Vacuum no-oxygen bulk grain warehouse

A granary and vacuum technology, which is applied in the field of grain storage and transportation equipment, can solve the problems of difficult promotion, less standardized and large-scale production methods, and failure to realize green grain storage, so as to solve the problem of complicated procedures and high costs, reduce soybean A large amount of loss of class, to achieve the effect of mechanized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

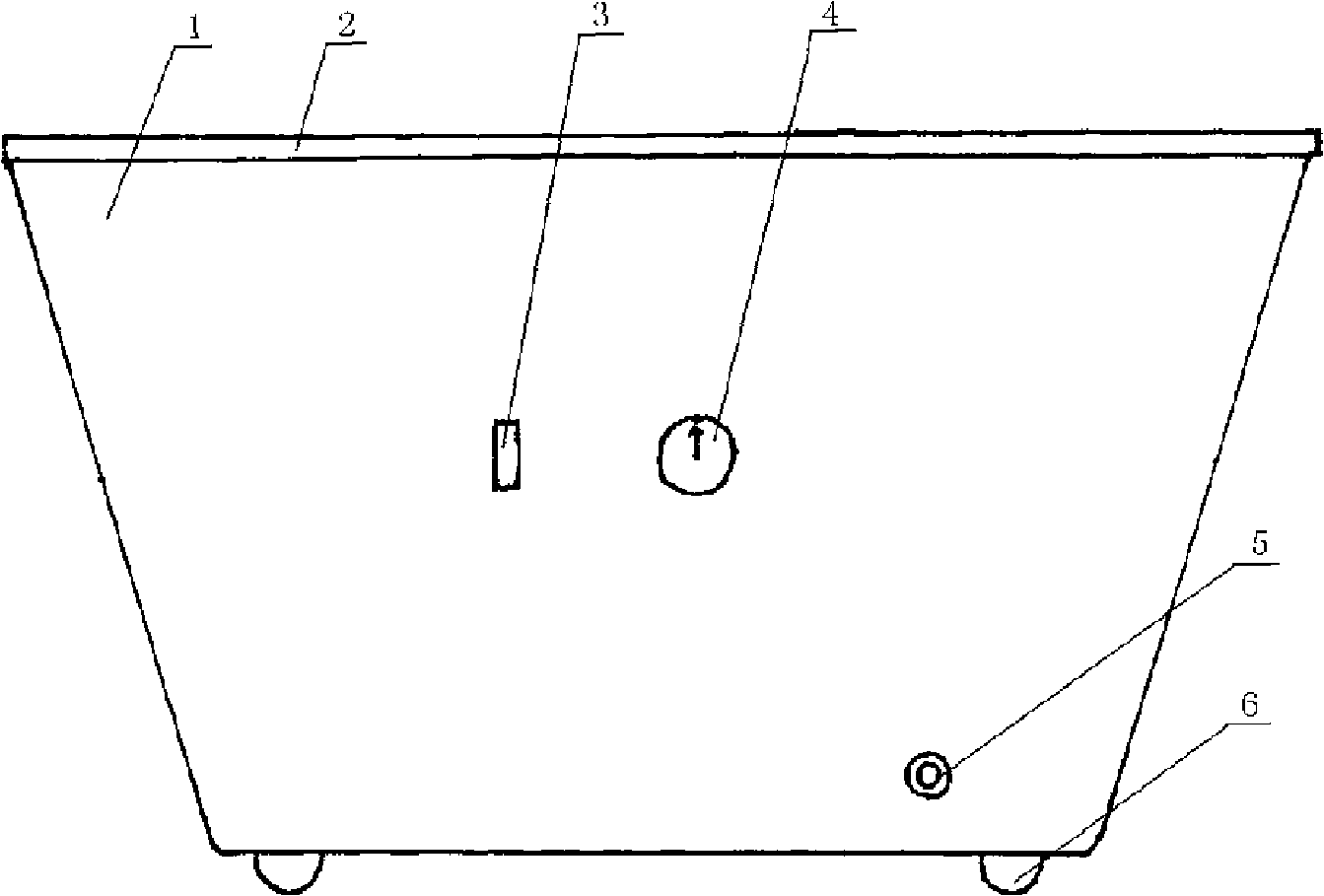

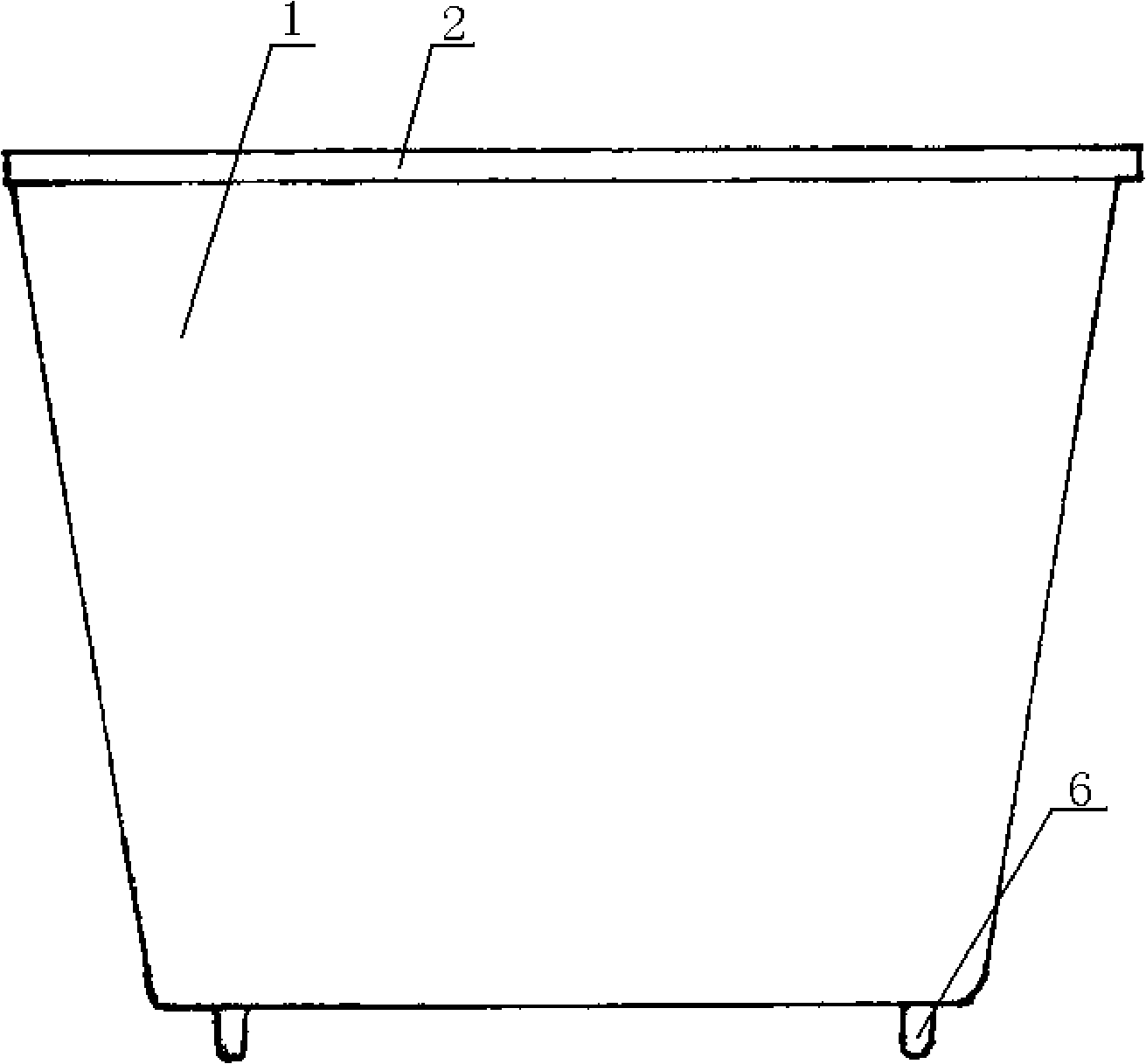

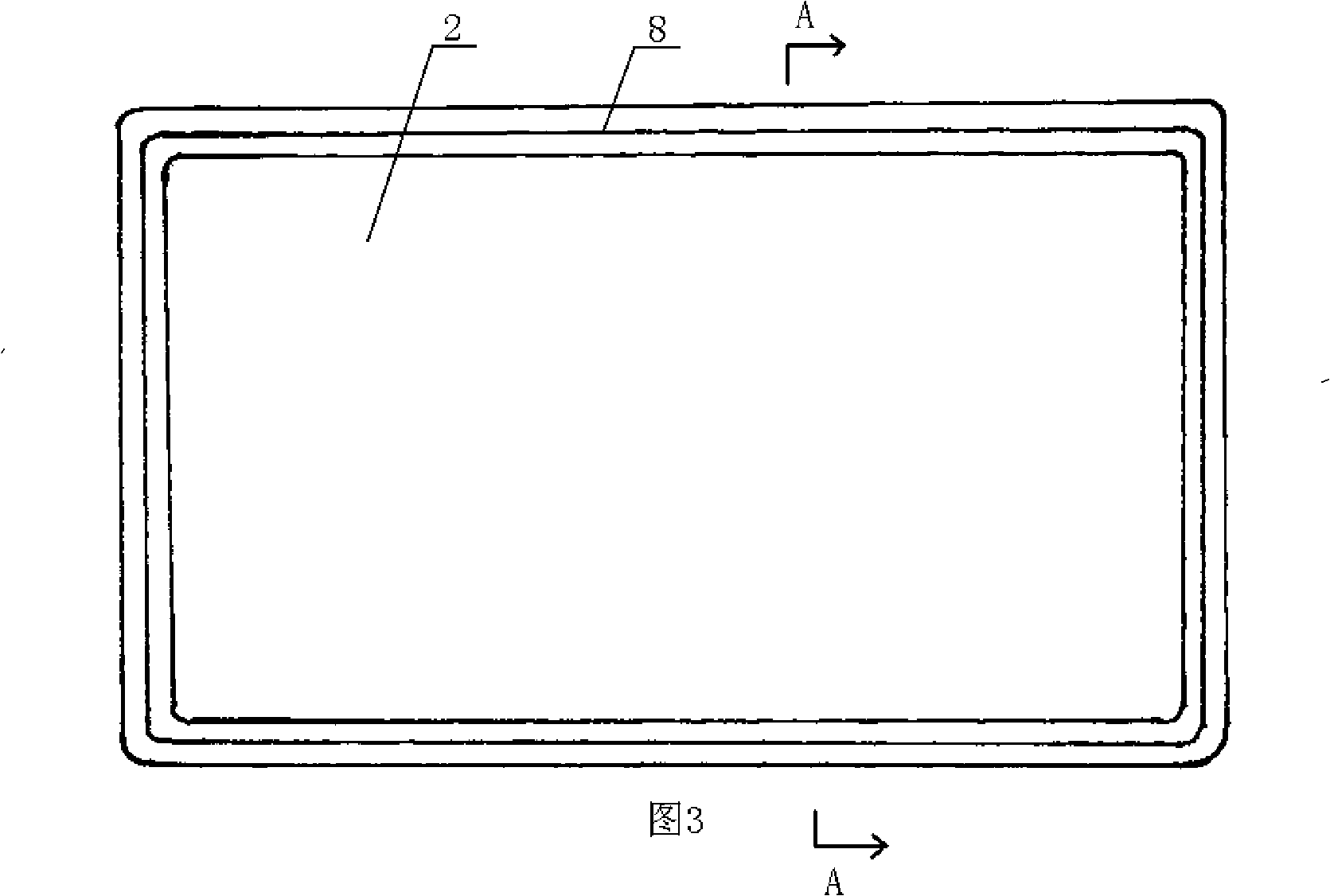

[0028] The present invention includes a bin body 1, a bin cover 2, a temperature measuring wire 3, a negative pressure gauge 4, an exhaust port 5, a roller 6, a brake lever 7, a seal ring 8, a brake hole 9, an air groove 10, a piston 11, and a seal ring 12, air outlet 13, sealing nut 14.

[0029] It has a granary surrounded by a silo body 1 and a silo cover 2 that closes the silo body 1, a sealing ring 8 is provided at the junction of the silo body 1 and the silo cover 2, and an exhaust port 5 is provided on the granary .

[0030] The granary is provided with a temperature-measuring wire 3 whose end extends into the silo body 1 .

[0031] On described granary, be provided with negative pressure gauge 4.

[0032] A roller 6 is installed at the bottom of the warehouse body 1, and a brake hole 9 is provided on the roller 6. A brake lever 7 is connected to the warehouse body 1, and the brake lever 7 restricts the movement of the roller 6. It is plugged into the brake hole 9 des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com