Coating system applied to surface of plastic substrate and plastic product prepared by coating system

A technology for plastic substrates and plastic products, applied in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of plastic substrates or plastic parts with imperfect surfaces, insufficient adhesion, and poor durability. Achieve high hardness, improve adhesion, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation of the UV curable primer coating in the present invention sprays the coating on the surface of the plastic substrate by spraying, and obtains the primer coating by UV curing. The UV energy is 500-1500mJ / cm 2 , UV intensity is 80-150mW / cm 2 .

[0035] PVD coatings in the present invention were deposited using an Innova coating device from Balzers with a rotating substrate carrier. The coatings produced in the present invention passed the following functional tests:

[0036] [Adhesion test]

[0037] According to ASTM D3359-02, the 100-grid test is carried out, and the binding force test is carried out, which is divided into 1B-5B in turn:

[0038] 5B: completely smooth, without any peeling off the edge of the grid;

[0039] 4B: Small flakes peeled off, actual clear coat in the cross-hatched area. For targets, manufactured using molten metallurgy or powder metallurgy

[0040] Ti-Al and / or Ti-Si targets were used to manufacture the coating; and the coat...

Embodiment 1

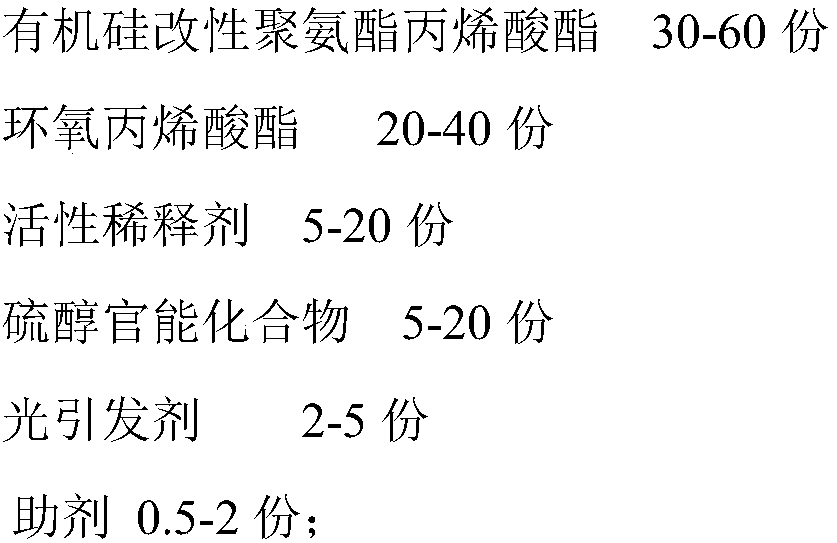

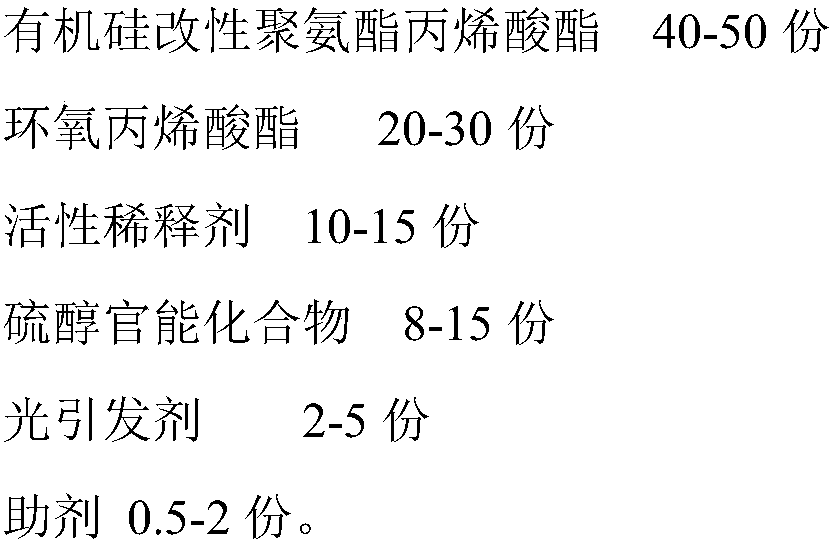

[0056] A coating system applied on the surface of a plastic substrate, comprising a UV-curable primer and a wear-resistant PVD coating, wherein the UV-curable primer consists of 30 parts of silicone-modified polyurethane acrylate, 30 parts of epoxy acrylate Parts, 10 parts of trimethylolpropane triacrylate, 10 parts of pentaerythritol tetramercaptoacetate, 3 parts of photoinitiator, 1 part of auxiliary agent; the PVD coating for wear protection is Ti 0.8 al 0.2 N coating with a thickness of 1 μm;

[0057] The primer is sprayed on the surface of the plastic substrate by spraying, and the primer coating is obtained by UV curing, and the UV energy is 1000mJ / cm 2 , UV intensity is 100mW / cm 2 ; Then the plastic substrate after photocuring is coated with PVD coating by PVD process to prepare plastic products.

[0058] The prepared plastic product has a metallic luster on the surface, the adhesion is 5B, the pencil hardness can reach 5H, it has passed the 16L falling sand impact t...

Embodiment 2

[0060] A coating system applied on the surface of a plastic substrate, comprising a UV-curable primer and a wear-resistant PVD coating, wherein the UV-curable primer consists of 60 parts of silicone-modified polyurethane acrylate, 40 parts of epoxy acrylate 20 parts, 20 parts of ethoxylated trimethylolpropane triacrylate, 15 parts of trimethylolpropane tri(3-mercaptopropionate), 5 parts of photoinitiator, 1 part of auxiliary agent; PVD coating for wear protection for Ti 0.6 al 0.4 N coating with a thickness of 2 μm;

[0061] Plastic products were prepared by the same process as in Example 1.

[0062] The prepared plastic product has a metallic luster on the surface, the adhesion is 5B, and the pencil hardness can reach 5H. It has passed the 16L falling sand impact test and RCA wear resistance test for 800 times. There is no abnormality in the appearance after cycling, the adhesion is 4B level, and there is no abnormality after the chemical resistance test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com