Production technology for dynode shell

A production process, dynode technology, applied in the manufacture of ships or leading wires, etc., to achieve high resistance to ion bombardment, solve the effect of uniformity of film formation, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below, and the description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0019] Such as Figure 1-5 The production process of a dynode shell shown includes the following steps:

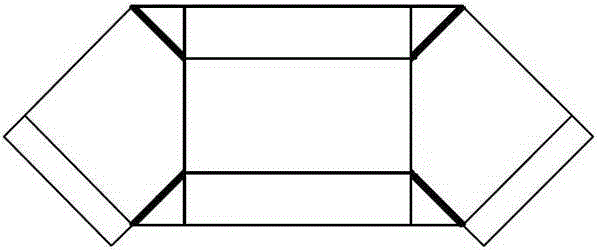

[0020] (1) Liner processing: According to the plane design drawing of the electron multiplier dynode shell, the plane liner is processed, the material is 304 stainless steel, the thickness is 0.1mm, and the surface roughness of the plane liner is required to be 15nm. Use laser beam to cut out folding lines, such as figure 1 As shown, the thick black solid line should be cut through, and the thin solid line should be cut;

[0021] (2) Clean the inner lining: put the No. 304 stainless steel inner lining into a clean container, rinse it with deionized water, and then ultrasonically clean the No. 304 stainless steel inner lining with analytical pure aceto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com