Vacuum magnetron sputtering color plating equipment

A vacuum magnetron sputtering and vacuum coating technology, which is applied in sputtering coating, vacuum evaporation coating, ion implantation coating, etc., can solve the problems of uneven coating, improve the quality of film formation, improve the technical level and The effect of technological level and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be further described below in conjunction with the accompanying drawings and embodiments.

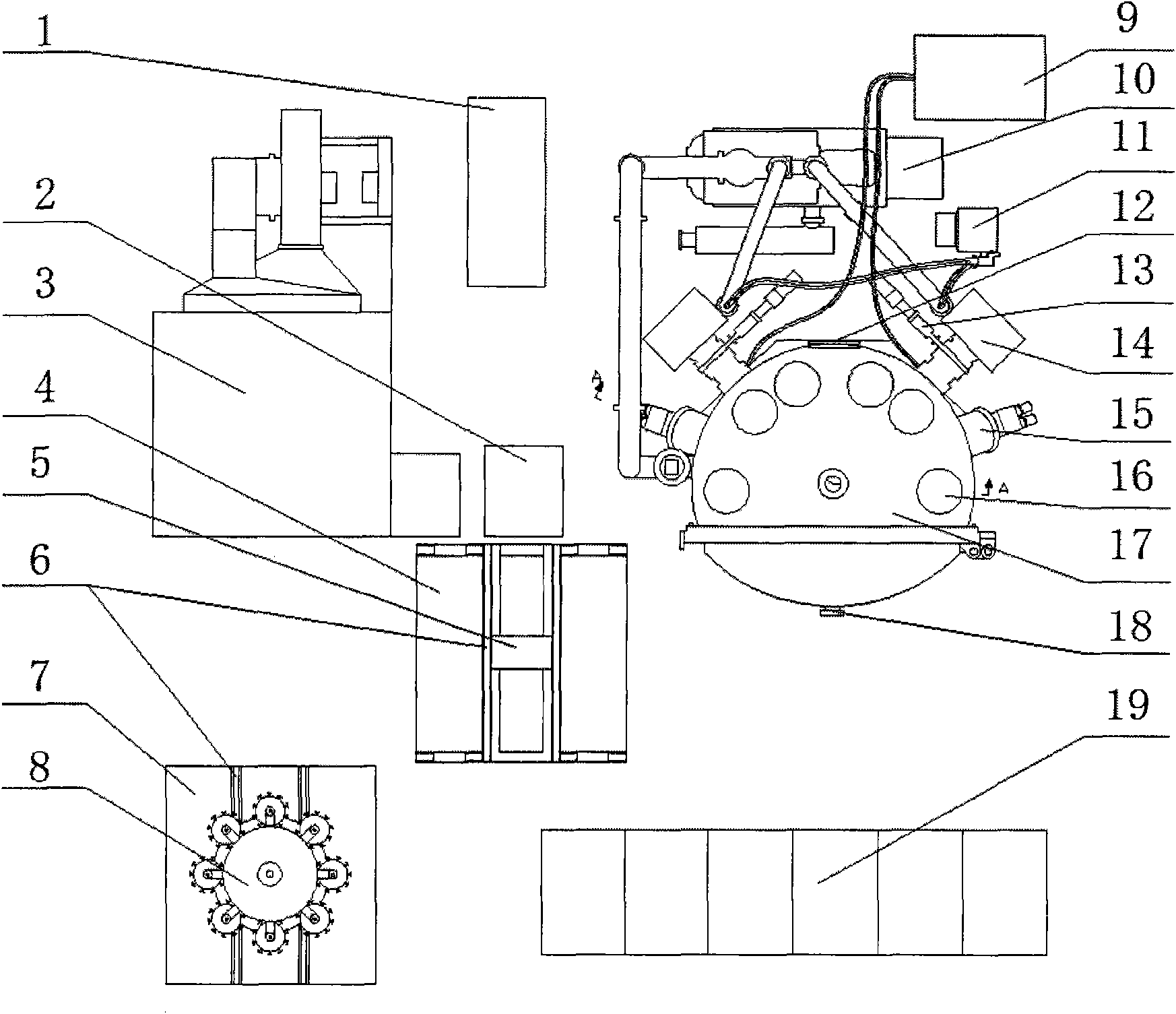

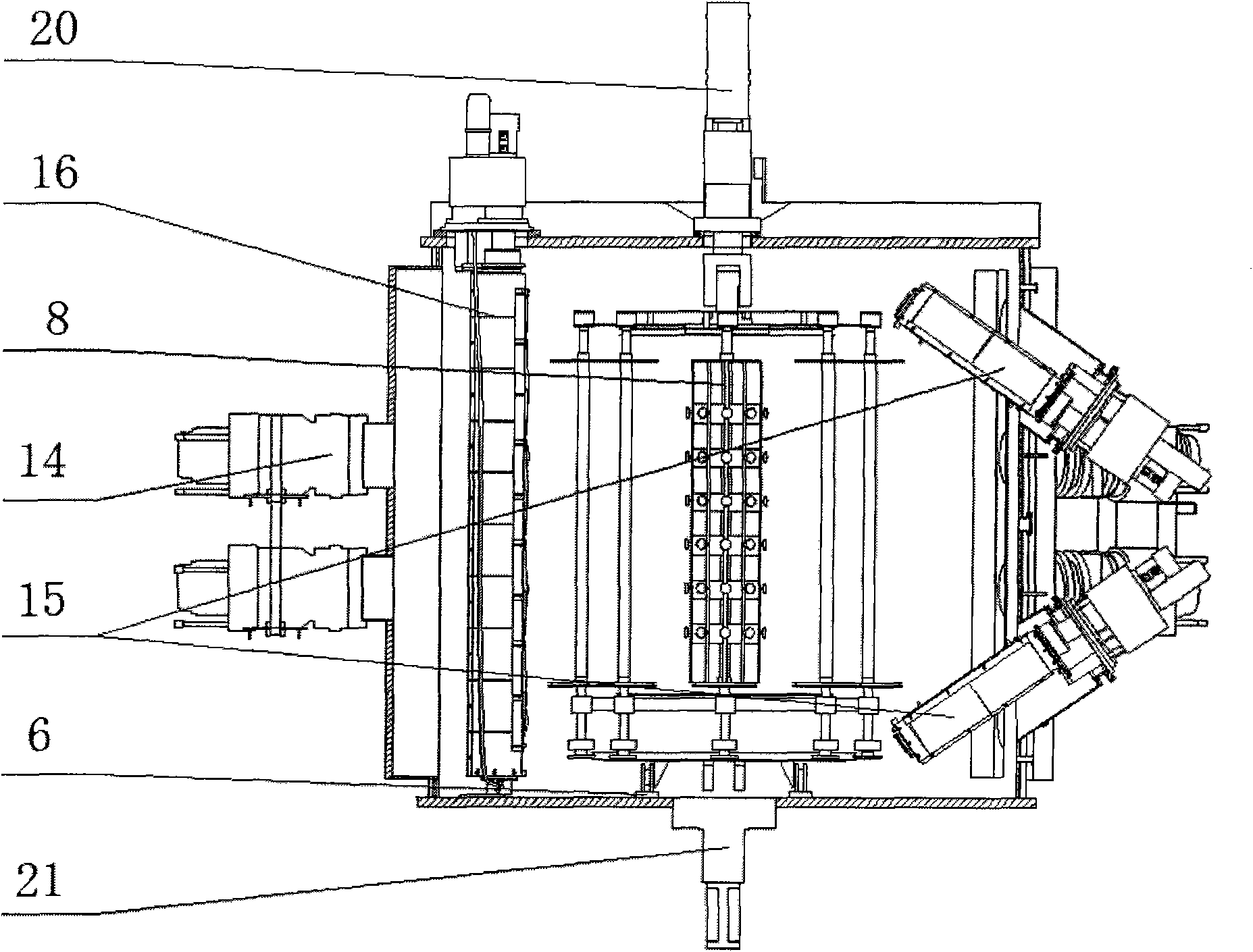

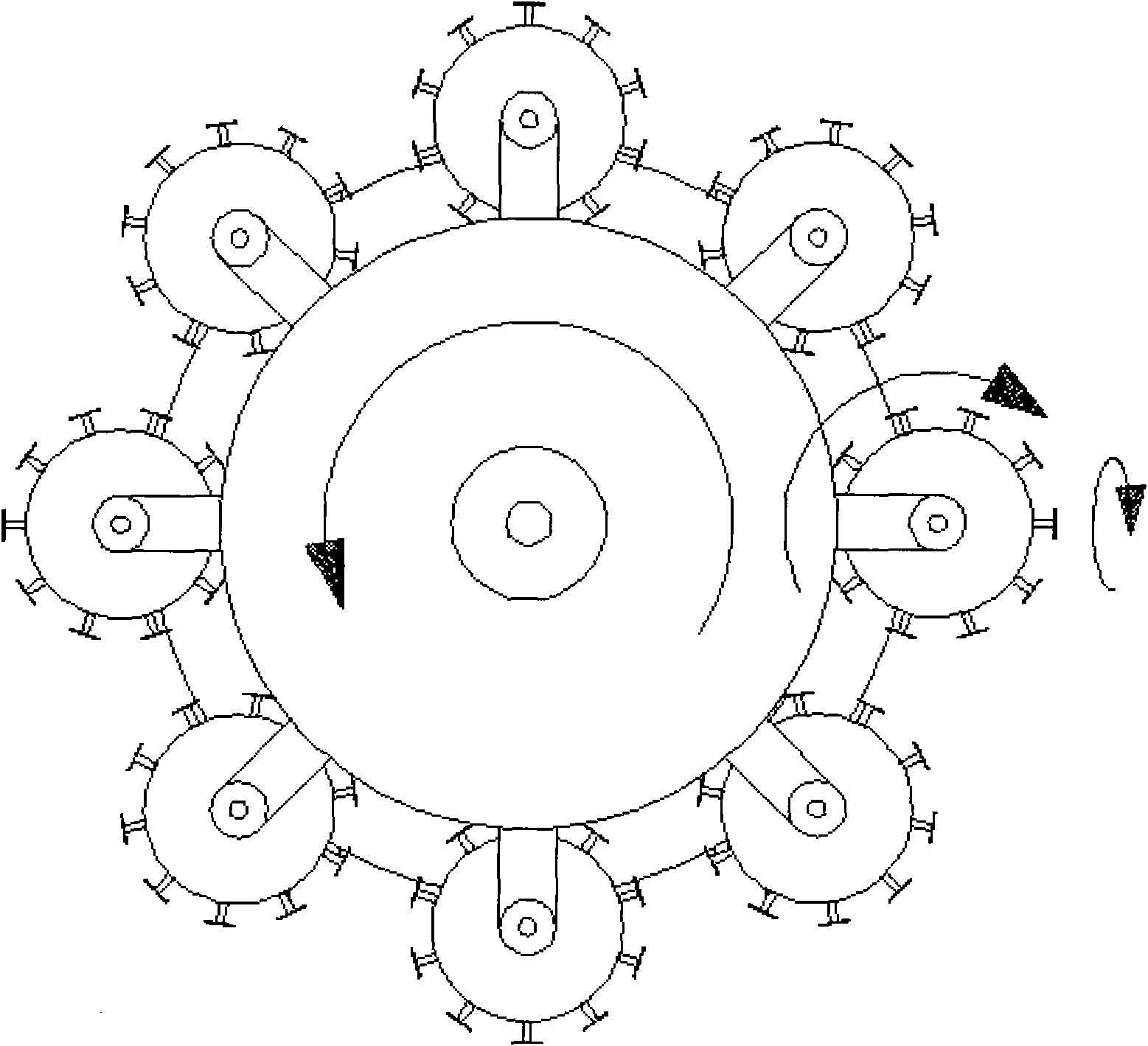

[0020] Such as figure 1 As shown, the baking chamber 3, the workpiece pre-suspension platform 7, and the vacuum coating chamber 17 are sequentially arranged in the working space, the sample suspension frame 8 is arranged above the workpiece pre-suspension platform 7, and the sample suspension frame pallet 5 and the sample suspension frame are above the transfer vehicle 4. Its trolley track 6 is also equipped with a trolley track 6 above the workpiece pre-suspension table 7, at the corresponding positions of the baking chamber 3 and the indoor bottom of the vacuum coating chamber 17, and the vacuum coating chamber 17 is equipped with multiple groups of columnar rotating magnetron targets. 16. Compensation inclined target 15 and cathode ion source 12. There is a bearing assembly 21 docked with the sample suspension frame 8 in the upper and lower centers of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com