Water-based epoxy antistatic floor primer and surface paint and preparation method thereof

A water-based epoxy resin, epoxy anti-corrosion technology, applied in the direction of epoxy resin coating, conductive coating, coating, etc., can solve the problems of poor anti-static performance, poor wet adhesion, poor safety, etc., and achieve good anti-static performance , Reliable adhesion, low odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

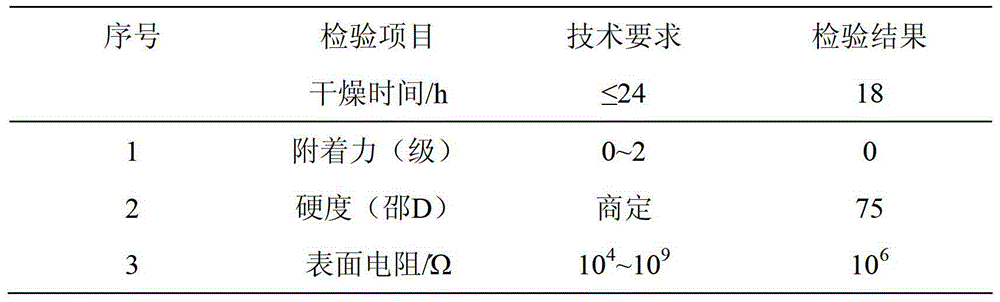

Embodiment 1

[0028] The preparation method of the first component of the floor primer coating:

[0029] Add 250g of waterborne epoxy resin curing agent II, 500g of water, and EFKA40506g to the dispersion kettle, disperse at 800rmp for 10 minutes, add 250g of conductive graphite, disperse at 3000rmp for 20 minutes, grind to The fineness is 30-50 μm, and it can be packaged after being filtered by a 200-mesh filter to obtain the first component of the water-based epoxy resin anti-static floor bottom and middle coating.

[0030] 150 g of bisphenol A epoxy resin with an epoxy equivalent of 185 and 17 g of o-phenyl glycidyl ether were stirred uniformly to form the B component.

[0031] When used as a primer, this component A and component B are mixed evenly, and evenly painted on the treated base surface.

[0032] When used as a middle coat, mix this component A and component B evenly, add an appropriate amount of quartz sand or quartz powder or talc powder or other volume pigments, mix well, a...

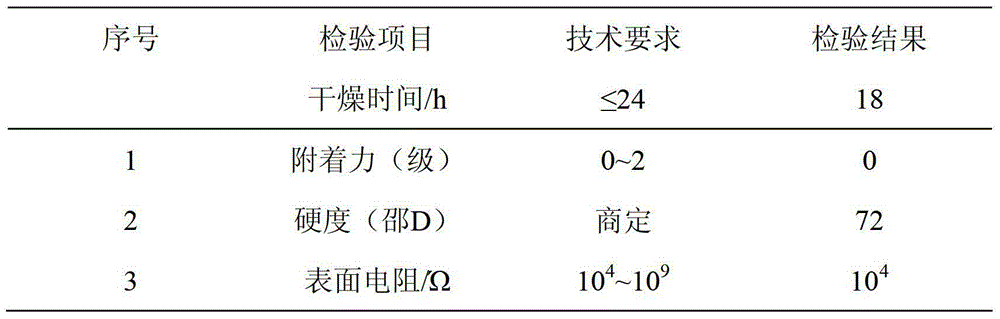

Embodiment 2

[0041] The preparation method of the first component of the floor primer coating:

[0042] Add metered II generation waterborne epoxy resin curing agent 210g, water 450g, EFKA40501g to the dispersion kettle, disperse at 600rmp for 10 minutes, add 260g of conductive graphite, disperse at 3000rmp for 20 minutes, grind to The fineness is 30-50 μm, and it can be packaged after being filtered by a 200-mesh filter to obtain the first component of the water-based epoxy resin anti-static floor bottom and middle coating.

[0043] 120 g of bisphenol A epoxy resin with an epoxy equivalent of 185 and 20 g of butyl glycidyl ether were stirred uniformly to form the B component.

[0044] When used as a primer, this component A and component B are mixed evenly, and evenly painted on the treated base surface.

[0045] When used as a middle coat, mix this component A and component B evenly, add an appropriate amount of quartz sand or quartz powder or talc powder or other volume pigments, mix w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com