Comb flying and dyeing all-in-one machine

An all-in-one machine and comb technology, applied in the direction of coating, etc., can solve the problems of comb needle grinding troubles, large manpower and material resources, and different sizes of round heads, so as to reduce the influence of human factors, improve quality stability, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

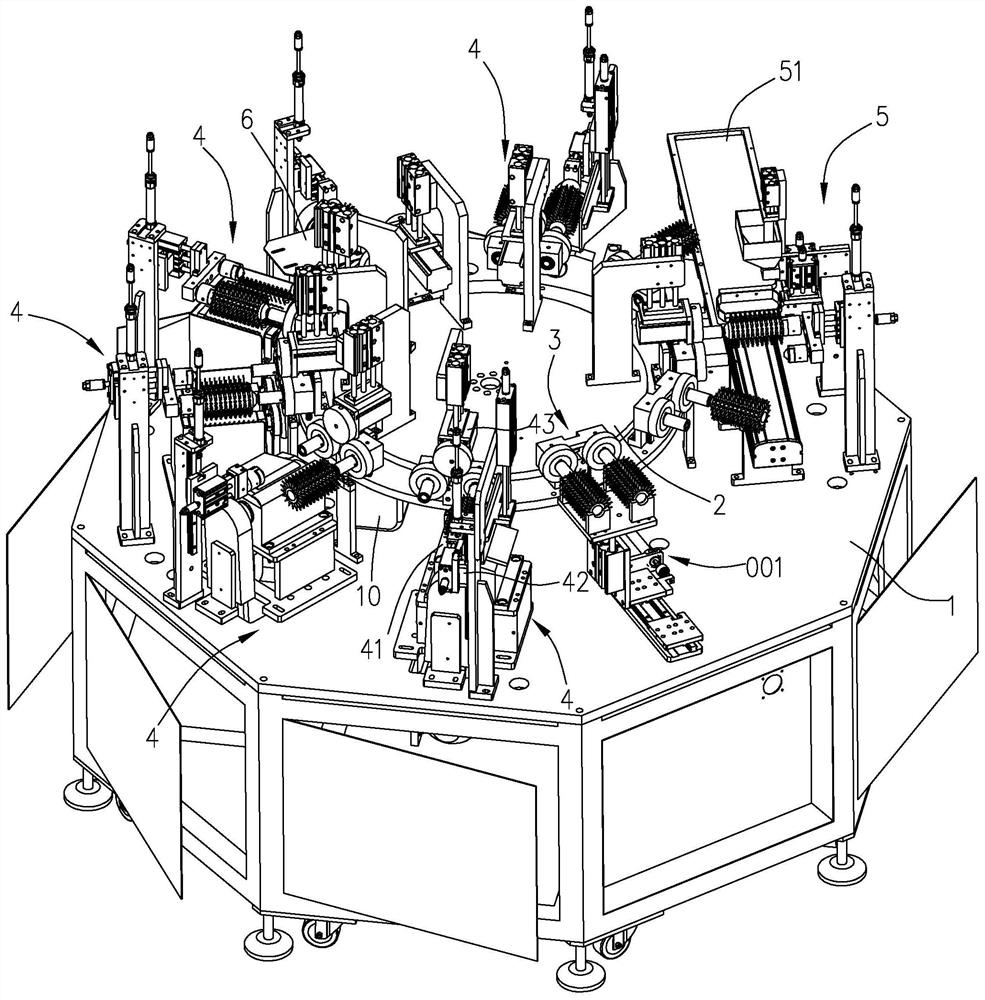

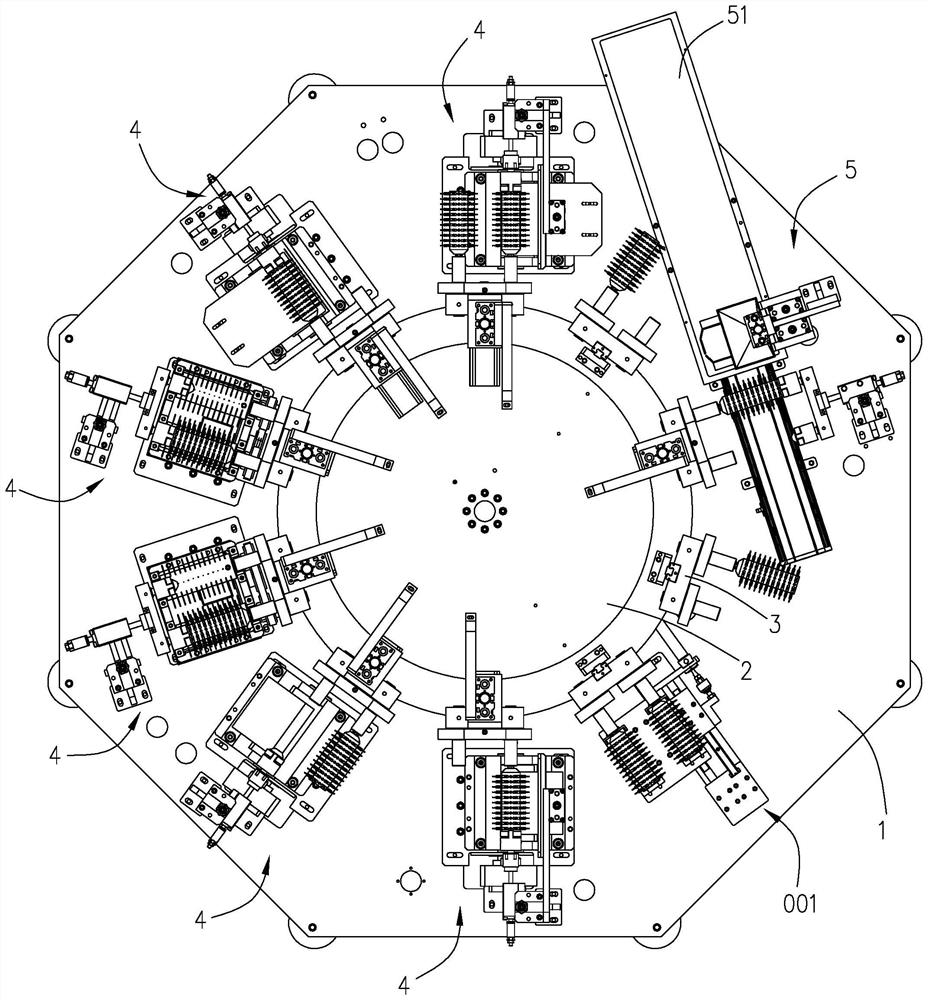

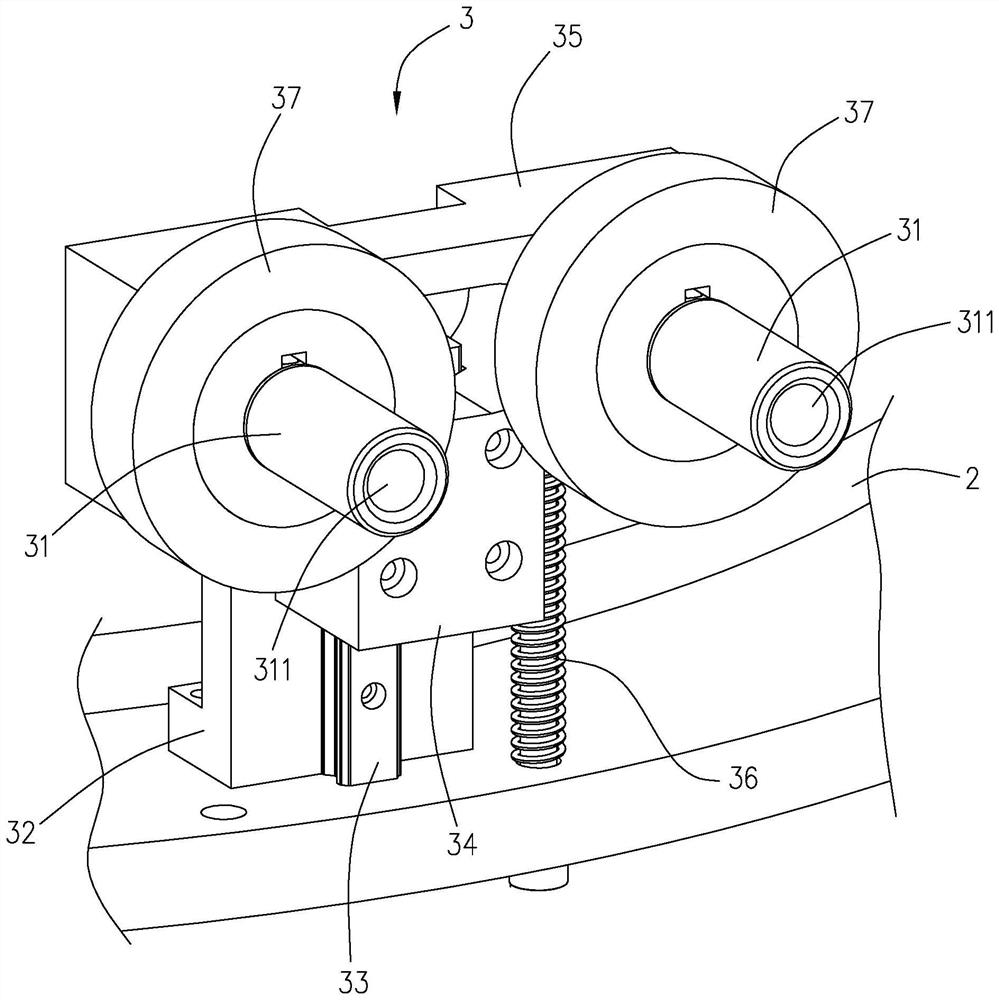

[0084] Such as Figure 1-17 As shown, the comb flying and dyeing integrated machine of this embodiment includes an assembly platform 1, a turntable 2, a first driving mechanism 10, a positioning component 3, a flying hair mechanism 4, a dyeing head mechanism 5, and a flexible stopper 6 for fully automatic completion Comb needle grinding and hair dyeing process. This embodiment can process one or more combs at the same time. In this embodiment, 4 combs are processed at a time. position, a head dyeing station.

[0085] Specifically, the turntable 2 is disc-shaped and rotatably provided on the assembly platform 1 , and the edge of the turntable 2 has a plurality of operating stations arranged at intervals along the circumferential direction. The first driving mechanism 10 is arranged at the bottom of the assembly platform 1 and is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com