example 1, the difference is that the reaction temperature should be lowered to 60-65° C., because the initiation temperature of azobisisoheptylnitrile is lower than that of azobisisoheptylnitrile.

Embodiment 3

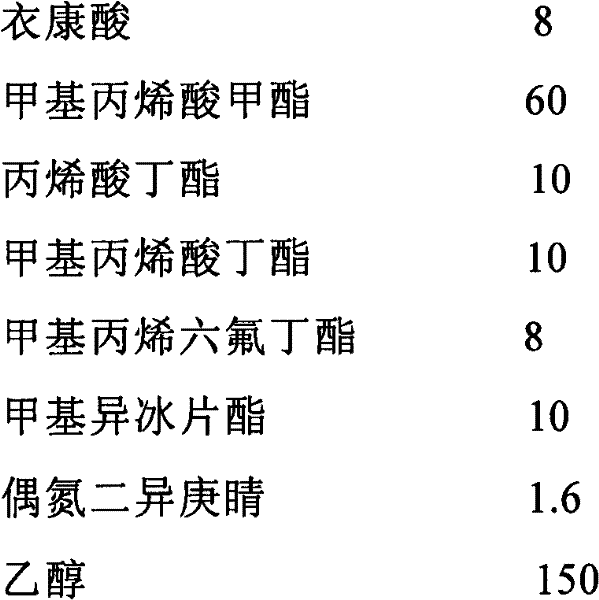

[0051] Prepare materials by weight:

[0052]

[0053]

[0054] Put 110 parts of ethanol into the reactor with condensation back, evenly add 1.6 parts of initiator and monomer mixed solvent into the dropping device, heat the ethanol in the reactor to 72°C, blow in nitrogen, and start dropping Monomer solution and initiator solution, control the flow rate, the monomer solution is controlled to be added dropwise within 3-3.5 hours, and a solution of 0.4 parts of initiator and 30 parts of ethanol is added, controlled to be dropped within 1-1.5 hours, and then kept at 75°C Respond for an hour. The obtained resin solution is vacuum degassed to recover the solvent, cooled and pulverized to obtain powdered resin.

[0055] The difference from Examples 1 and 2 is that azobisisobutyronitrile has low solubility in ethanol, so a part is used to dissolve in the monomer, and then a part of azobisisobutyronitrile ethanol solution is added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com