Shirt processing cutting bed and adjusting method thereof

A shirt and scissors technology, applied in the field of shirts, can solve the problems of troublesome adjustment and cutting, cumbersome use, poor cloth fixation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

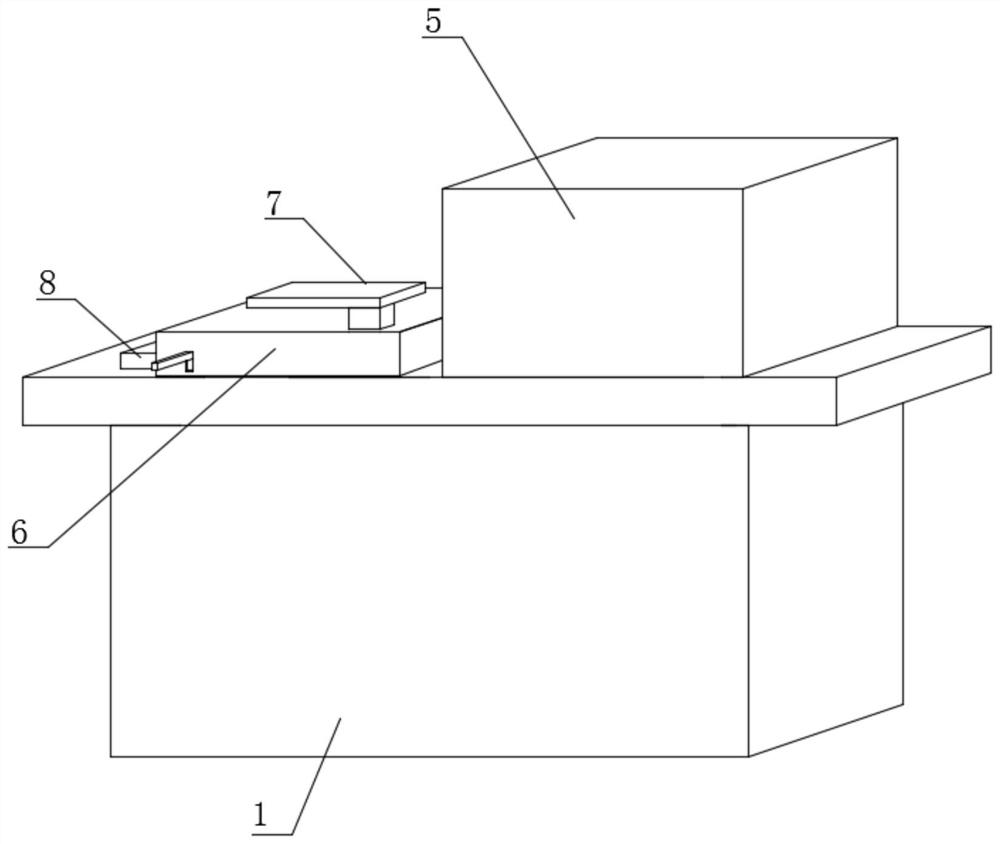

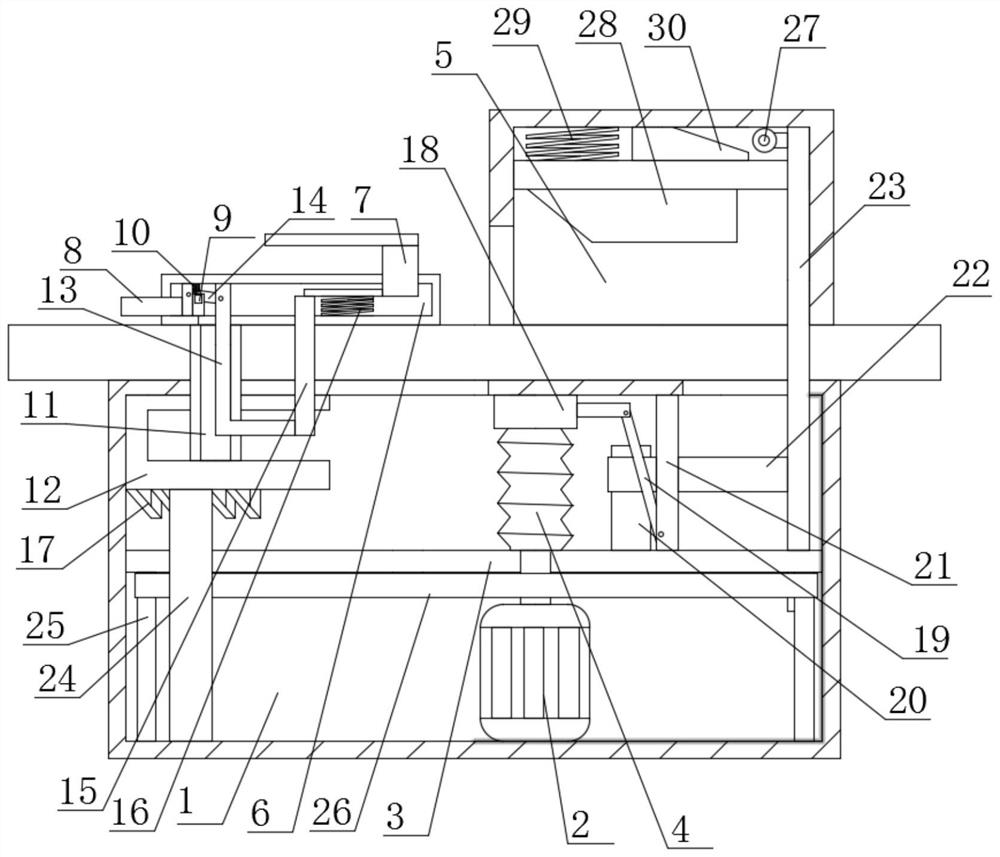

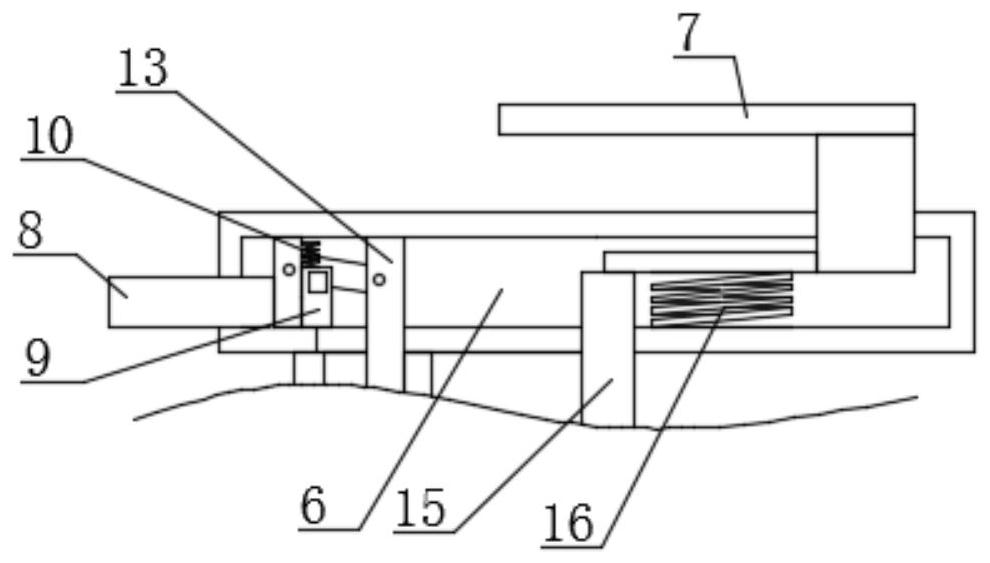

[0032] refer to Figure 1-5 , In this embodiment, a shirt processing and cutting bed is proposed, including a casing 1, a control box 5 is fixedly connected to the top of the casing 1, a baffle 3 is fixedly connected in the casing 1, and the baffle 3 serves to carry the movable column 20 and assist The movable column 20 performs the role of rotation, and the bottom inner wall of the casing 1 is fixedly installed with the motor 2, one end of the output shaft of the motor 2 penetrates the baffle 3 and is fixedly connected with a threaded column 4, and the threaded column 4 rotates with the output shaft of the motor 2 , the threaded ring 18 can be controlled to move up and down through its own thread, the top of the casing 1 is slidably connected with the hollow plate 6, the bottom of the hollow plate 6 is fixedly connected with the extension pipe 11, and the bottom of the extension pipe 11 extends into the casing 1 and is fixedly connected There is an auxiliary plate 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com