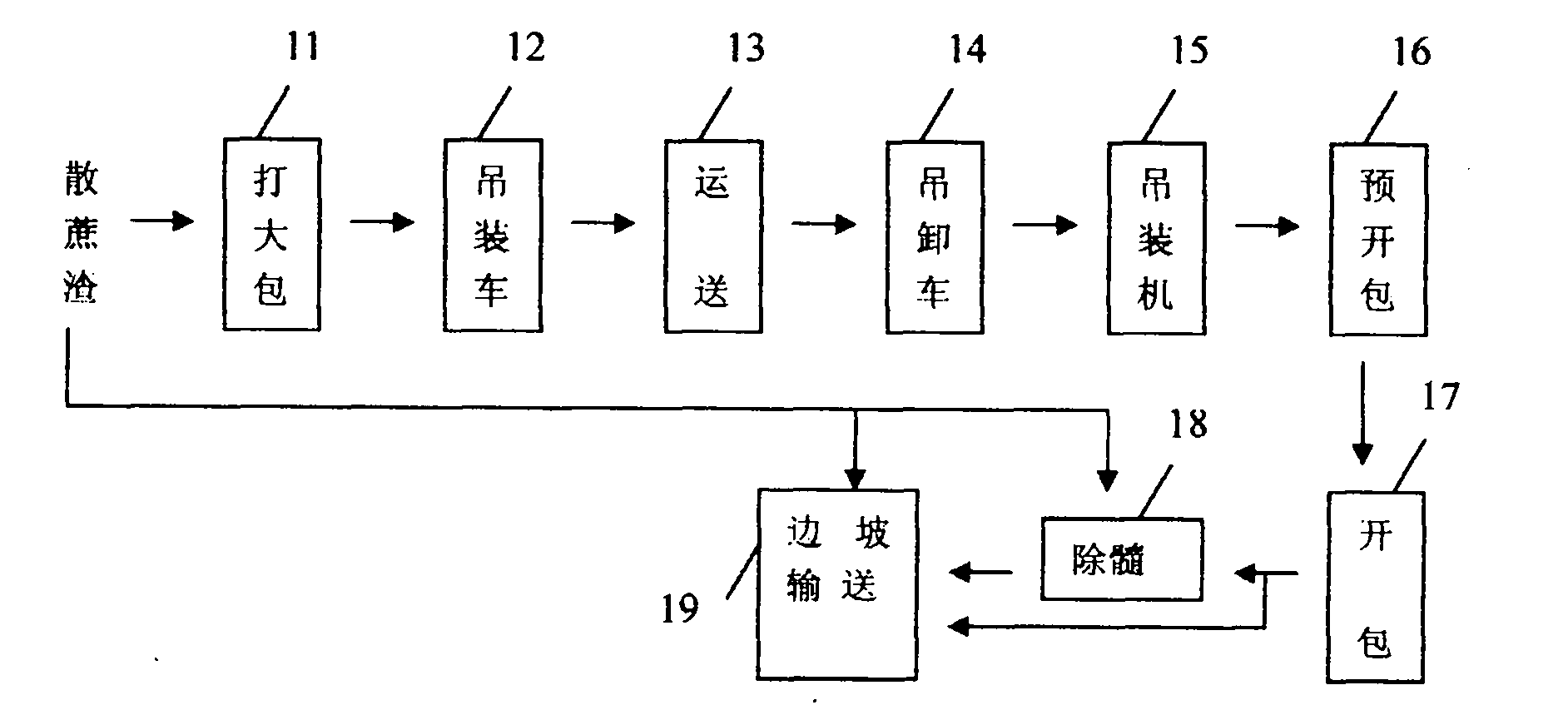

Bagasse transportation operation flow and equipment

A technology of bagasse and process, applied in the field of bagasse transportation operation process, which can solve the problems of high labor intensity, plastic packaging rope mixed into bagasse production, endangering the safety of pedestrians and vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

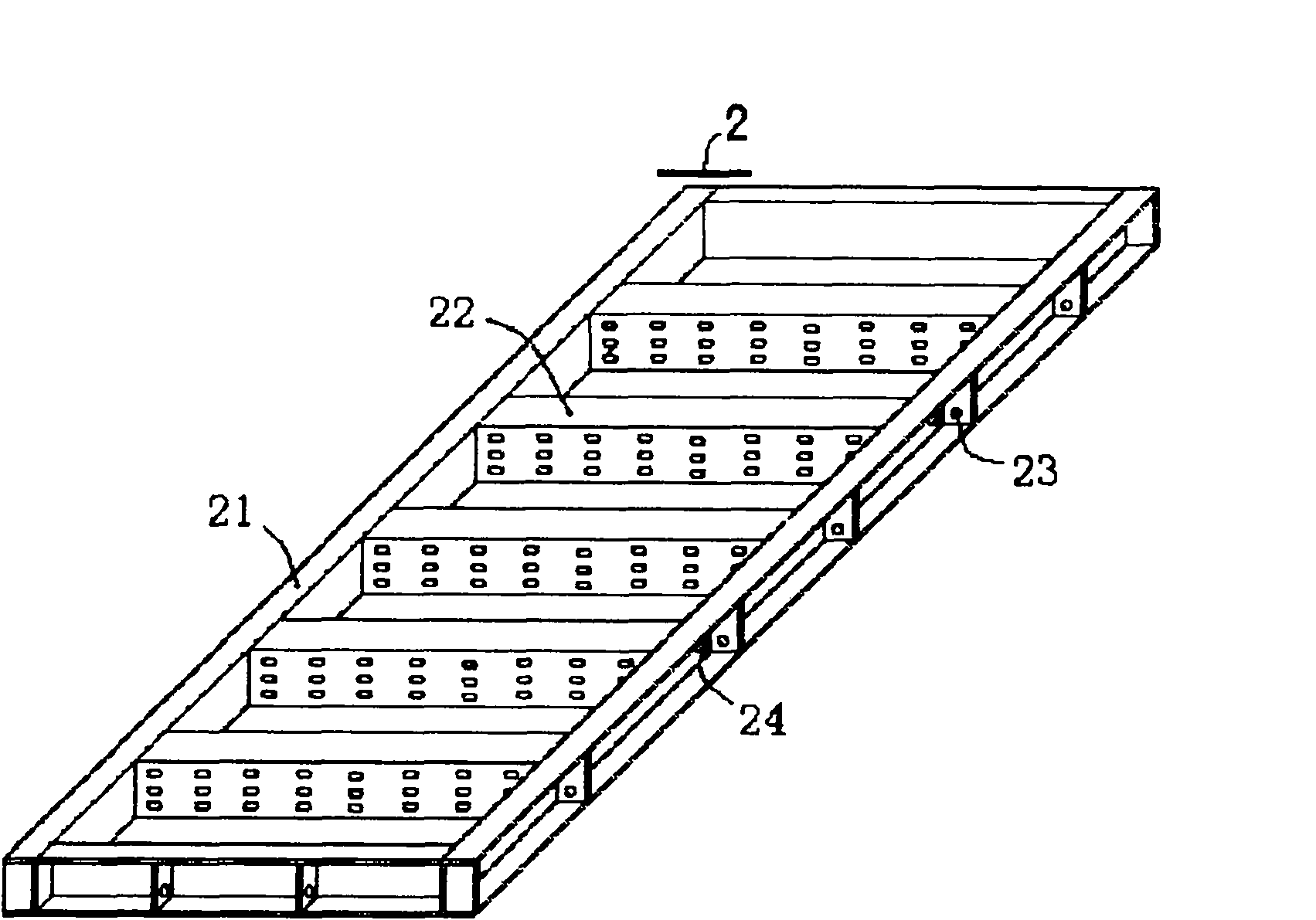

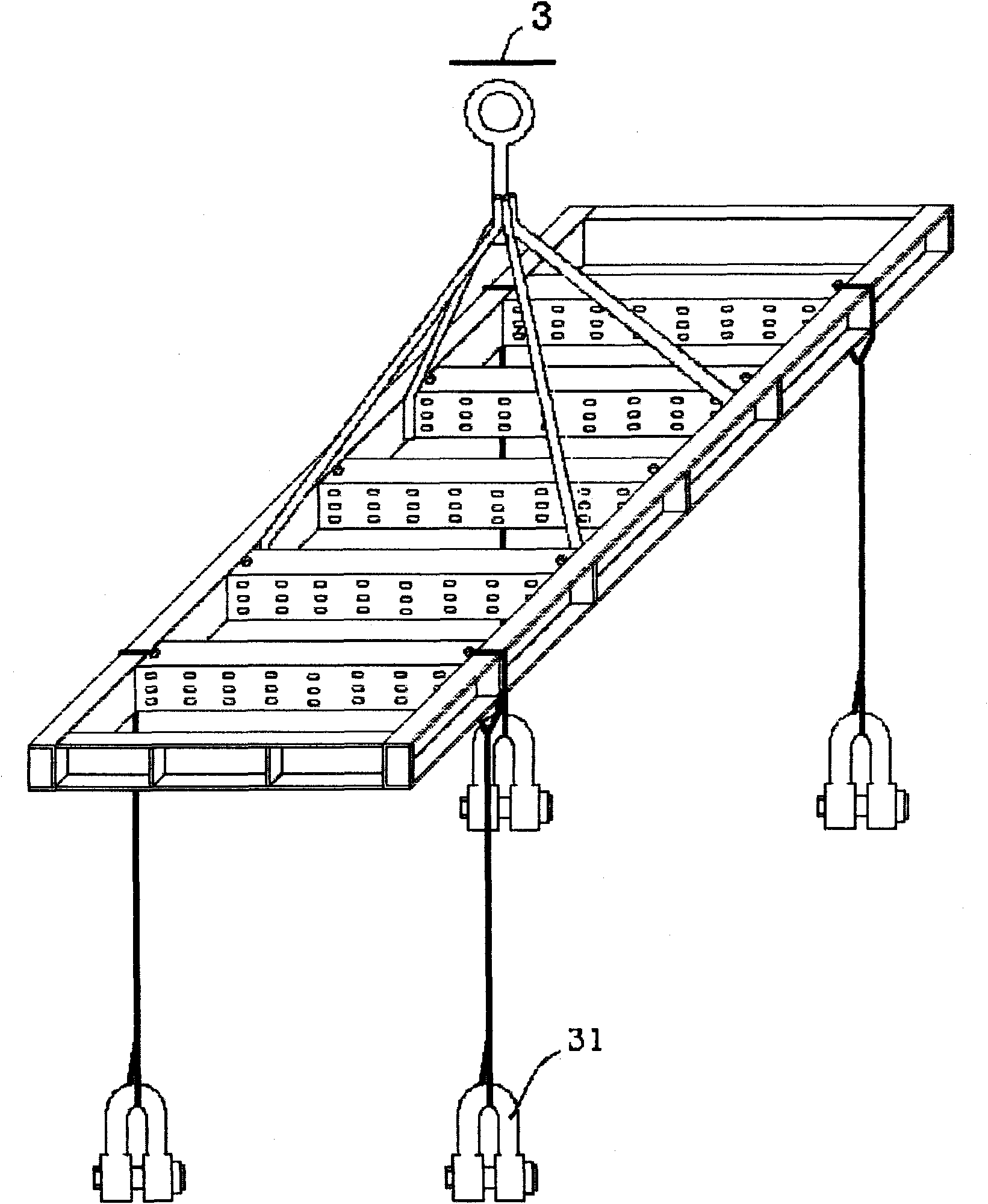

[0041] like figure 2 and image 3 Shown, for the convenience of operation, this example is provided with a plurality of lifting lugs (23) used for lifting in each side of the bottom frame (2), and a plurality of through holes (24) for inserting forklift yokes are set. The suspension rope lower end of suspension frame (3) is then connected with shackle (31). In order to reduce the weight of the bottom frame (2), a plurality of through holes are drilled thereon.

[0042] For pre-open charter (4), such as Figure 4 Shown, this example adopts hydraulic jack (45) and " Y " type push rod (46) to come the rear end of lifting bagasse bag slideway support frame. The hydraulic jack (45) and the frame (41) are hingedly connected (44), and the head of the ejector rod is inserted into the hole on the lower end surface of the "Y" type ejector rod (46), and the "Y" type ejector rod The upper end of (46) is then hingedly connected (43) with the bagasse bag slideway support frame. And wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com