Multi-cavity horizontal magnetron sputtering film-coating production line and film-coating method thereof

A magnetron sputtering coating and magnetron sputtering technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problem of affecting the performance of coating devices, unclear boundaries, and low production efficiency. problems, to achieve the effect of improving the film forming effect, preventing pollution and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

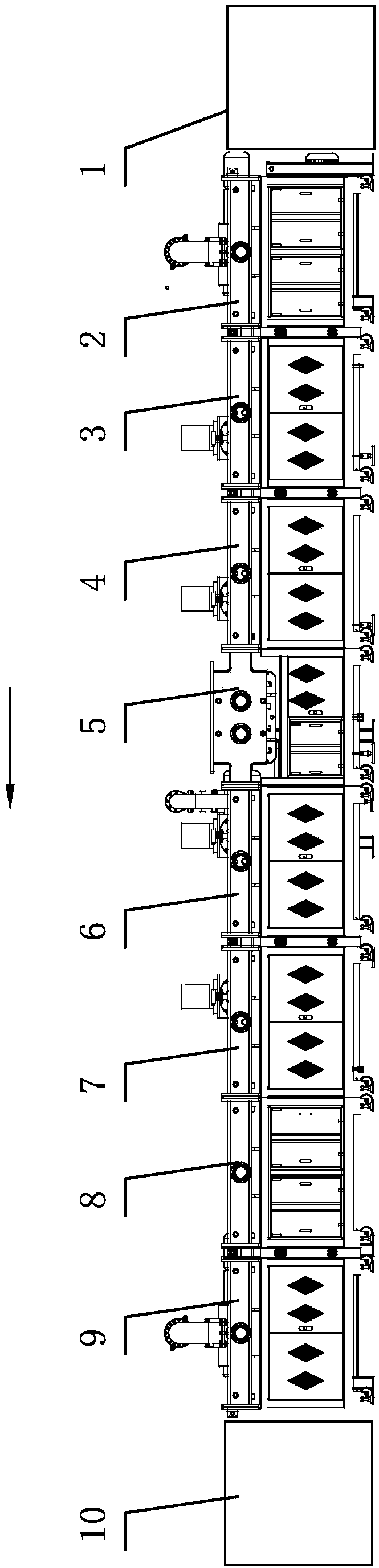

[0028] A multi-chamber horizontal magnetron sputtering coating production line according to the present invention sequentially includes a feeding table 1, a film feeding chamber 2, a heating chamber 3, a front buffer chamber 4, three mutual Independent magnetron sputtering vacuum coating chambers 5, 6, 7, rear buffer chamber 8, cooling chamber 9 and unloading table 10 also include a transport mechanism (not shown) for transporting substrates.

[0029] In the present invention, three mutually independent magnetron sputtering vacuum coating chambers 5, 6, 7 are provided with cylindrical magnetron sputtering targets.

[0030] In the present invention, the transmission mechanism is a variable frequency motor reducer transmission mechanism.

[0031] The invention also discloses a coating method of the multi-chamber horizontal magnetron sputtering coating production line, the specific steps of which are:

[0032] (1) Pre-vacuumization and ion discharge cleaning pretreatment process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com