Workpiece feeding and discharging device of water heater inner container automatic spraying and acid pickling system and water heater inner container automatic spraying and acid pickling system

A water heater liner, automatic spray technology, applied in chemical instruments and methods, cleaning hollow objects, cleaning methods and utensils, etc., can solve the problems of affecting production efficiency, low production efficiency, and long time, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

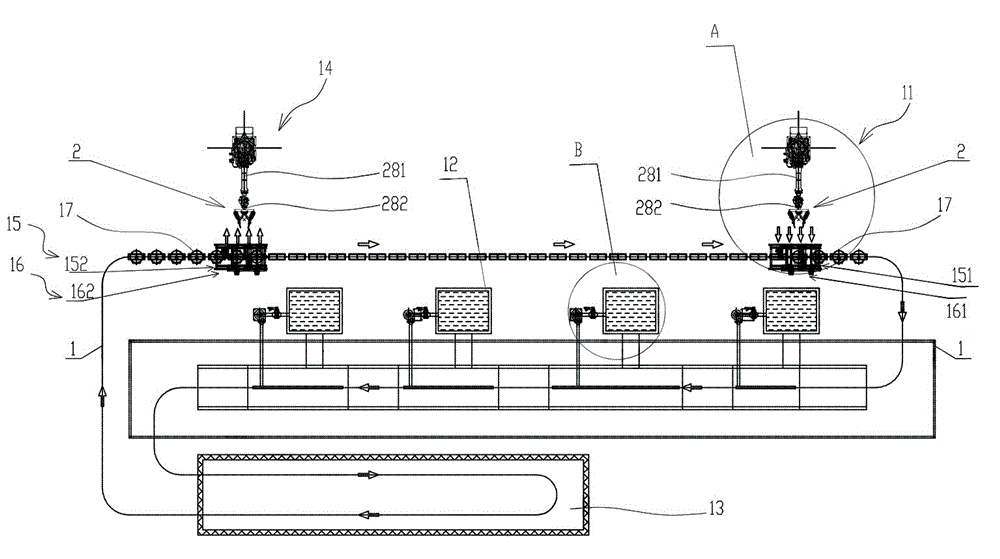

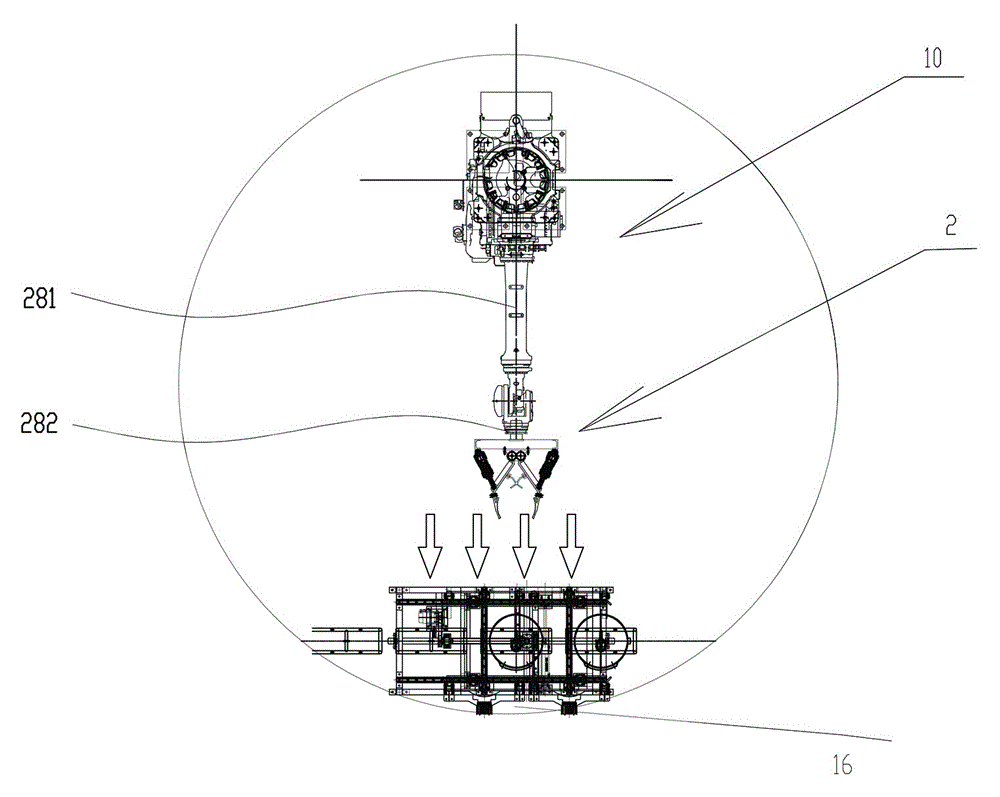

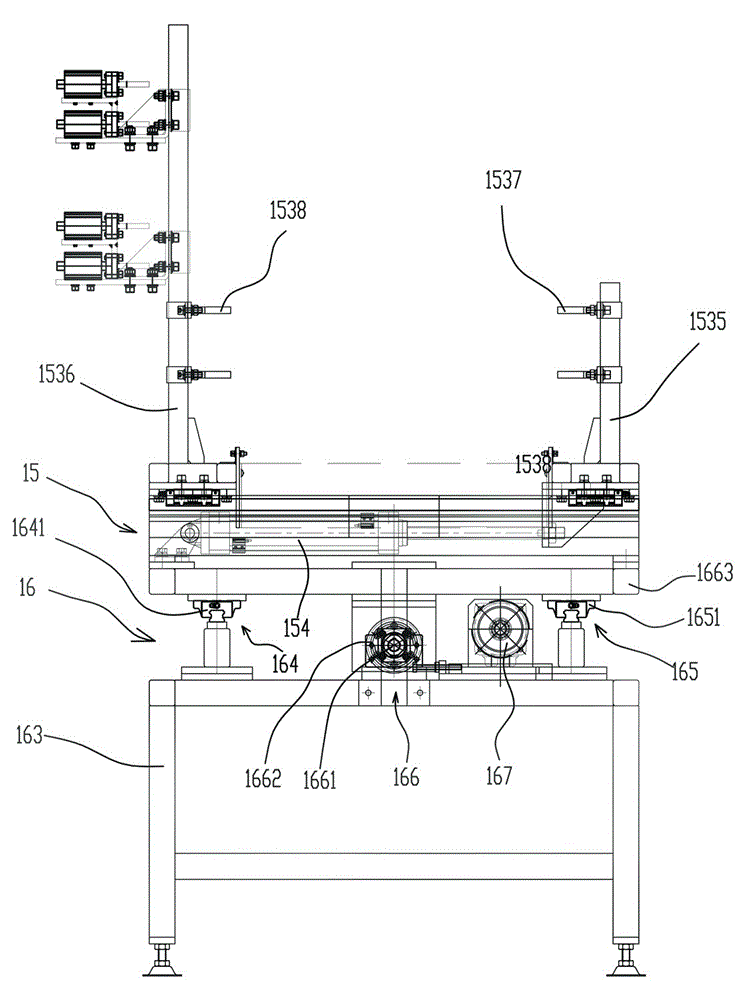

[0038] See Figure 1 to Figure 12 , Figure 1 to Figure 12 What is disclosed is the first embodiment of the upper and lower parts device of the water heater liner automatic spray pickling system, please refer to Figure 1 to Figure 2 , a device for loading and unloading parts of an automatic spray pickling system for water heater inner tanks, including a robot 10 for automatic loading and unloading on one side of a circulating conveyor chain 1, and a telescopic clamping basket 17 Or the unclamped centralizing device 15, when going up or down, described centralizing device 15 clamps described hanging basket 17, and the claw 2 of described robot 10 then places water heater liner 90 in described hanging basket 17 or The water heater liner 90 is taken out from the hanging basket 17, and the righting device 15 releases the hanging basket 17 to complete the upper or lower moving parts. In this way, it can be realized that when loading and unloading parts, the swinging of the hangi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com