External device for preventing PLC module from being burnt out due to high input voltage

An external device, high-voltage technology, applied in the direction of emergency protection circuit devices, circuit devices, emergency protection circuit devices, etc. for limiting overcurrent/overvoltage, to achieve the effects of ensuring continuity, easy operation, and saving costs and resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

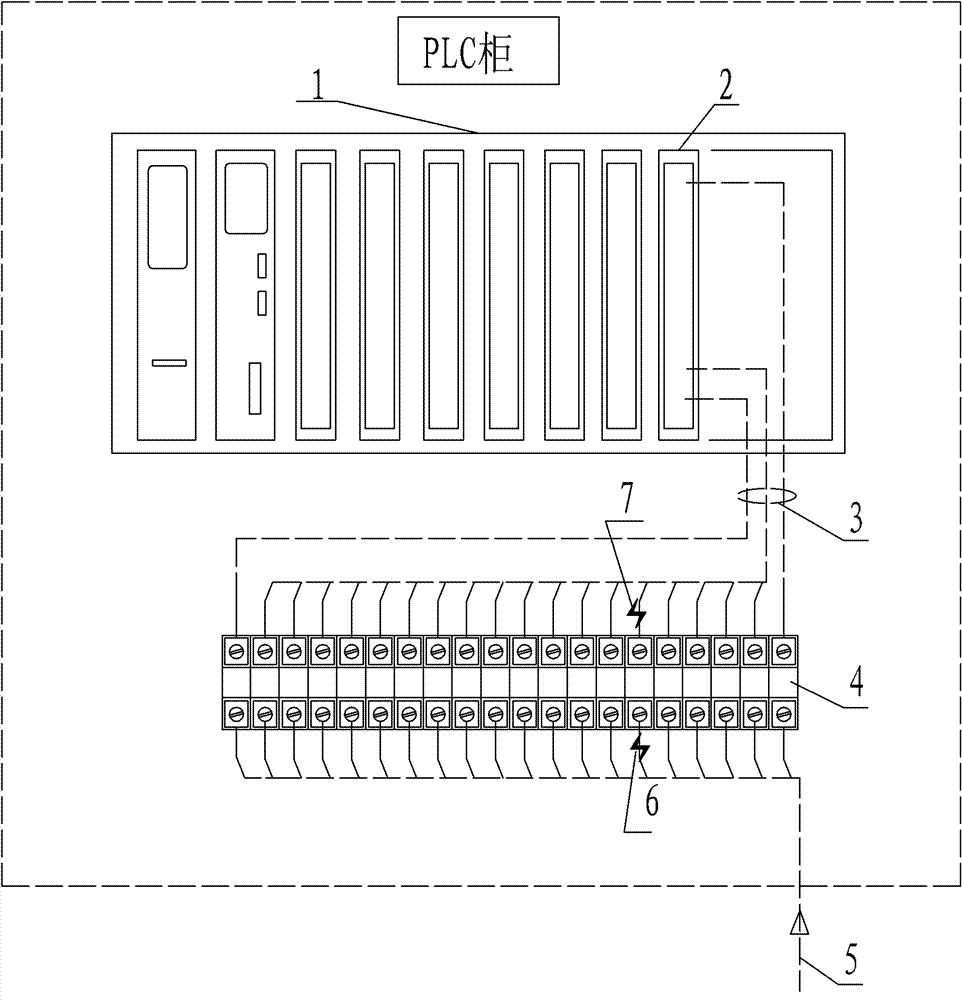

[0034] In the prior art, the connection methods adopted are as figure 1 As shown, the PLC cabinet includes a PLC rack 1. There is a PLC module 2 in the PLC rack 1. The PLC module 2 is connected to the terminal 4 inside the cabinet through the cable 3 inside the cabinet. The other end of the terminal 4 inside the cabinet is connected to the cable 5 outside the cabinet. Connection, if the high voltage 6 introduced by the cable outside the cabinet is introduced in the cable 5 outside the cabinet, the high voltage 7 entering the PLC module will inevitably be brought into the cable 3 in the cabinet so, thereby burning out the PLC module.

[0035] This embodiment includes 20 wiring units and 1 grounding unit, which are connected by connectors.

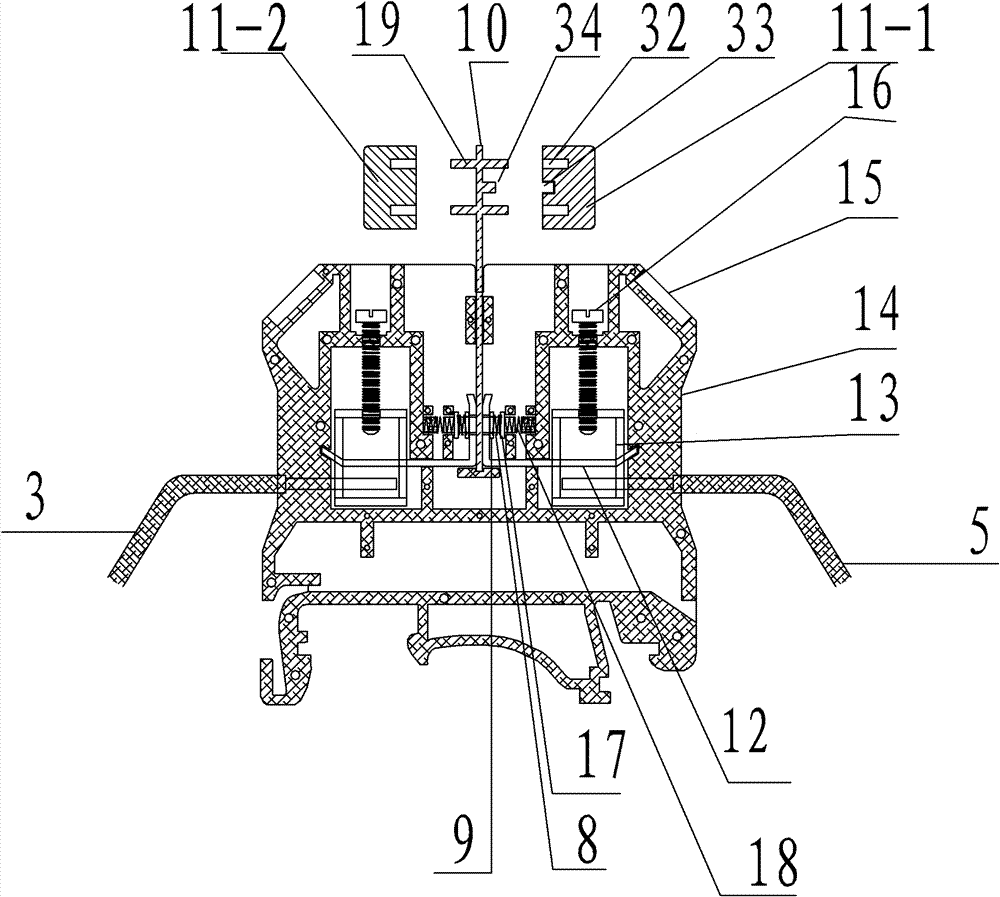

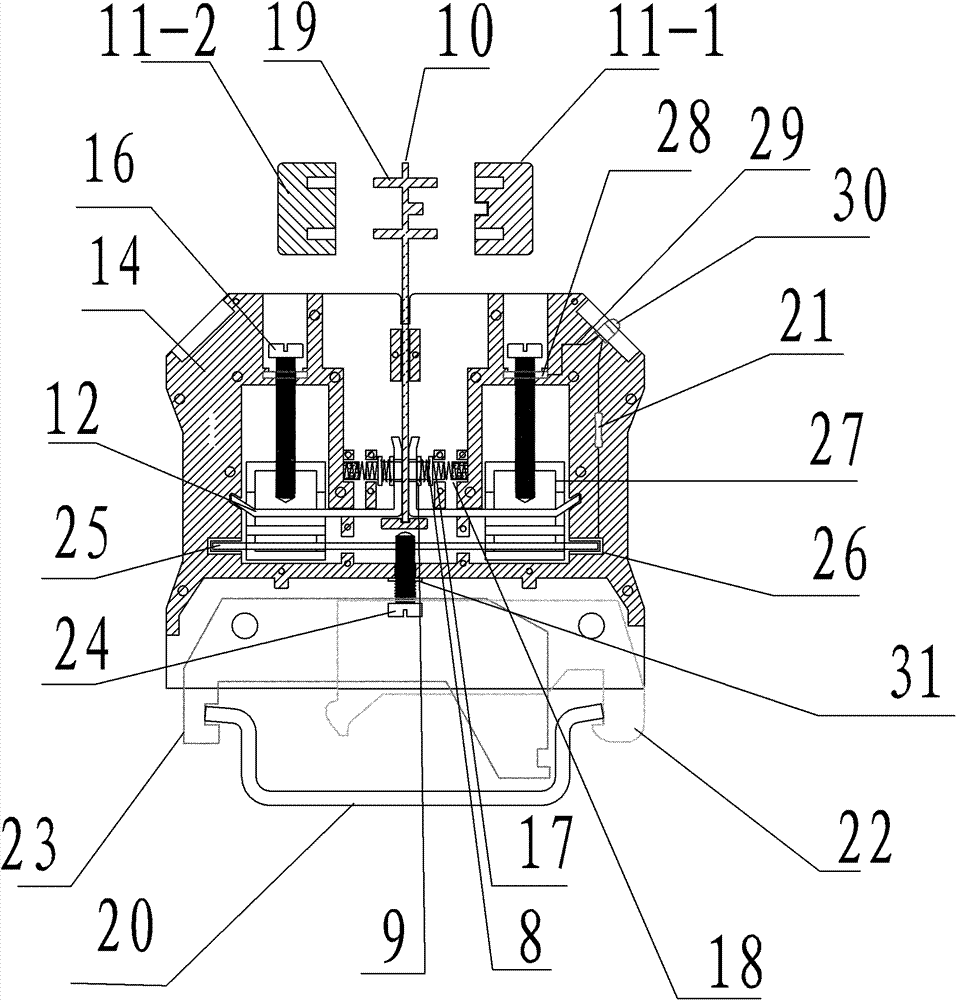

[0036] The wiring unit structure is as figure 2 As shown, it includes an insulated terminal module 14, and the insulated terminal module 14 is provided with two first conductive sheets 12 separated by a spacer 10. One side of the spacer 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com