Underground flowering pile driver used in cooperation with excavator

A technology for excavators and pile drivers, which is applied to sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of heavy equipment configuration, heavy construction and operation labor, and inconvenient operation, so as to ensure safety and operation. Convenient, easy-to-connect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

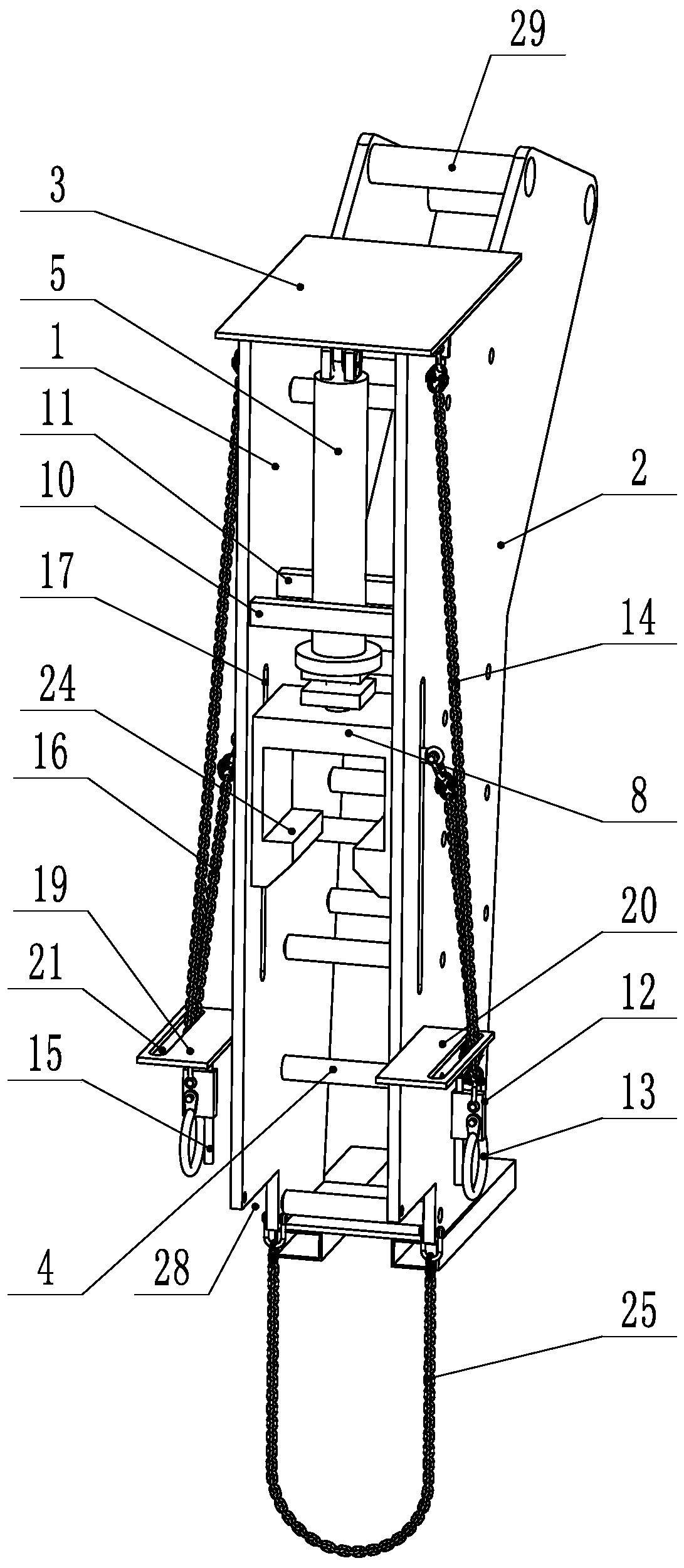

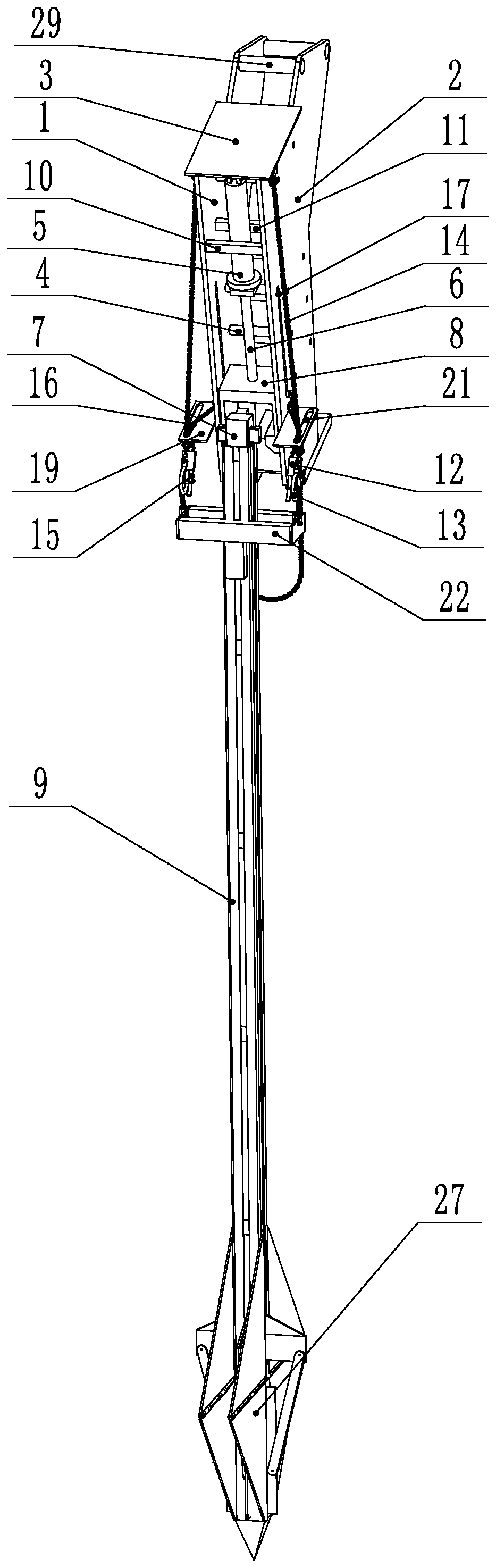

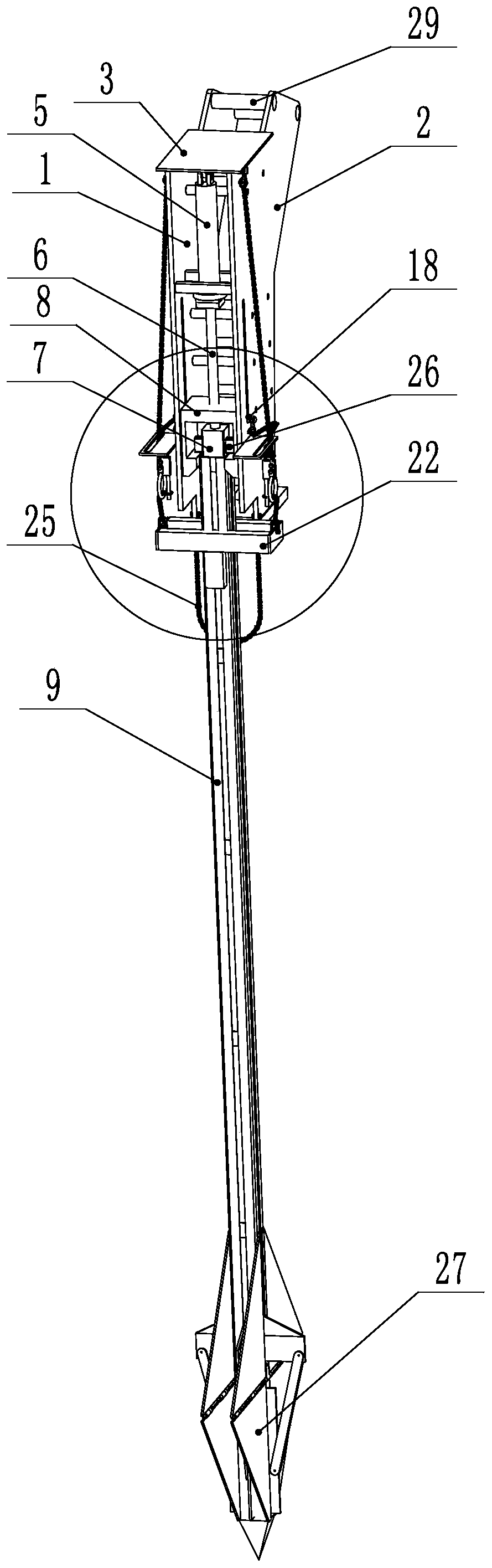

[0026] The present invention will be further described below with specific embodiment, see figure 1 -6:

[0027] A driving device for piling equipment, used in conjunction with an excavator, including a pile driver assembly, the pile driver assembly includes a left side plate 1, a right side plate 2, a left side plate 1, and a right side plate 2 arranged at intervals from left to right The top plate 3 is arranged on the upper end of the top plate, and the left side plate 1 and the right side plate 2 are connected by several connecting columns 4 . The connecting column 4 can keep a certain distance between the left side plate 1 and the right side plate 2 . Between the left side plate 1 and the right side plate 2, an oil cylinder 5 is arranged, and there should be a ready-made oil circuit on the excavator itself, so the present invention has an oil cylinder, and certainly structures such as cylinders and screw mandrels can also be used. The oil cylinder 5 is connected on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com