Coating machine for anti-reflection film of photovoltaic glass

A technology of anti-reflection and anti-reflection and photovoltaic glass, which is applied in the field of glass deep processing, can solve the problems that the precision cannot reach imported equipment, inconvenient after-sales service, low coating quality, etc., and achieve easy control of process, optimization of equipment structure, and high control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

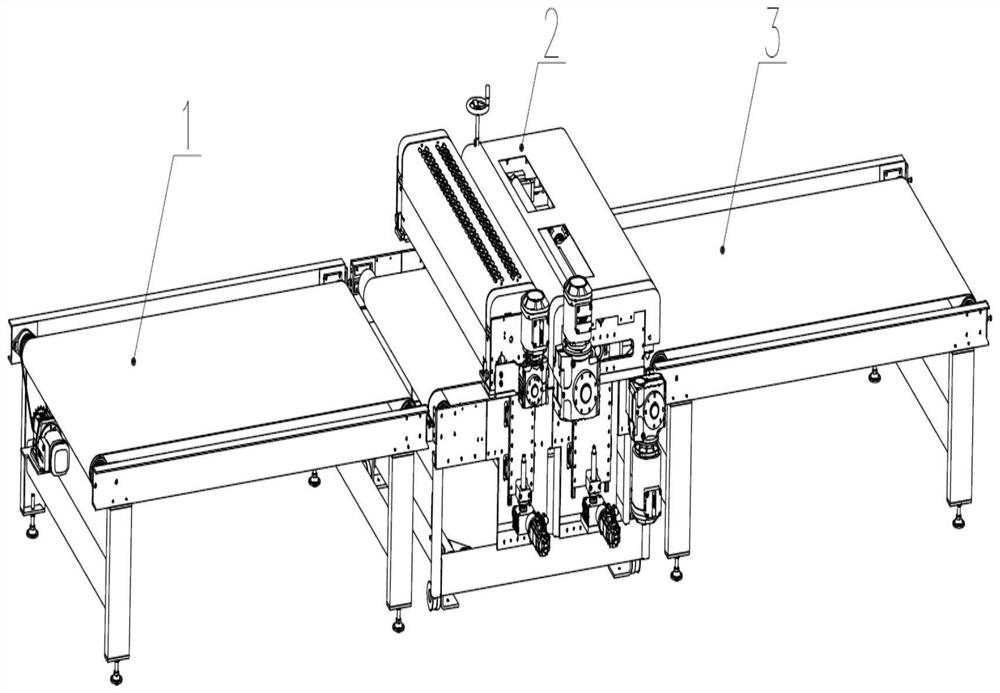

[0062] Embodiment 1, the front belt conveying device 1 is mainly used to pick up the glass sent from the front, and smoothly send the glass into the main machine 2 of the coating machine for roller coating and coating treatment; all the coating processes of the glass plate are completed in the main machine. , and control the thickness and precision of the film layer; after the coating process is completed, the glass is sent to the rear belt conveyor 3 to be sent to the next process, and the coating process is completed. All coating processes are placed in a single mold chamber.

Embodiment 2

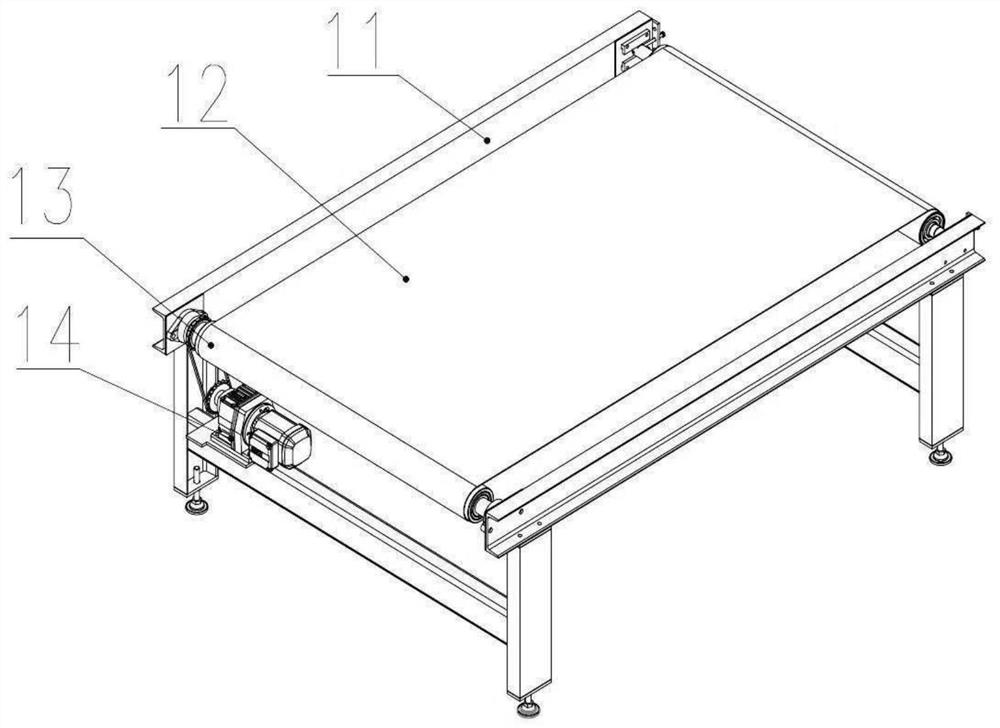

[0063] Embodiment 2, the front belt conveyor 1 includes the front belt conveyor 1 includes a first support frame 11, a second belt 12, a second motor 14, a second driving roller and a second driven roller frame 25, a seamless belt, The driving roller and the follower roller, the second belt 12 is driven by the second motor 14 installed at one end of the second driving roller, the second driving roller is a rubber roller, the material is nitrile rubber, the follower roller is a steel roller, and the second driving roller is a steel roller. Roller speed defaults to coating belt speed

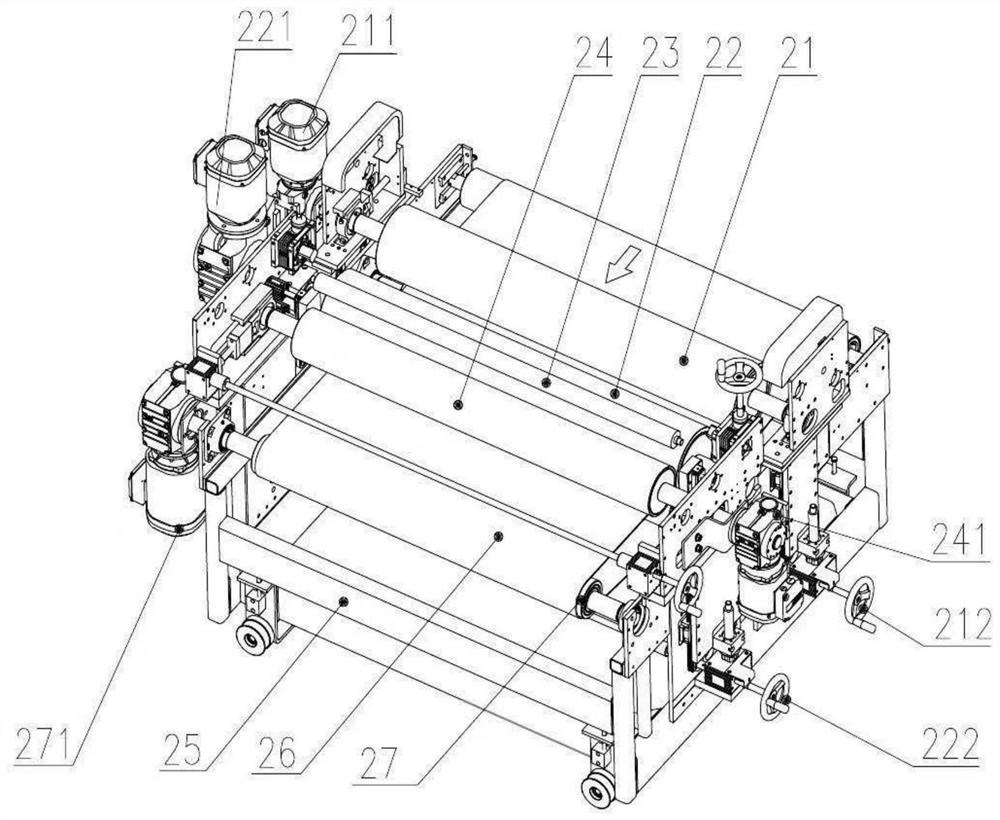

[0064] The main machine 2 of the coating machine includes: a nip roller 21 , a coating roller 22 , a de-texture roller 23 , a quantitative roller 24 , a frame 25 , a first belt 26 and a middle belt conveying device 27 . The main function of the nip roller 21 is to ensure that the glass remains stable during the feeding process. Before the front edge of the glass reaches the nip roller 21, the nip ...

Embodiment 3

[0069] In the third embodiment, the lifting and lowering of the pressing roller 21 is performed up and down by the first lifting device through the first lead screw elevator, and at the same time, it can also be manually adjusted up and down through the first hand wheel 212; the first lifting device can be a lead screw lifting device. Or cylinder lifting device;

[0070] The lifting and lowering of the coating roller 22 and the quantitative roller 24 is performed up and down by the second lifting device through the second screw lifter 223 , and can also be manually adjusted up and down by the second hand wheel 222 .

[0071] In addition, the structure of the rear belt conveyor 3 is the same as that of the front belt conveyor 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com