Actuation balance-free type single-reducing coupling

A coupling and balanced technology, which is applied in the field of single variable diameter couplings that are not used as dynamic balance, can solve the problems of unsightly appearance, complex coupling structure, cumbersome operation procedures, etc., and achieve saving raw materials and joint clearance Small, reduce the effect of starting current power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

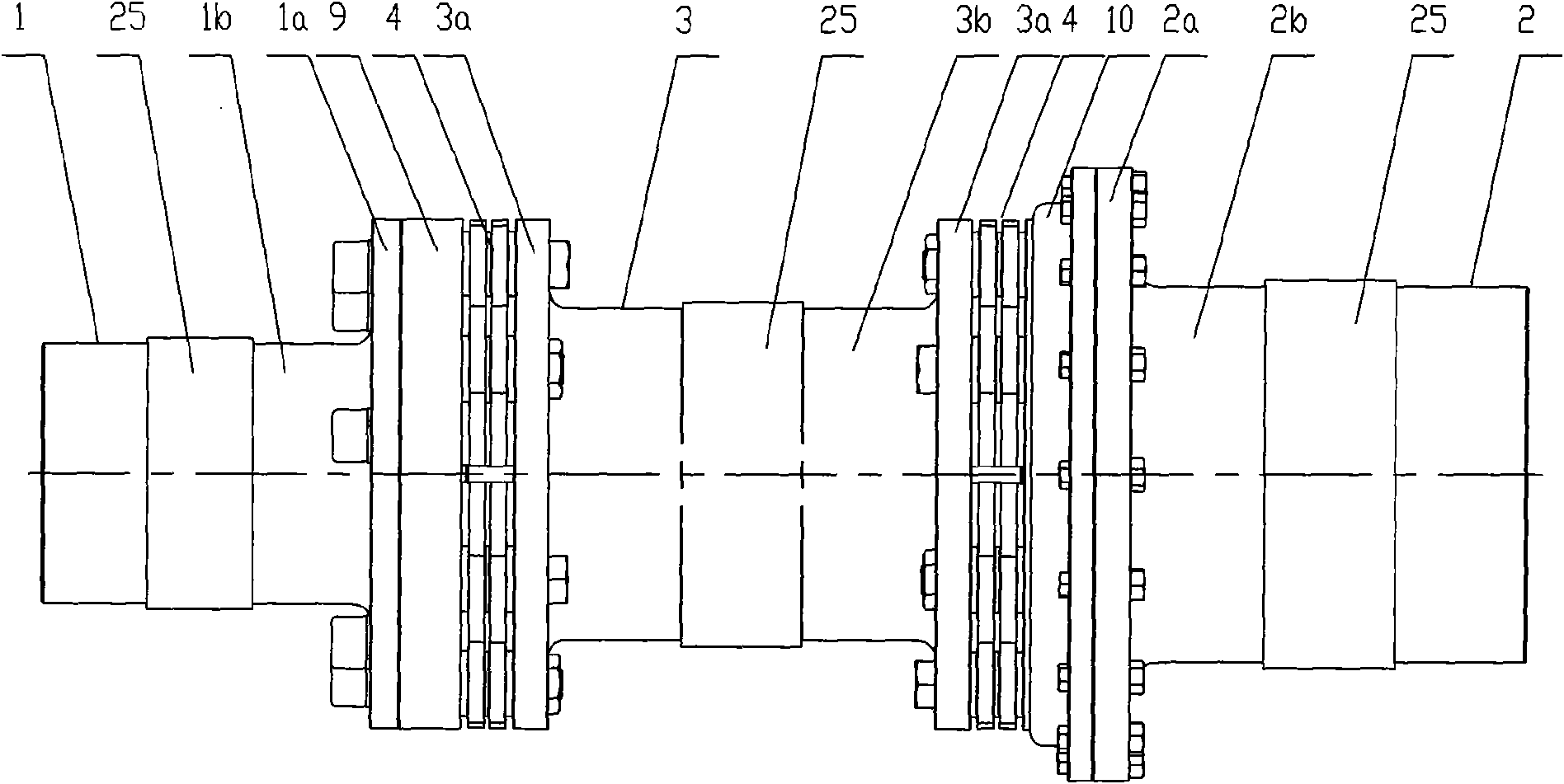

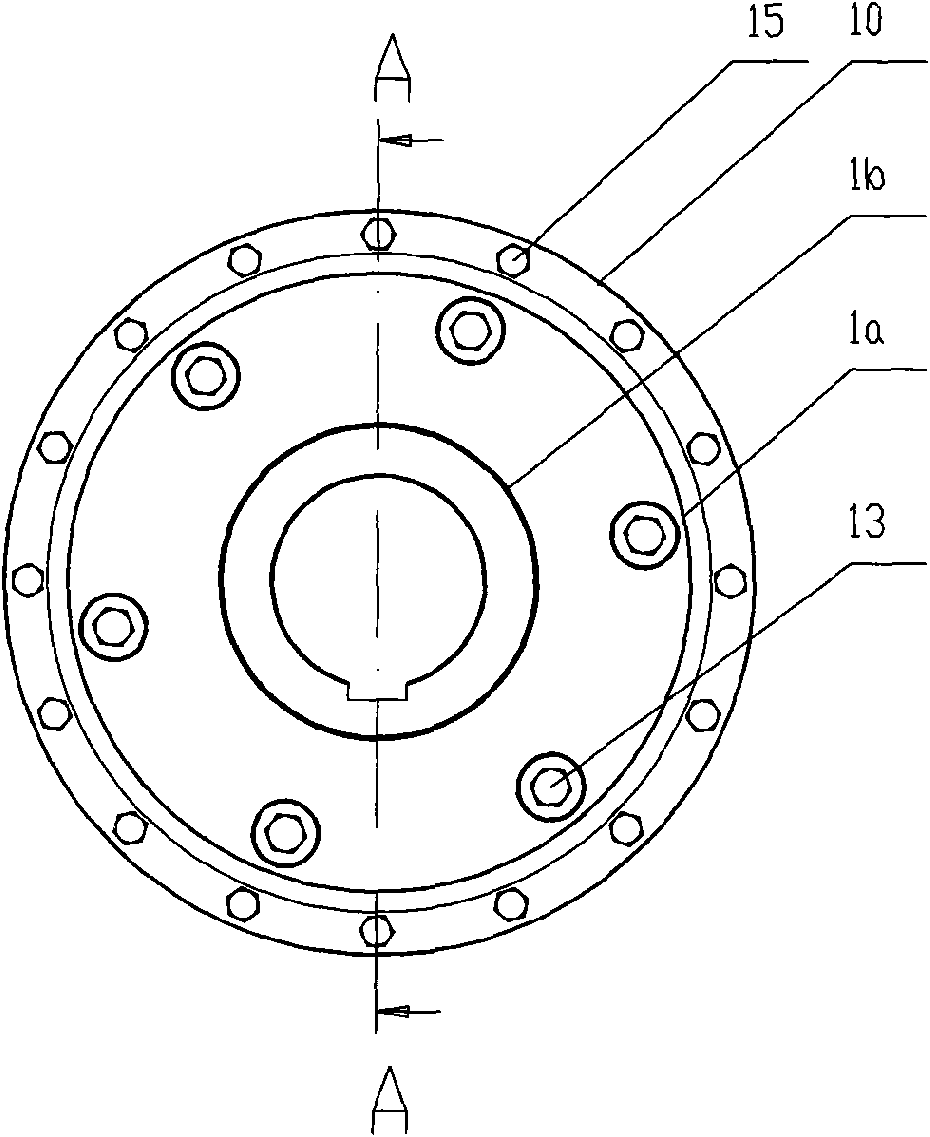

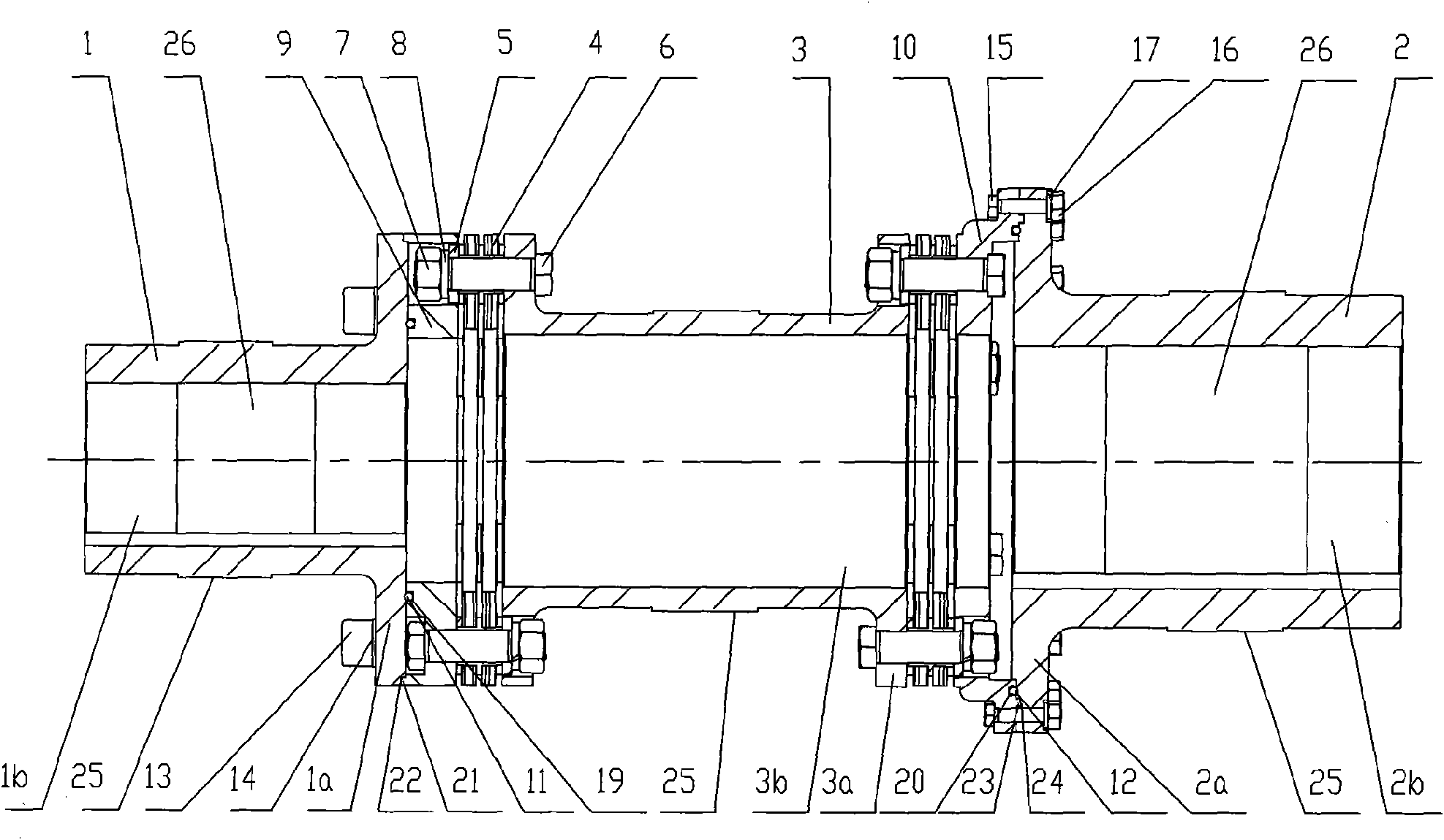

[0027] Such as Figure 1-4 As shown, the coupling of the present invention includes two half-couplings 1, 2, an intermediate section 3, two laminated diaphragm sets 4, a butt joint disc 9, a reducing disc 10 and two elastic rings 11, 12. The elastic rings are preferably high-strength elastic rings 11 and 12 made of polyurethane and high-strength rubber. The outer diameter of the docking disc is equal to the outer diameter of the flange of the half-coupling connected to it , the diameter reducing disc 10 is a flange whose diameter gradually increases from the inside to the outside, and a disc edge with the same diameter as the flange of the half-coupling is provided on the outer disc surface, and the laminated diaphragm group 4 Use double-sided rivets to penetrate dozens of elastic sheets at both ends, and then install two rivet caps, which are stamped twice by hydraulic force. The shafts of the two half-couplings 1, 2 and the middle section 3 are A ring of outer bosses 25 are...

Embodiment 2

[0031] The structure and connection relationship of the shaft coupling described in this example are the same as those in Example 1, except that:

[0032] In use, in order to better realize the assembly of the middle section, three elastic devices 18 for adjusting the distance between the docking disc and the reducing disc 10 are installed between the docking disc 9 and the reducing disc 10 of the coupling described in this example ,Such as Figure 5As shown, the elastic device 18 includes two bolts 18a, 18b and a long nut 18c. The long nut in this example adopts a turnbuckle nut with positive and negative threaded holes at both ends, and the two bolts have positive and negative threads at both ends. Straight bolts, one end of the bolt 18a passes through the flange plate 3a of the middle section and the laminated diaphragm group 4 in sequence, and is screwed with the screw hole on the docking plate 9, and the other end of the bolt 18a is screwed with the threaded hole of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com