Overturning machining mechanism for central hole of steering knuckle

A processing mechanism and center hole technology, which is applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problem that the steering knuckle fixture cannot meet the processing requirements of fast loading and unloading, the processing efficiency of the steering knuckle is strict, and it is difficult to meet the output requirements and other issues to achieve the effect of optimizing the overall layout, optimizing the clamping parts, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described below in conjunction with accompanying drawing.

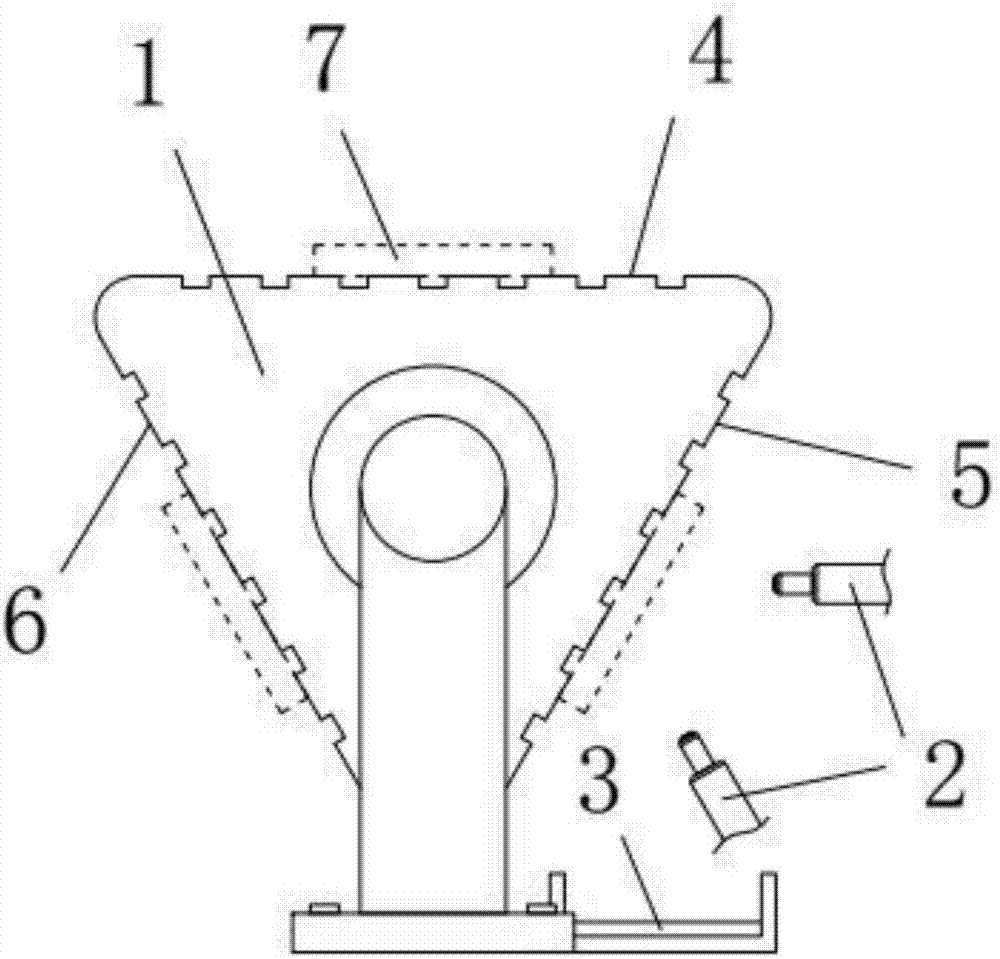

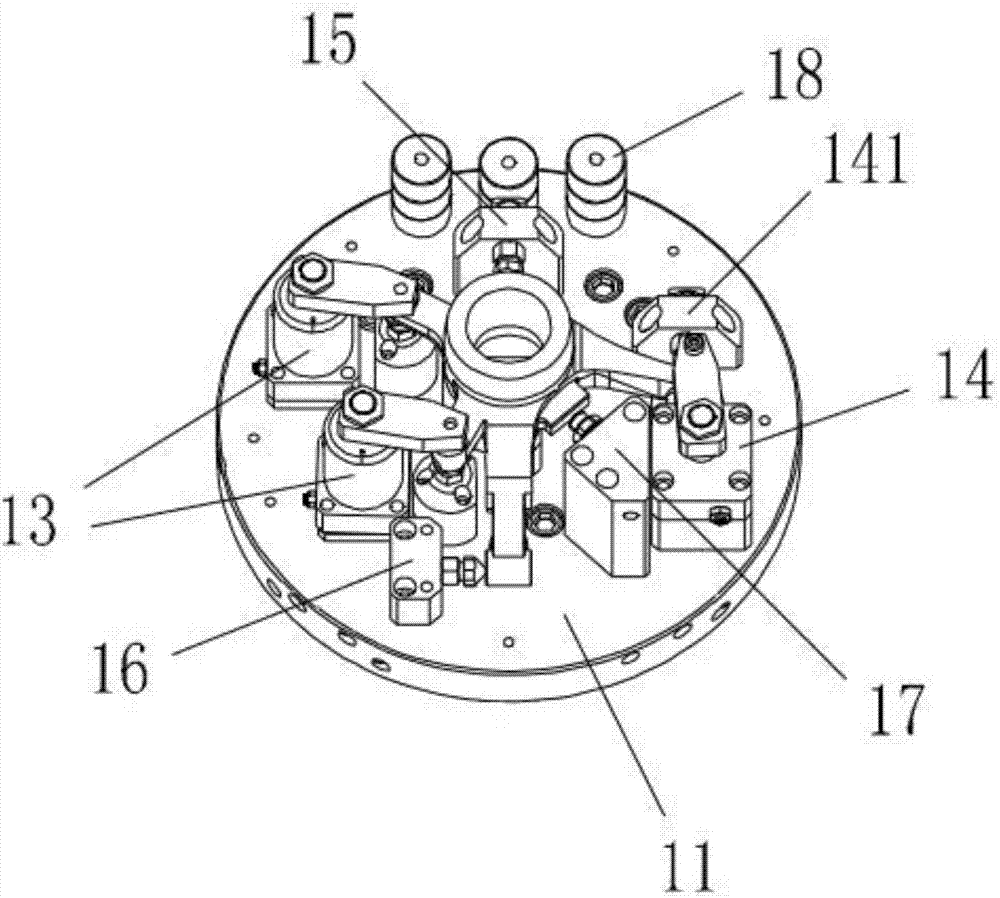

[0013] as attached Figure 1-2 As shown, the turning mechanism of a steering knuckle center hole according to the present invention includes a turning table 1, a flushing device 2 and a chip removal mechanism 3; the turning workbench 1 is a three-sided turning workbench consisting of Equilateral triangular structure, the three surfaces are the processing table 4, the cleaning table 5 and the clamping table 6, but the working properties of the three table tops are constantly changing with the turning action; 5, the flushing device 2 is generally connected to the processing frame, and the flushing device 2 can include multiple nozzles, corresponding to different positions of the cleaning table 5, and the chip removal mechanism 3 is a conveying mechanism, and is correspondingly arranged on the lower side of the cleaning table 5 A center hole processing fixture 7 is installed on each said ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com