Purging structure special for rolling mill

A rolling mill and bottom plate technology, which is applied in the field of special purging structure for rolling mills, can solve problems such as poor purging effect, and achieve the effect of promoting cleaning, improving efficiency and expanding area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

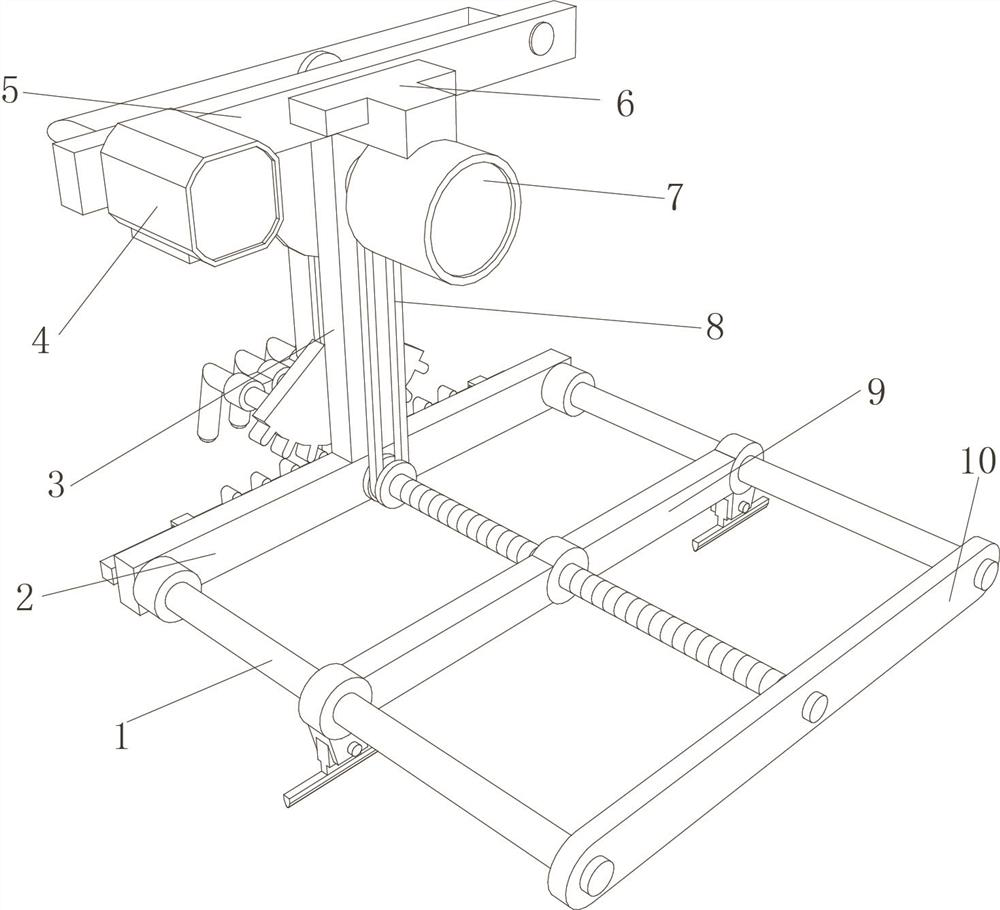

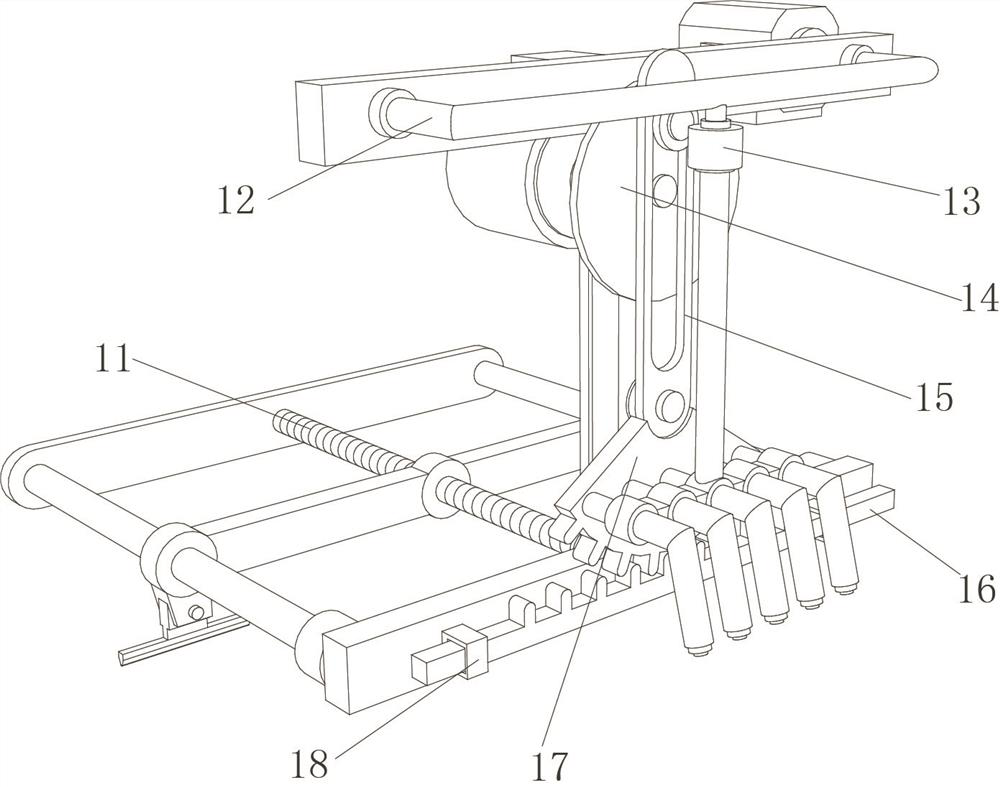

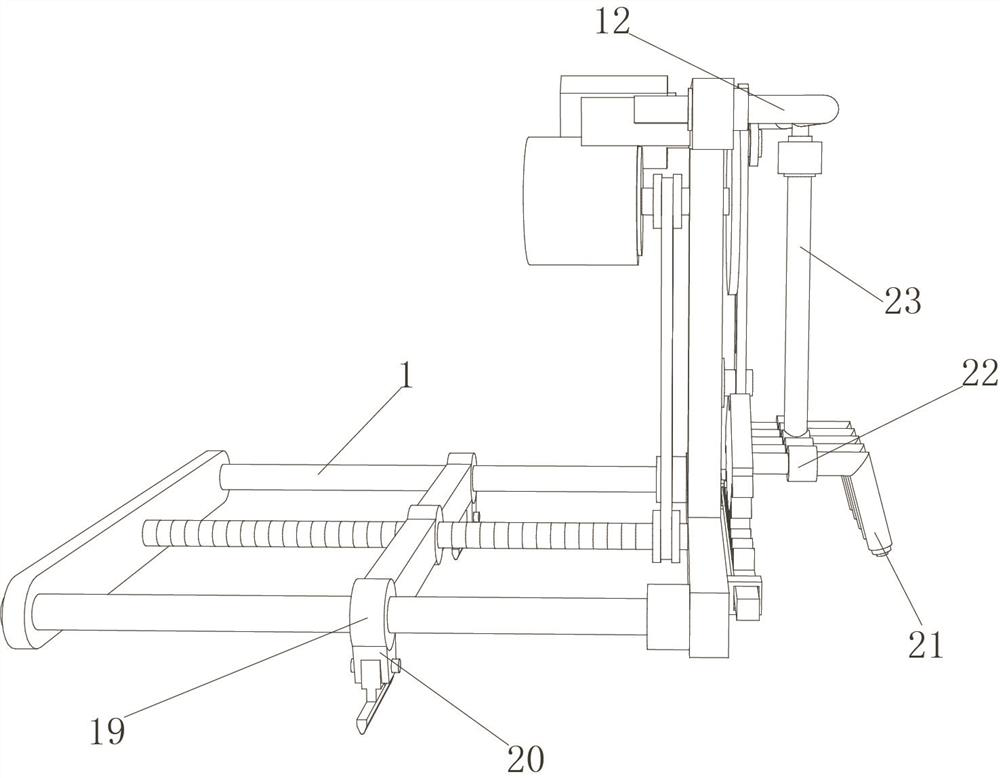

[0033] Rolling mill special purging structure, such as Figure 1-4As shown, it includes a base plate 2, a fixed plate 3 and a top plate 5. The outer wall on the opposite side of the bottom plate 2 and the top plate 5 is connected by the fixed plate 3, and the outer wall on one side of the top plate 5 is fixed with a support plate 6 by bolts. The outer wall of the bottom is fixed with a motor 7 by bolts, and the output end of the motor 7 is connected with a swing blowing mechanism through threads, and the outer wall of the bottom plate 2 near the bottom of the motor 7 is fixed with a screw rod 11 through a bearing, and the screw rod 11 and the output end of the motor 7 are respectively sleeved. Pulleys are connected, and the outer walls of the two pulleys are sleeved with the same transmission belt 8, and the outer walls of the ends of the bottom plate 2 near both sides of the screw rod 11 are respectively connected with guide rods 1 through threaded fixing rings, and the two gu...

Embodiment 2

[0038] Rolling mill special purging structure, such as Figure 5 As shown, in order to improve the effect of blowing air out of the trachea 21; this embodiment makes the following improvements on the basis of Embodiment 1: each of the trachea 21 is bonded with heating guide boxes 26 distributed equidistantly, and each The inside of the heating guide box 26 is filled with solid mixed sodium, and the inner wall of the output end of each air pipe 21 is bonded with an I-shaped air guide ring 27 and an air nozzle 28; when the air passes through the inside of the air pipe 21, the solid mixture in the heating guide box 26 The sodium element in sodium will react with oxygen to produce sodium peroxide, and absorb water vapor to release heat, thereby effectively heating the passing air, and then when the heated air passes through the I-shaped air guide ring 27, due to the narrow diameter of the middle port , which effectively promotes the accelerated flow of hot air, and is finally expo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com