Actuation balance-free type large-torque flexible coupling

An elastic coupling, high torque technology, applied in elastic couplings, couplings, mechanical equipment, etc., can solve the problems of difficult loading and unloading, large docking clearance, short service life, etc., to reduce the starting current power, transmission The effect of high power torque and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

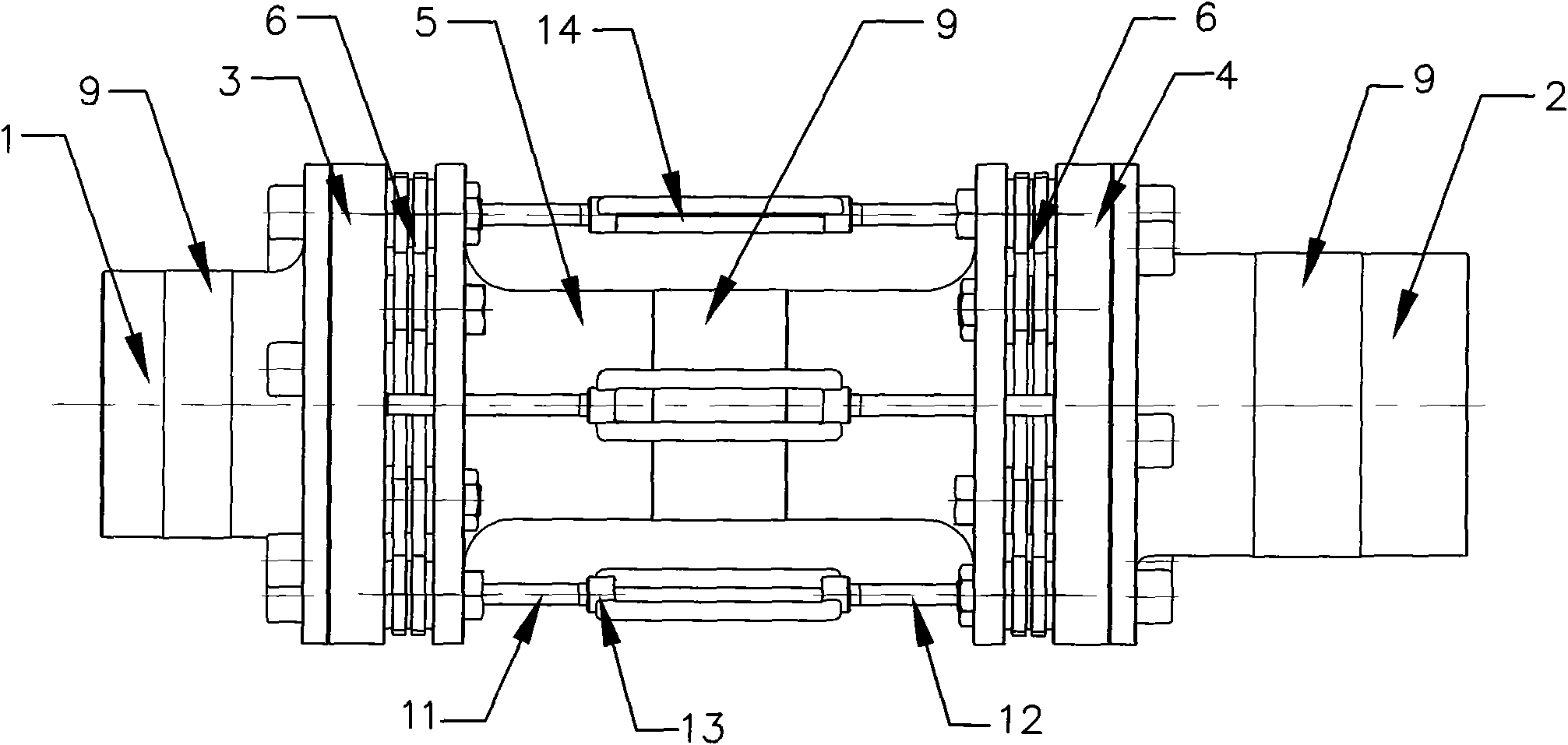

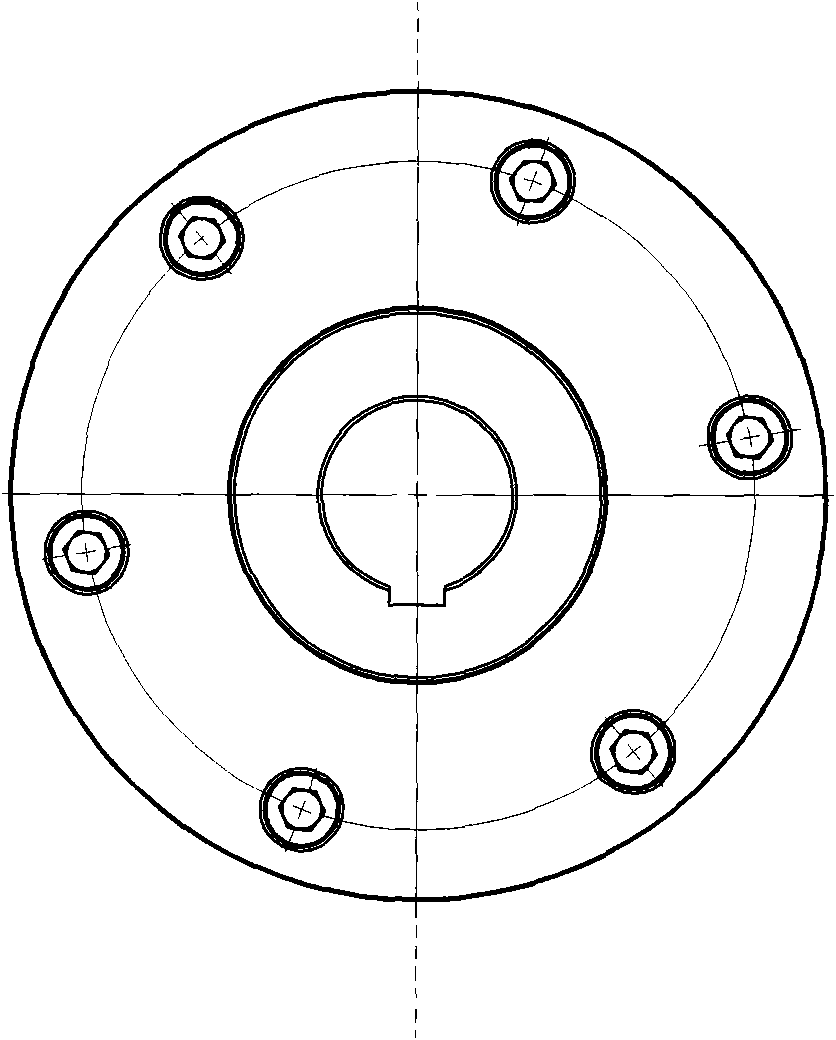

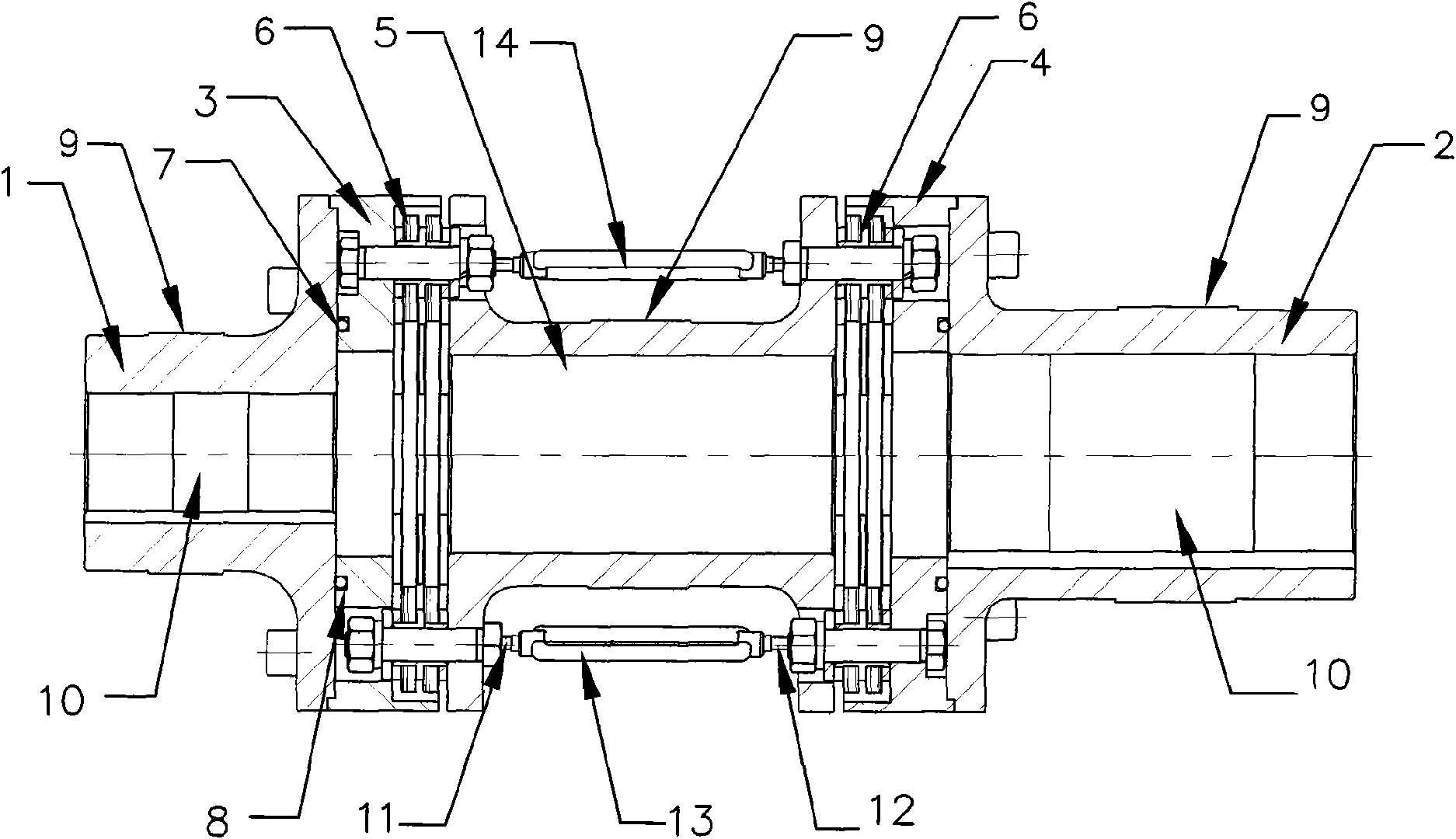

[0022] Such as figure 1 one image 3 As shown, the present invention is not used as a dynamic balance type high-torque elastic coupling including: two half-couplings 1, 2, two docking discs 3, 4, middle section 5, diaphragm group 6, high-strength elastic ring 7, The two half-couplings 1 and 2 are shaft connecting sleeves with connecting flanges at one end, the middle section 5 is a shaft connecting sleeve with flanges at both ends, two docking discs 3 and 4 and two half couplings The shaft joints 1 and 2 are installed at both ends of the middle section 5 through bolts, and the outer surfaces of the two docking discs 3 and 4 are connected with the two half-coupling joints 1 and 2 by means of spigot positioning. The two docking discs 3 and 4 The inner surface of the inner surface is respectively connected with the flanges at both ends of the middle section 5, and the diaphragm group 6 is installed between the two docking plates 3, 4 and the middle section 5. Diaphragm group 6 ...

Embodiment 2

[0025] Such as Figure 5 As shown, on the basis of the coupling in Example 1, when the length of the middle section 5 of the coupling of the present invention is less than 230 mm, the elastic device 14 of the coupling adopts an external connection type, and its two elastic bolts 11 and 12 adopt a 90-degree knuckle and only one end has threaded bolts, and the long nut 13 adopts a hexagonal long nut. And the outer edges of the two docking plates 3,4 are also provided with jacks 15 for installing external elastic devices, and the threadless ends of the two long bolts 11,12 are inserted into the sockets on the outer edges of the two docking plates 3,4 In the hole 15, the threaded end is screwed with the long nut 13.

[0026] When installing and using, first twist the threaded ends of the two long bolts 11, 12 into the long nut 13, and then insert the two ends of the two long bolts 11, 12 without threads into the outer edge of the coupling disc 3, 4 in the jack. Tighten or loose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com