Automatic control system and method for diesel locomotive in factory

An automatic control system and a technology for internal combustion locomotives, which are applied to locomotives with internal combustion engines, locomotive propulsion methods, and locomotives with gas turbines, etc., to reduce labor costs, reduce safety risks, and improve operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Such as figure 1 , figure 2 , according to the plant area diesel locomotive automatic control system provided by the present invention, comprising:

[0046] Module M1: Add a locomotive control cabinet in the locomotive control room, with built-in locomotive controllers and access modules, etc., so as to complete the automation transformation of the locomotive control system and equip it with a remote control equipment foundation.

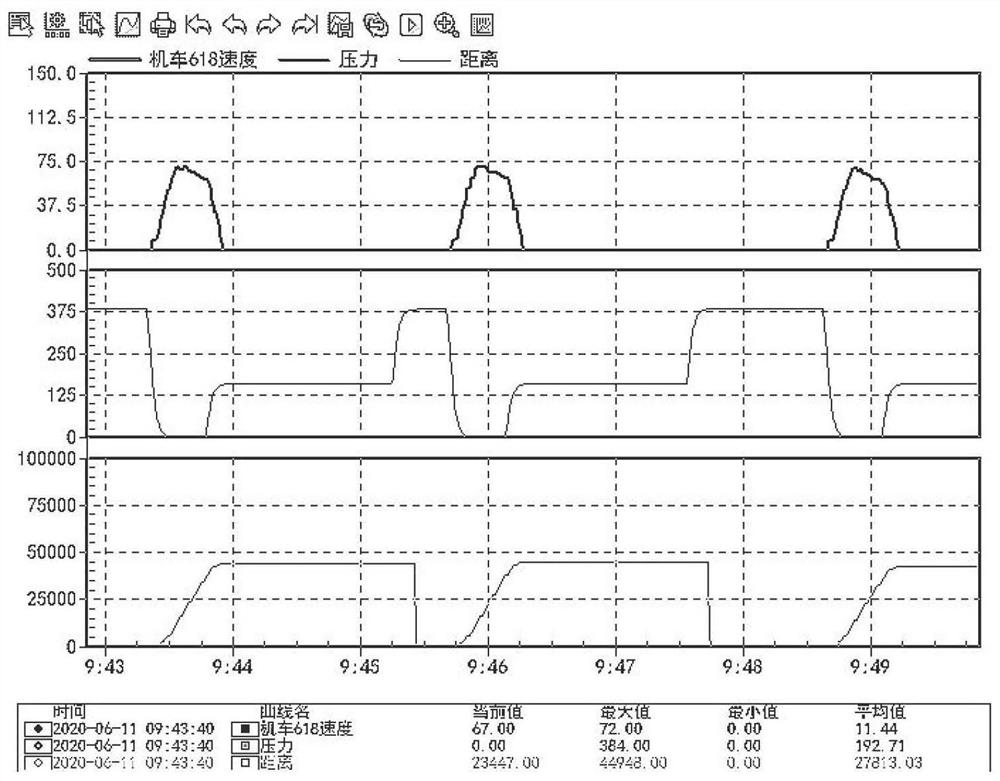

[0047] Module M2: Establish a distance-speed model by fitting the speed and distance state curves of diesel locomotives under multi-level loads. At the same time, by comparing the real-time gear status of the train, the multi-level speed gear, multi-level brake pressure gear and coasting acceleration\deceleration empirical range values are obtained, and the locomotive is customized according to the empirical operation steps of the locomotive operation under different working conditions. Expert library model. Then use the speed, distance...

Embodiment 2

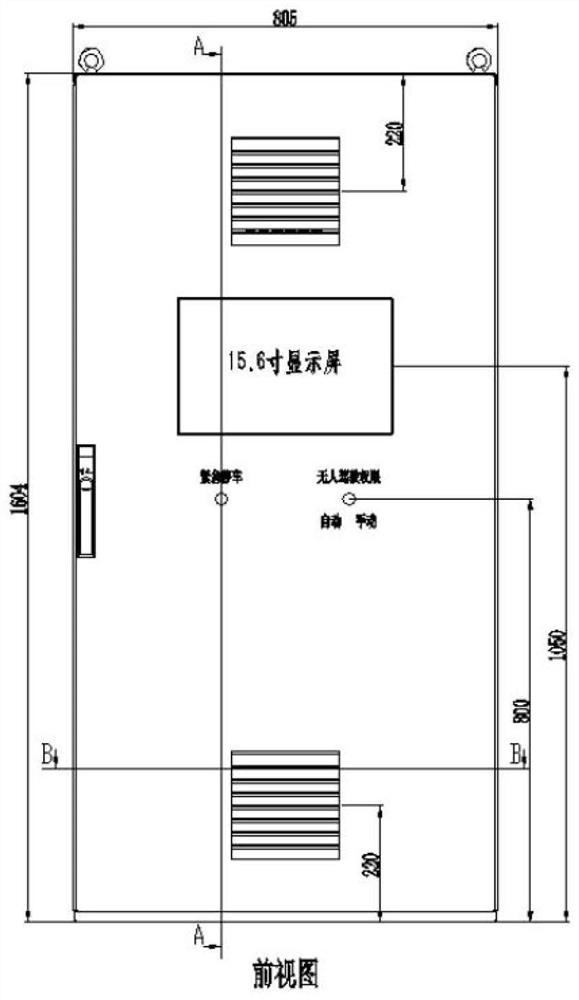

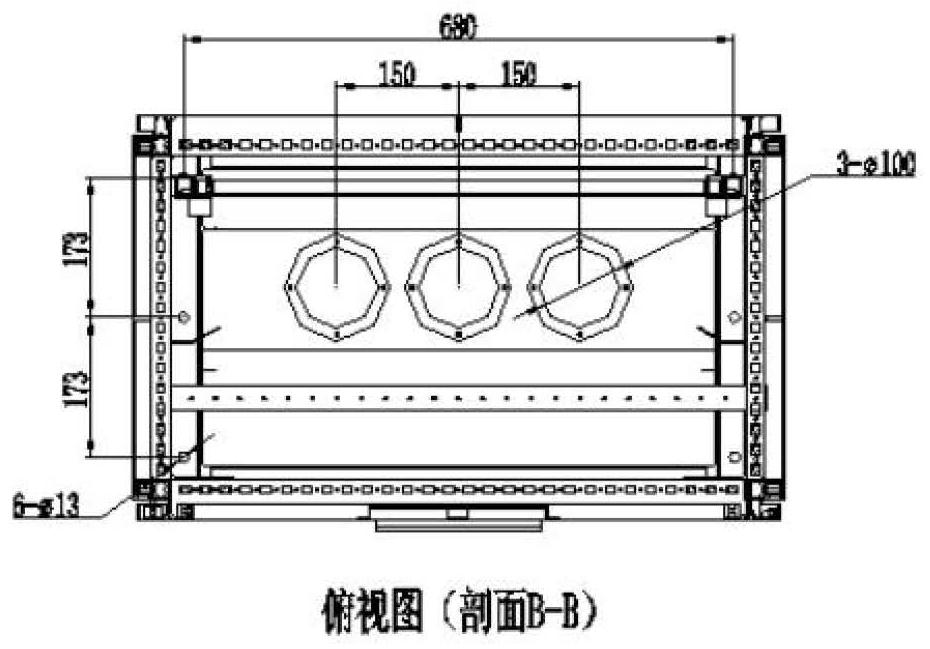

[0054] Such as Figure 7 The locomotive control cabinet is installed in the locomotive control room, and the locomotive controller, display device, switch, access module, power module, emergency stop button and relay are built in the cabinet to realize the access to the locomotive signal and the control command. send, and remotely control the locomotive. Specifically: the upper platform uses the wireless network to issue operation instructions to the locomotive controller through the switch, and the expert system in the controller controls the locomotive operation instructions, and realizes the safety protection function of the locomotive according to the protection strategy. The command needs to issue control operations such as valve gear position, and realize the signal access and equipment control of various equipment of the locomotive through the signal access module, so as to realize the automatic control function of the locomotive; the display device is mainly used to di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com