Modified polyamide acid resin slurry and preparation method thereof, and adhesive-free copper-clad plate

A technology of polyamic acid resin and copper clad laminate, applied in chemical instruments and methods, synthetic resin layered products, other household appliances, etc., can solve the problems of poor dielectric properties, environmental problems, poor dimensional stability of copper foil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

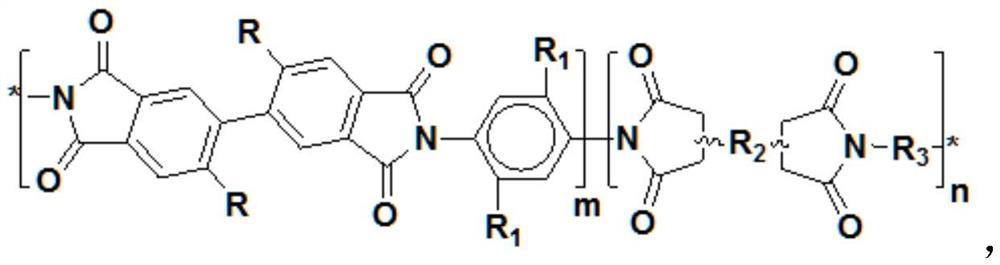

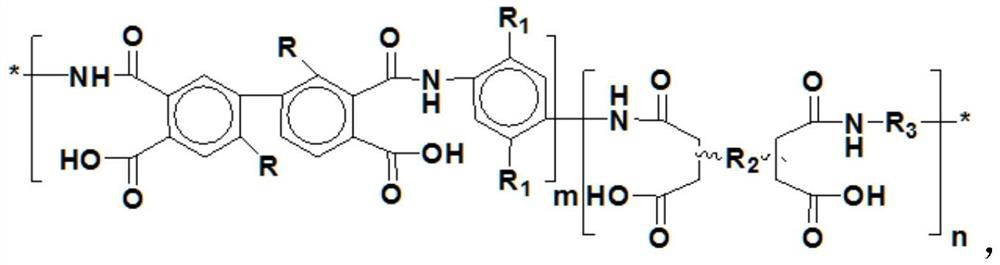

Method used

Image

Examples

Embodiment 1

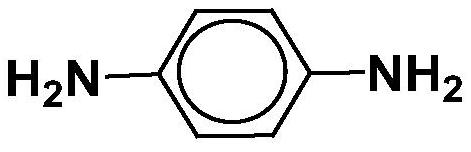

[0092] 4,4'-biphenyldianhydride (11.77g), 2,2'-difluoro-4,4'-biphenyldianhydride (3.30g), p-phenylenediamine (3.78g), 3,3' -bis(trifluoromethyl)-4,4'-diaminobiphenyl (3.20g), 2'-trifluoromethyl-2-phenylbenzimidazole-6,4-diamine (1.40g), Porous silica (2.61g), 3-aminopropyltrimethoxysilane (1.74g) and N-methylpyrrolidone (228mL, 234.45g) were mixed, and after copolymerization and blending (room temperature, nitrogen atmosphere) for 16h, Obtain polyamic acid resin slurry;

[0093] The polyamic acid resin slurry is mixed with 4-picoline (9.31g) and acetic anhydride (12.76g) at room temperature to obtain a homogeneous mixture of polyamic acid-imidization reagent; Spread a copper foil film on the platform, then cast the above-mentioned polyamic acid-imidization reagent uniform mixture on the copper foil at a speed of 200-300mm / min, and then coat the polyamic acid resin slurry layer The copper foil is imidized, that is, the temperature is raised from 15°C to 130°C at a rate of 5-1...

Embodiment 2

[0098] 4,4'-biphenyldianhydride (11.77g), 2,2'-difluoro-4,4'-biphenyldianhydride (3.30g), p-phenylenediamine (3.24g), 3,3' -bis(trifluoromethyl)-4,4'-diaminobiphenyl (4.8g), 2'-trifluoromethyl-2-phenylbenzimidazole-6,4-diamine (1.40g), Porous silica (2.72g), 3-aminopropyltrimethoxysilane (1.82g) and N-methylpyrrolidone (239mL, 245.10g) were mixed, and after copolymerization and blending (room temperature, nitrogen atmosphere) for 16h, Obtain polyamic acid resin slurry;

[0099] The polyamic acid resin slurry is mixed with 4-picoline (9.31g) and acetic anhydride (12.76g) at room temperature to obtain a homogeneous mixture of polyamic acid-imidization reagent; Spread a copper foil film on the platform, then cast the above-mentioned polyamic acid-imidization reagent uniform mixture on the copper foil at a speed of 200-300mm / min, and then coat the polyamic acid resin slurry layer The copper foil is imidized, that is, the temperature is raised from 15°C to 130°C at a rate of 5-10...

Embodiment 3

[0104] 4,4'-biphenyl dianhydride (10.30g), 2,2'-difluoro-4,4'-biphenyl dianhydride (3.30g), pyromellitic dianhydride (1.09g), terephthalic Diamine (3.24g), 2'-trifluoromethyl-2-phenylbenzimidazole-6,4'-diamine (1.40g), 3,3'-bis(trifluoromethyl)-4, 4'-diaminobiphenyl (4.8g), porous silica (2.68g), 3-aminopropyltrimethoxysilane (1.78g) and N-methylpyrrolidone (235mL, 241.29g) were mixed for copolymerization And after blending (room temperature, nitrogen atmosphere) 16h, obtain polyamic acid resin slurry;

[0105] The polyamic acid resin slurry is mixed with 4-picoline (9.31g) and acetic anhydride (12.76g) at room temperature to obtain a homogeneous mixture of polyamic acid-imidization reagent; Spread a copper foil film on the platform, then cast the above-mentioned polyamic acid-imidization reagent uniform mixture on the copper foil at a speed of 200-300mm / min, and then coat the polyamic acid resin slurry layer The copper foil is imidized, that is, the temperature is raised fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com