Automatically-released hoist ring and combined loading and unloading frame with same

A technology of hoisting rings and loading and unloading racks, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problem that the shipment cannot be realized at one time, and achieve the effects of saving manpower, saving labor, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

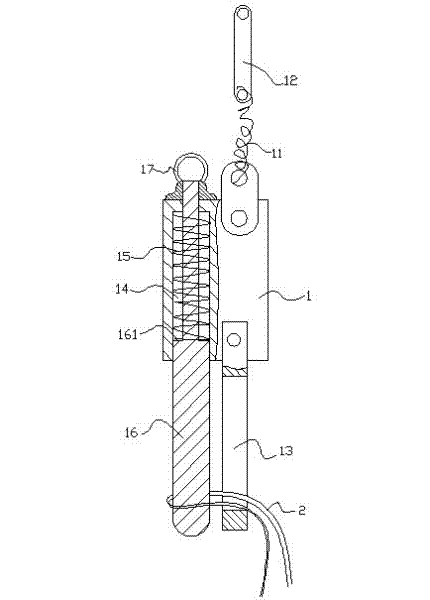

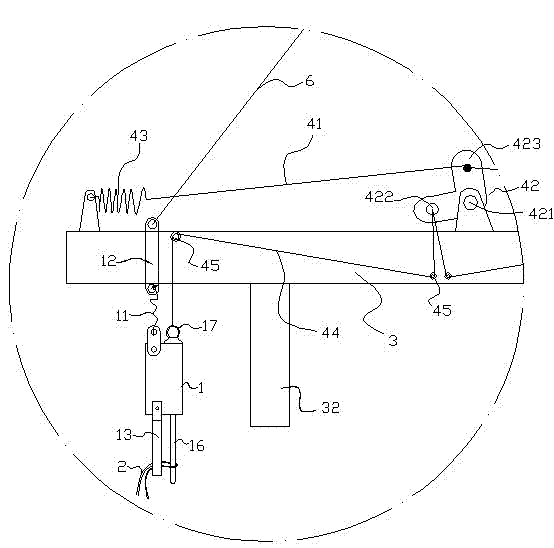

[0032] Such as figure 1 As shown, an automatic detachable hoisting ring, the whole detachable hoisting ring includes a body 1, the upper end of the body 1 is hingedly provided with a connecting cable chain 11 and a connecting ring 12, and the lower end of the body 1 is hingedly provided with a snap ring 13. The main body 1 is provided with a two-stage stepped installation hole 14 , which is small at the top and large at the bottom, and an elastic telescopic device is arranged in the installation hole.

[0033] The elastic telescopic device includes a spring 15 and a pull rod 16 . Wherein the spring 15 is arranged in the lower step hole of the mounting hole 14; the spring seat 161 supporting the spring 15 is arranged on the pull rod 16, and the upper end of the pull rod 16 passes through the spring 15 and stretches out from the mounting hole 14 upper end of the body 1, and the pull rod 16 The upper end protrudes from the main body and is provided with a nut ring 17 for positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com