Milling positioning tool for shaft sleeve

A technology for positioning tooling and milling, which is applied in the field of milling and positioning tooling for shaft sleeves, and can solve problems such as poor adjustment effect and long adjustment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

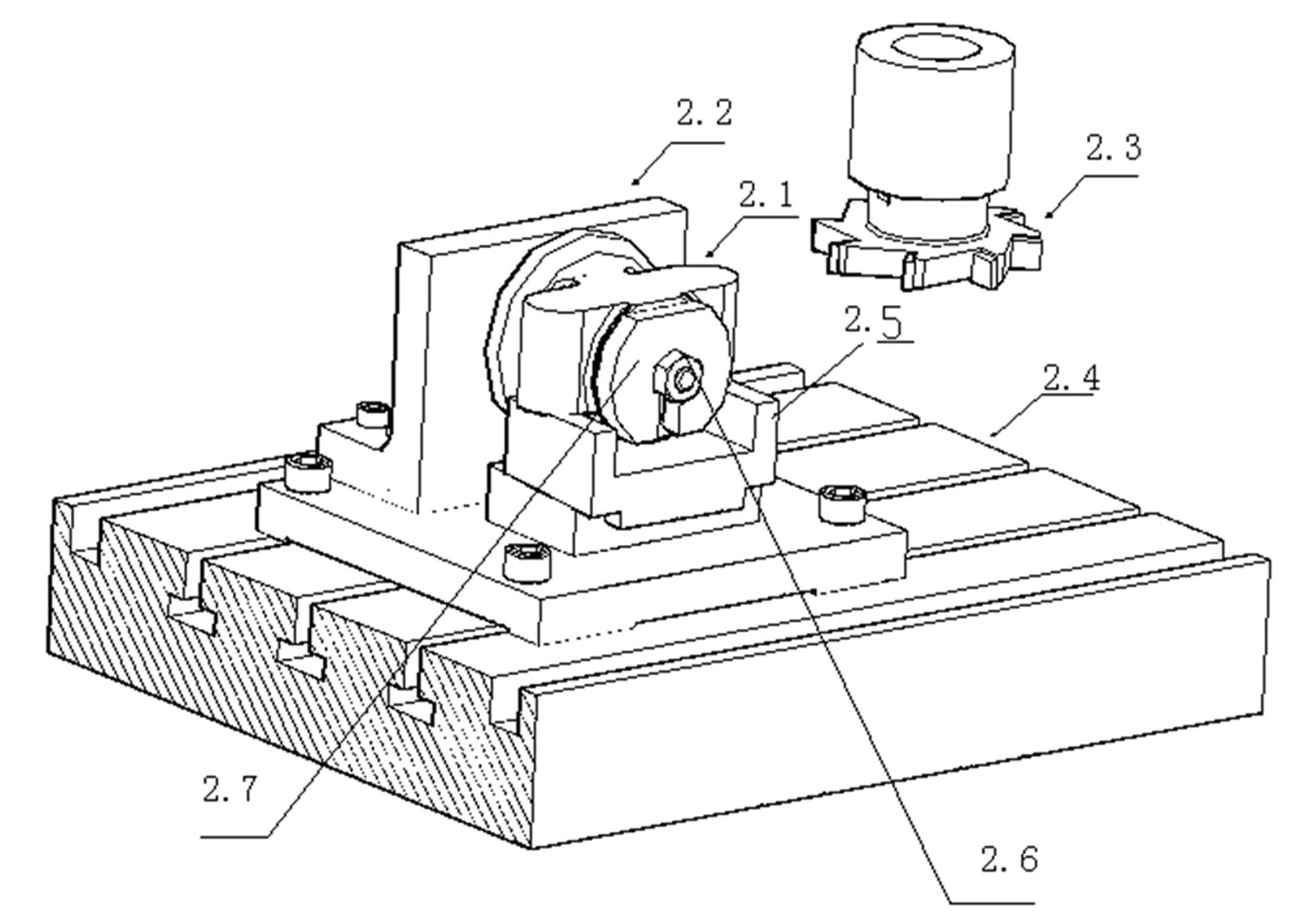

[0017] The technical solution will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0018] A milling positioning tool for a shaft sleeve, including an angle iron mandrel positioning seat 2.2, and an oblique plug iron 2.5; the oblique plug iron 2.5 includes upper and lower parts:

[0019] The bottom surface of the lower part 3.2 is horizontal, and the top surface is provided with inclined grooves;

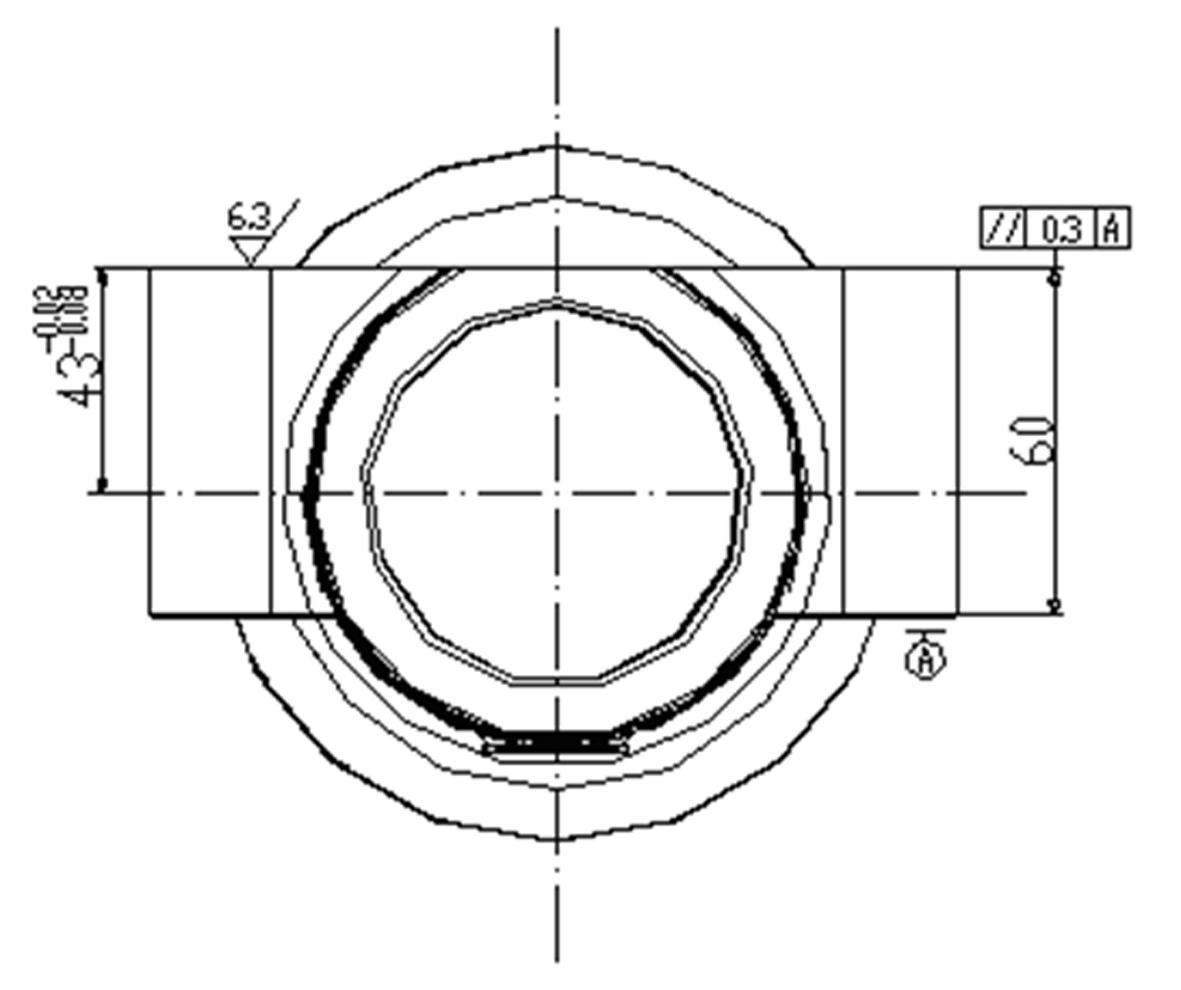

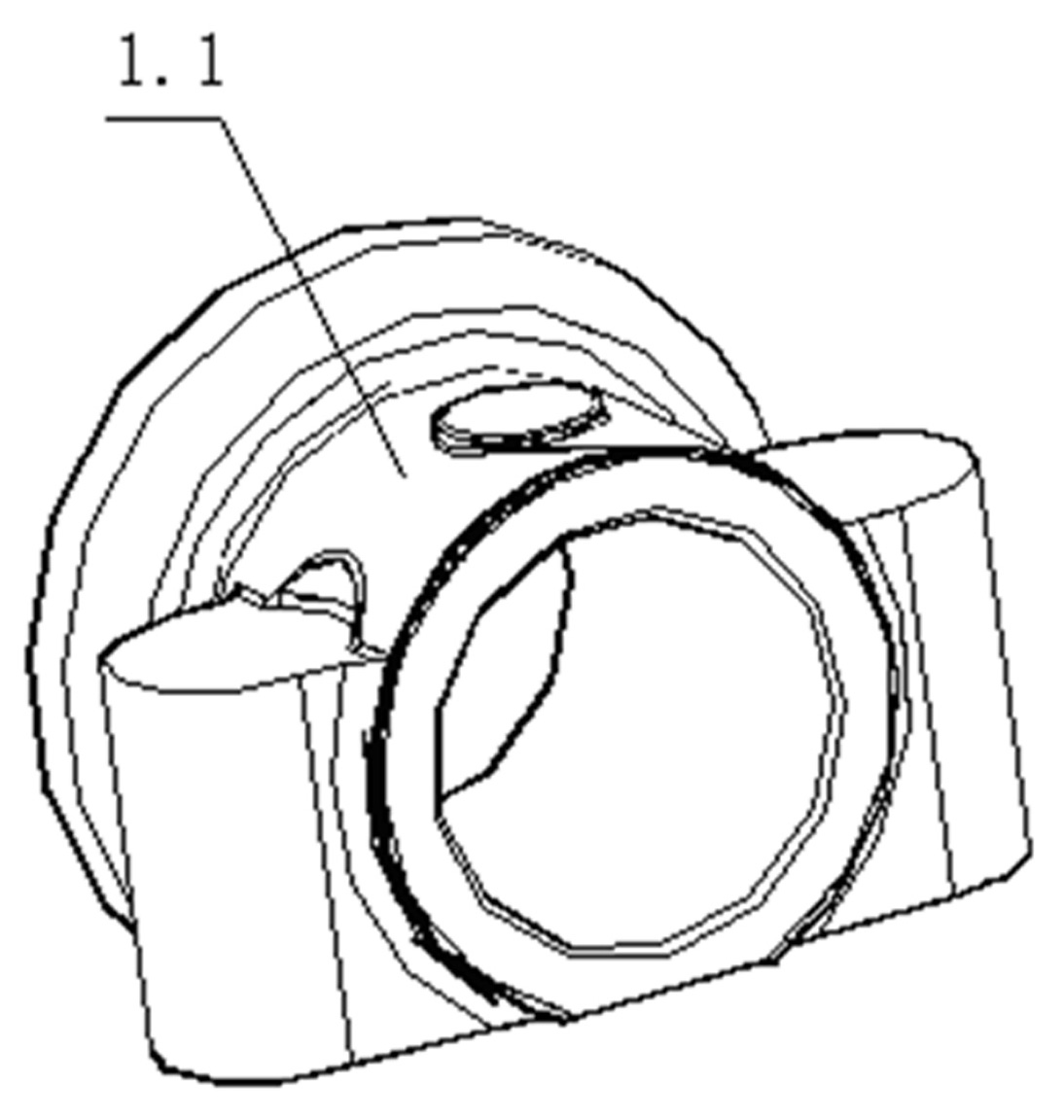

[0020] The top surface of the upper part 3.1 is provided with a horizontal groove, the width of the horizontal groove is not less than the width of the outer arc portion 1.1 of the processed bushing, and the depth of the horizontal groove is not smaller than the outer arc portion of the processed bushing 1.1 in height, the upper edge of the horizontal groove is horizontal;

[0021] The bottom surface of the upper part 3.1 is provided with an inclined protrusion corresponding to the inclined groove; the inclined protrusion slides i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com