Inverse circular sand washing adapter connector in rotary type of twin pipe

A rotary, reverse-circulation technology, used in flushing wellbore, wellbore/well components, earth-moving drilling, etc., can solve the problem that fluid cannot be in and out at the same time, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

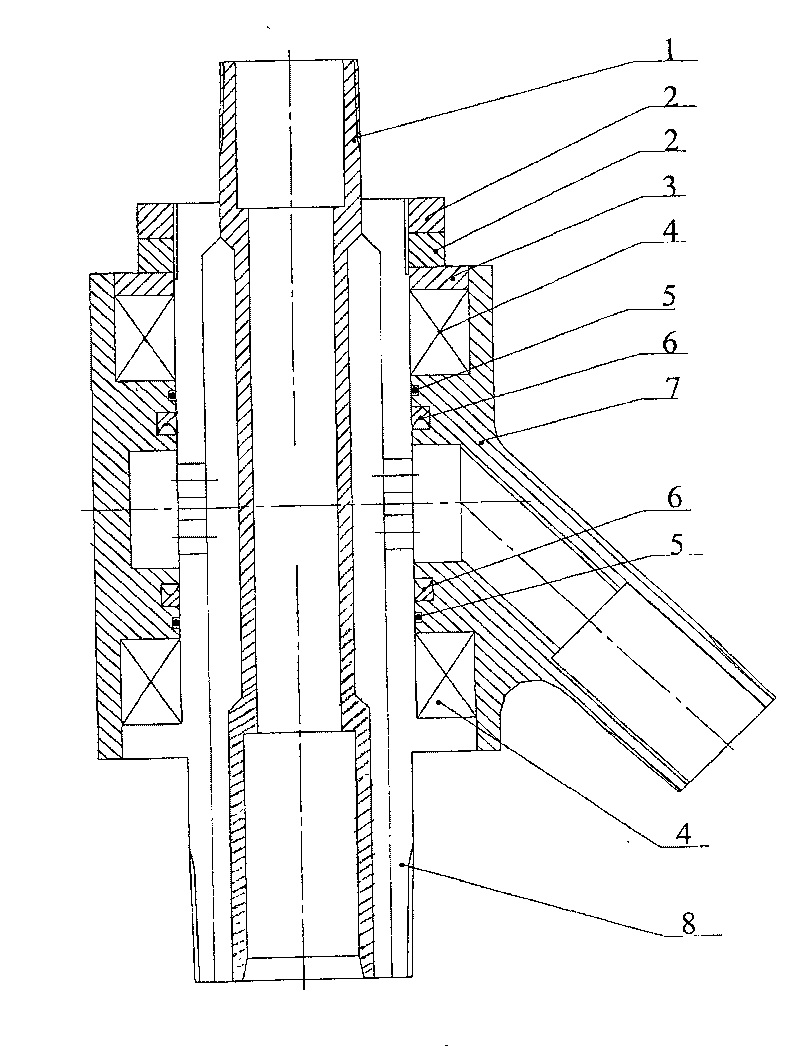

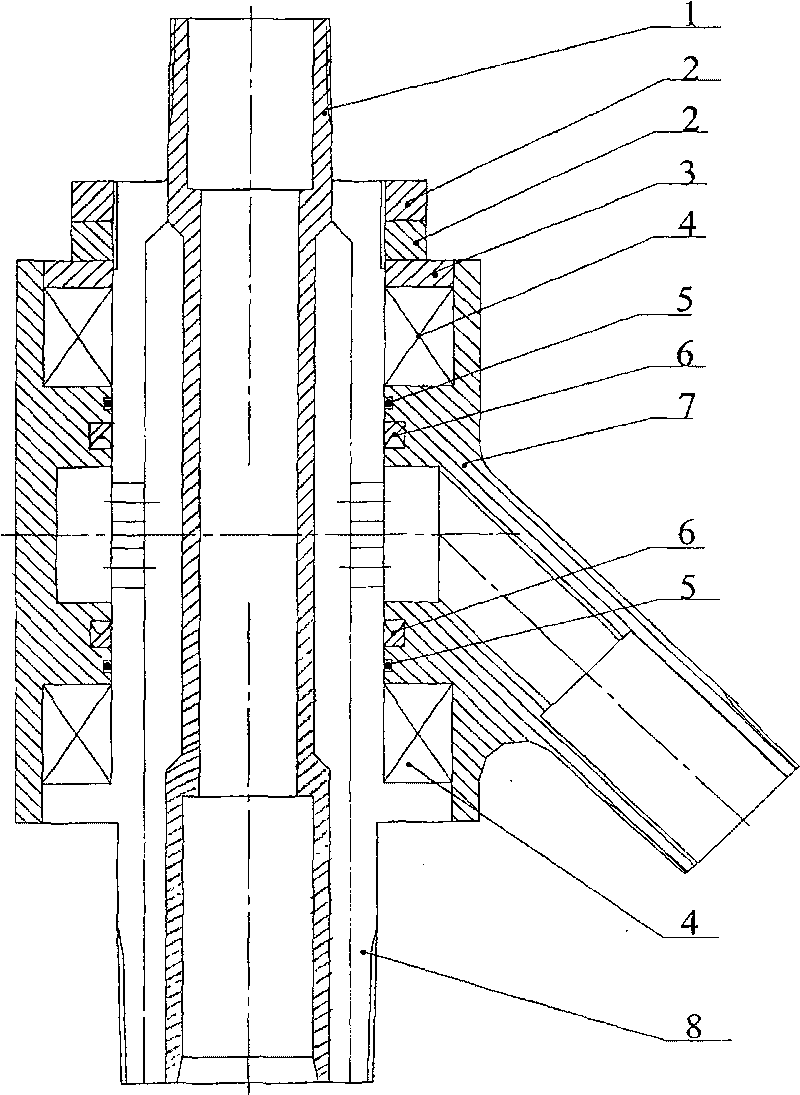

[0008] In the accompanying drawings, a double-pipe rotary reverse circulation sand flushing joint consists of a sand flushing connecting pipe and an elbow joint 1, a compression ring 2, a backing ring 3, a thrust bearing 4, an O-ring 5, and a special sealing ring 6. The three-way conical shell 7 and the support shell 8 are composed. One side of the three-way conical shell 7 is provided with an oblique water inlet hole, and the other side is a closed shell. On the three-way conical shell, The lower part is respectively provided with reserved grooves for the thrust bearing 4, O-ring 5 and special sealing ring 6; the thrust bearing 4, O-ring 5 and special sealing ring 6 are respectively put into the reserved grooves, The thrust bearing 4 reserved groove on the upper part of the conical shell 7 is equipped with a backing ring 3 and a compression ring 2, and the backing ring 3 and the compression ring 2 are connected with the supporting shell 8 with threads, the sand washing connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com