Multifunctional substrate frame for vacuum coating equipment

A technology of vacuum coating and substrate holder, applied in vacuum evaporation coating, sputtering coating, ion implantation coating and other directions, to achieve the effect of simple installation and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

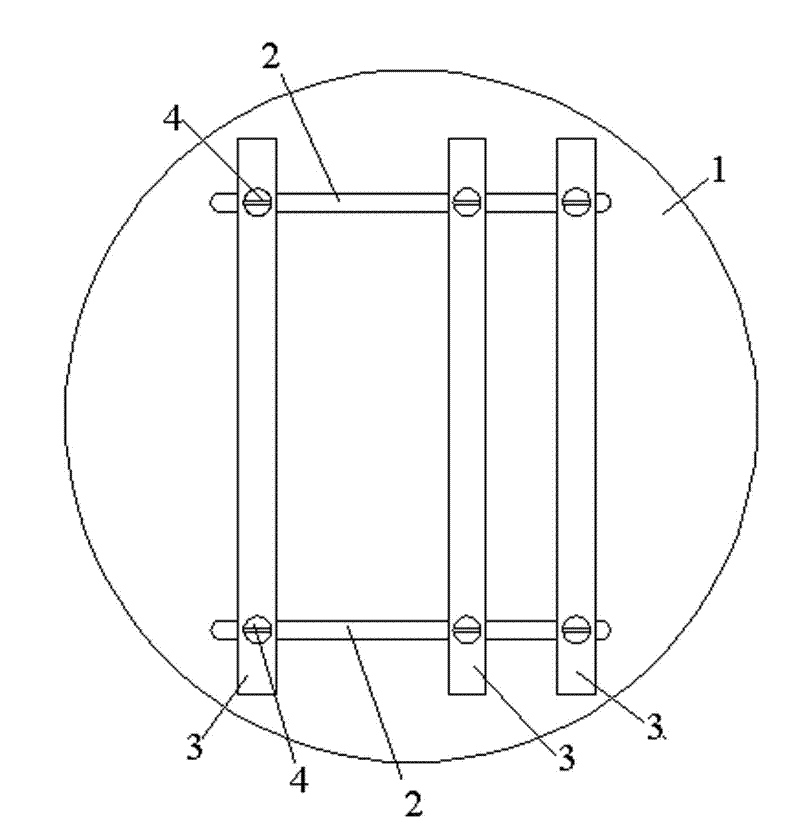

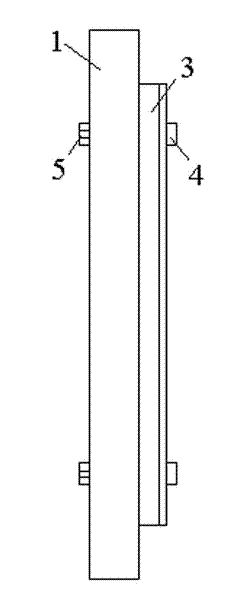

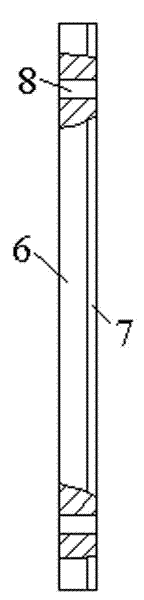

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0015] In the field of surface engineering technology, physical vapor deposition is a relatively mature technology, mainly including various deposition methods such as magnetron sputtering, ion beam sputtering, arc ion plating, and electron gun evaporation. In these methods of deposition equipment, generally A special deposition substrate installation mechanism is required, and in the field of coating, we call it a substrate frame. At present, the common substrate frames on deposition equipment are mainly circular metal structures. In order to meet different shapes of coating substrates, in the actual coating process, a certain number of holes of the same size as the substrate are often processed on a stainless steel plate of a certain size, and then the substrate to be coated is placed into the holes on the stainless steel plate middle. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com