Insert and insert core disassembling and assembling device

A technology for assembling devices and inserts, which is applied in the direction of coating, etc., can solve the problems of poor consistency of insert assembly dimensions, uneven shear gate quality, high labor intensity, etc., and achieve high automatic cutting precision and consistent gate residue Good performance, improve the effect of cutting and pouring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In view of the above-mentioned solutions to the existing insert feeding, removal and shearing of injection molded bracket products, manual operations are used in the production process, resulting in high labor intensity, poor consistency of insert assembly dimensions, low efficiency, and gate shearing. To solve problems such as uneven quality, the present invention provides a device for disassembling and assembling inserts and inserts.

[0055] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

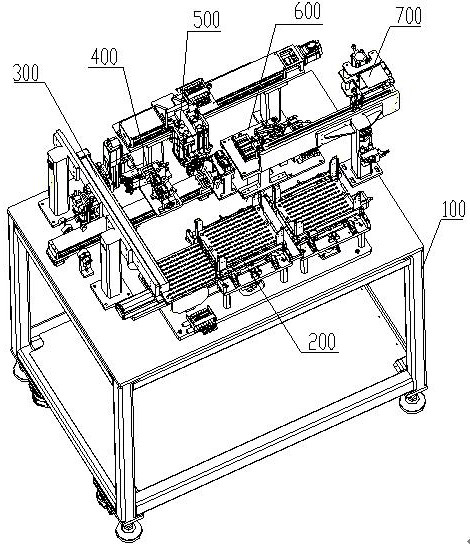

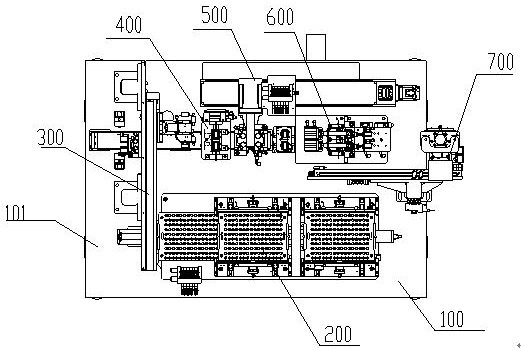

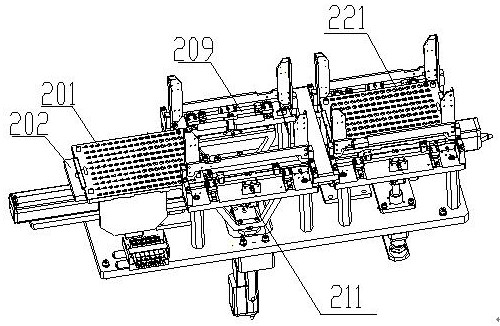

[0056] In order to illustrate the structure of the insert and insert disassembly and assembly device provided by the present invention, Figure 1-1 to Figure 1-2 The structures of the disassembly and assembly devices for inserts and inserts are exemplarily marked from different angles. specifically, Picture 1-1 The three-dimensional structure of the disassembly and assembly device for inserts and inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com