Iron-chromium-boron-silicon/FeS composite solid lubrication thin film and method for making same

A solid lubrication, borosilicate technology, applied in engine lubrication, mechanical equipment, coatings, etc., can solve problems such as poor performance, unsatisfactory metal matrix binding ability, and difficult to master.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

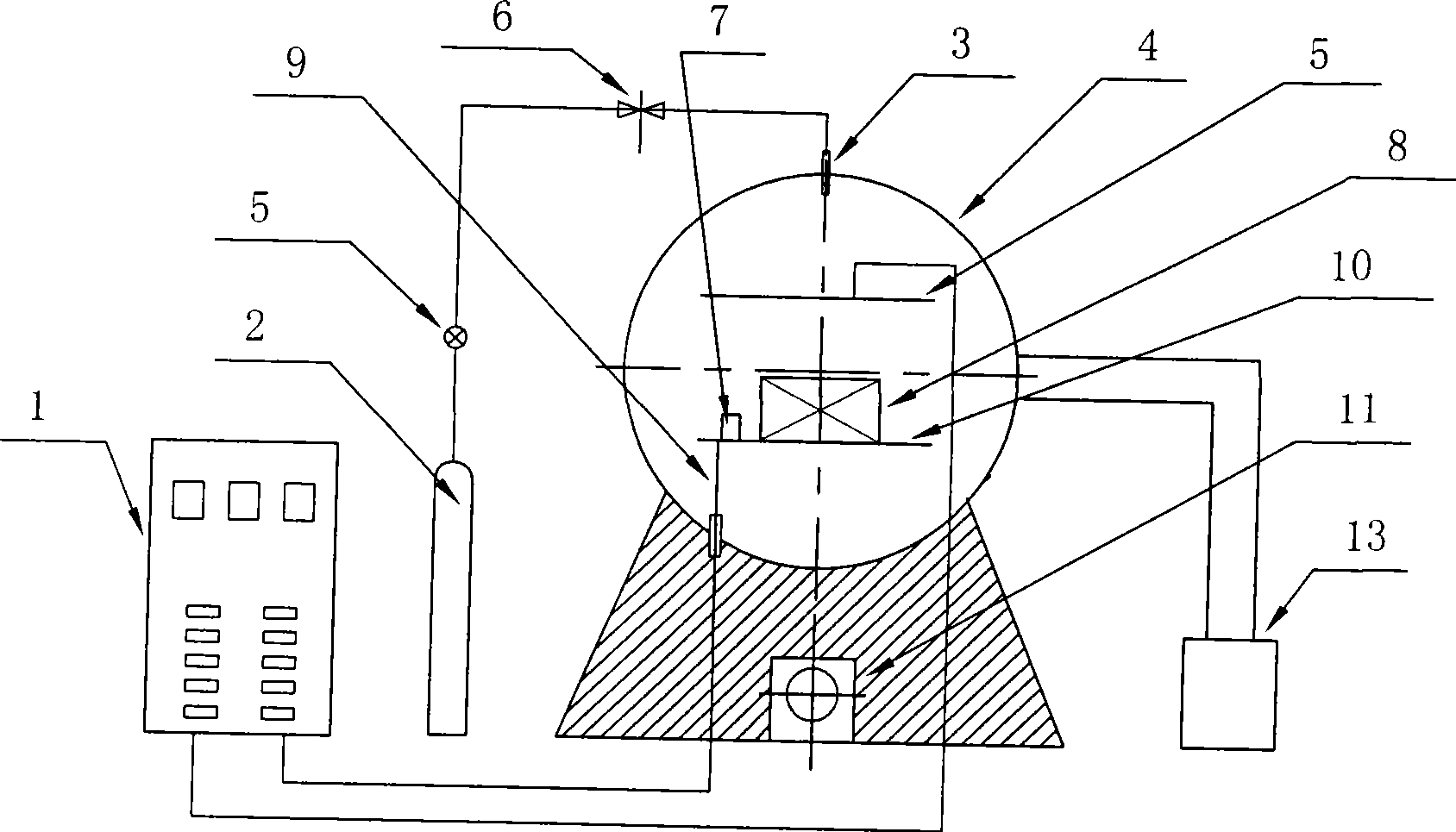

[0054] Firstly, the 45# steel is quenched, the hardness is HRC55, and the surface roughness is 0.8μm; Sand distance 130mm. Then clean the sandblasting surface with an appropriate amount of acetone with a purity of 99.5%; then supersonic plasma spray the iron-chromium-borosilicate coating on the surface of the substrate, and the thickness of the sprayed iron-chromium-borosilicate coating is about 300-400 μm. The specific process parameters are shown in Table 1;

[0055] Table 1

[0056] Spraying voltage / V Spraying current / A Spraying power / kW Spray distance / mm Spraying time / S 130 350 40 90 60S

[0057] The 45# steel coated with iron chromium borosilicate coating is subjected to low temperature ion sulfurization treatment, the specific steps and process parameters are: the reaction gas of ion sulfurization is solid sulfur vapor, and the 45# steel coated with iron chromium borosilicate coating Connect the cathode, and connect the anode to the furna...

Embodiment 2

[0073] Firstly, the 45# steel is quenched, the hardness is HRC55, and the surface roughness is 0.8μm; Sand distance 150mm.

[0074] Then wash with acetone; then supersonic plasma spraying iron chromium borosilicate coating on the surface of the substrate; the thickness of the sprayed iron chromium borosilicate coating is about 300-400 μm. Process parameters are shown in Table 2;

[0075] Table 2

[0076] Spraying voltage / V Spraying current / A Spraying power / kW Spray distance / mm Spraying time / S 140 360 40 100 60S

[0077] The 45# steel coated with iron chromium borosilicate coating is subjected to low temperature ion sulfurization treatment, the specific steps and process parameters are: the reaction gas of ion sulfurization is solid sulfur vapor, and the 45# steel coated with iron chromium borosilicate coating Connect the cathode, and connect the anode to the furnace wall. When the vacuum reaches 10Pa, feed ammonia gas into the furnace, fill it...

Embodiment 3

[0093] Firstly, the 45# steel is quenched, the hardness is HRC55, and the surface roughness is 0.8μm; Sand distance 160mm. Then wash with acetone; then supersonic plasma spraying iron chromium borosilicate coating on the surface of the substrate; the thickness of the sprayed iron chromium borosilicate coating is about 300-400 μm. Process parameters are shown in Table 3;

[0094] table 3

[0095] Spraying voltage / V Spraying current / A Spraying power / kW Spray distance / mm Spraying time / S 150 370 40 110 60S

[0096] The 45# steel coated with iron chromium borosilicate coating is subjected to low temperature ion sulfurization treatment, the specific steps and process parameters are: the reaction gas of ion sulfurization is solid sulfur vapor, and the 45# steel coated with iron chromium borosilicate coating Connect the cathode, and connect the anode to the furnace wall. When the vacuum reaches 10Pa, feed ammonia gas into the furnace, fill it up to 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com