Method for simultaneously and stably dispersing laminated nanosheets and spherical nanoparticles in oily medium and application thereof

A nanoparticle and layered nanotechnology, applied in the field of materials, can solve the problems of dangerous HF, needs further development, cannot form long-term stable emulsion, etc., and achieves the effect of good anti-friction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

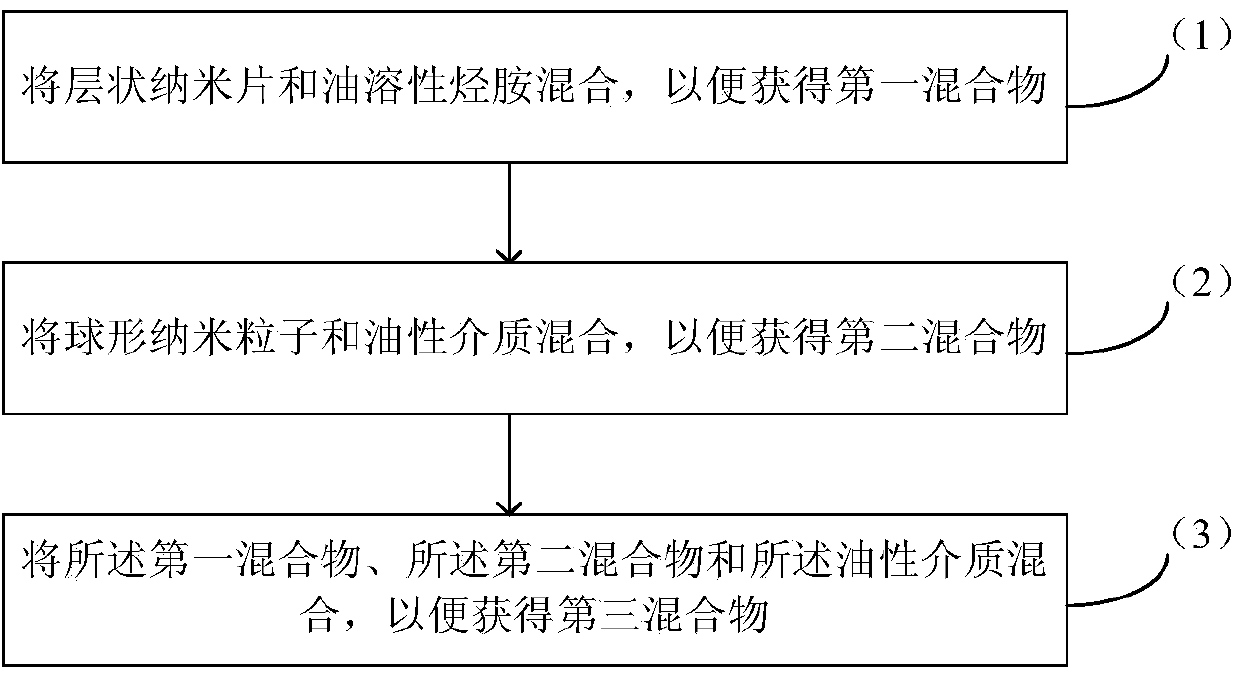

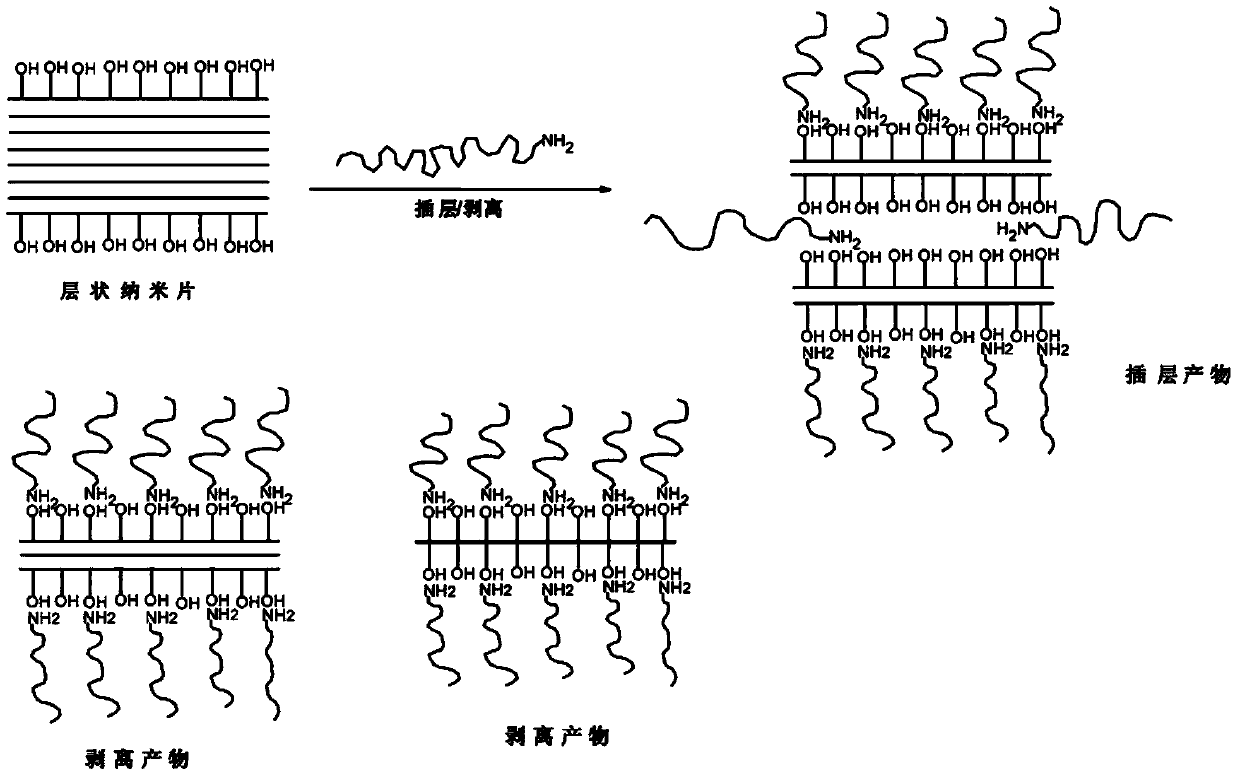

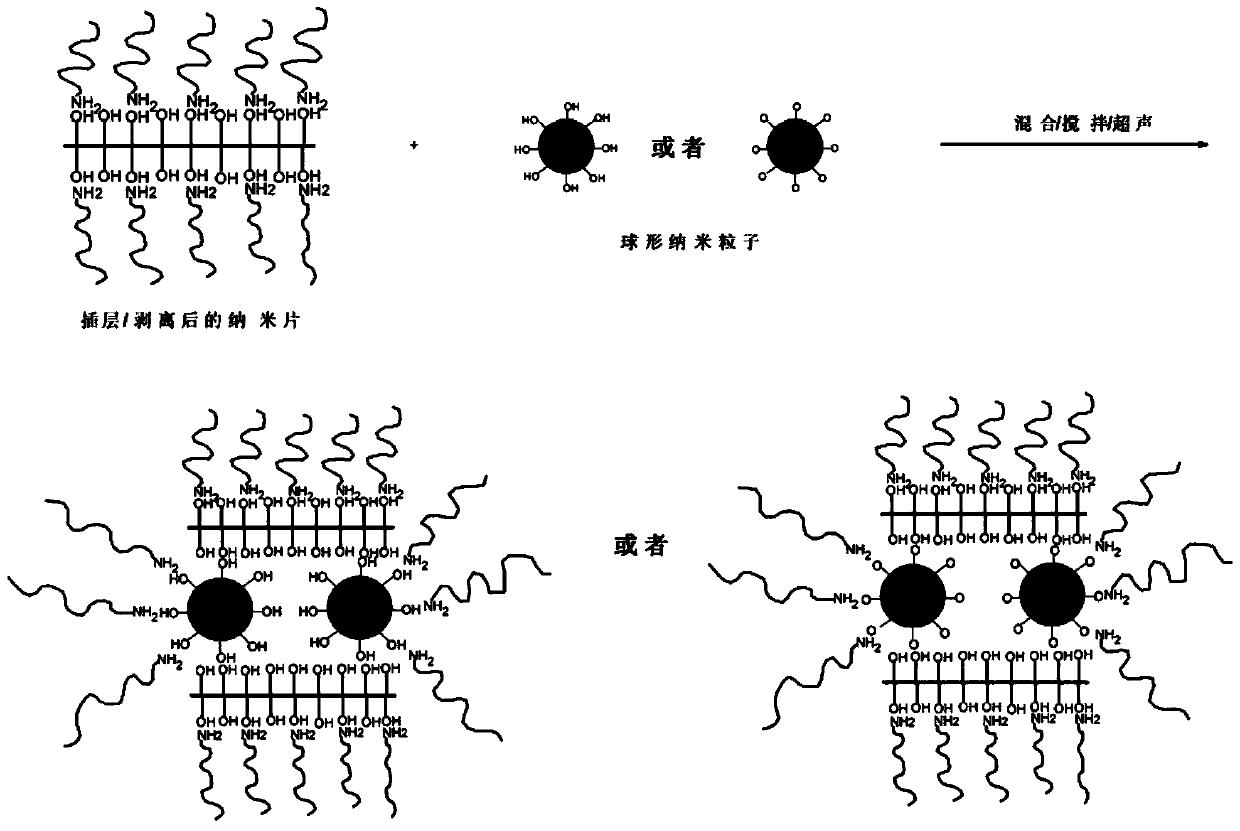

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: the synthesis of α-zirconium hypophosphite

[0086] 8.0g ZrOCl 2 .8H 2 O and 80.0ml of H with a concentration of 3.0mol / L, 6.0mol / L, 9.0mol / L and 12.0mol / L respectively 3 PO 4 (mass fraction 85%) was placed in a three-necked glass flask, and refluxed at 100°C for 24h. After the reaction was over, the reaction product was washed three times, and the product was collected by centrifugation to obtain α-ZrP (3M) and α-ZrP respectively. (6M), the product of α-ZrP (9M) and α-ZrP (12M). Among them, α-ZrP(3M), α-ZrP(6M), α-ZrP(9M) and α-ZrP(12M) are the concentration of reactant phosphoric acid respectively 3.0mol / L, 6.0mol / L, 9.0mol / L L, the product at 12.0mol / L. Then, dry the obtained product at 65°C for 24 hours, and then grind the dried product into α-ZrP fine powder. At 25°C, the density of the obtained α-ZrP solid powder is about 2.72g.cm -3 . The obtained α-ZrP fine powder is carried out XRD experiment, the XRD spectrogram of α-ZrP (theta-ZrP of dehy...

Embodiment 2

[0087] Embodiment 2: the synthesis of θ-zirconium hypophosphite

[0088] In a beaker, 3.116g of ZrOCl 2 .8H 2 O was dissolved in 200ml of deionized water, followed by 82.19ml of H in a round bottom flask 3 PO 4 (mass fraction 85%) mixed with 117.81ml deionized water. Then, under stirring conditions, the H 3 PO 4 The round-bottomed flask of the solution was placed in a constant temperature oil bath at 94°C, when H 3 PO 4 After the solution reached equilibrium at a temperature of 94°C, the ZrOCl 2 .8H 2 O solution was added dropwise to the 3 PO 4 The solution was placed in a round-bottomed flask, and then the resulting solution was stirred at 94 °C for 48 h. After the reaction is finished, the solution is filtered, and the solid product obtained by filtering is washed with a large amount of deionized water, that is, θ-ZrP. Next, the obtained θ-ZrP was dried in a desiccator for 72 hours at room temperature, and then the dried θ-ZrP was ground into a fine powder, and t...

Embodiment 3

[0089] Embodiment 3: the synthesis of gamma-zirconium hypophosphite

[0090] NaH 2 PO 4 .H 2 O (677g, 4.91mol) dissolved in distilled water (376ml) and 85% H 3 PO 4 (182.6g, 1.58mol) in a mixed solution. The resulting solution was then refluxed for 30 min, and then the ZrOCl concentration of 1mol / L was added into the refluxed solution 2 .8H 2 O (76g) solution was 238ml, and then the obtained colloid was refluxed for 72h. Subsequently, the refluxed colloidal solution was transferred to a hydrothermal reactor, and heated to 190° C. for 120 h. After the reaction, the white precipitate was filtered out and washed with 4mol / L HCl to remove sodium ions, and then washed with 0.2mol / L HCl 3 PO 4 Wash to remove chloride ions. Finally, it was washed with deionized water to obtain γ-ZrP. Next, the obtained γ-ZrP was dried in a desiccator at room temperature for 72 hours, and then the dried γ-ZrP was ground into a fine powder, and the particle size of the obtained γ-ZrP nanoshe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com