Method for manufacturing size-controllable two-dimensional nanostructure of CrN nanopore array

A technology of two-dimensional nanostructure and nanohole array, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of low anti-adhesive effect, achieve no pollution, simple equipment, surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

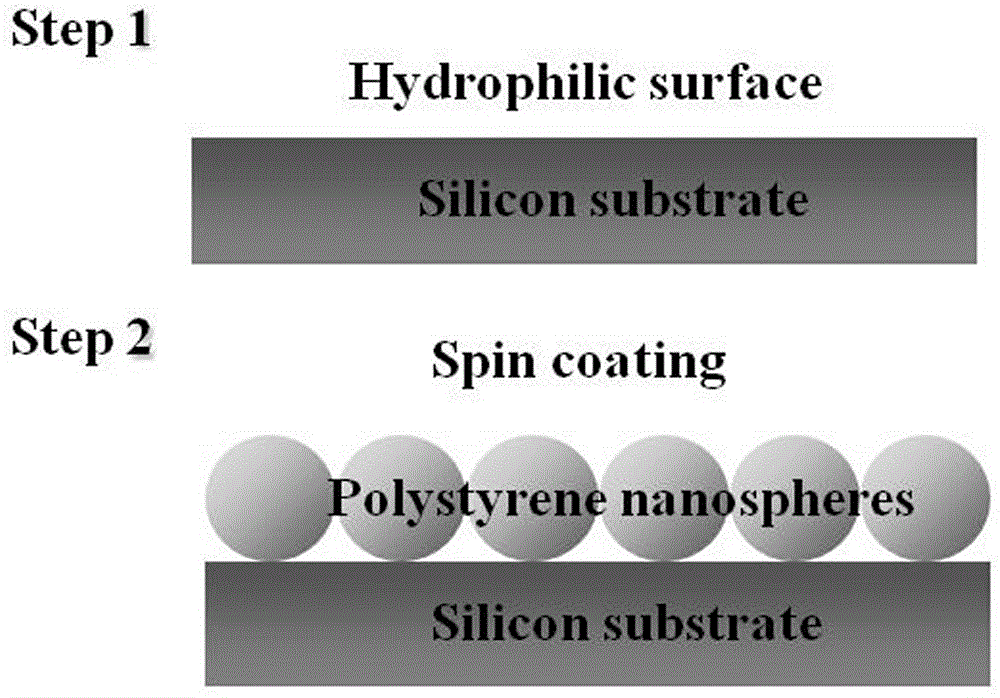

[0031] Embodiment 1 includes the following steps: (1) immersing the silicon substrate into a volume ratio of 1:1 ammonia water (NH 4 OH) and hydrogen peroxide (H 2 o 2 ) in the mixed solution, perform ultrasonic cleaning for 30 minutes, and then wash with deionized water for 10 minutes.

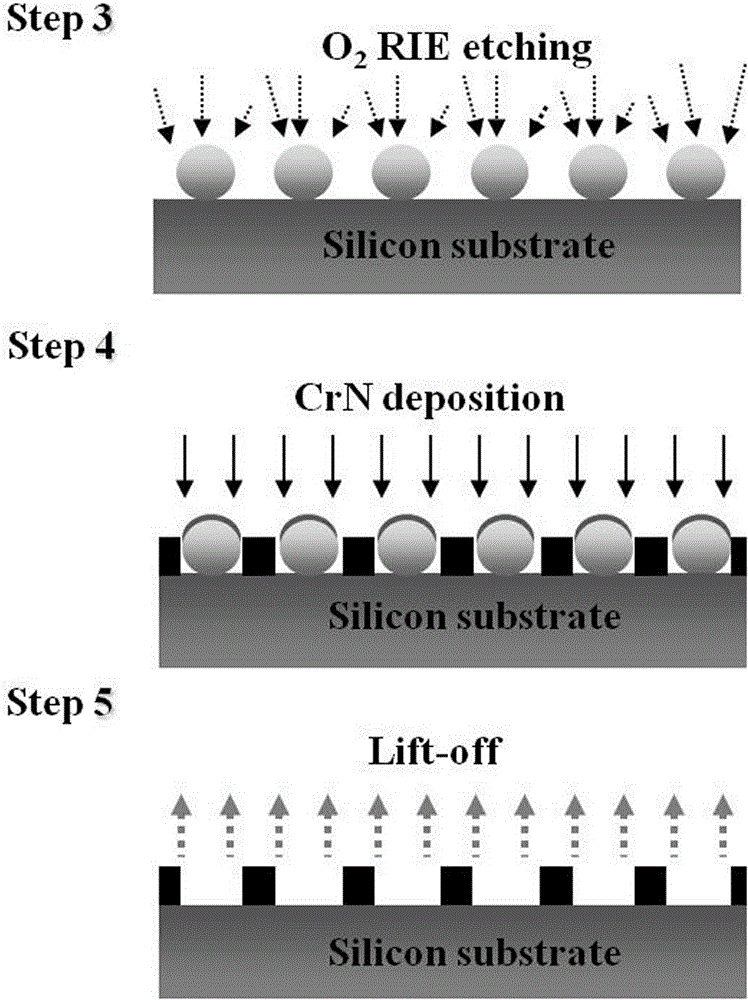

[0032] (2) Using polystyrene (PS) as the polymer raw material, use a spin coater for spin coating, set the speed at 1200 rpm, and proceed for 4 min. After stopping, you can get a self-assembled periodically arranged polystyrene Ethylene (PS) nanosphere monolayer template such as image 3 (a) shown.

[0033] (3) The size of the nanospheres on the single-layer template was adjusted by reactive ion etching. The power parameters were set to 50W, the etching time was 10min, and oxygen was used as the etching gas to obtain the size-controlled polystyrene nanospheres. layer template.

[0034] (4) Then use the closed-field unbalanced magnetron sputtering ion plating system (CBUBMIP) to install t...

Embodiment 2

[0037] Embodiment 2 includes the following steps: (1) immersing the silicon substrate into a volume ratio of 1:1 ammonia water (NH 4 OH) and hydrogen peroxide (H 2 o 2 ) in the mixed solution, perform ultrasonic cleaning for 30 minutes, and then wash with deionized water for 10 minutes.

[0038] (2) Using polystyrene (PS) as the polymer raw material, use a spin coater for spin coating, set the speed at 1200 rpm, and proceed for 4 min. After stopping, you can get a self-assembled periodically arranged polystyrene Ethylene (PS) nanosphere monolayer template such as image 3 (a) shown.

[0039] (3) The size of the nanospheres on the single-layer template is controlled by reactive ion etching, the power parameter is set to 50W, the etching time is 20min, and oxygen is used as the etching gas, such as image 3 (b) shows the polystyrene nanosphere monolayer template after size regulation.

[0040] (4) Then use the closed-field unbalanced magnetron sputtering ion plating system...

Embodiment 3

[0044] Embodiment 3 includes the following steps: (1) immersing the silicon substrate in a volume ratio of 1:1 ammonia water (NH 4 OH) and hydrogen peroxide (H 2 o 2 ) in the mixed solution, perform ultrasonic cleaning for 30 minutes, and then wash with deionized water for 10 minutes.

[0045] (2) Using polystyrene (PS) as the polymer raw material, use a spin coater for spin coating, set the speed at 1200 rpm, and proceed for 4 min. After stopping, you can get a self-assembled periodically arranged polystyrene Ethylene (PS) nanosphere monolayer template such as image 3 (a) shown.

[0046] (3) The size of the nanospheres on the single-layer template was adjusted by reactive ion etching. The power parameter was set to 50W, the etching time was 25min, and oxygen was used as the etching gas to obtain a single layer of polystyrene nanospheres after size adjustment. template.

[0047] (4) Then use the closed-field unbalanced magnetron sputtering ion plating system (CBUBMIP) to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com