High-wear-resistant and high-gloss UV coating for PC base material of automobile interior trim optical components and preparation method thereof

A technology for optical components and automotive interiors, applied in fire-resistant coatings, polyurea/polyurethane coatings, coatings, etc., can solve poor scratch resistance and abrasion resistance, cannot achieve wear resistance, and cannot meet light transmission Degree and other issues, to achieve the effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

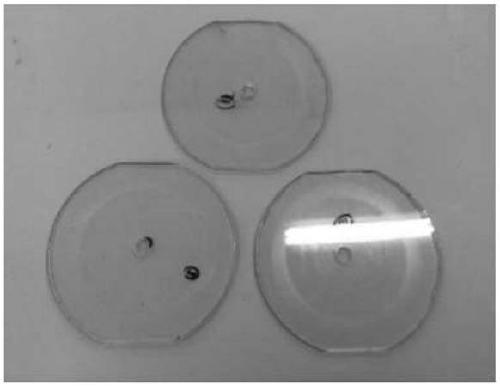

Image

Examples

Embodiment 1

[0031] This embodiment 1 investigated the impact of the consumption of polyurethane acrylic resin A and polyurethane acrylic resin B on the performance of high wear-resistant and high-gloss UV coatings, wherein, at first, the items that those skilled in the art usually detect the performance of coatings are selected, i.e. appearance, adhesion and It is evaluated by the 90°C high temperature cracking test; secondly, it is tested by GMW16877-2013.

[0032] The high-abrasion-resistant high-gloss UV coating for the PC base material of the automotive interior optical parts of the present embodiment 1 is made from the raw materials comprising the following parts by weight: 10 parts of 1,6-hexanediol diacrylate (HDDA), 5 parts of grinding aid (Tivida AS1010), 1 part of leveling agent (BYK333), 1 part of UV absorber (Tinuvin400), 3 parts of photoinitiator (Irgacure184), 7.5 parts of butyl acetate, 4.5 parts of methyl isobutyl ketone part and 3 parts of ethyl lactate, wherein, the cons...

Embodiment 2

[0055] This embodiment 2 investigates the influence of the consumption of different wear-resistant additives on the performance of high-wear-resistant high-gloss UV coatings. Specifically, the high-wear-resistant high-gloss UV coating used for automotive interior optical parts PC substrates in this embodiment 1, 45 parts of polyurethane acrylic resin A (LaromerUA9047), 15 parts of polyurethane acrylic resin B (EB4680), 10 parts of 1,6-hexanediol diacrylate (HDDA), leveling agent (BYK333 ) 1 part, 1 part of UV absorber (Tinuvin400), 3 parts of photoinitiator (Irgacure184), 7.5 parts of butyl acetate, 4.5 parts of methyl isobutyl ketone and 3 parts of ethyl lactate, the mixed solvent and diluent are butyl acetate A mixed solvent of 20 parts of ester, 12 parts of methyl isobutyl ketone and 8 parts of ethyl lactate, wherein the amount of anti-wear additive is shown in Table 3.

[0056] This embodiment is used for the preparation method of the high wear-resisting high-gloss UV coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com