Anti-frost-crack hard downpipe and processing technology thereof

A processing technology and downspout technology, applied in the downspout field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

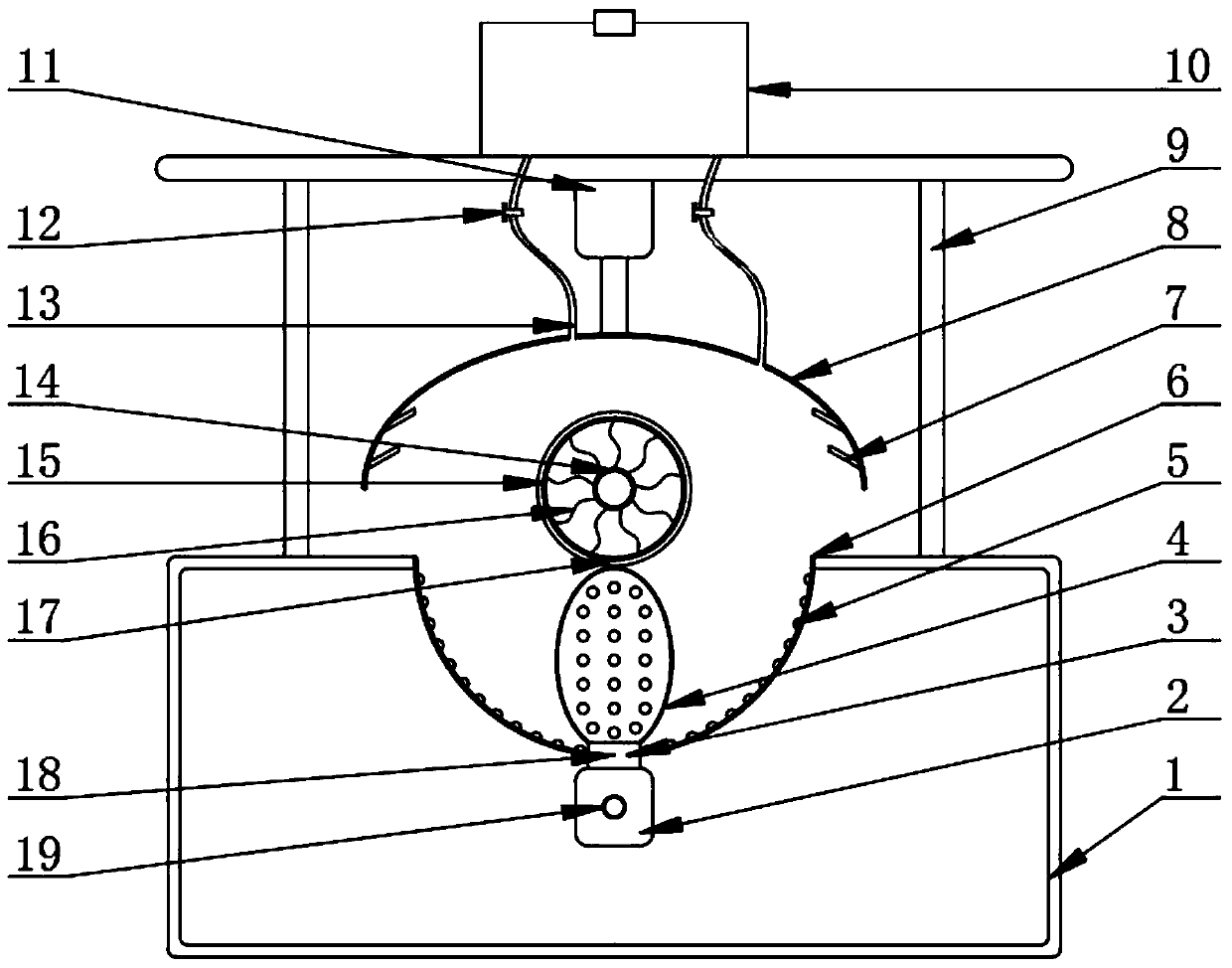

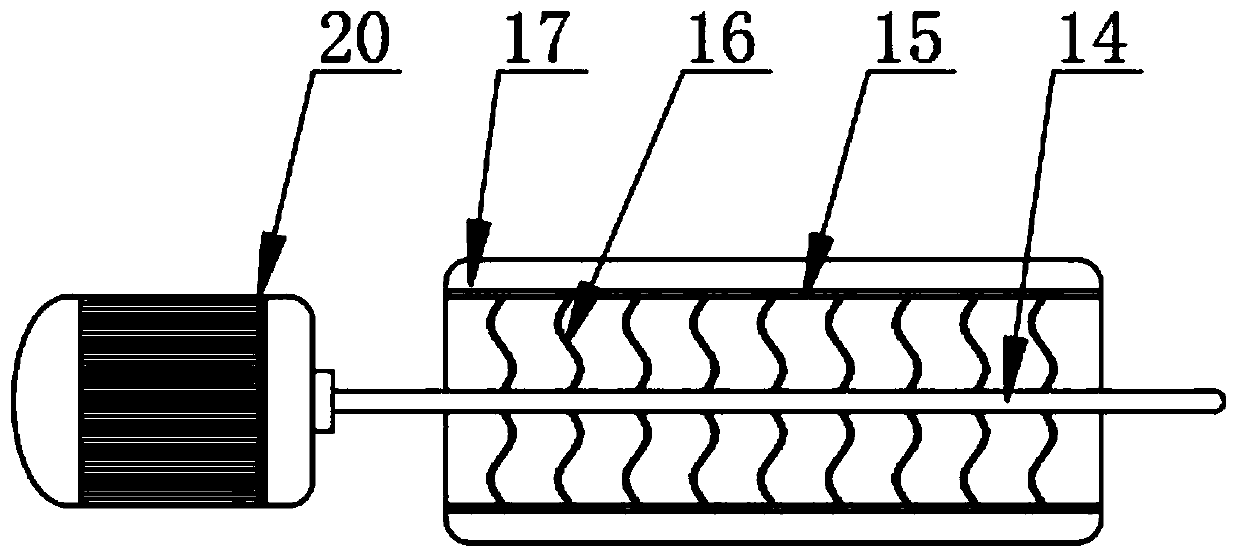

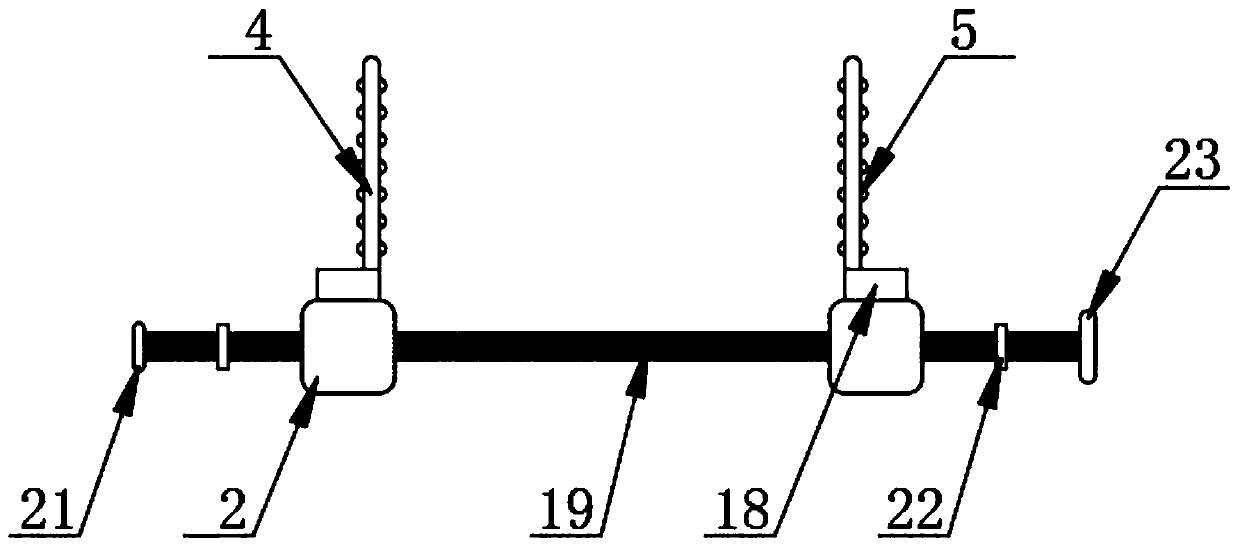

Image

Examples

Embodiment 1

[0038] An anti-freezing and cracking hard downpipe, comprising an inner pipe layer and an outer cladding paint;

[0039] And the raw materials of the inner pipe layer are 90 parts by weight of PVC resin, 25 parts of PVDF resin, 5 parts of triphenyl phosphite, 5 parts of vinyl triperoxy tert-butyl silane, 2 parts of zinc oxide Nanoparticles, 2 parts of aluminum nitride nanoparticles and 2 parts of silver nanowires;

[0040] Among them, the particle diameter of zinc oxide nanoparticles is 300 nanometers, the particle diameter of aluminum nitride nanoparticles is 500 nanometers, and the length of silver nanowires is 1150 nanometers;

[0041] And the raw materials of the outer coating are 70 parts by weight of PVC resin, 35 parts of dioctyl phthalate, 15 parts of neoprene rubber, 5 parts of dioctyl sebacate, 5 parts of glass Fiber and 5 parts of silicon carbide nanoparticles;

[0042] Wherein, the length of the glass fiber is 7 micrometers, and the particle diameter of the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com