Patents

Literature

67results about How to "Accurate graduation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

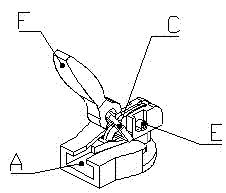

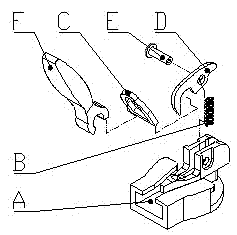

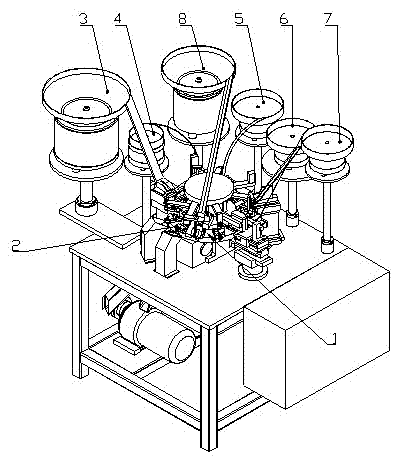

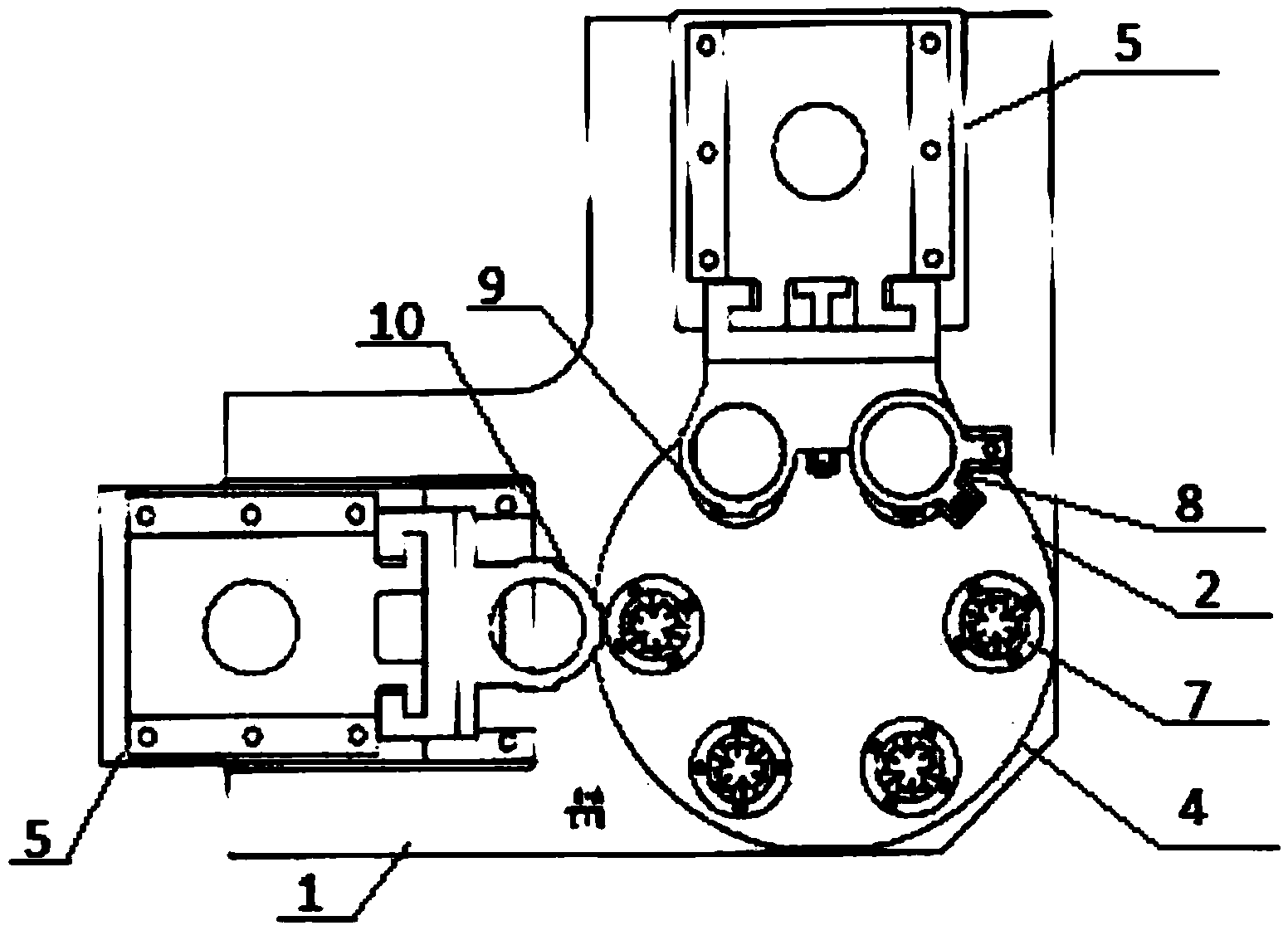

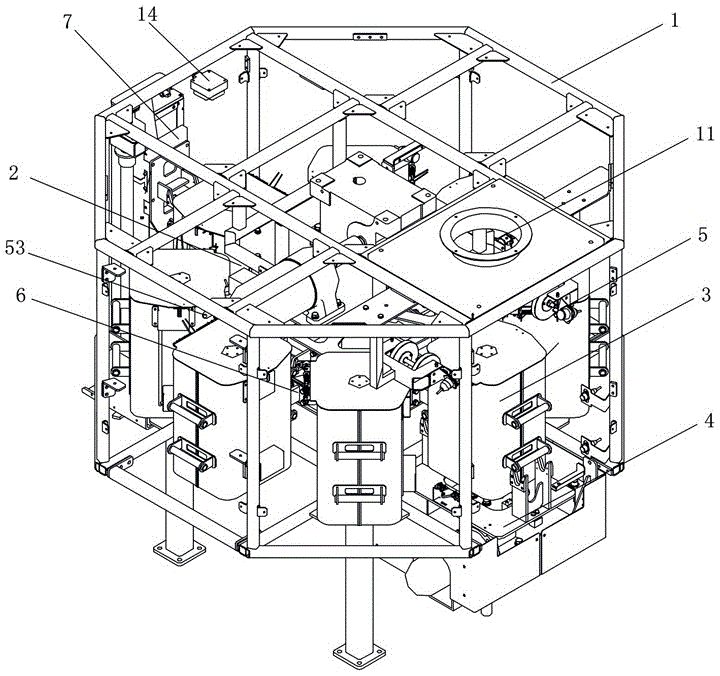

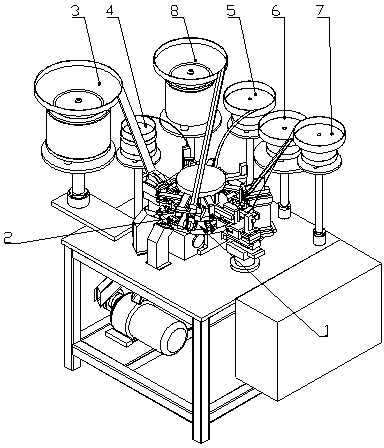

Six-part full-automatic assembly machine for invisible zipper puller

InactiveCN102525044AHigh degree of automationRealize automatic feedingSlide fastenersEngineeringStructural engineering

The invention discloses a six-part full-automatic assembly machine for invisible zipper puller and is characterized in that a moving assembly that is connected with a power device is arranged at the table top of a frame; twelve die cavities for fixing zipper pullers are arranged at equal intervals on the margin of the division main rotor plate of the moving assembly; and a zipper puller feeding mechanism, a zipper puller detection mechanism, a zipper puller spring feeding mechanism, a spring detection mechanism, a triangular collar feeding mechanism, a triangular collar detection mechanism, a horse hooker feeding mechanism, a copper pin feeding mechanism, a copper pin detection mechanism, a puller detection mechanism, a puller detection mechanism rejected puller discharge mechanism, and a qualified product discharge mechanism are arranged on the frame and used for assembling zipper pullers. The six-part full-automatic assembly machine integrates the functions of two machines, the detection mechanisms are arranged behind the corresponding feeding mechanism to automatically identify parts in the die cavities, and the start-up or shut-down of the assembly machine is automatically controlled according to the assembly information of parts, so as to prevent defected parts from entering the next procedure or prevent idle running of the assembly machine, as a result, the rate of rejected products is reduced and the assembly machine is guaranteed to run safely and reliably.

Owner:义乌市振宏机械科技有限公司

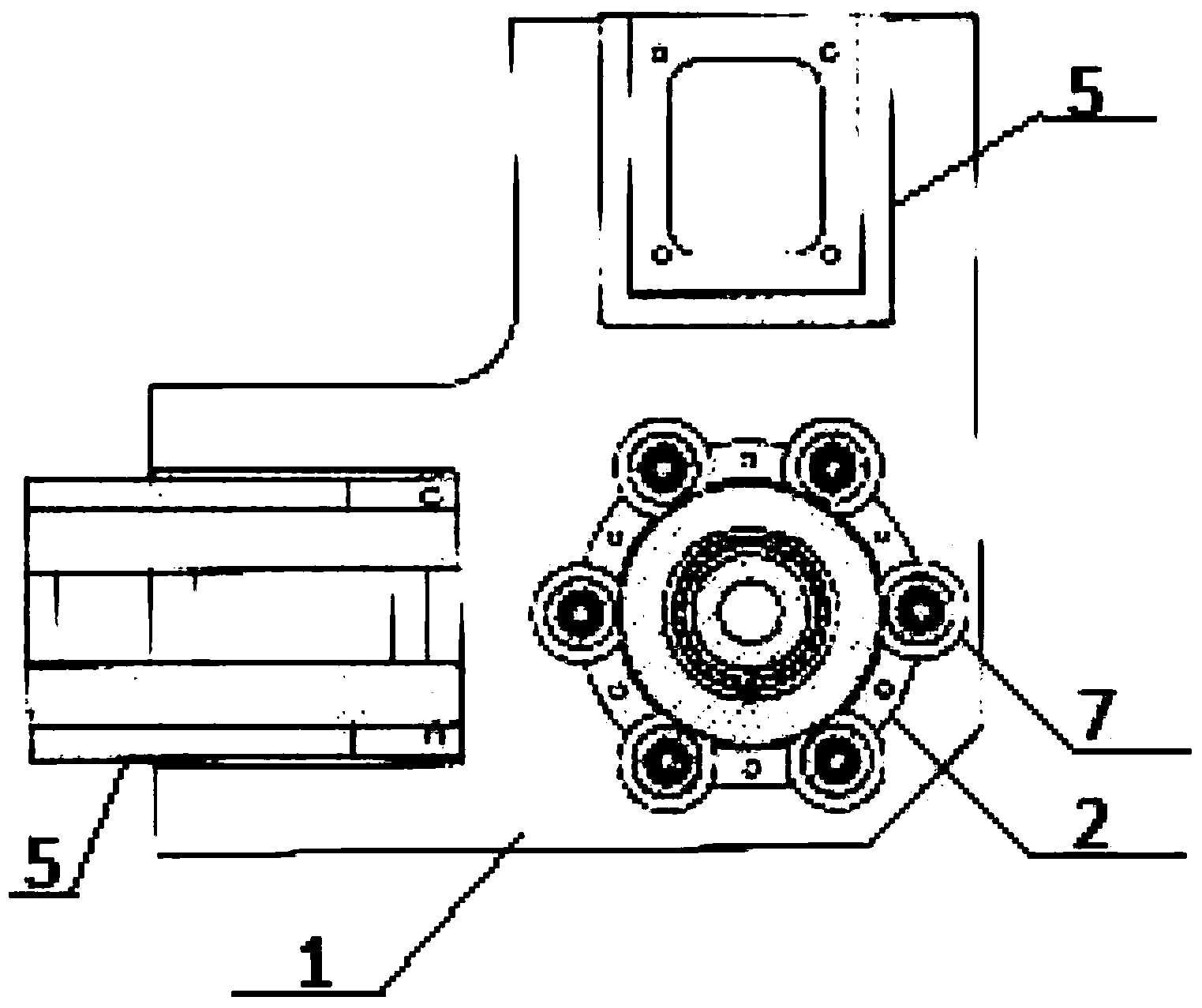

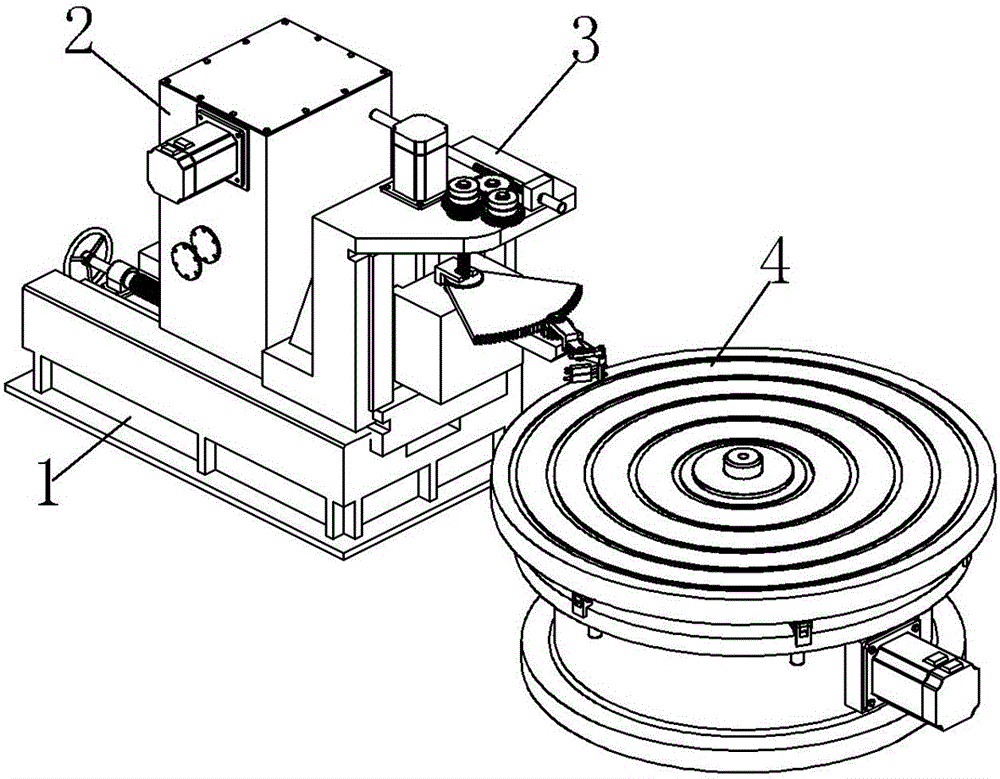

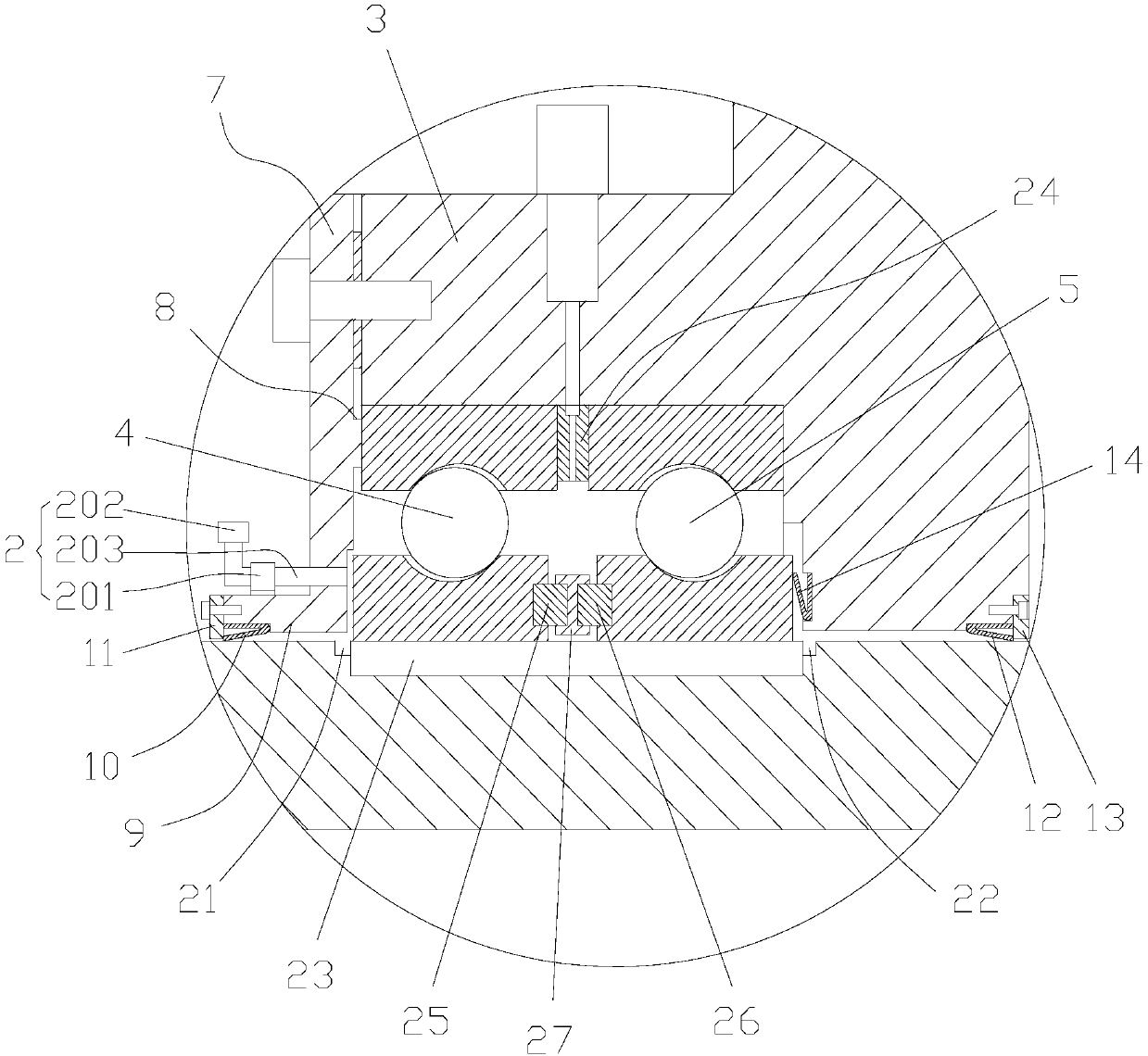

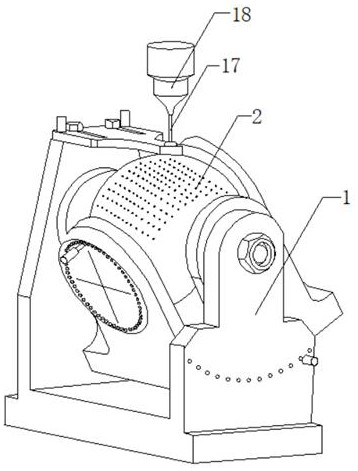

Automatic milling and grinding machine

InactiveCN104385092AImprove work efficiencyHigh degree of mechanized continuous operationEdge grinding machinesOptical surface grinding machinesEngineeringIntegrated processing

The invention relates to an energy-saving and environment-friendly optics cold processing and glass processing automatic milling and grinding machine. The automatic milling and grinding machine mainly comprises a working table (1), a revolution disc (2), a waterproof sleeve (3), processing machine shafts (4), a main shaft supporting board (5), a servo motor (6) and rotation clamp sleeves (7), wherein three processing main shafts (4) are arranged, the three processing main shafts are fixed on the working table (1) through the main shaft supporting board (5), the other ends of the three processing main shafts (4) are respectively connected with a rough grinding head (8), an accurate grinding head (9) and a polishing grinding head (10), six rotation clamp sleeves (7) are arranged and fixed on the revolution disc (2), the revolution disc (2) is fixedly connected on the working table, and the revolution disc can rotate. The milling and grinding machine uses six working positions and three main shaft heads, three working positions are respectively used for conducting the rough grinding, the accurate grinding and the polishing, the working procedure can be successfully conducted through the rotating of the revolution disc, the rest three working positions are used for placing and taking milled and ground products, the three-function integrated processing is realized, the streamlined working degree is high, and the working efficiency is greatly improved compared with the existing machine type.

Owner:NANTONG JINYA OPTOELECTRONICS EQUIP

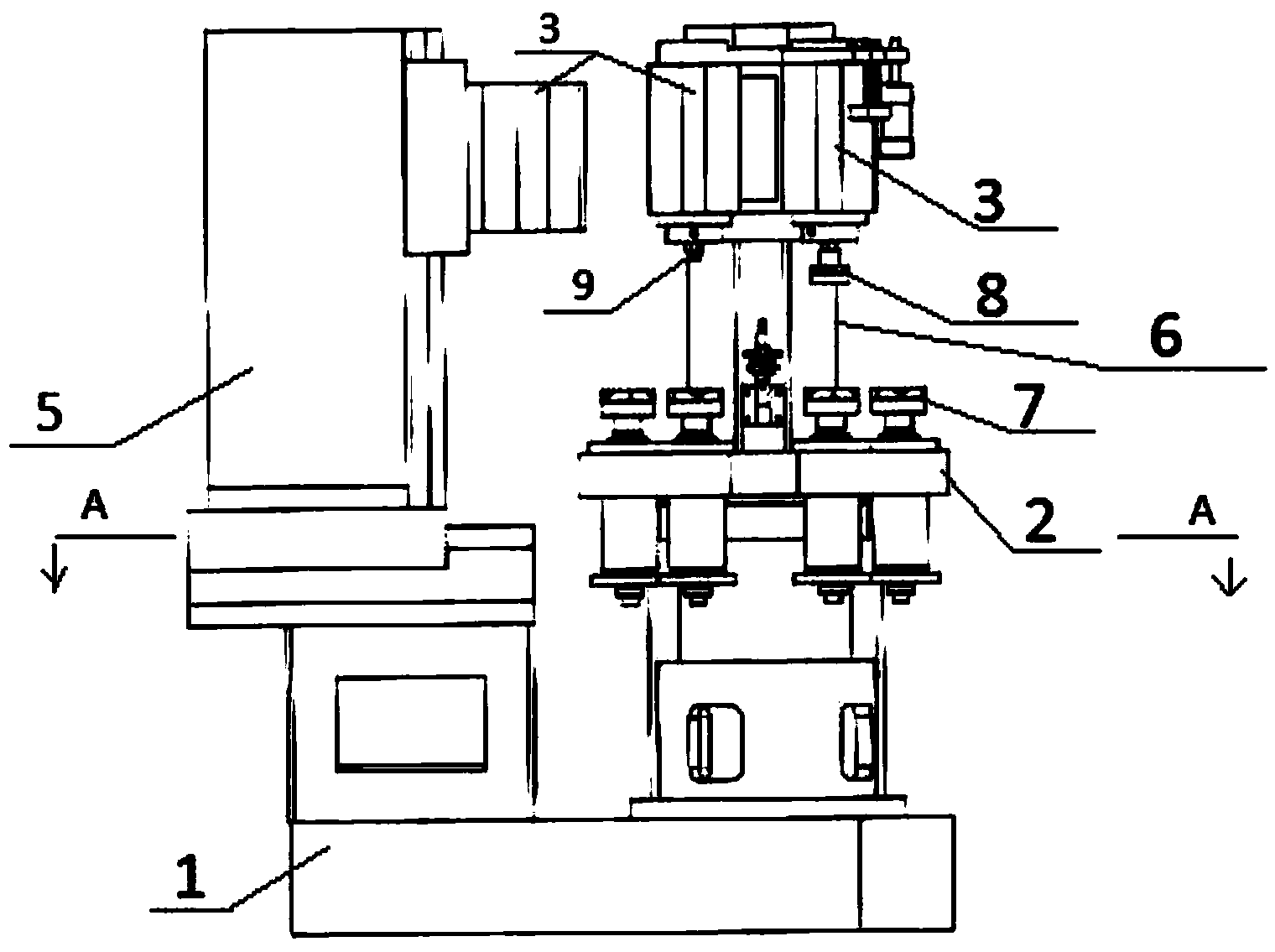

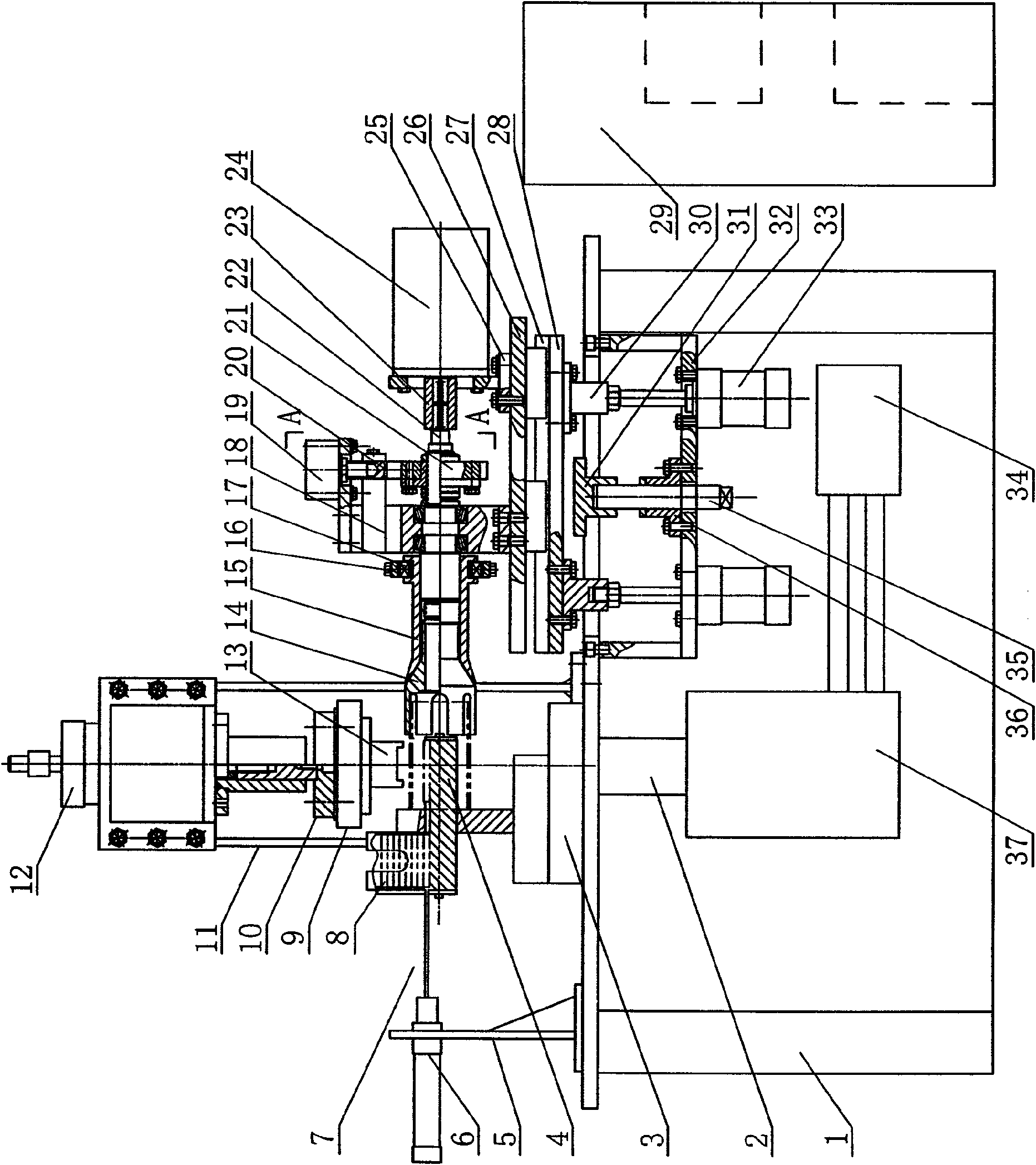

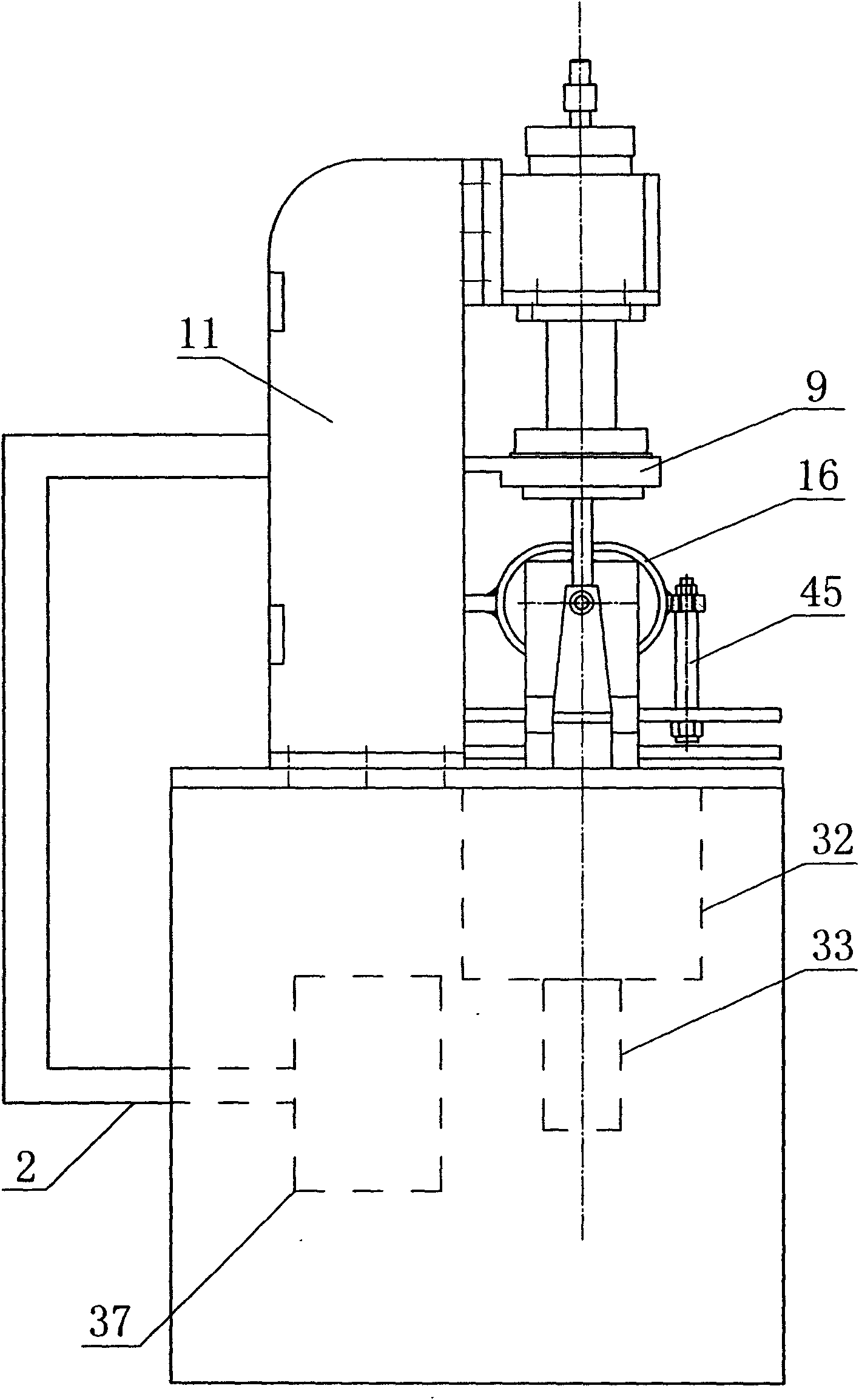

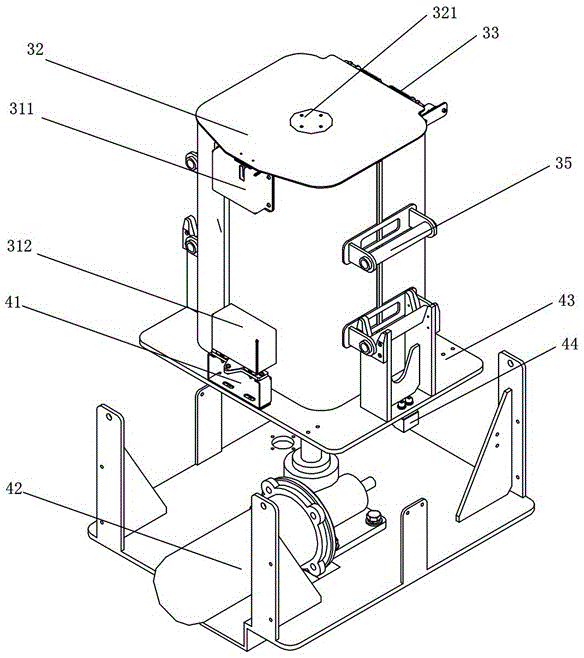

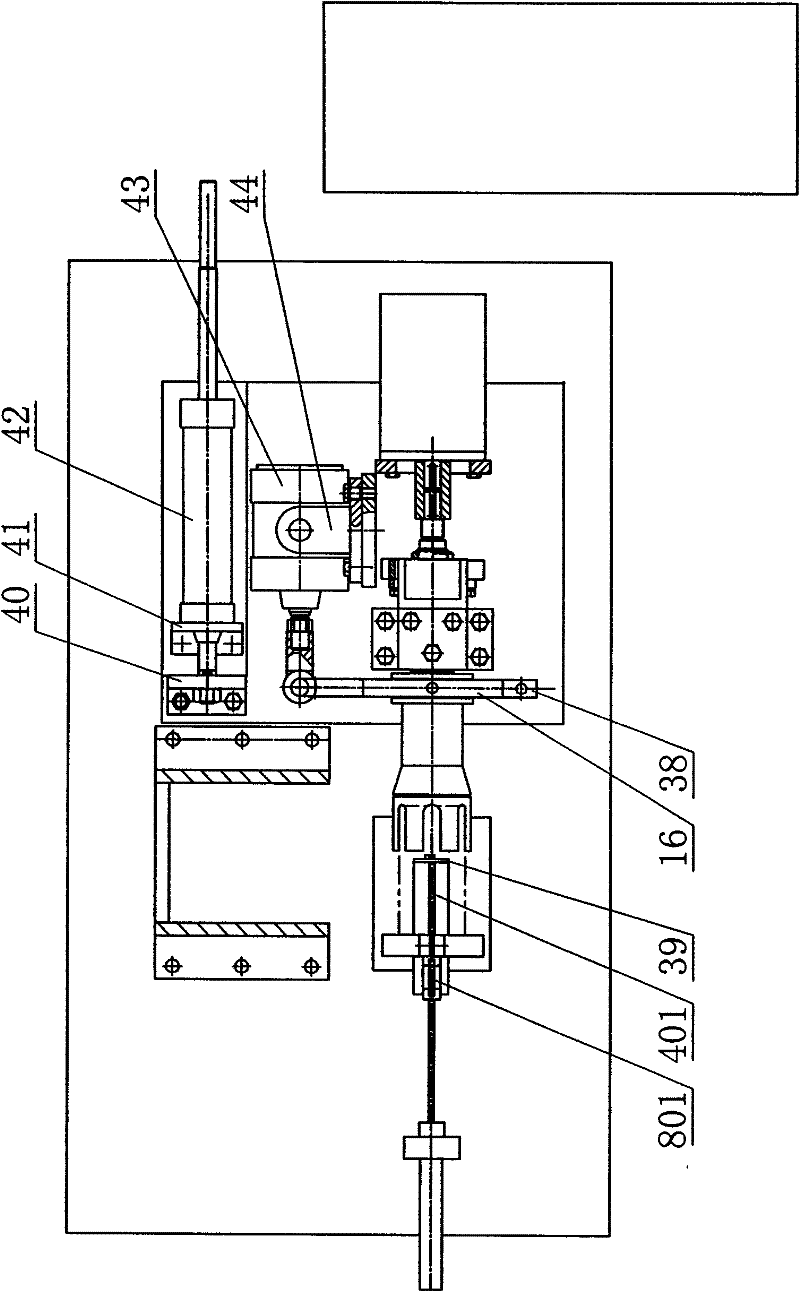

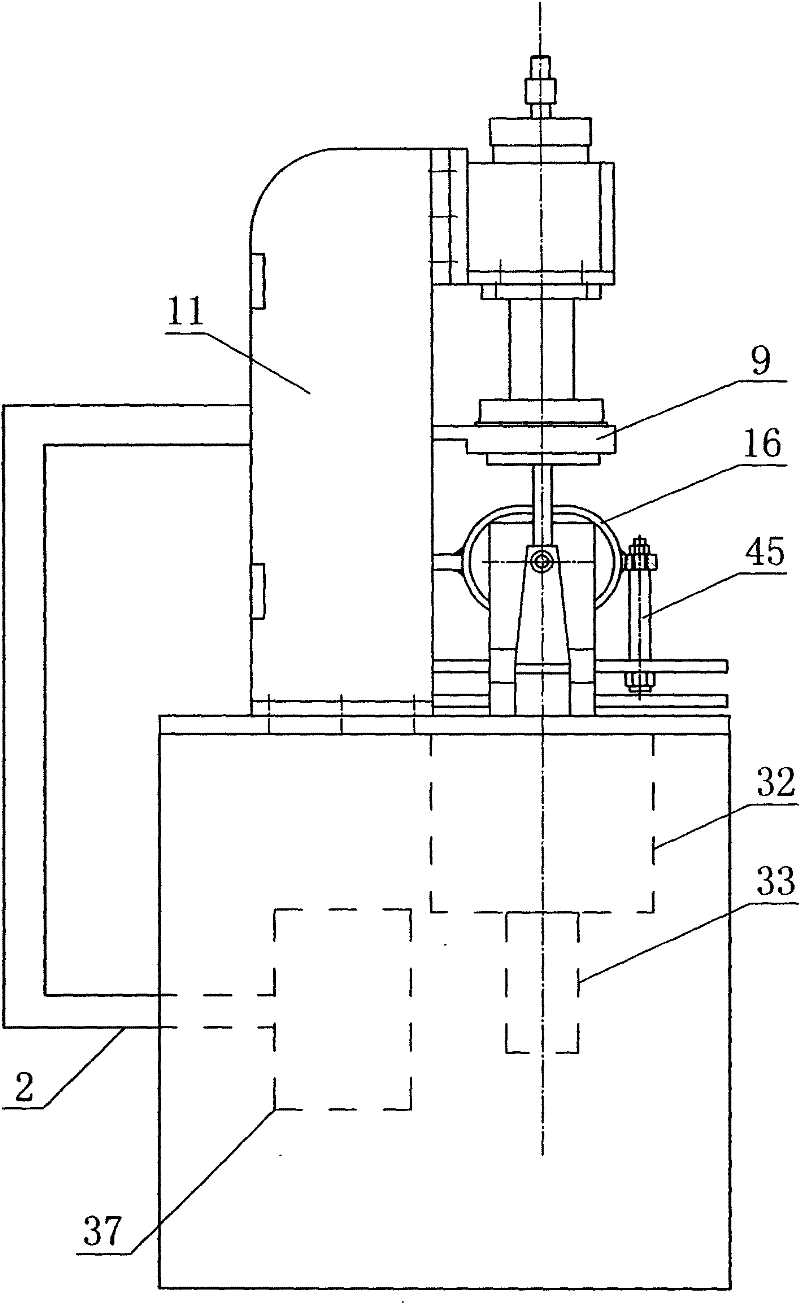

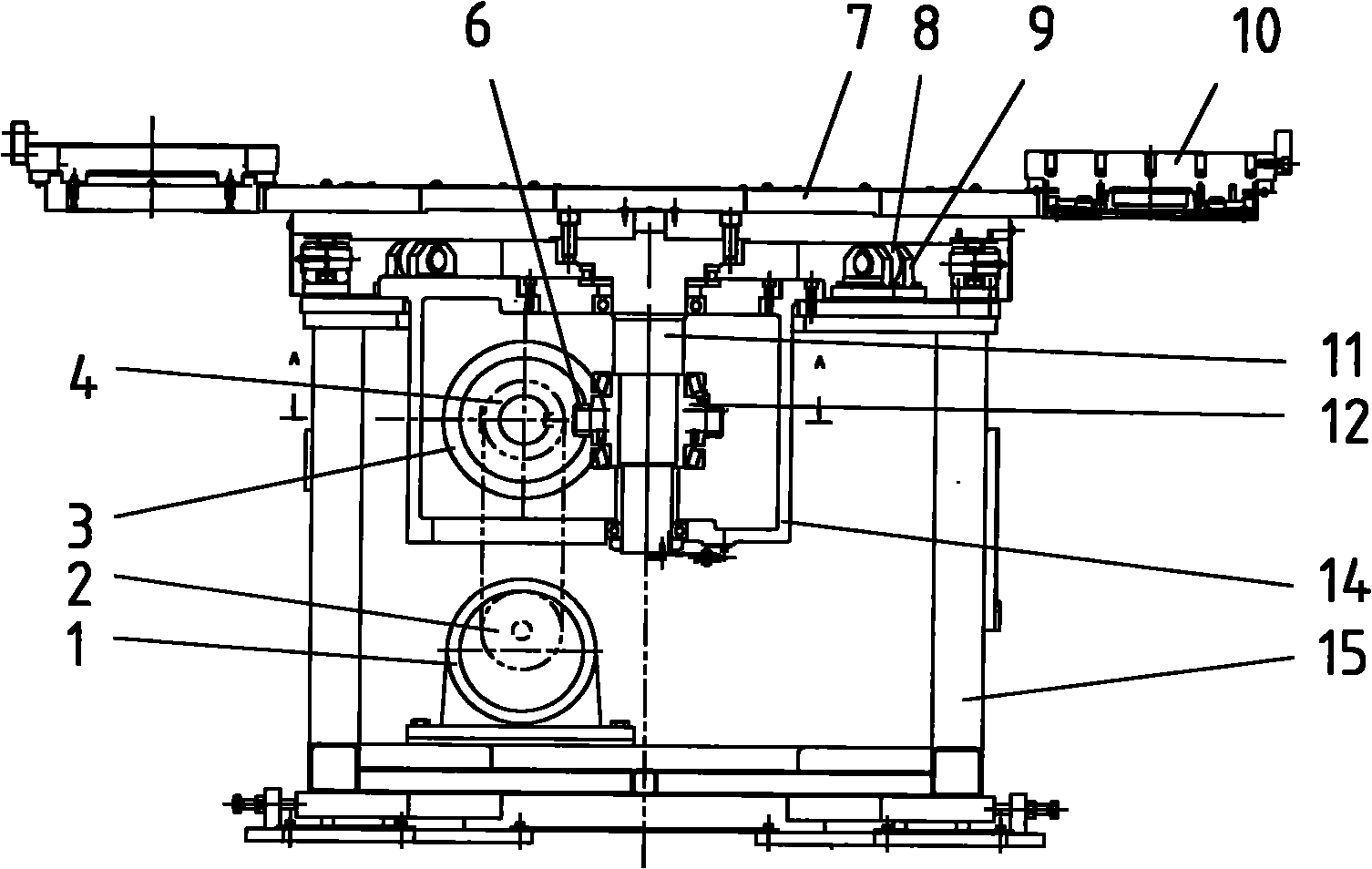

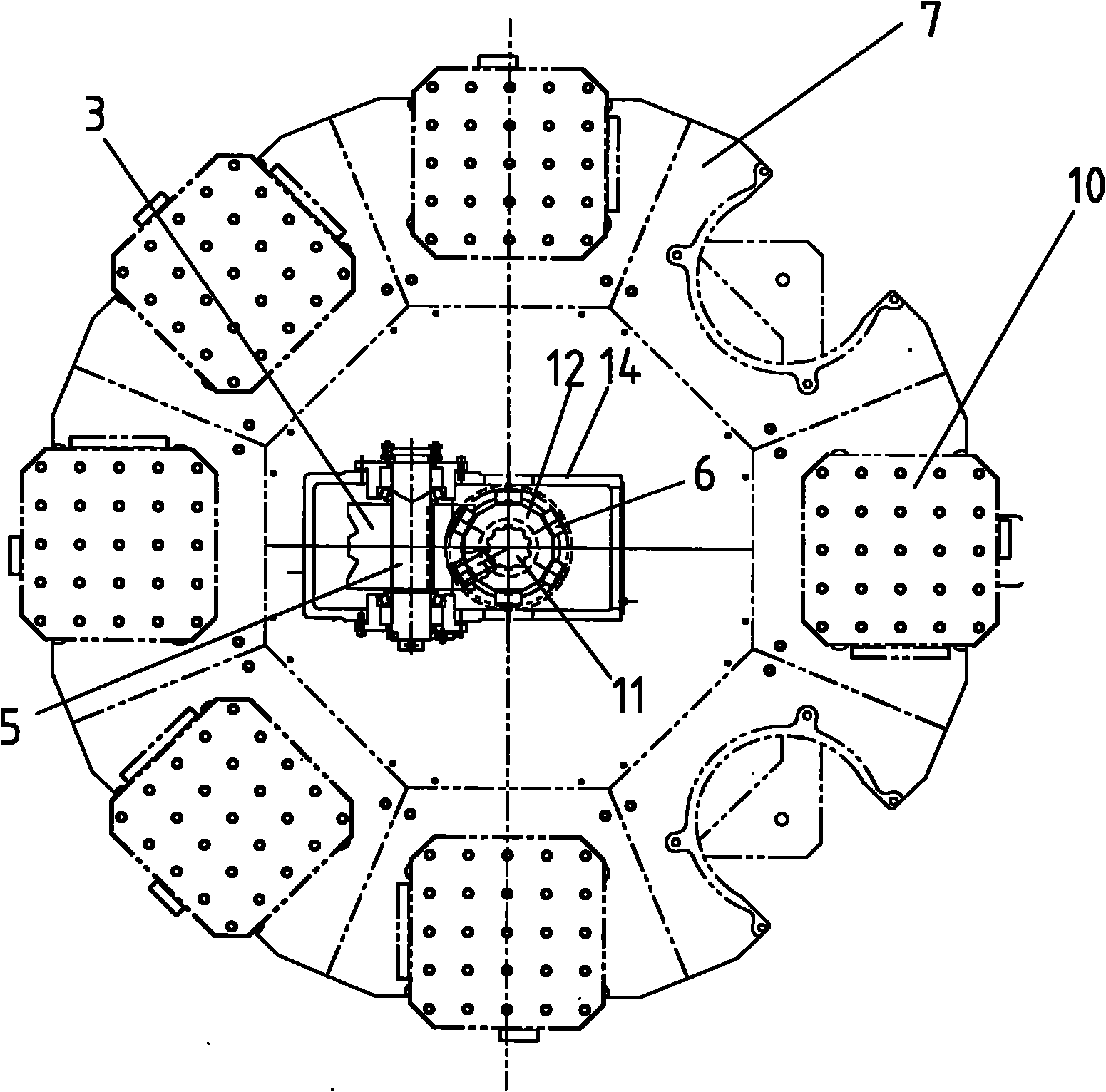

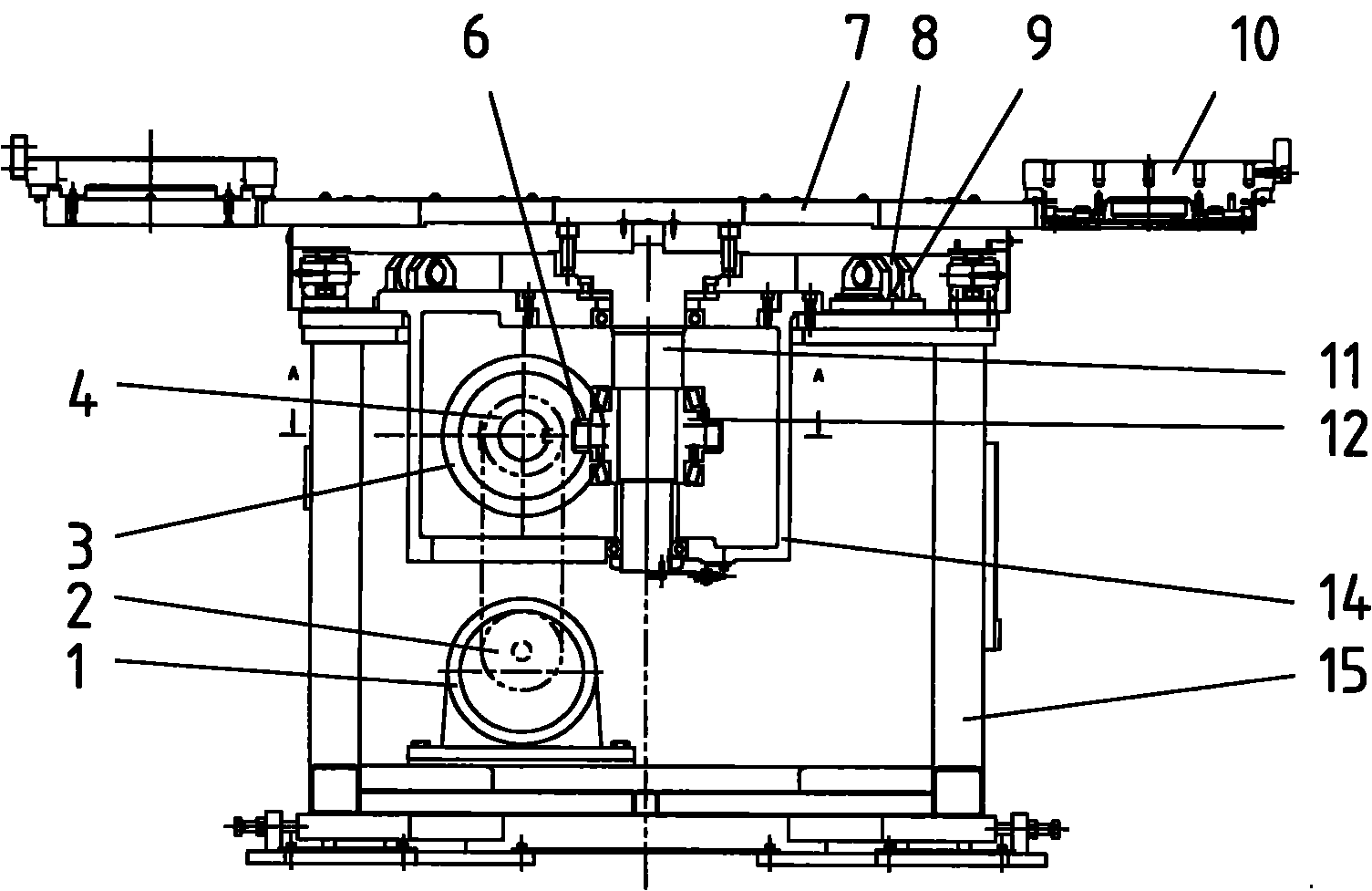

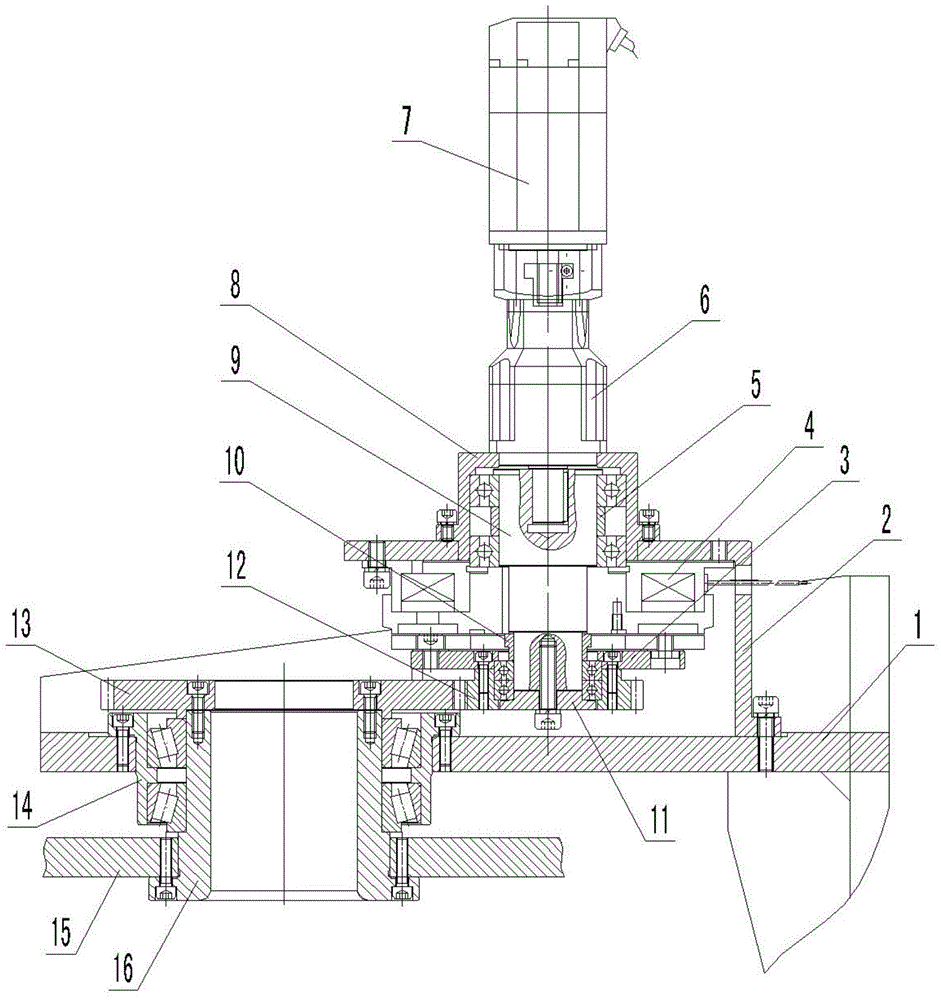

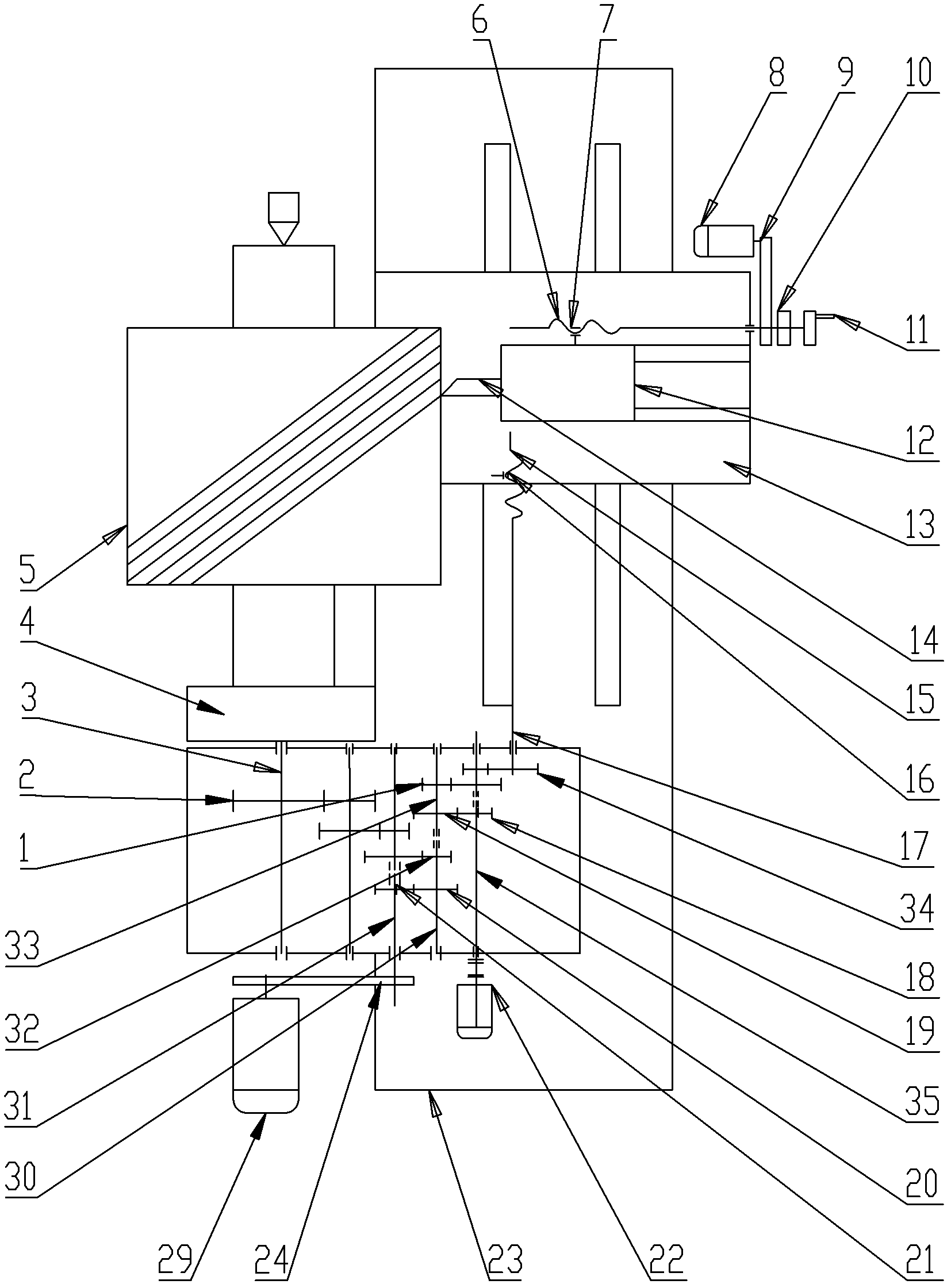

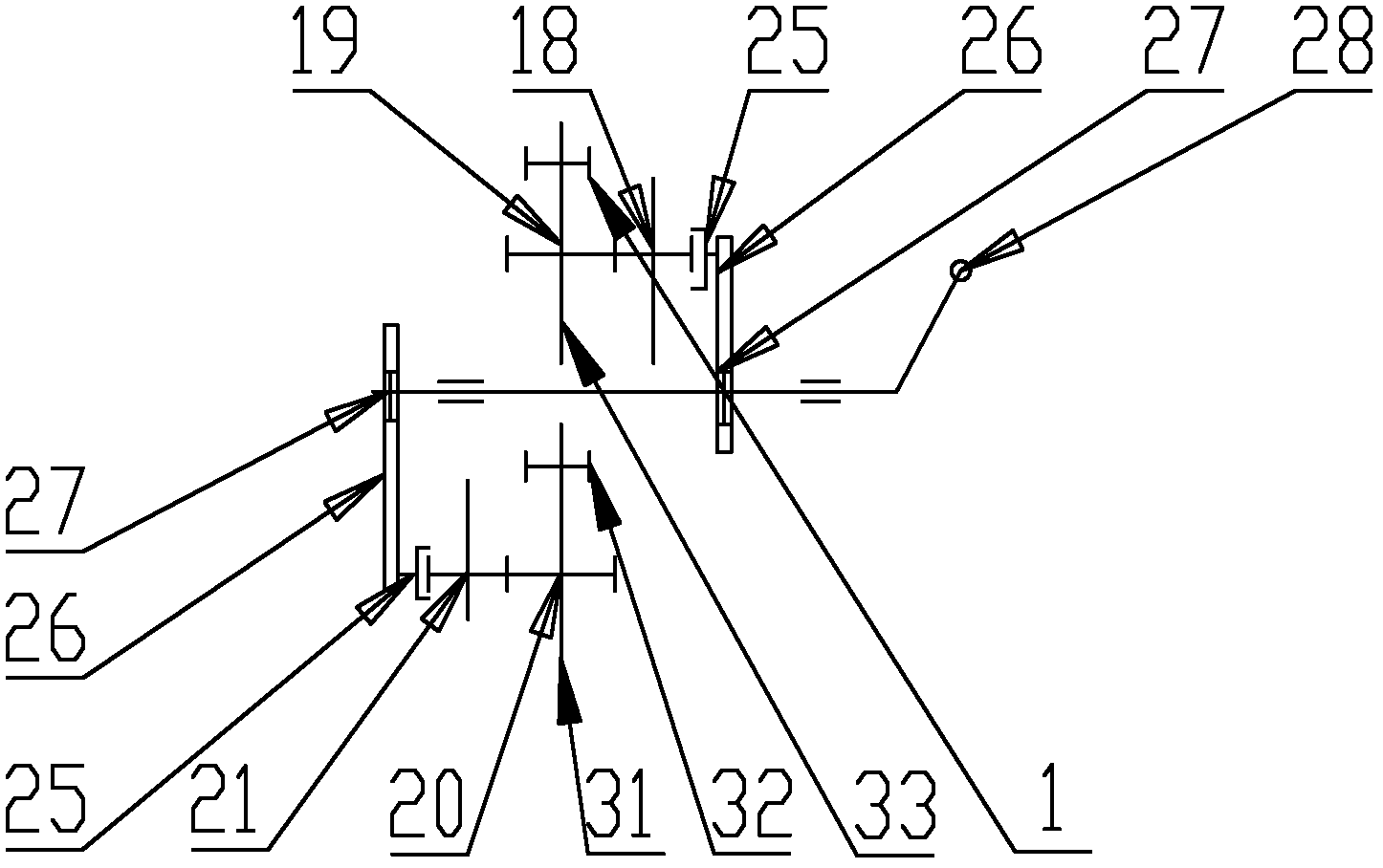

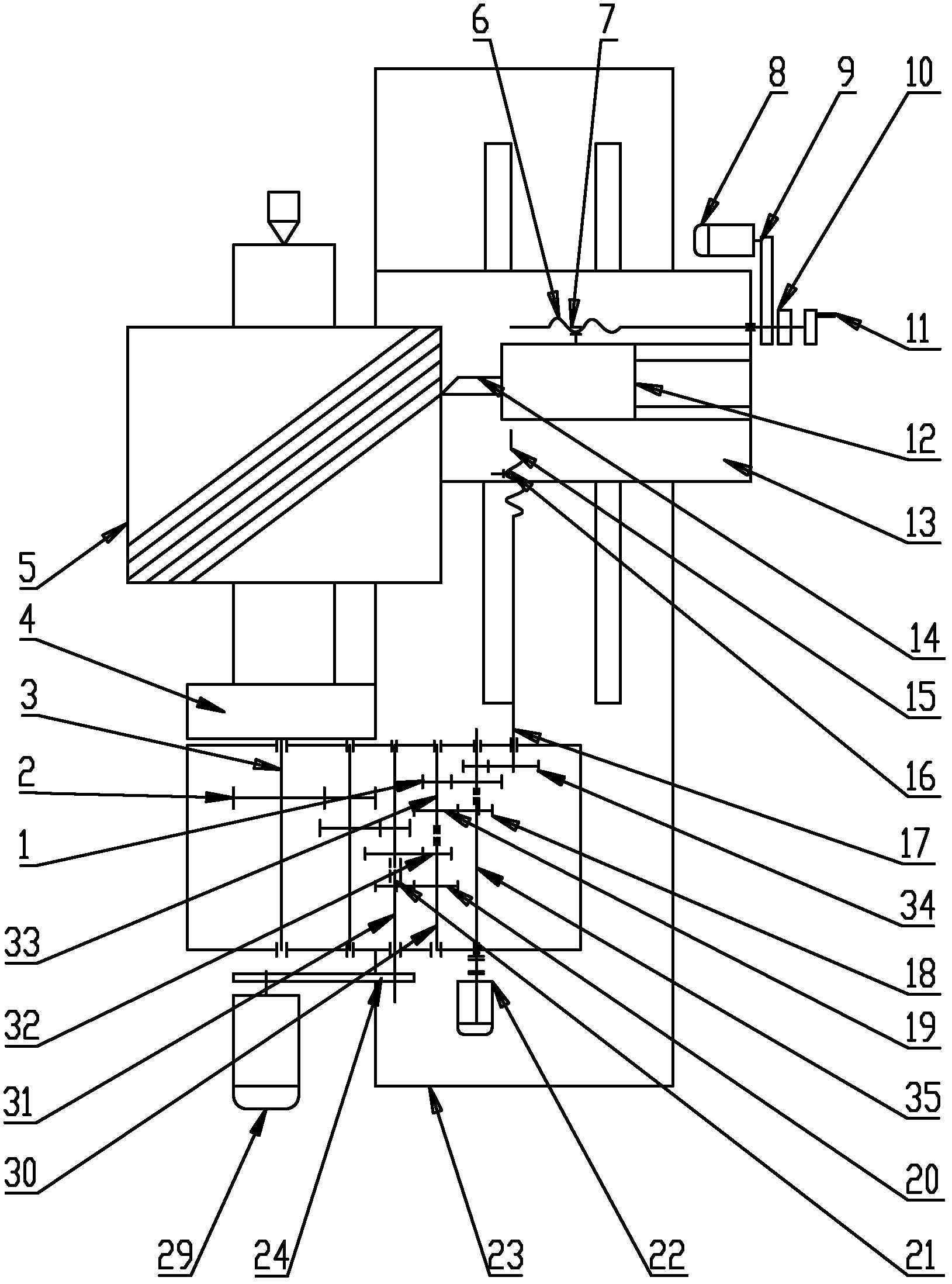

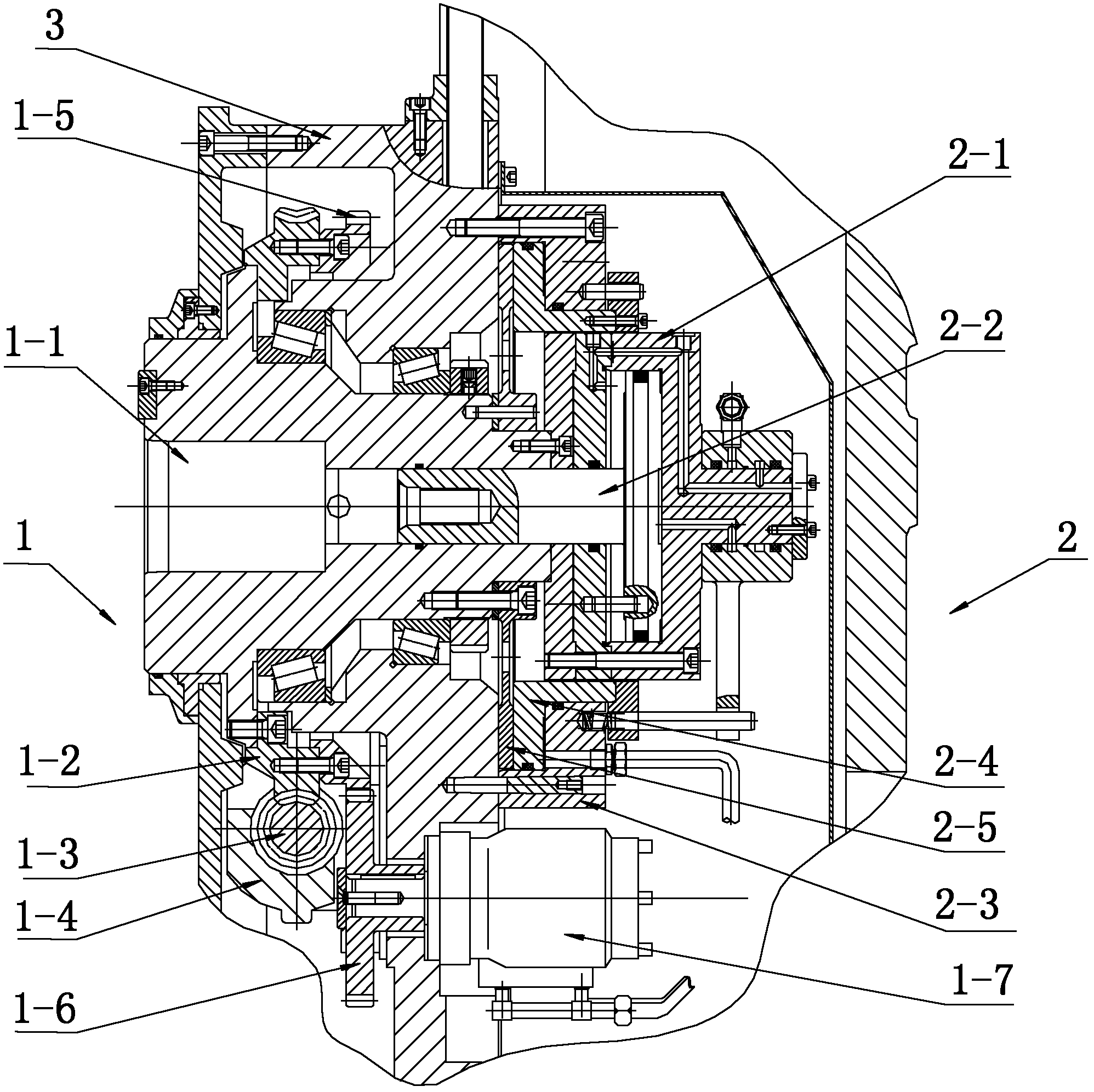

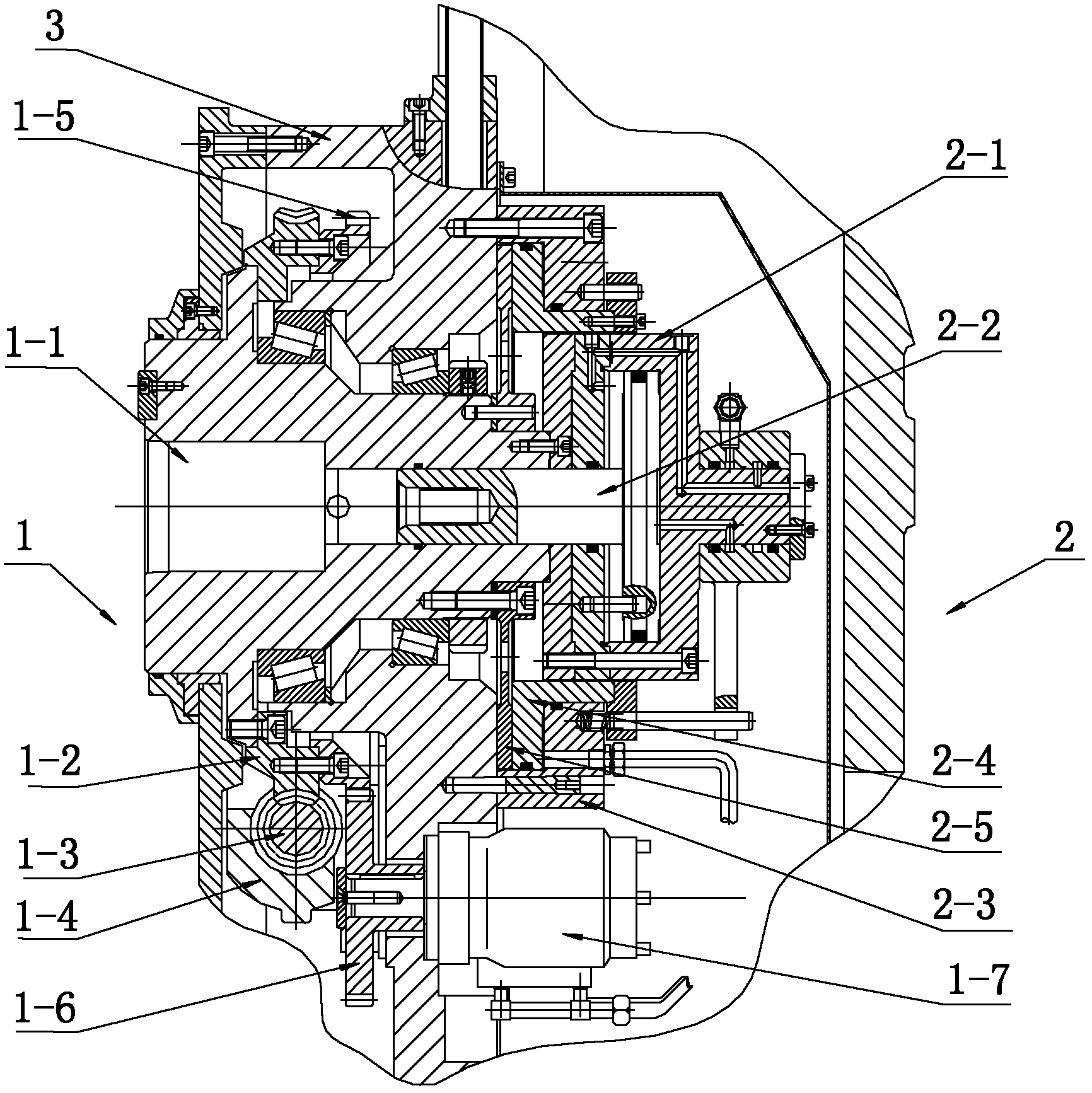

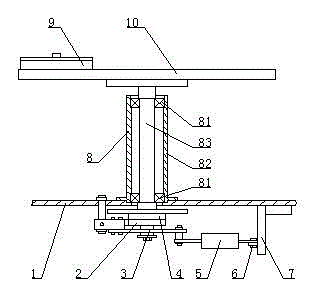

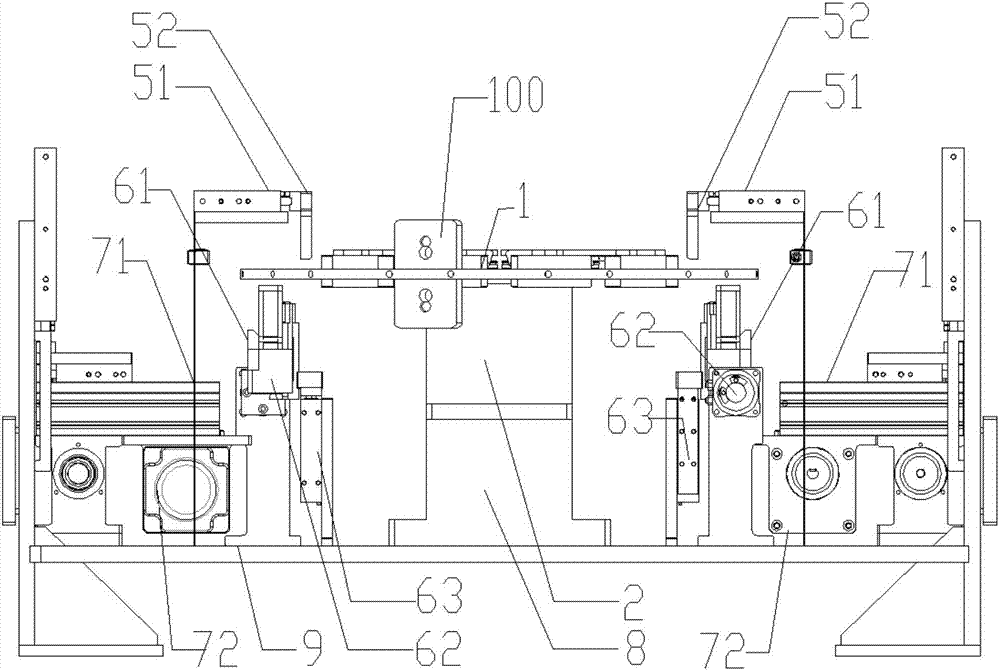

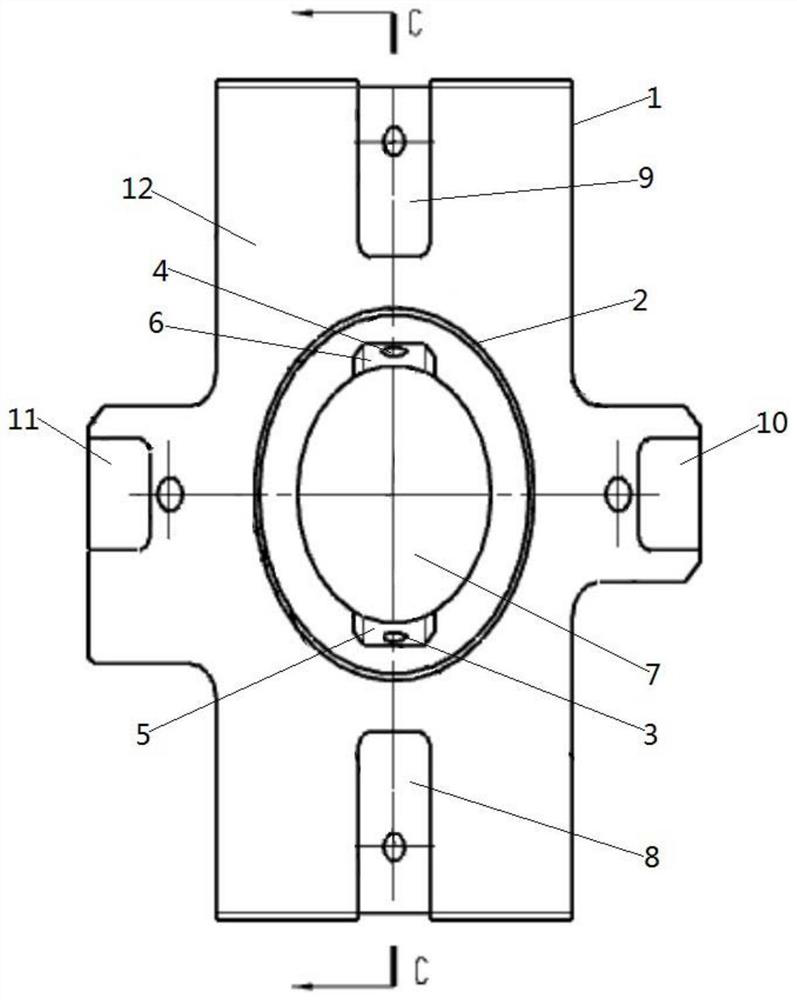

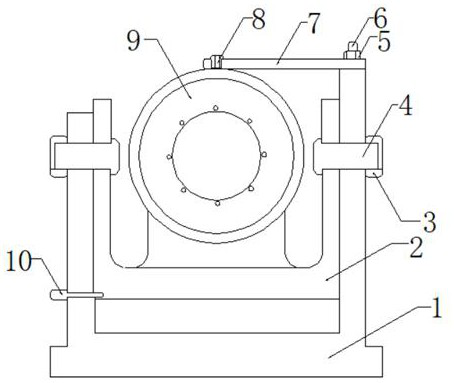

Automobile starter motor stator auxiliary pole automatic welder

InactiveCN101623792AAccurate graduationEvenly distributedWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAuxiliary electrode

The invention discloses an automobile starter motor stator auxiliary pole automatic welder comprising a chassis, and a resistance welder is installed on the chassis. The invention is characterized in that a lifting seat board is arranged on the chassis, a reciprocating lifting mechanism is connected below the lifting seat board, and a sliding seat board which can breadthwise slide is supported on the lifting seat board; the lifting seat board is provided with a straight reciprocating mechanism connected with the sliding seat board; the sliding seat board is provided with a stepper motor and a rotary main shaft, one end of the main shaft is connected with a clamping device, and the other end of the main shaft is connected with the shaft of the stepper motor; the lower electrode of the resistance welder is provided with a material storing block; one side of the chassis, which is provided with the material storing block, is provided with a feeding device, and the feeding pushing rod of the feeding device is inserted into the lower electrode. The invention has the advantages of ensuring precise scale division of a stator housing so as to ensure even distribution of the auxiliary electrode, which is favourable for processing subsequent working procedures; the product has high processing precision, good quality and firm welding; the invention can realize automatic feeding of the auxiliary electrode, improves working efficiency and has high degree of automation.

Owner:锦州华一汽车部件有限公司

Intelligent sample collecting device

ActiveCN105752470ARisks Affecting Mass AccuracyHigh security for collection and transferLidsNon-removalbe lids/coversLocking mechanismEngineering

The invention discloses an intelligent sample collecting device which comprises a machine frame. The machine frame is provided with a feed inlet. A rotatable rotating disc mechanism and multiple sample storage barrels used for collecting samples are arranged in a collecting cavity formed by the machine frame. The sample storage barrels are hung on the rotating disc mechanism. Each sample storage barrel is provided with a hinged barrel cover and an induction locking mechanism used for locking the barrel cover. The hinged position of the barrel cover is provided with an elastic part so that the barrel cover can bounce upwards to be opened when not locked. The feed inlet is provided with a liftable weighing mechanism. The weighing mechanism is provided with an induction unlocking assembly matched with the induction locking mechanism. When the rotating disc mechanism drives the sample storage barrels to rotate to the position below the feed inlet, the weighing mechanism raises to lift up the sample storage barrels, so that the induction locking mechanism induces an unlocking signal of the induction unlocking assembly to open the barrel covers for sample connection and weighing operation. The intelligent sample collecting device has the advantages that the structure is simple and compact, the intelligence degree is high, sample collection and transfer safety is high, sample collection quality precision is high, working efficiency is high, and the production cost is low.

Owner:HUNAN SUNDY SCI & TECH DEV

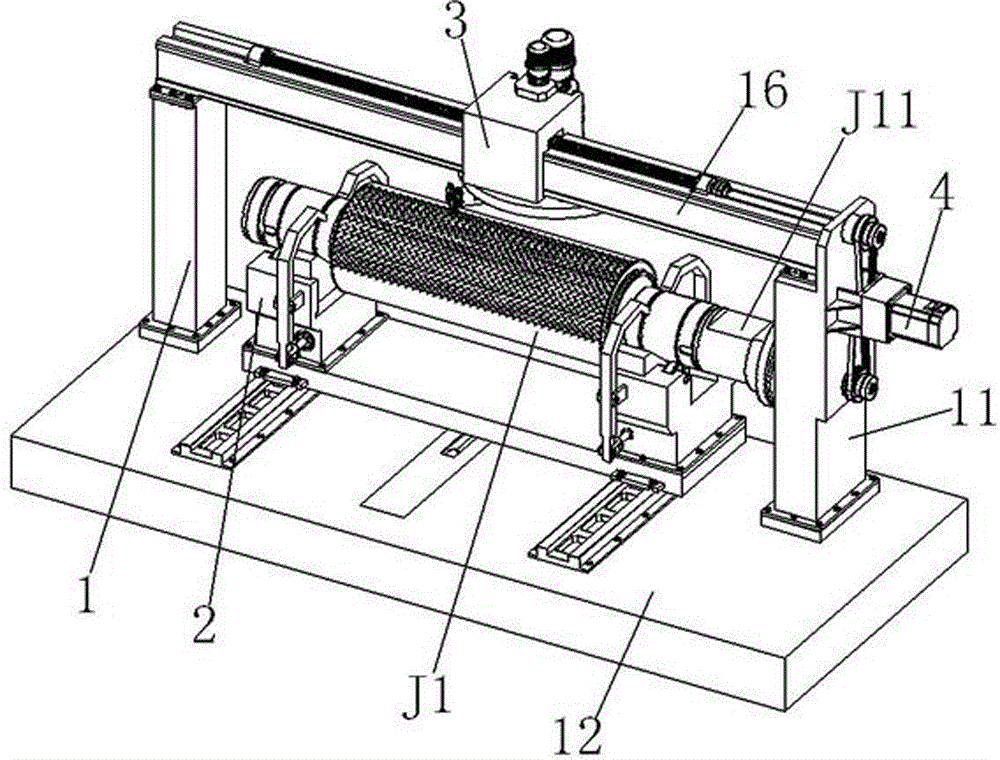

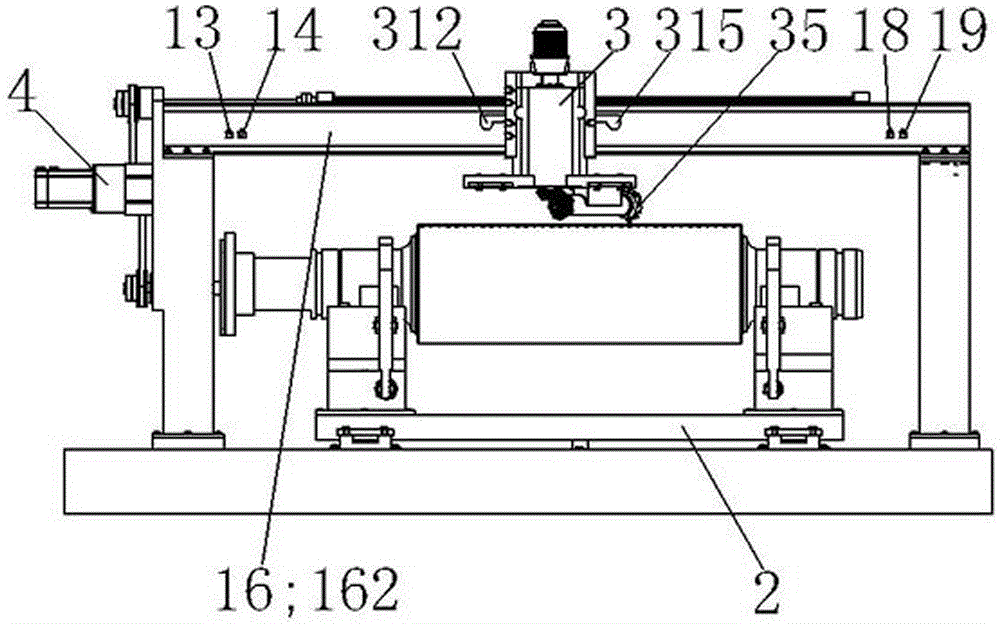

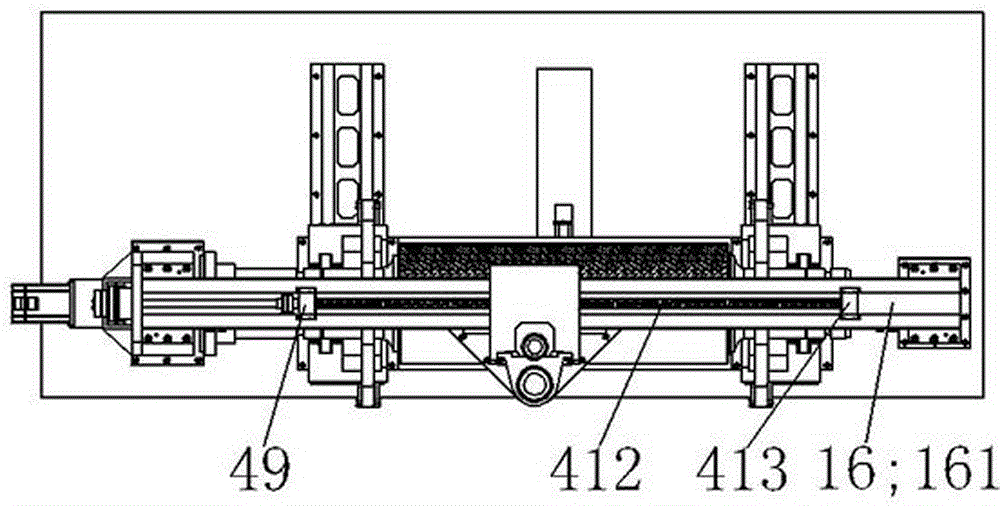

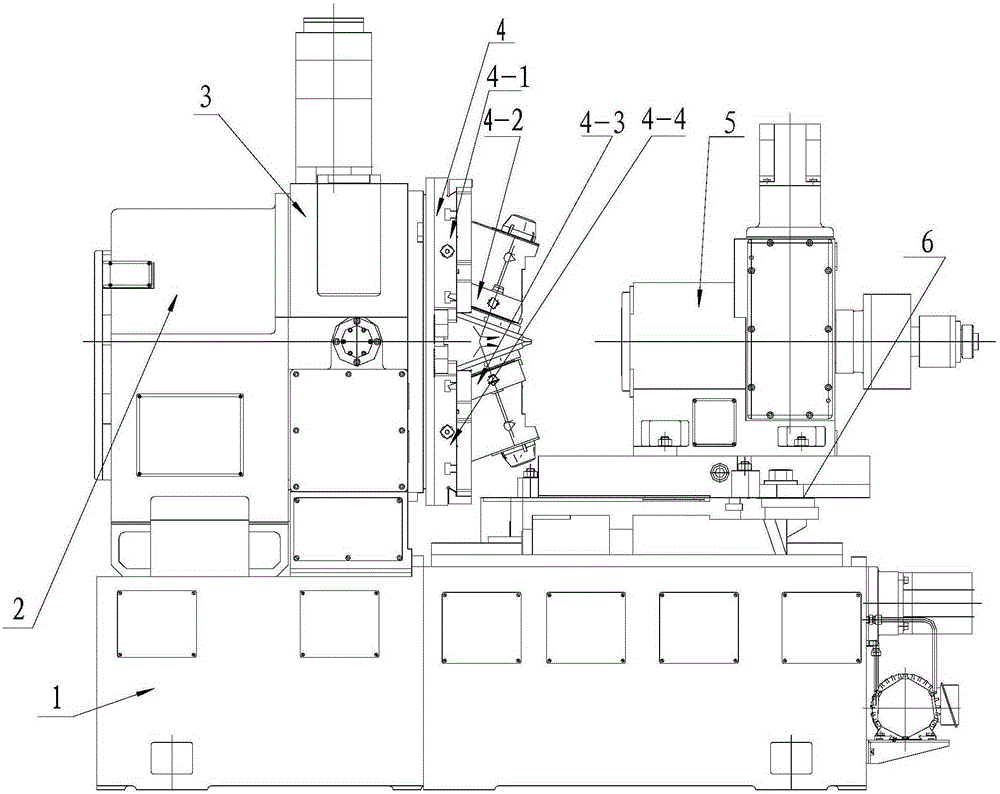

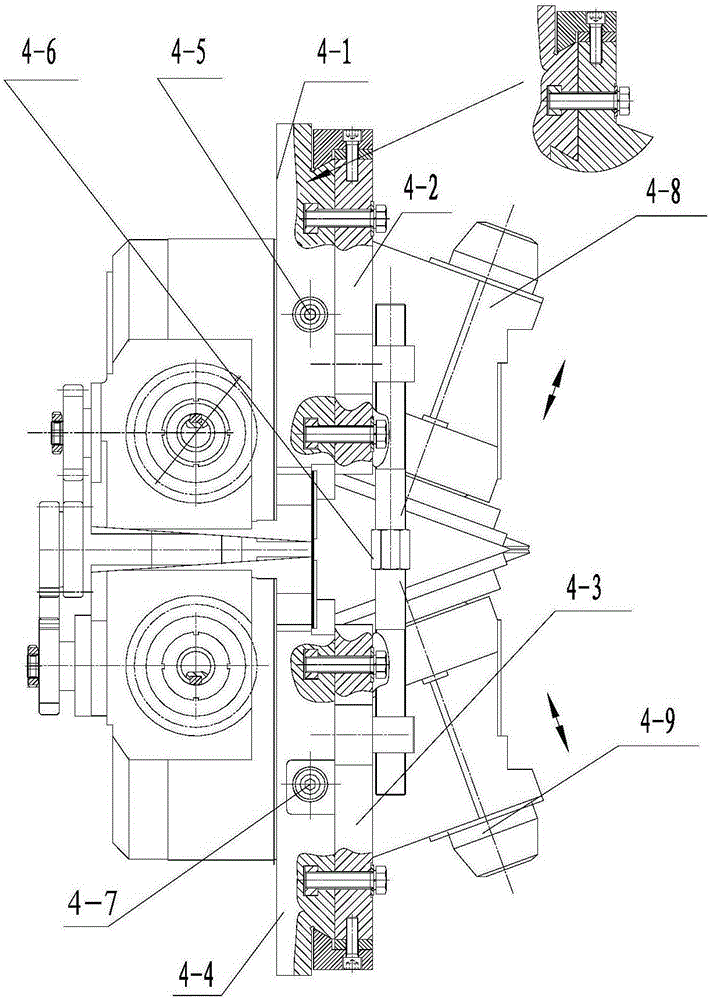

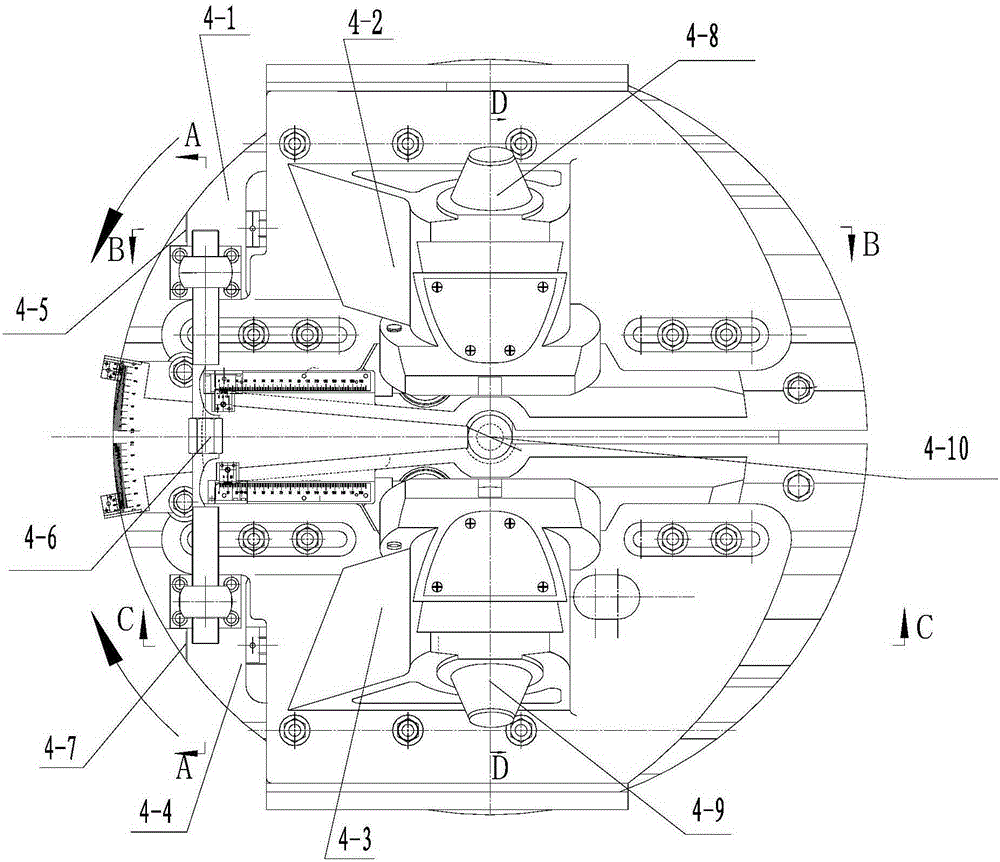

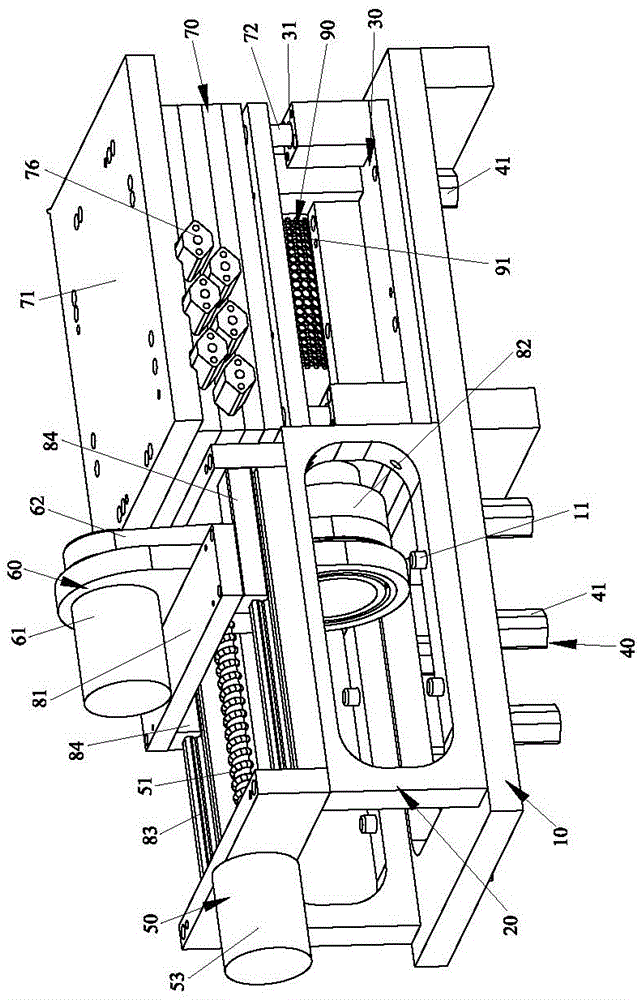

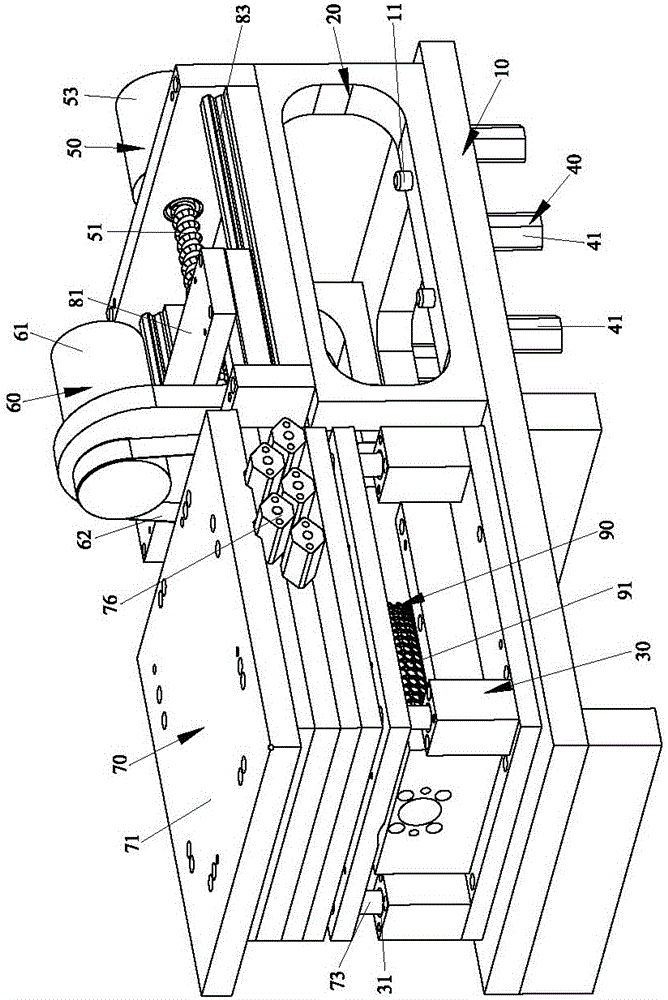

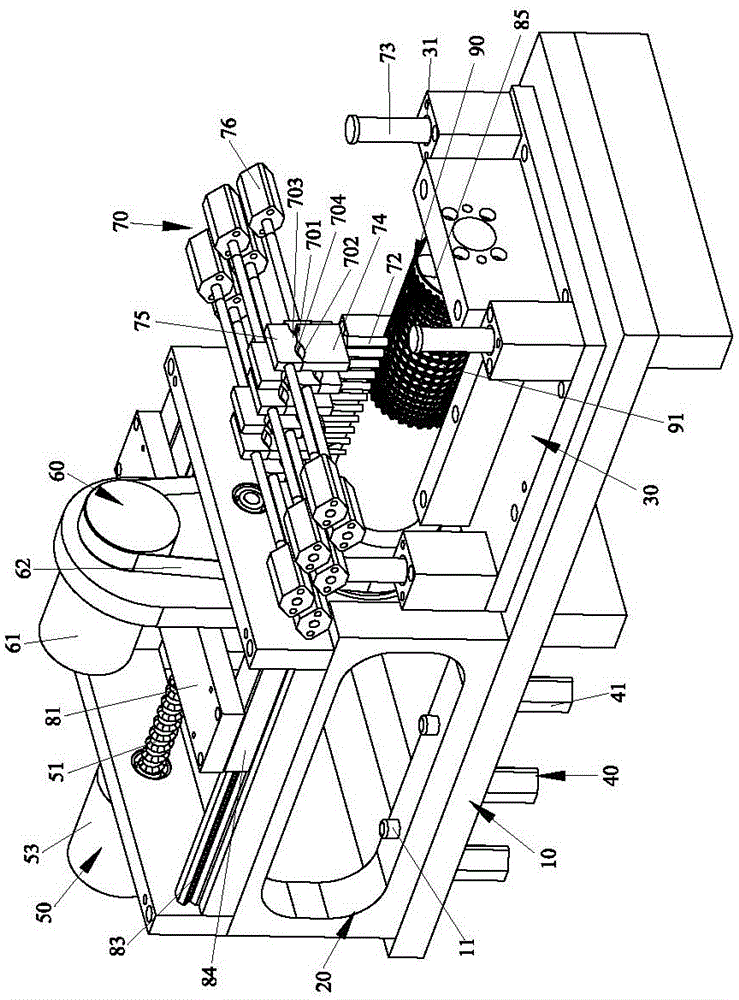

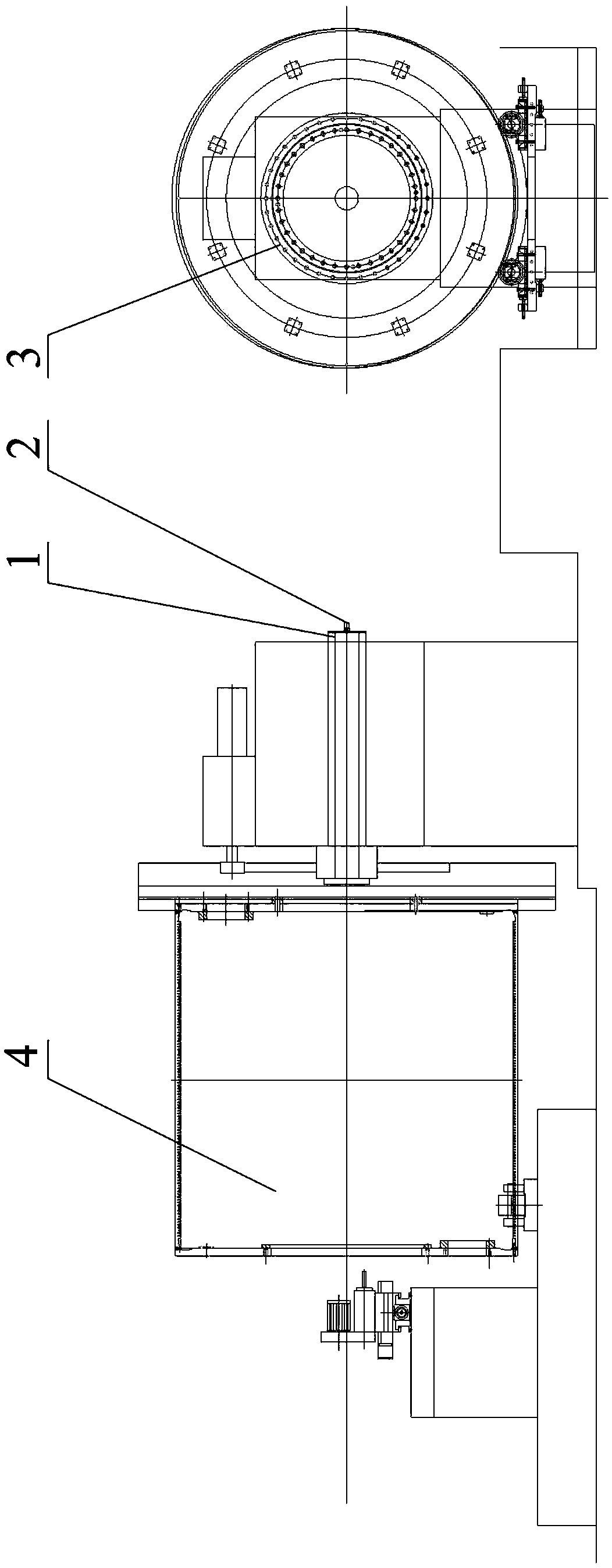

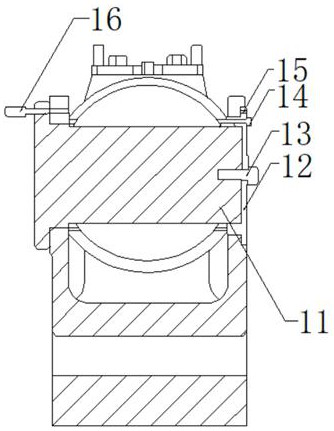

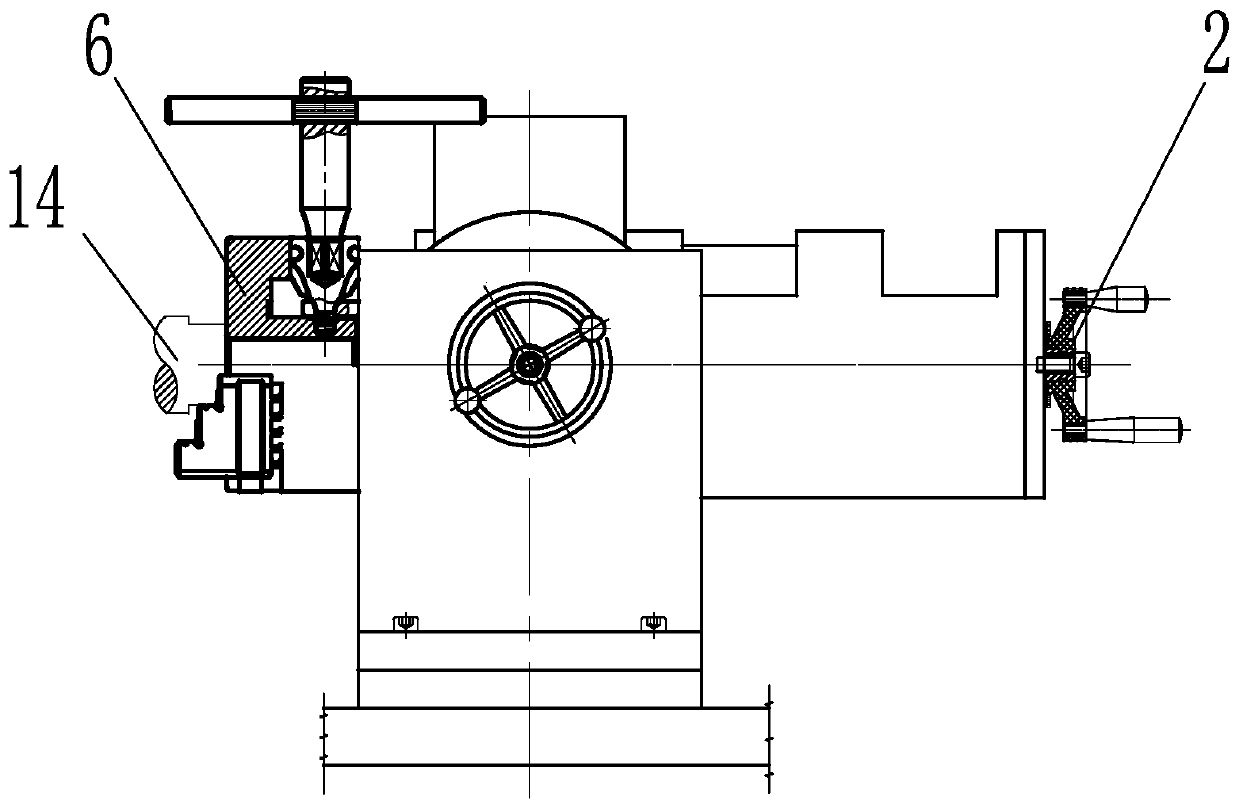

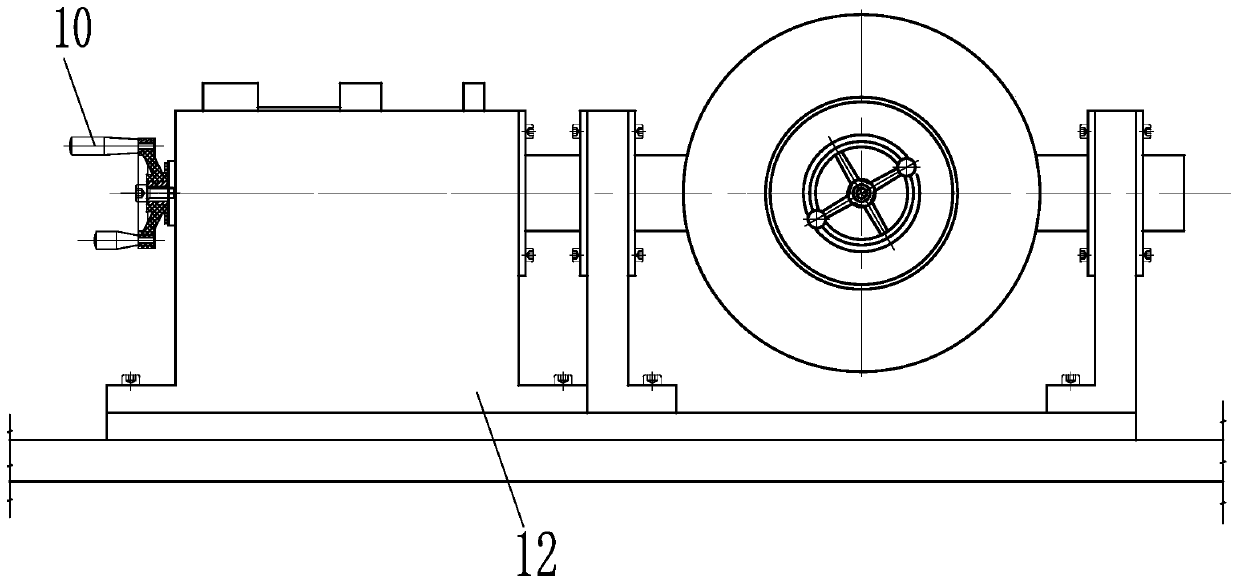

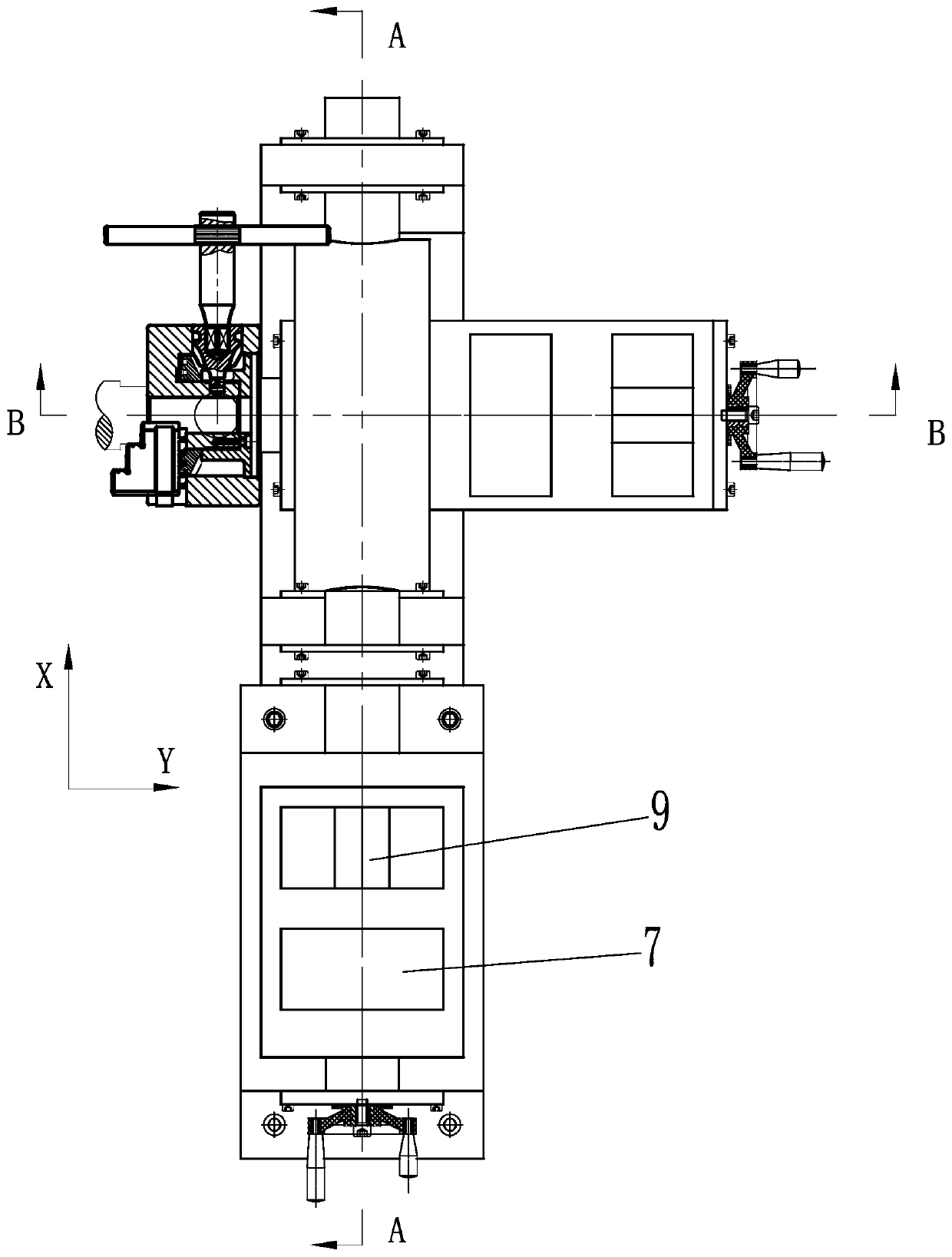

Special machine tool for machining pattern roller lentil-shaped groove

InactiveCN106001723ARealize processingClamp firmlyMilling machinesMilling equipment detailsHydraulic cylinderElectrical control

The invention discloses a special machine tool for machining a pattern roller lentil-shaped groove, and aims to provide a special machine tool in the field of metallurgical machining. The machine tool is provided with a frame module, a positioning and clamping device, a power head milling device and a feed indexing device; and the positioning and clamping device, the power head milling device and the feed indexing device are all arranged on the frame module. The whole structure of the machine tool adopts a gantry vertical milling machine layout; the rigidity of a machining process system is good; the workpiece positioning and clamping are realized by using a support roller and V-shaped block combined effect; a roller is fast in rotation and reliable in clamping; the workpiece maneuvering clamping and loosening are realized by using a hydraulic cylinder to achieve the effects of labor saving and fastness; a servo motor is adopted to provide power for peripheral indexing of the roller and positioning of a multi-station feeding position; the indexing and positioning precision is high; the automatic workpiece machining can be realized through electric control; and the machine tool is used for machining workpieces, low in vibration, few in surface vibration patterns, high in machining quality, simple in structure, convenient for maintenance and low in equipment investment.

Owner:KUNMING UNIV

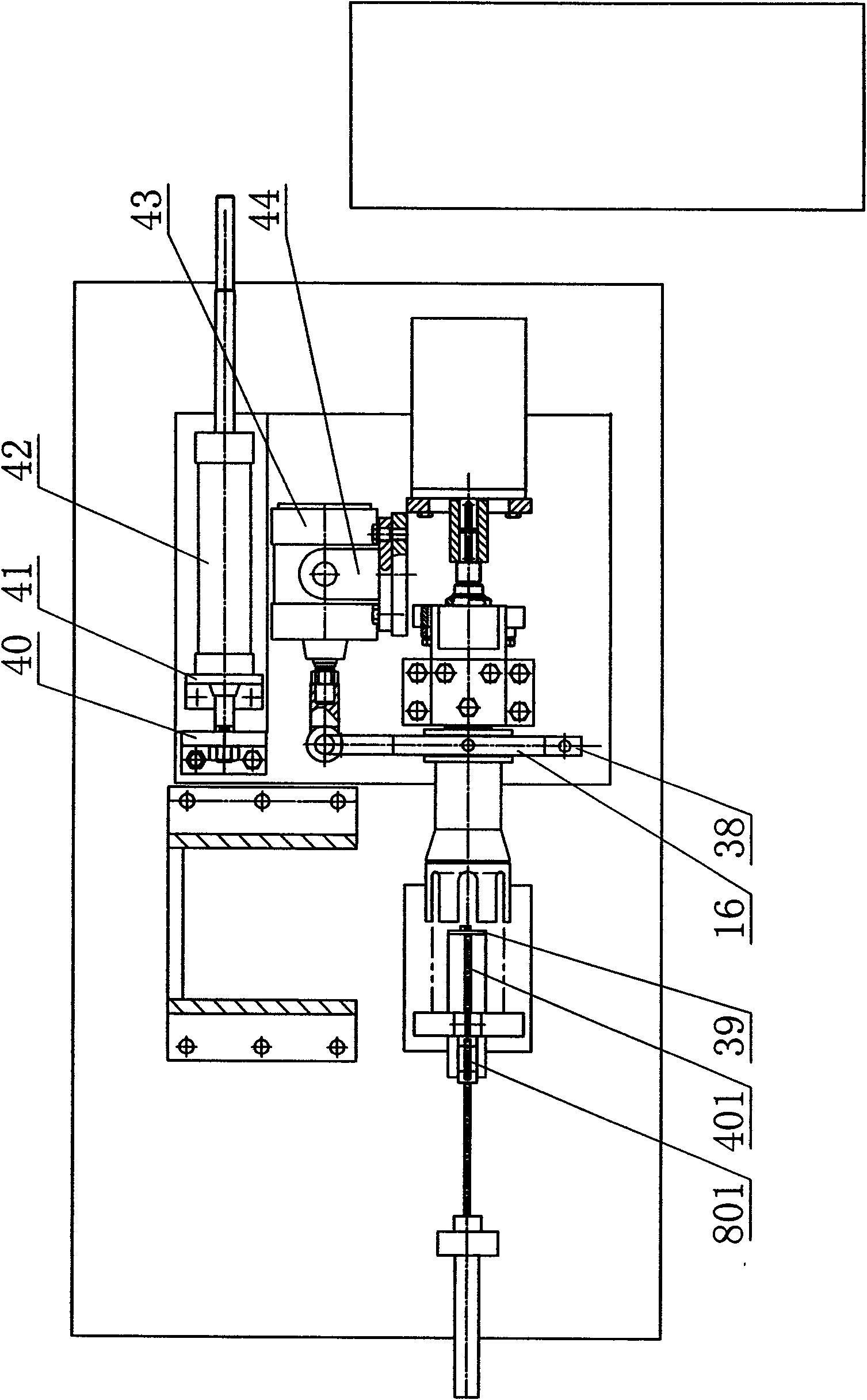

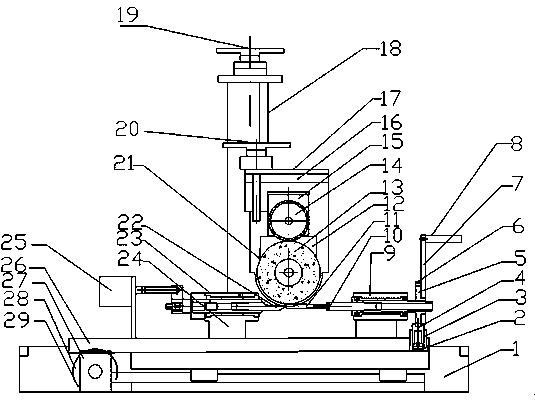

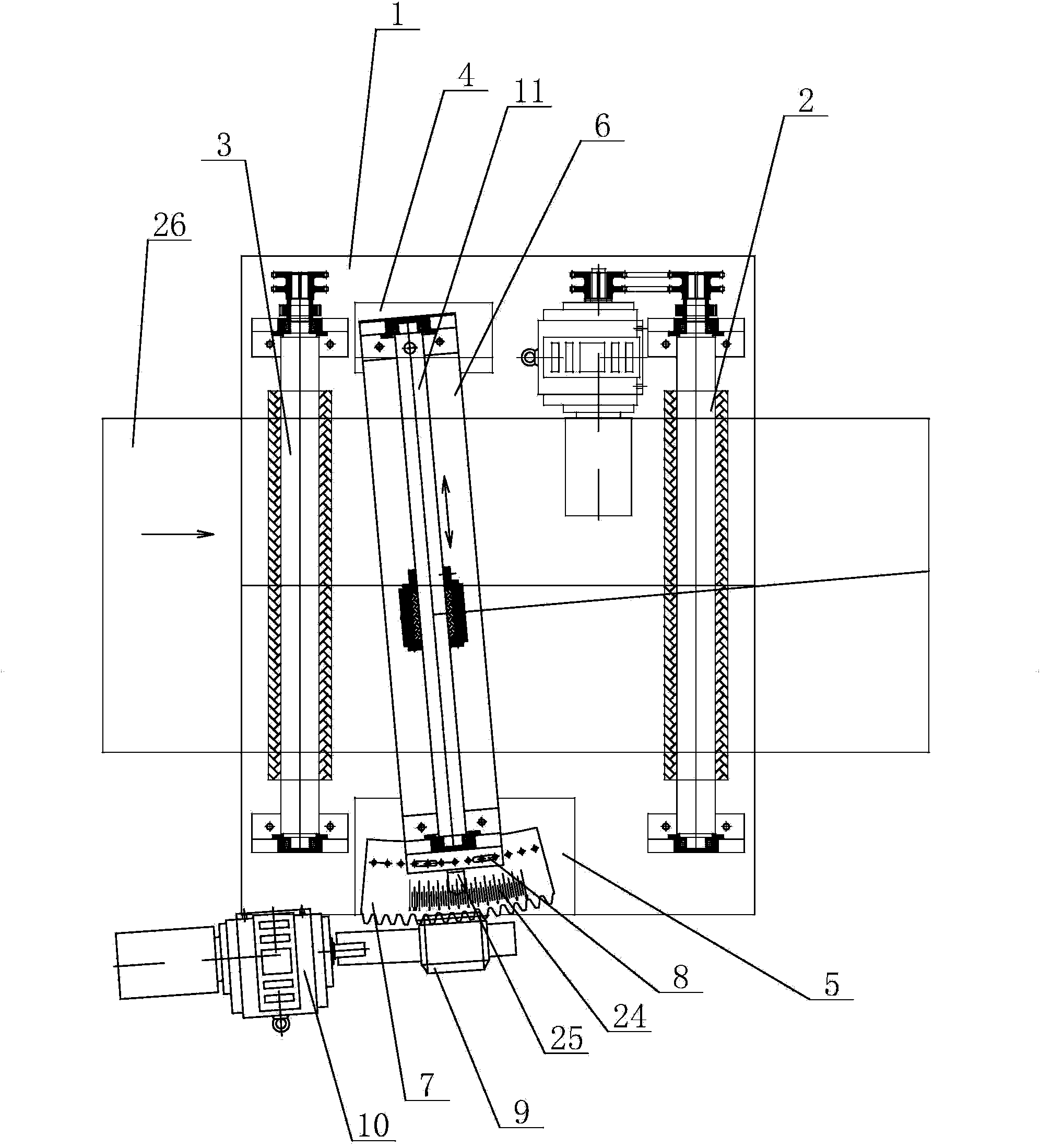

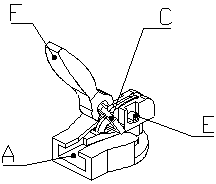

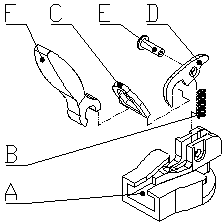

Groove grinding machine for automatically correcting screw tap

InactiveCN104209838AAccurate graduationQuality improvementGrinding machine componentsGrinding machinesMechanical engineeringUltimate tensile strength

The invention discloses a groove grinding machine for automatically correcting a screw tap. The groove grinding machine comprises a first base, a second base, a grinding assembly, an indexing assembly, a feeding assembly and a correcting assembly, wherein a clamping assembly and the feeding assembly are arranged on the first base, the grinding assembly is arranged on the second base, the first base is provided with the indexing assembly, and the second base is provided with the correcting assembly. According to the groove grinding machine for automatically correcting the screw tap, disclosed by the invention, error which is caused by a former process can be corrected, the indexing is accurate due to the arrangement of the indexing assembly, the product quality is increased, the operation is simple, and the labor intensity of a worker is reduced.

Owner:ZHENGJIANG DANTU DISTRICT NINGBO RUN TOOLS

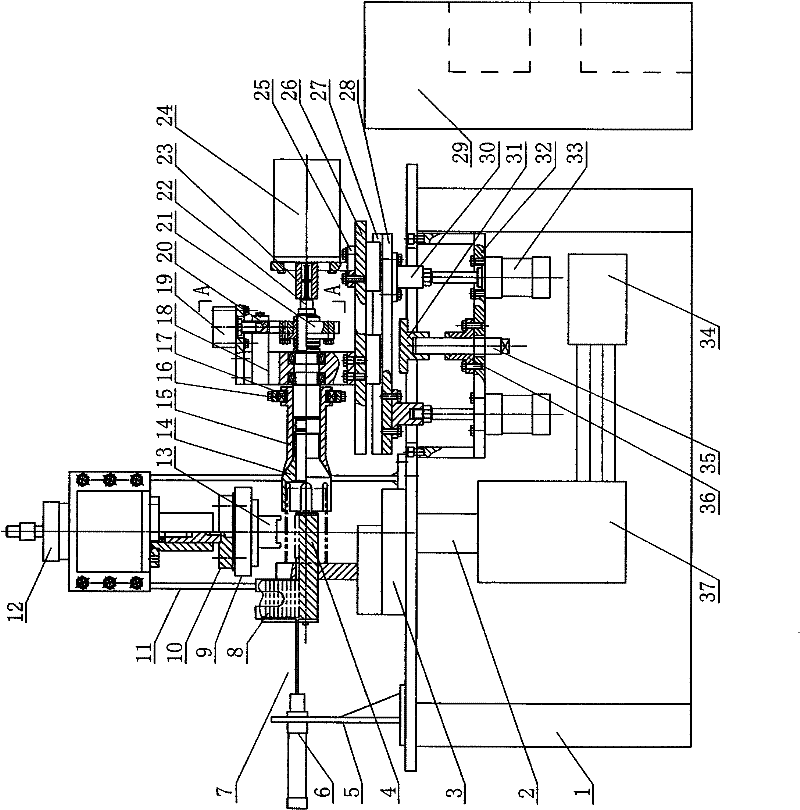

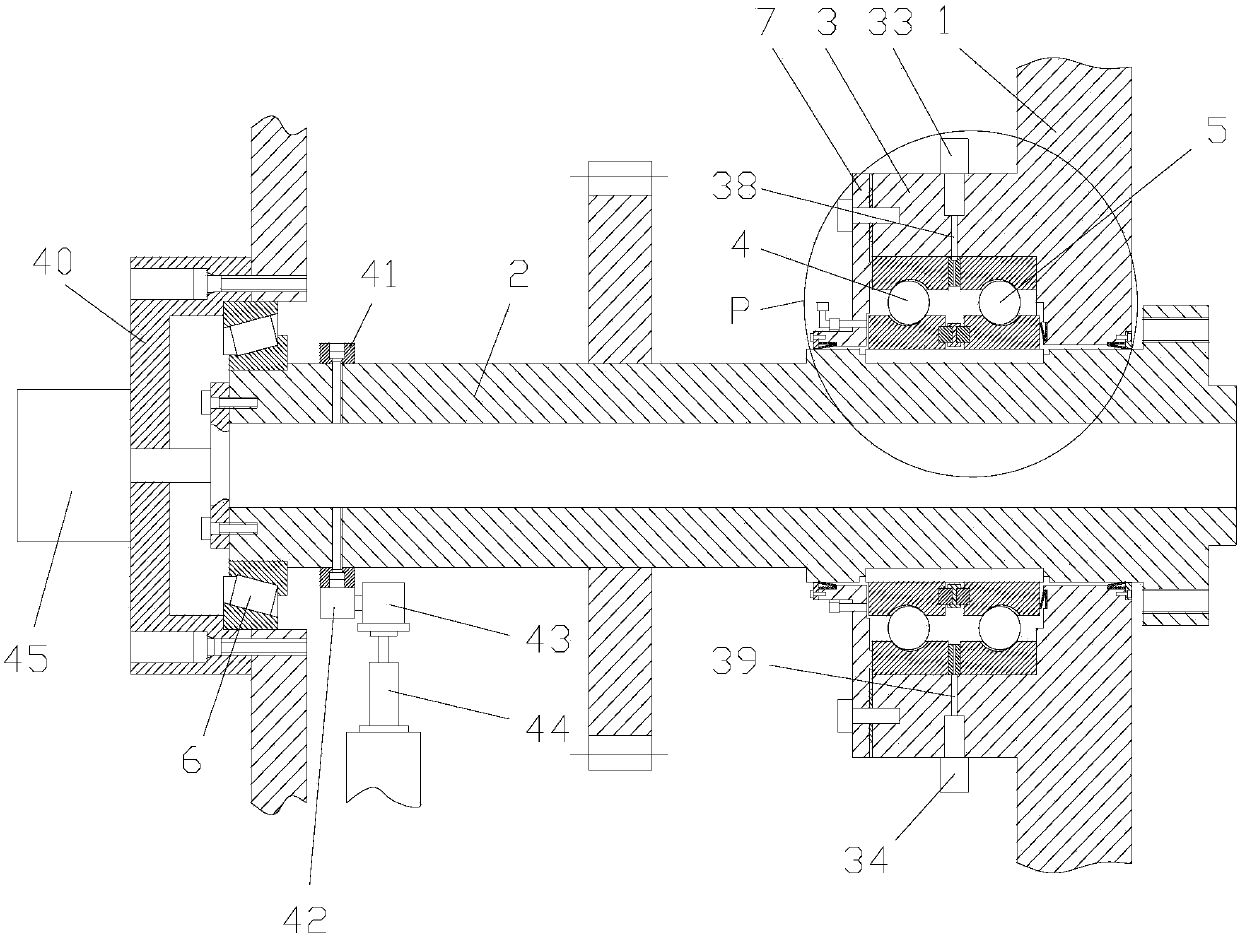

Numerical-control double-cutter-head gear milling machine for straight bevel gears

ActiveCN105215475AImprove cutting precisionAccurate graduationMetal working apparatusGear-cutting machinesNumerical controlManufacturing cost reduction

The invention relates to a numerical-control double-cutter-head gear milling machine for straight bevel gears. The numerical-control double-cutter-head gear milling machine comprises a tool body assembly, a main driving box assembly, a cradle assembly, a cutting tool box assembly, a workpiece box assembly, a saddle turnplate assembly and the like. The numerical-control double-cutter-head gear milling machine is characterized in that the cutting tool box assembly comprises an upper tool holder component, a lower tool holder component, an upper tool box component, a lower tool box component, an upper-lower tool holder angle adjusting mechanism, an upper tool box transverse movement adjusting device and a lower tool box transverse movement adjusting device, and the upper tool holder component, the lower tool holder component, the upper tool box component, the lower tool box component, the upper-lower tool holder angle adjusting mechanism, the upper tool box transverse movement adjusting device and the lower tool box transverse movement adjusting device are installed on drum wheels of the cradle assembly. A spring damping device used for eliminating movement gaps during scale division actions is arranged in the workpiece box assembly. The numerical-control double-cutter-head gear milling machine has the advantages that the overall rigidity of a gear machine tool can be improved, the structure of the machine tool, various movement axis transmission chains and adjustment calculation programs are sufficiently simplified, the manufacturing cost is reduced, and the gear cutting machining accuracy is substantially improved; large-scale gear machining can be achieved, and requirements for machining a single gear or a small batch of various gears can be met.

Owner:天津第一机床有限公司

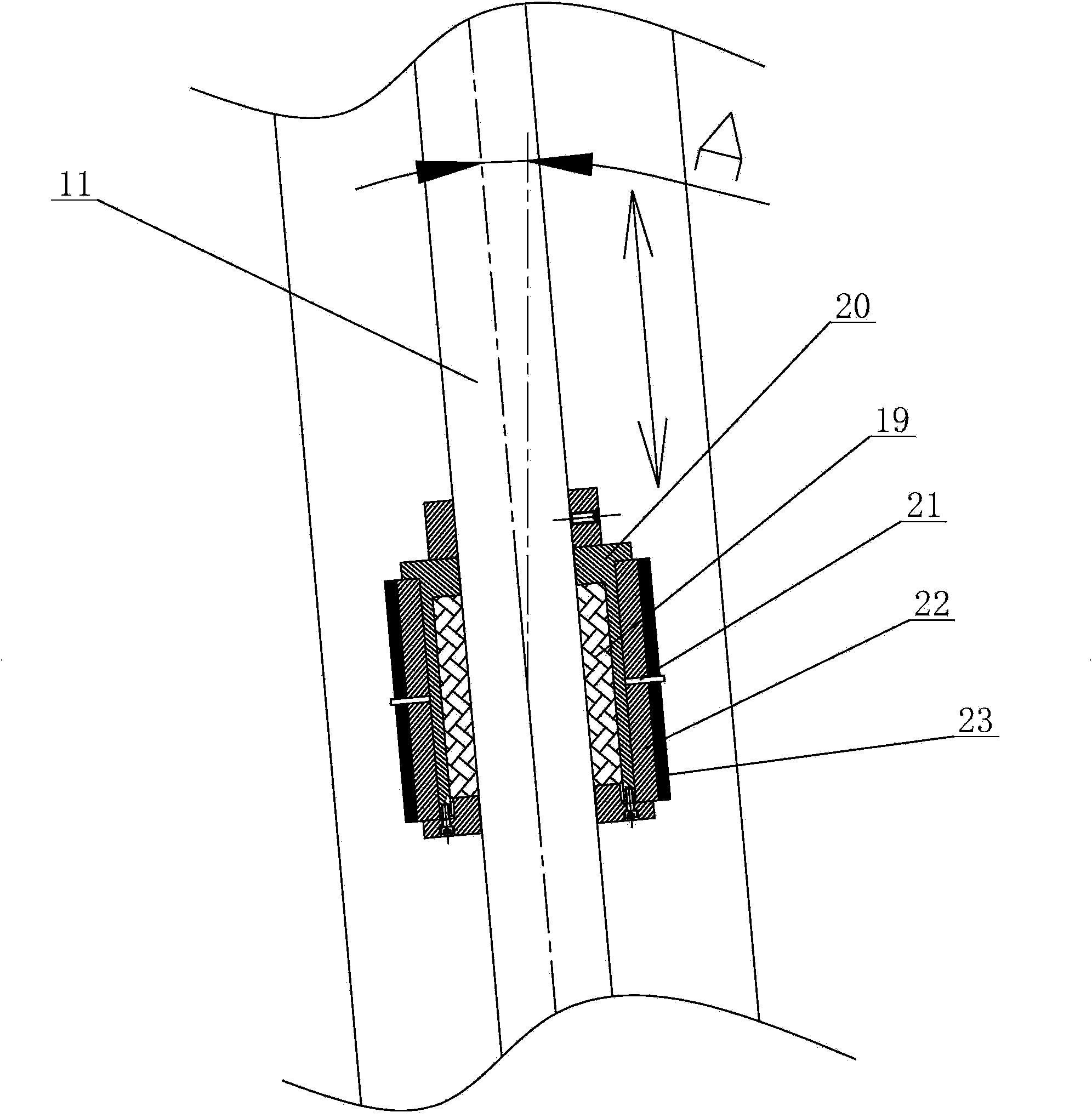

Automobile starter motor stator auxiliary pole automatic welder

InactiveCN101623792BAccurate graduationEvenly distributedWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAuxiliary electrode

The invention discloses an automobile starter motor stator auxiliary pole automatic welder comprising a chassis, and a resistance welder is installed on the chassis. The invention is characterized in that a lifting seat board is arranged on the chassis, a reciprocating lifting mechanism is connected below the lifting seat board, and a sliding seat board which can breadthwise slide is supported onthe lifting seat board; the lifting seat board is provided with a straight reciprocating mechanism connected with the sliding seat board; the sliding seat board is provided with a stepper motor and arotary main shaft, one end of the main shaft is connected with a clamping device, and the other end of the main shaft is connected with the shaft of the stepper motor; the lower electrode of the resistance welder is provided with a material storing block; one side of the chassis, which is provided with the material storing block, is provided with a feeding device, and the feeding pushing rod of the feeding device is inserted into the lower electrode. The invention has the advantages of ensuring precise scale division of a stator housing so as to ensure even distribution of the auxiliary electrode, which is favourable for processing subsequent working procedures; the product has high processing precision, good quality and firm welding; the invention can realize automatic feeding of the auxiliary electrode, improves working efficiency and has high degree of automation.

Owner:锦州华一汽车部件有限公司

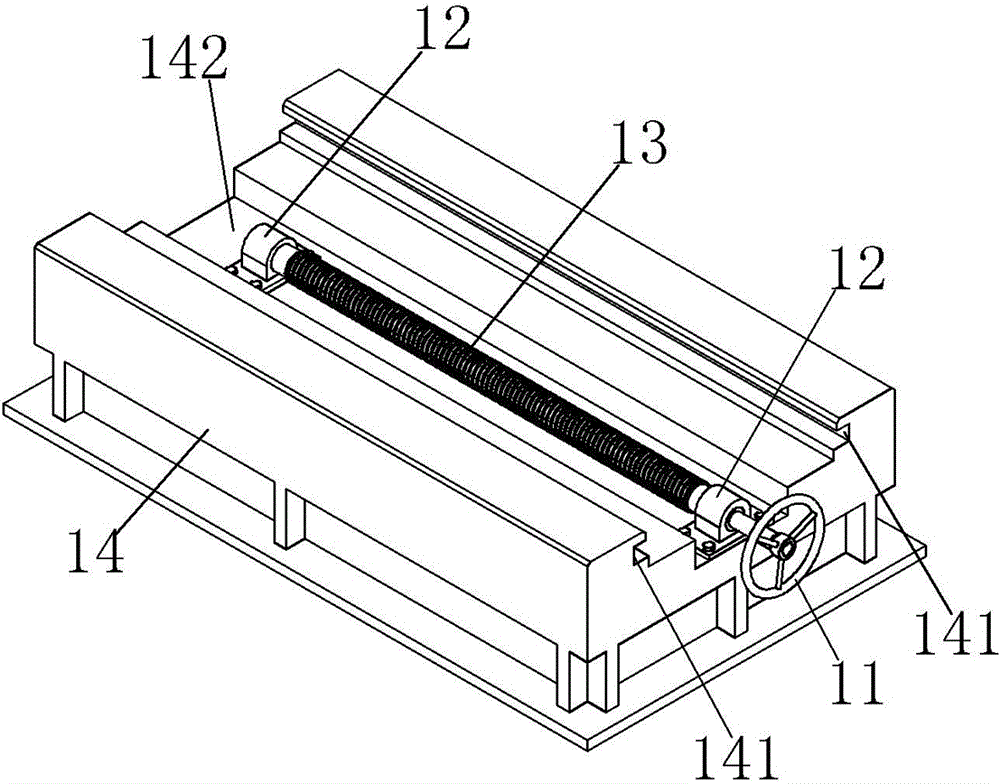

Automatic division slitting mechanism

ActiveCN103447604AAccurate graduationSheet levelingShearing machinesMetal working apparatusNonferrous metalEngineering

The invention discloses an automatic division slitting mechanism, which is suitable for slitting a single or a plurality of inclined slits or straight slits for materials such as nonferrous metal thin plates, plastic and leather. The automatic division slitting mechanism comprises a pedestal, a first mounting seat and a second mounting seat, wherein the first mounting seat and the second mounting seat are arranged on the two side edges of the pedestal; the first mounting seat is hinged to one end of a rotary rack; the other end of the rotary rack is rotatablely arranged on the second mounting seat, and the end is fixedly connected with a cambered toothed plate; the cambered toothed plate is engaged with a transmission gear; the transmission gear is connected with a driving device; the rotary rack is provided with an upper main shaft with adjustable height; a lower main shaft is correspondingly arranged below the upper main shaft; the upper main shaft and the lower main shaft are provided with upper and lower shearing cutters which can freely slide along the main shafts; a cutter resetting mechanism is arranged on one side of the lower main shaft in coordination with the shearing cutters; the driving device is electrically connected with an electric control box. The slitting mechanism is easy and convenient to operate and accurate in division; the plate is tidy, economic and practical.

Owner:WUXI GUANGCAI MACHINERY MFG

Method for processing Sendzimir roll wobbler slot

ActiveCN102248466AAccurate graduationImprove shape and position accuracyGrinding machinesMechanical engineeringLinkage concept

The invention discloses a method for processing a Sendzimir roll wobbler slot. A grinding device is used in the method. The grinding device comprises a grinding head linkage component, a measuring plate, a centre frame, a V-shaped bracket, a trisection correcting plate, an indexing component and a fixing component which are arranged on a lathe in turn. Under the condition of using the grinding device, the method provided by the invention comprises the following steps: positioning a workpiece; horizontally moving a lathe saddle; driving the grinding head linkage component to move; starting a motor and dry grinding; grinding a first wobbler slot working surface at first; releasing the centre frame; pulling out a bolt and rotating the indexing component so as to index; verifying precision bythe trisection correcting plate; plugging the bolt again and tightly blocking the workpiece, thereby grinding a second wobbler slot working surface at the same side; and similarly, grinding the otherwobbler slot working surfaces at the same side. The wobbler slot working surfaces ground by using the device and the method provided by the invention are low in roughness degree and high in accuracy of form and position.

Owner:MCC SFRE HEAVY IND EQUIP

Eight-station sorting mechanism indexed by cambered surface cam

InactiveCN101982294ASimple structureSmall footprintPrecision positioning equipmentMetal working apparatusEngineeringCam

The invention discloses an eight-station sorting mechanism indexed by a cambered surface cam, comprising a rack and a motor installed on the rack, wherein an eight-station index plate is arranged above the rack, the center below the eight-station index plate is fixedly connected with a vertical shaft, the vertical shaft is installed on an installation rack fixedly connected with the rack, a supporting wheel is arranged above the rack to support the eight-station index plate, and a link transmission mechanism and a cambered surface cam transmission mechanism are arranged between the vertical shaft and the motor. The mechanism has simple integral structure, few workpieces and small land occupation, does not generate a driving gap during the conversion of positive rotation and reverse rotation, and has accurate indexing and high processing precision of workpieces.

Owner:DALIAN HUAGEN MACHINERY

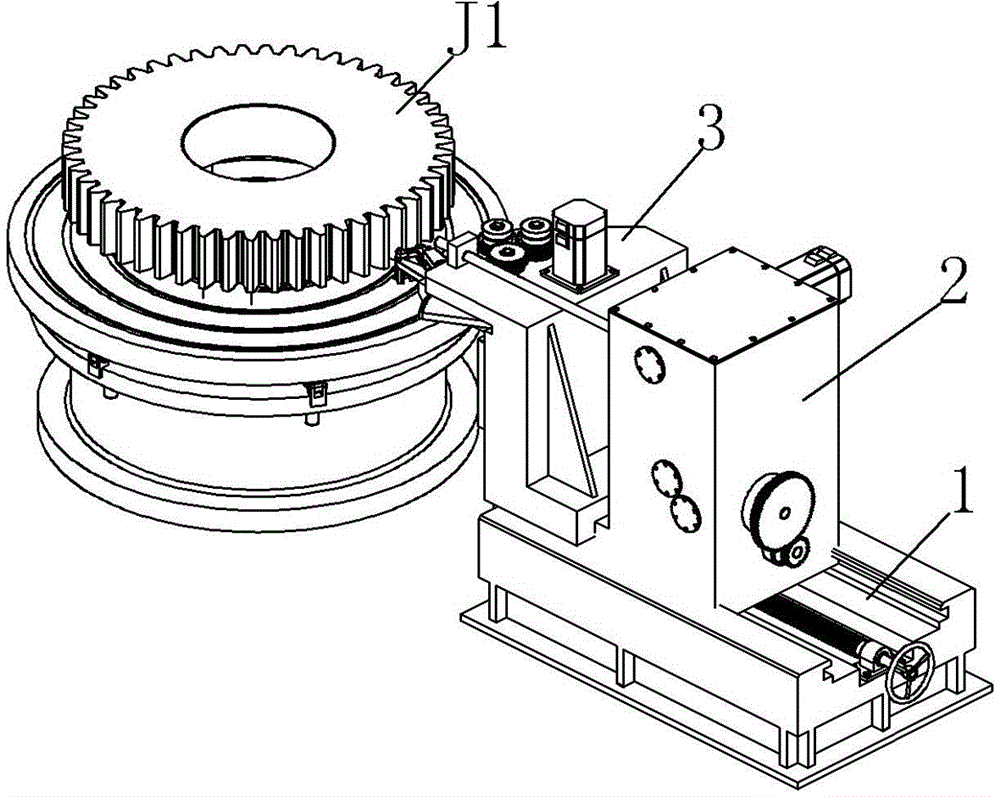

Large gear flame surface quenching machine

InactiveCN106676234AWide range of sizesAccurate graduationFurnace typesHeat treatment furnacesMechanical equipmentCam

The invention discloses a large gear flame surface quenching machine and aims to provide mechanical equipment in the field of machine manufacturing. By means of the large gear flame surface quenching machine, automatic flame surface quenching treatment can be conducted on tooth surfaces of large gears and tooth surfaces of large module gears. The large gear flame surface quenching machine is provided with a base assembly, a speed change device, a quenching device and an indexing rotary workbench. According to the technical scheme of the large gear flame surface quenching machine, the indexing rotary workbench and the quenching device adopt a separated structure, so that the size range of machined workpieces is wide; the quenching device is provided with a flame spray head and a cooling water spray head, and the flame spray head and the cooling water spray head move synchronously, work in the sequence from bottom to top and work in the mode of spirally climb along tooth profiles line by line. According to the large gear flame surface quenching machine, two cams are adopted to control the motion trails of the flame spray head and the cooling water spray head in a linkage mode, and a gear hanging mechanism is adopted to precisely adjust the quenching trail; and the large gear flame surface quenching machine is easy to control, suitable for batch production, small in equipment investment, simple in structure and convenient to maintain.

Owner:KUNMING UNIV

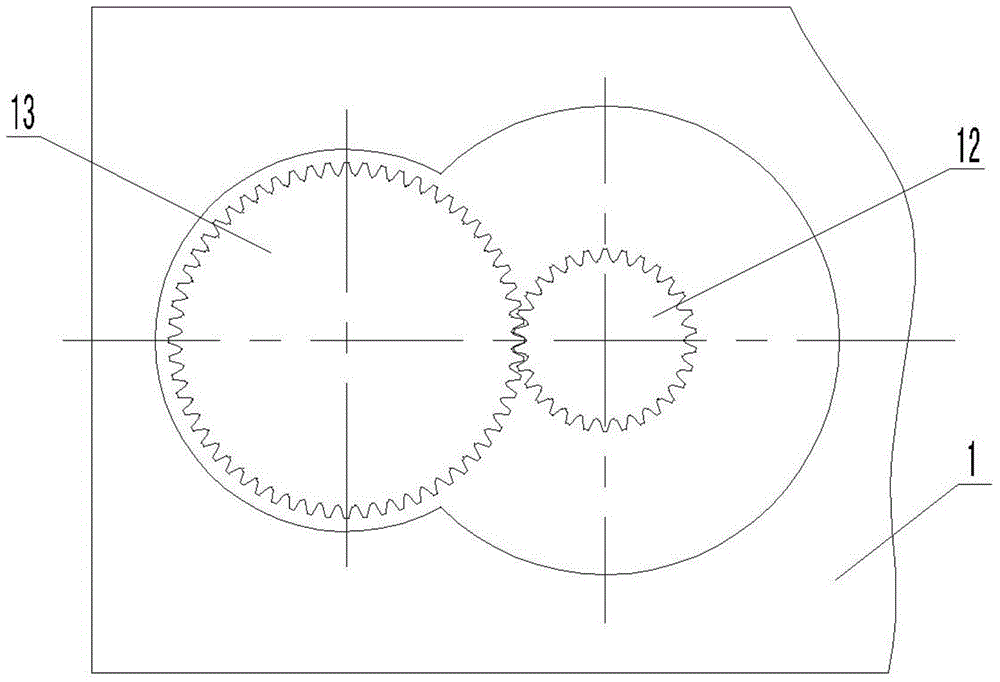

Automatic rotary indexing mechanism of tightening machine

ActiveCN104400409ARealize automatic rotation indexingSimple structureMetal working apparatusRotational axisAutomatic indexing

The invention discloses an automatic rotary indexing mechanism of a tightening machine. The automatic rotary indexing mechanism is characterized by being provided with a pair of a driving gear and a driven gear engaged to each other, is provided with a servo driving mechanism for driving the driving gear to rotate with the center point O of the driving gear as the rotating center and driving the driven gear to rotate by surrounding the driving gear with the center point O as the circle center according to set scale marks, and is provided with an upper rotating plate fixedly connected with the driven gear through an upper rotating shaft and used for realizing the indexing function of the driven gear, the upper rotating plate and the upper rotating shaft. The automatic rotary indexing mechanism enables the tightening machine to be suitable for automatic indexing among any angles of indexing round bolts of various products, and improves the beat for an automatic production line.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

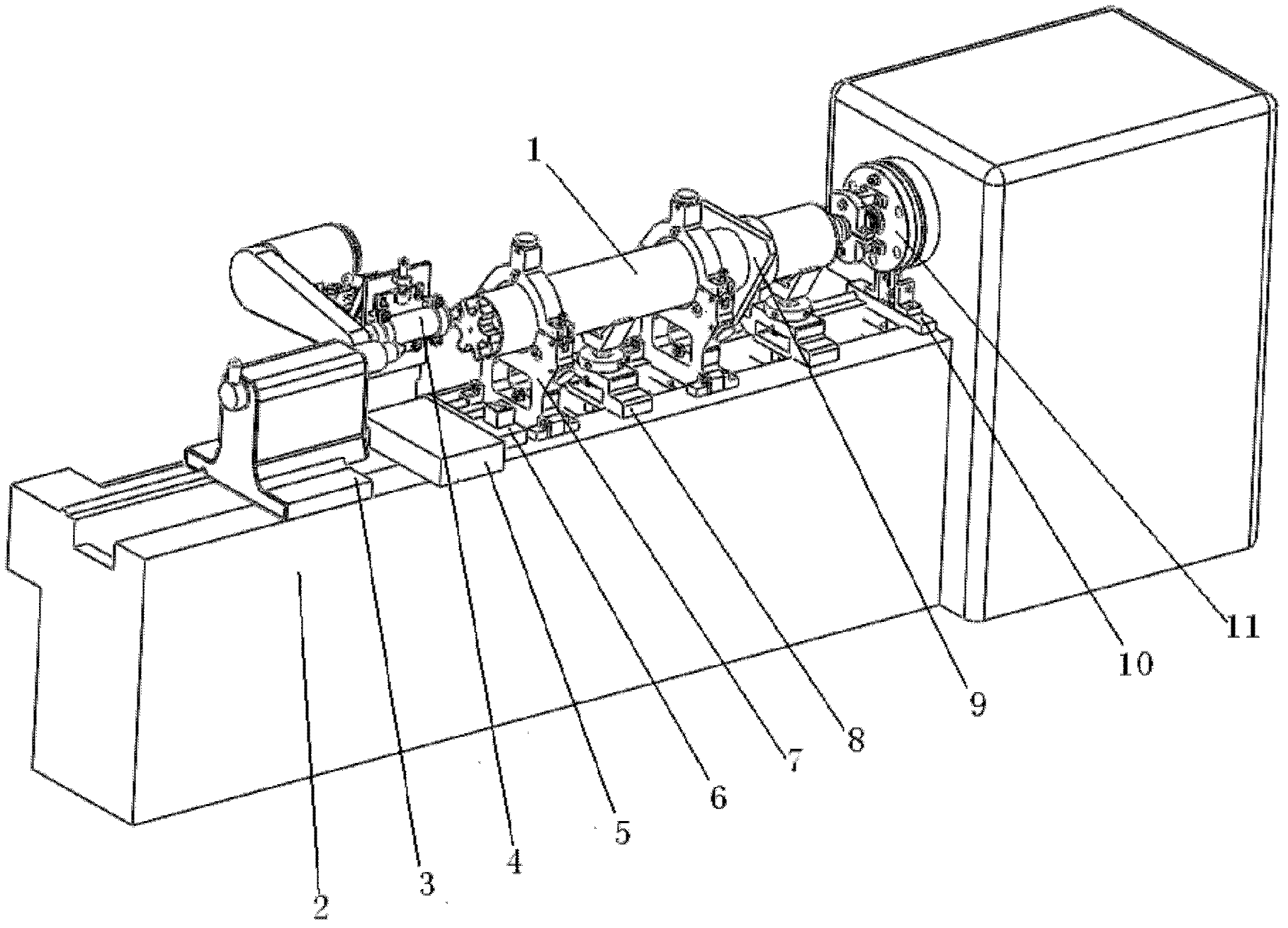

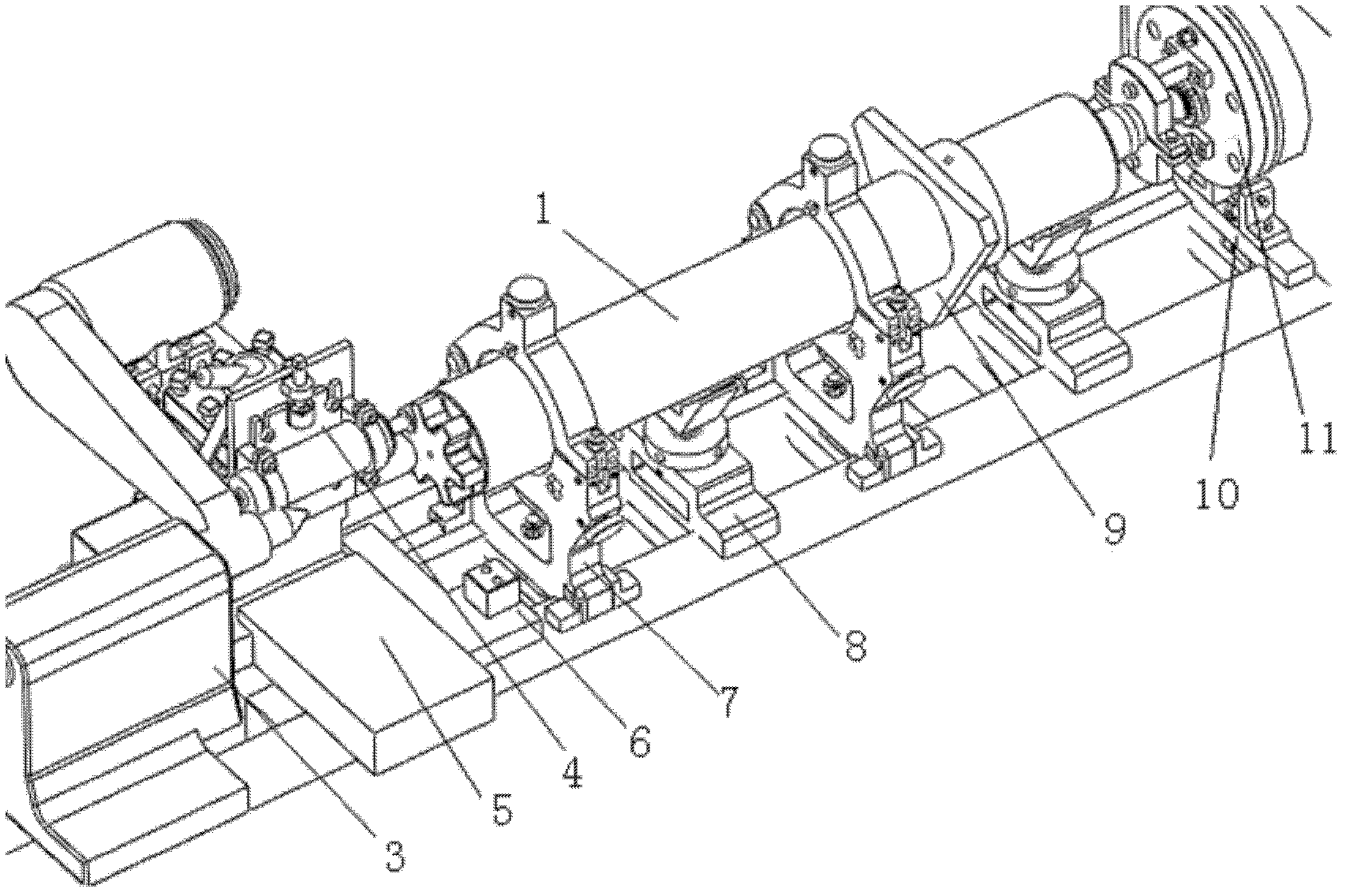

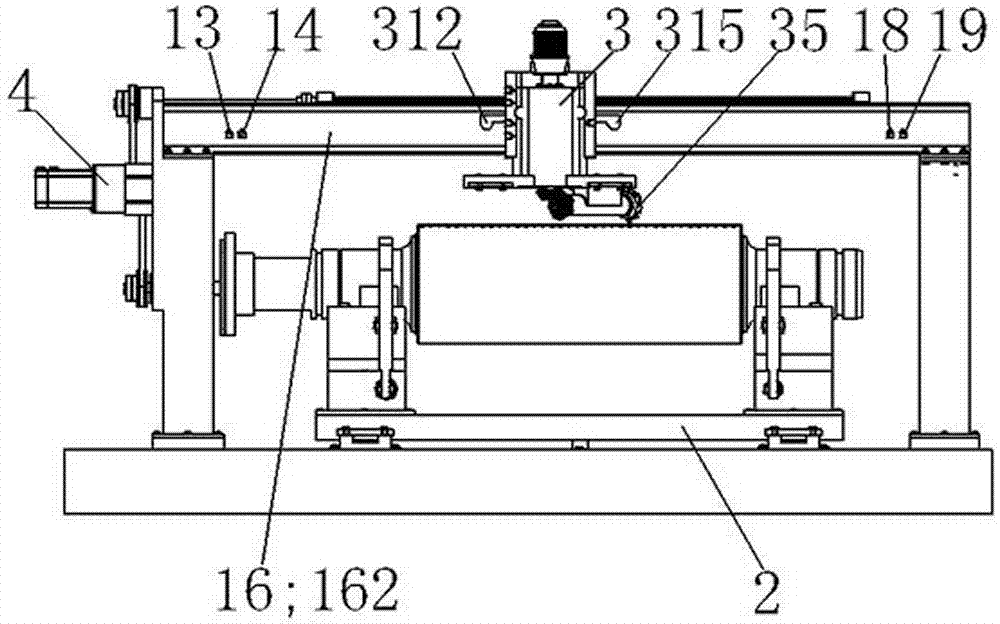

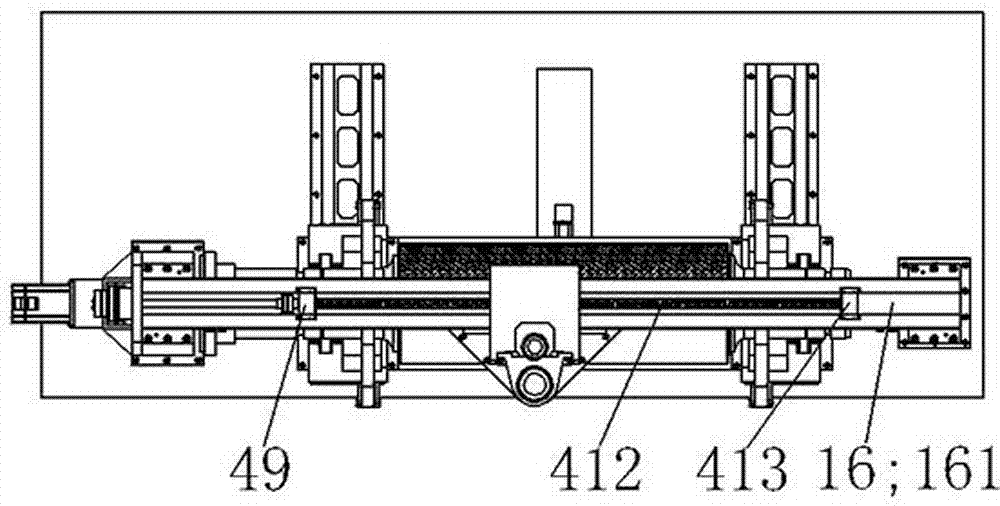

Roller processing machine

InactiveCN102350511AAccurate graduationMachining accuracy is easy to guaranteeFeeding apparatusTurning machinesEnergy consumptionMachine tool

The invention discloses a roller processing machine which comprises a turning tool radial feed mechanism and a gear box, wherein a first input shaft, a second input shaft, a first output shaft and a second output shaft which are parallel to each other and a first transition shaft and a second transition shaft which are coaxially arranged are mounted in the gear box; the first transition shaft is provided with an input gear A and a transmission gear A; the second transition shaft is provided with an input gear B and a transmission gear B; the first input shaft is connected with a first slidinggear; the second input shaft is connected with a second sliding gear; when the first sliding gear is meshed with the input gear A, the second sliding gear is meshed with the input gear B; and when the first sliding gear is meshed with the input gear B, the second sliding gear is meshed with the input gear A. Through the invention, the indexing is accurate, the processing precision is easily guaranteed, the working efficiency is high, and the energy consumption is low.

Owner:杨文风 +5

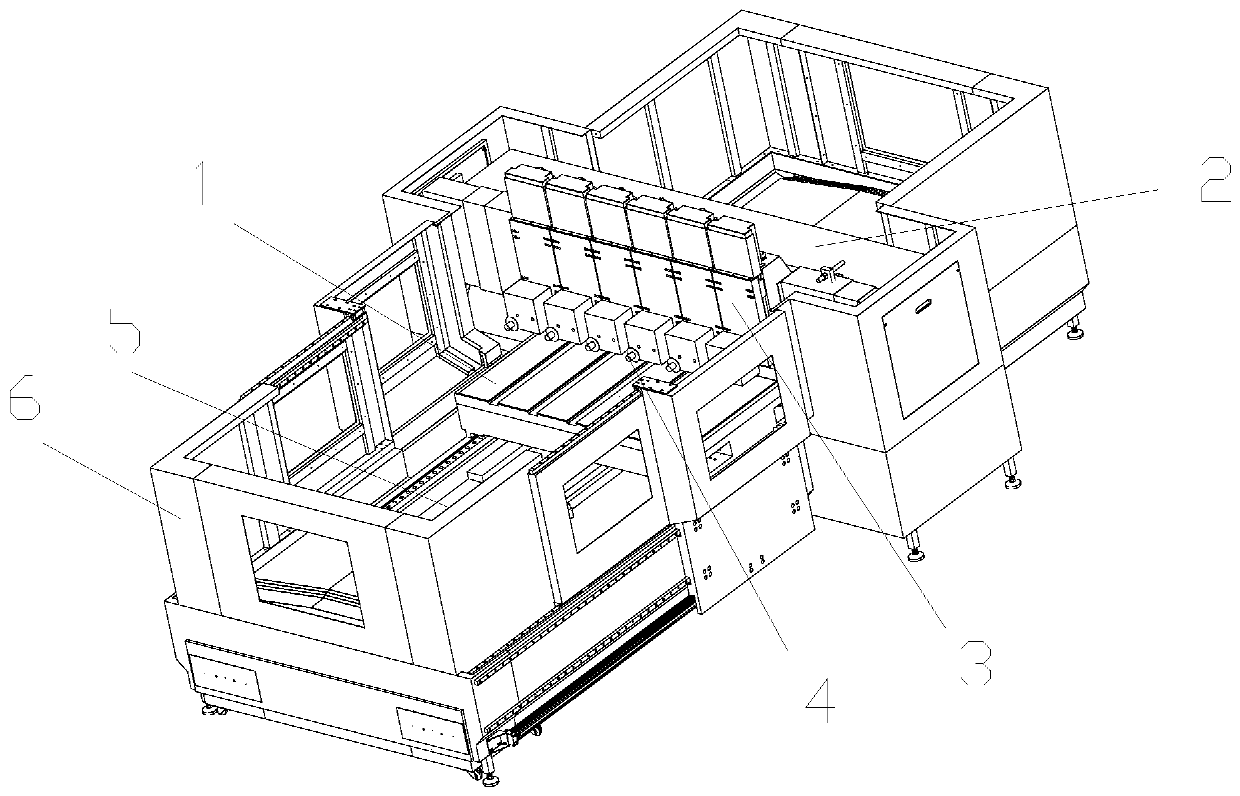

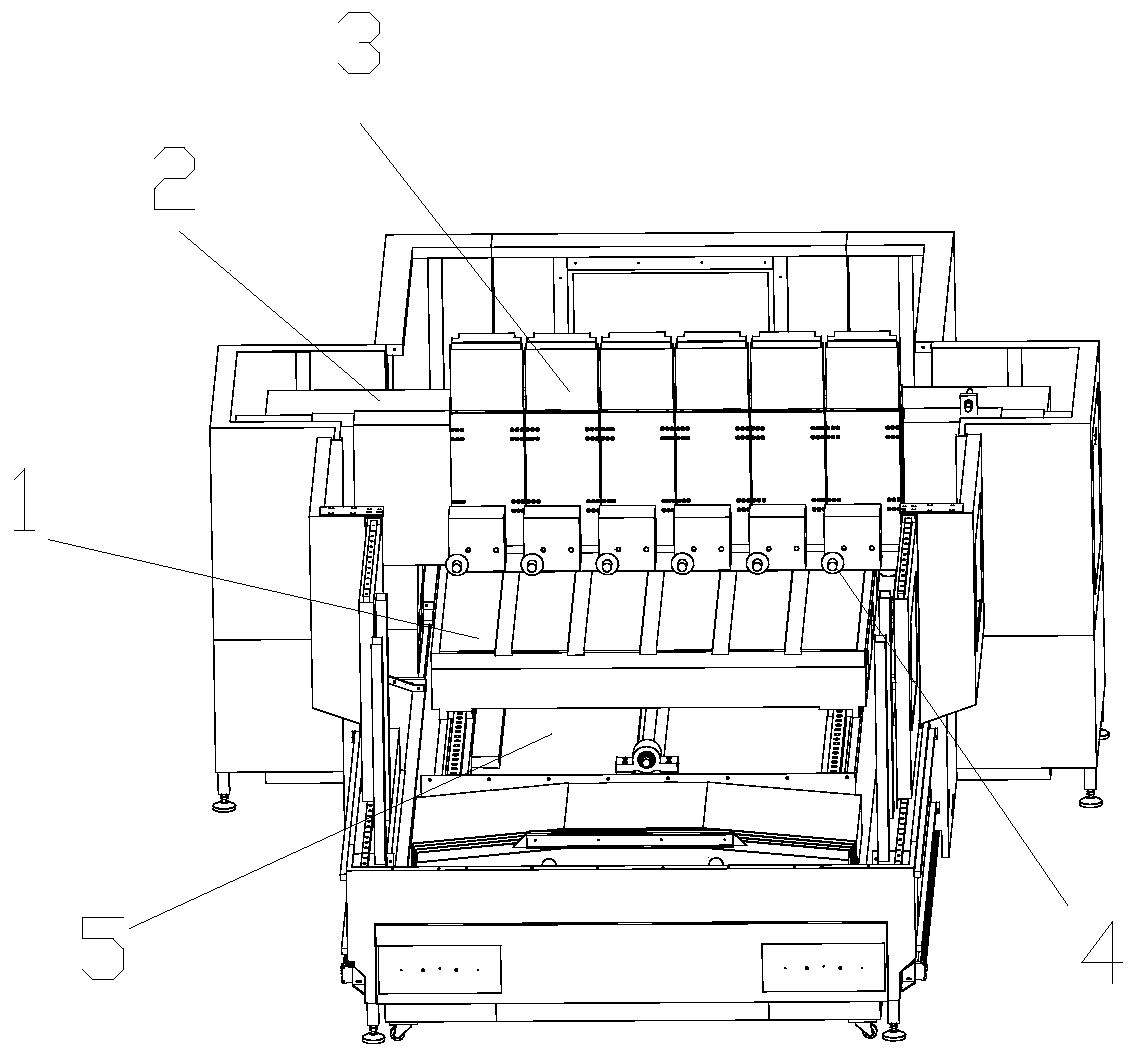

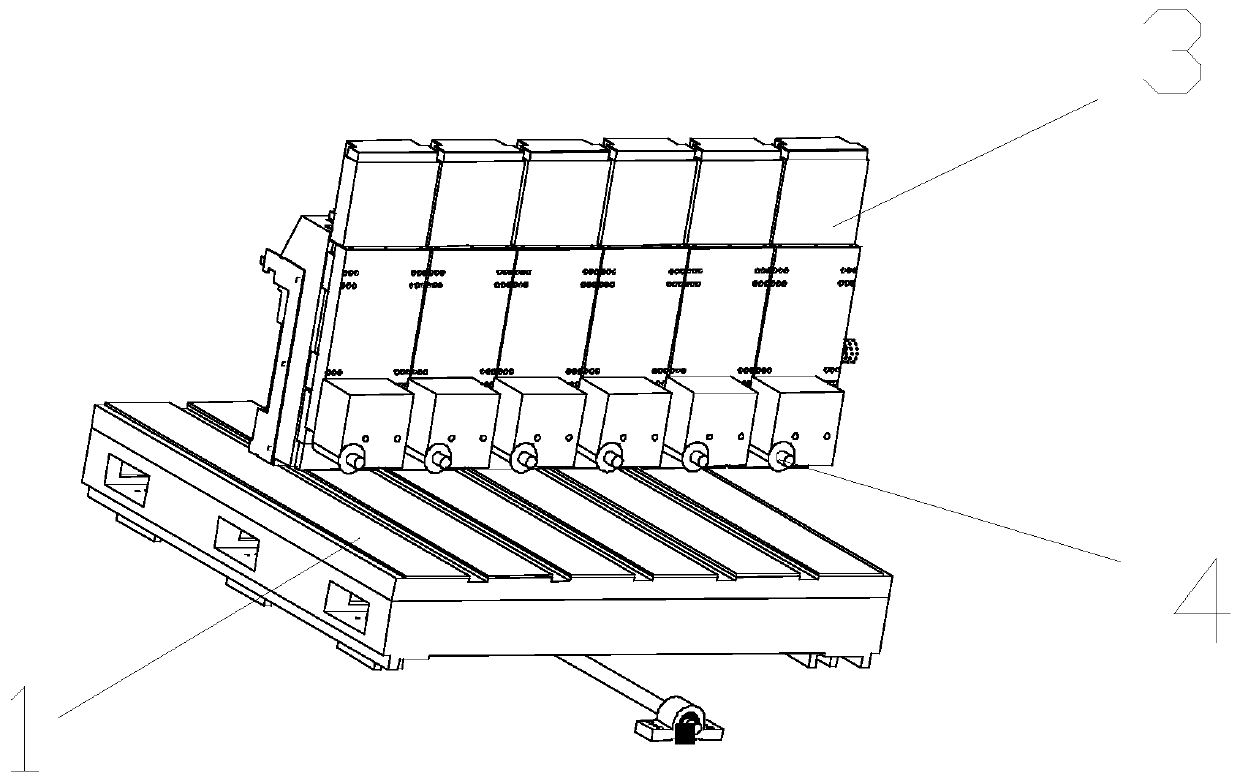

Numerical control gantry needle groove milling machine

InactiveCN109940208AEasy to replaceEasy maintenanceMilling equipment detailsNumerical controlMilling cutter

The invention discloses a numerical control gantry needle groove milling machine. The numerical control gantry needle groove milling machine comprises a milling machine body and milling heads, whereinthe plurality of milling heads capable of carrying out tool setting independently are arranged on the milling machine body, and each milling head is provided with a milling tool. The numerical control gantry needle groove milling machine has the advantages that the scale division is accurate, the replacement and the maintenance of a single blade are convenient, the cost is low, the width of needle grooves of a cutting needle plate can be consistent, the milling tool of each milling head is capable of undergoing fine tool setting independently, and the problem that the machining depth is different due to different milling tool radiuses can be effectively solved

Owner:ZHEJIANG BAIXIN KNITTING MACHINERY

A worm cam indexing mechanism

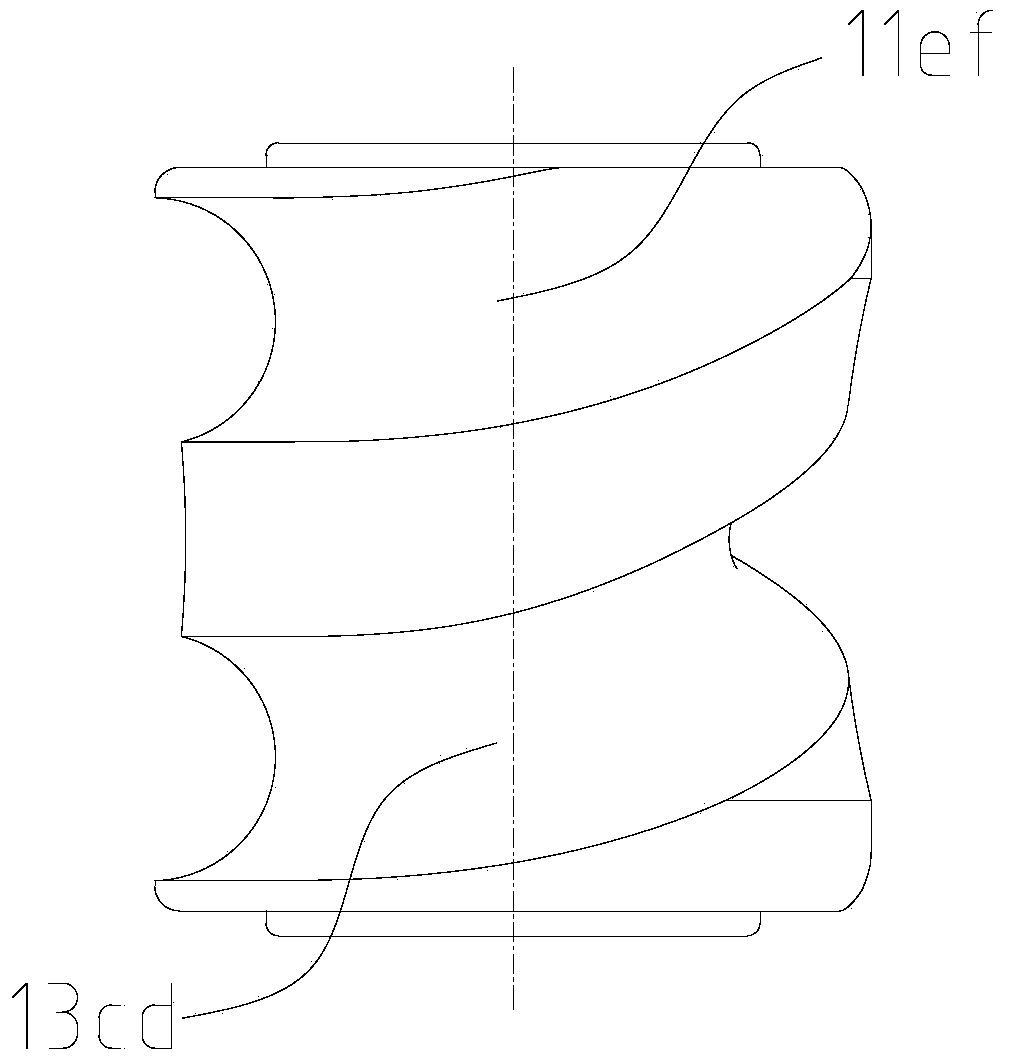

ActiveCN106239258BImprove athletic abilityNo rigid impactPrecision positioning equipmentEngineeringCam

A worm cam indexing mechanism, comprising a worm cam and a roller disc, the worm cam comprises a worm and a cam fixed on the worm, a channel is opened on the outside of the cam, and the channel is helical; the roller disc is A plurality of rollers are provided, and the plurality of rollers are distributed at intervals along the circumference of the roller disc. The rollers are used to move in the groove, and the groove is provided with an engaging section, a first stop Segment, sinusoidal acceleration segment, constant velocity segment, sinusoidal deceleration segment, second rest segment and engagement segment. The invention can improve the overall movement performance of the mechanism, and avoid the interference of the rollers when engaging in and out of the groove.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

Netted gradually-changed servo annular punching equipment applied to metal pipe wall

ActiveCN105033028AAvoid badStrong arbitrary arrangementPerforating toolsMetal-working feeding devicesPunchingEngineering

The invention discloses a piece of netted gradually-changed servo annular punching equipment applied to a metal pipe wall. The equipment comprises a fixed seat, a first moving seat, a second moving seat, a first driving mechanism, a second driving mechanism, a third driving mechanism, and a punching die. A sliding seat that can move forward and backward is arranged on the first moving seat; and a docking element that can be connected and fixed with a metal pipe is arranged on the sliding seat, wherein the docking element can be installed on the sliding seat in a rotatable mode. A die core is arranged on the second moving seat. The punching die contains a die seat and a plurality of punching pins arranged in the die seat. With cooperation of the punching die and all driving mechanisms, the metal pipe can move axially in a rotatable mode, so that the equipment can punch through holes with various shapes on the metal pipe automatically; the through holes can be arranged randomly; the punching process indexing is precise; objectives of annular punching and gradually-changed hole punching can be achieved; and the work efficiency and product precision are substantially improved. Meanwhile, the equipment can cooperate with a vacuum system and thus a problem that waste material can not be outputted smoothly can be solved.

Owner:DONGGUAN HOPCHI METAL & PLASTIC

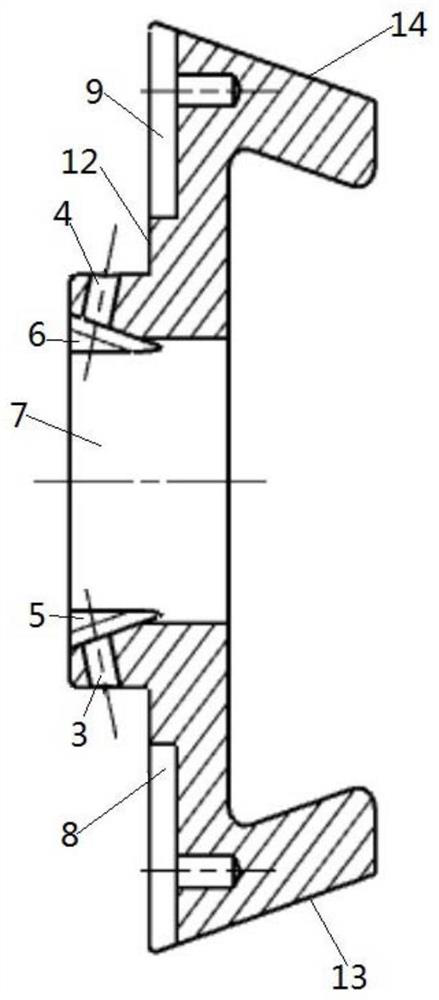

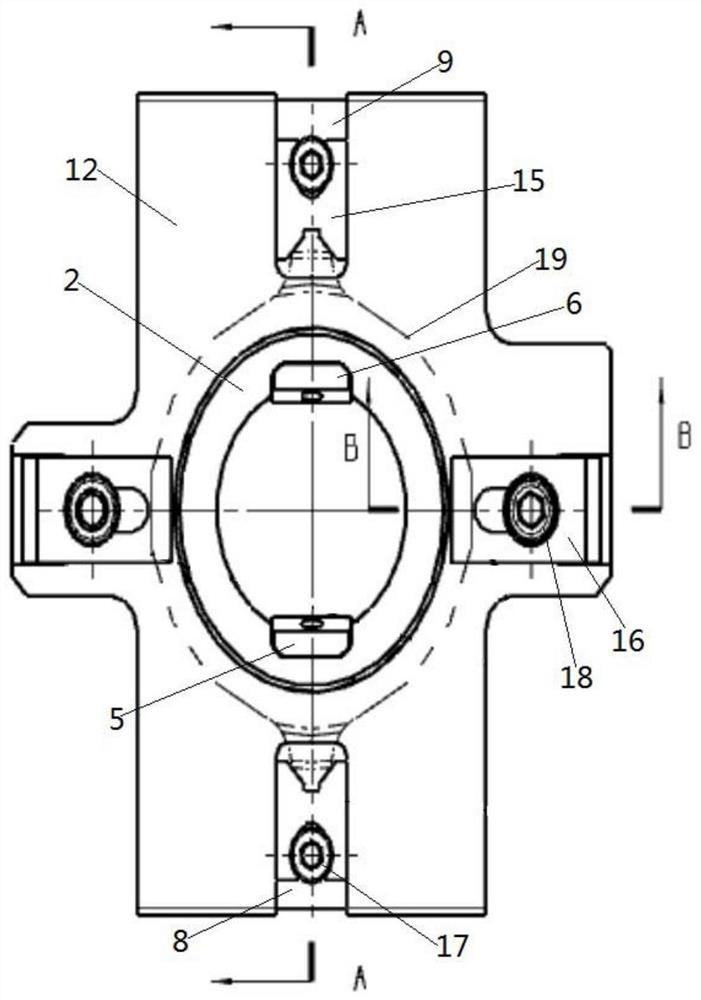

Indexing and clamping device for numerically-controlled large spiral bevel gear broaching machine

InactiveCN102357681ANo offsetEliminate play gapGear-cutting machinesGear teethHydraulic cylinderGear wheel

The invention relates to an indexing and clamping device for a numerically-controlled large spiral bevel gear broaching machine. The device comprises an indexing mechanism driven by a servo motor, and is characterized by further comprising a hydraulic clamping mechanism. The hydraulic clamping mechanism comprises a workpiece clamping part and a main shaft clamping part, wherein the workpiece clamping part comprises a miniature hydraulic piston cylinder fixedly connected with one end of a workpiece main shaft; a piston rod of the miniature hydraulic piston cylinder is extended out of a cylinder body and into the workpiece main shaft; the head part of the piston rod is connected with a tension rod; the main shaft clamping part comprises a hydraulic cylinder sleeved outside the miniature hydraulic piston cylinder; a friction plate fixed with one end of the workpiece main shaft is arranged in the hydraulic cylinder; and a piston piece is arranged between the friction plate and the hydraulic cylinder. The device has the advantages that: a numerically-controlled indexing and auxiliary indexing damping device and an indexing hydraulic clamping device are adopted, so the indexing operation of a lathe is smoother, accurate and reliable, the slight reciprocation of a workpiece in a cutting process is avoided and gear machining accuracy is improved; and a large gear can be machined and the requirements for small quantities and many varieties in the industrial production of automobiles are met.

Owner:TIANJIN NO 1 MACHINE TOOL WORKS

Precision positioning device capable of rotating by 360 degrees

InactiveCN104625809APrecise positioningAccurate graduationPrecision positioning equipmentLarge fixed membersScrew threadMachining

The invention discloses a precise positioning device capable of rotating by 360 degrees. The precise positioning device capable of rotating by 360 degrees comprises a base, a shaft sleeve, a rotary shaft, a positioning disc, a graduated disc, a locking ring and a locking screw, wherein the base is fixed to the side wall of the shaft sleeve, threaded sections are arranged at the two ends of the rotary shaft, a limiting disc is arranged on the rotary shaft, the rotary shaft penetrates through a shaft hole of the shaft sleeve from the limiting end of the limiting disc and is sleeved with a locking ring, the graduated disc and the positioning disc in sequence from outside to inside, the positioning disc is connected and fixed to the end face of the shaft sleeve, the graduated disc is fixed to the rotary shaft, the locking ring is connected with the end of the rotary shaft in a threaded mode, and a locking screw used for locking the rotary shaft is installed on the shaft sleeve. According to the precise positioning device capable of rotating by 360 degrees, a part can be positioned accurately, indexing is precise, operation is easy, using is convenient, both installation and dismantling are rapid, and clamping and dismantling can be achieved by a single person. The precise positioning device can be installed on a working table of any electric cutting device to be used and is mainly used for machining of narrow gaps and complicated shapes, such as special shapes, on a rotary body.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

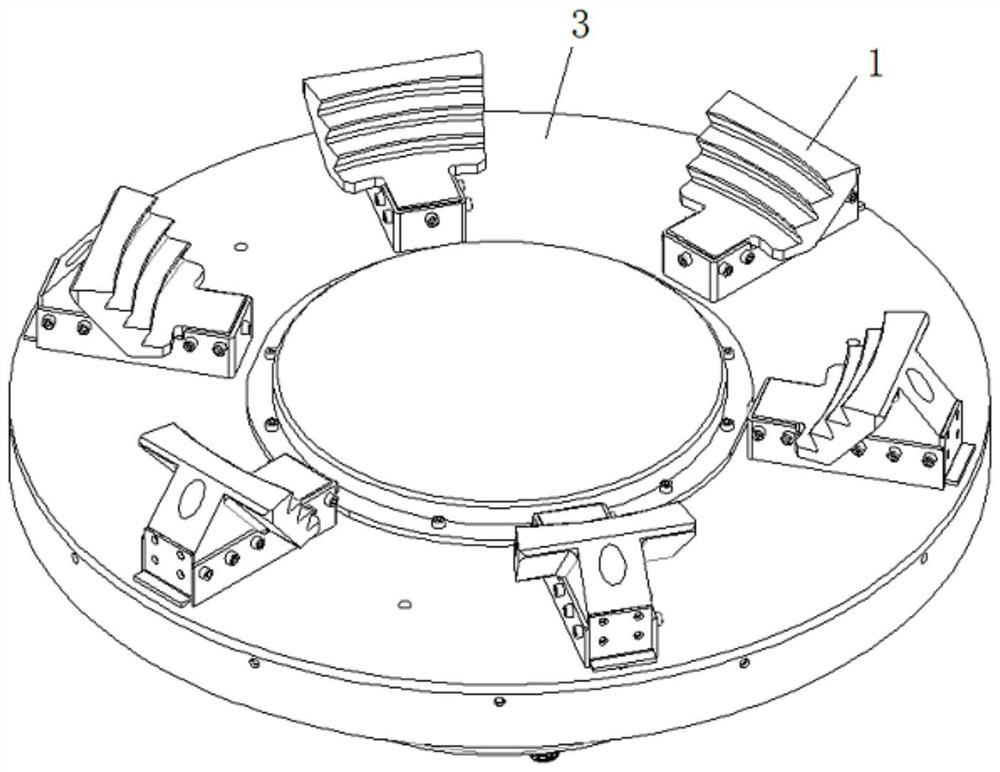

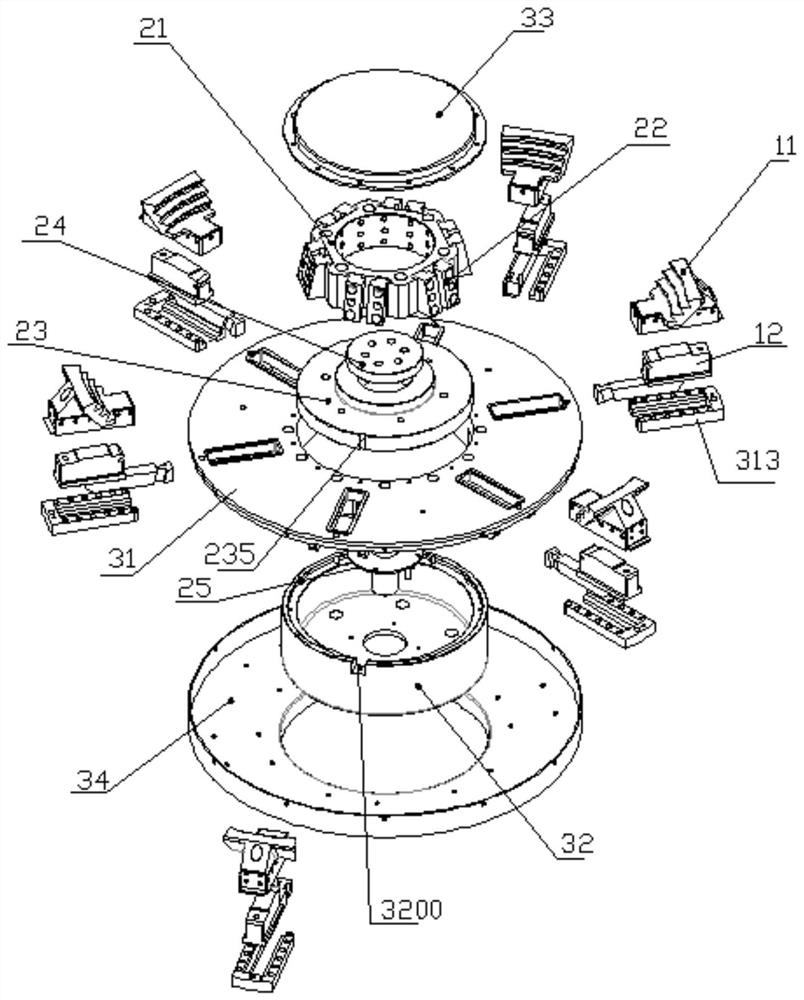

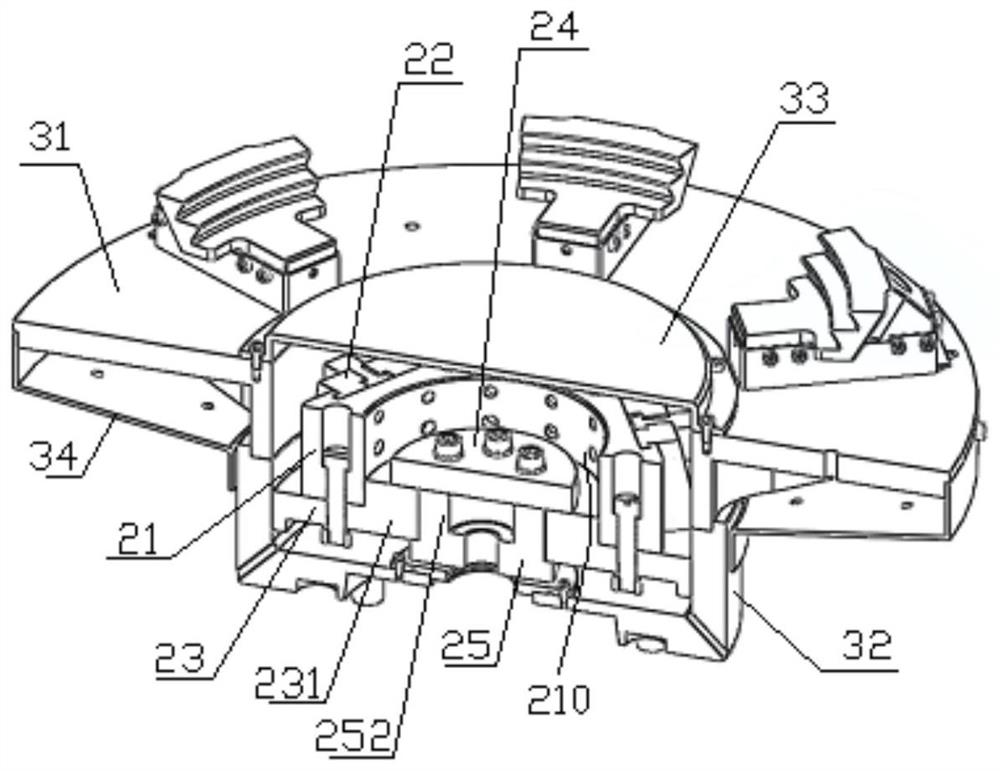

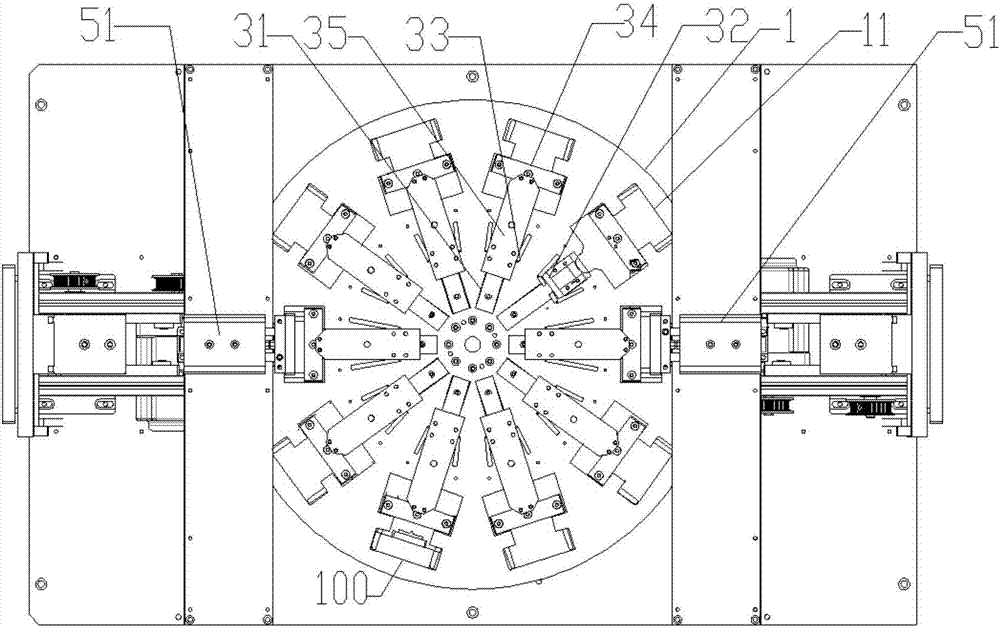

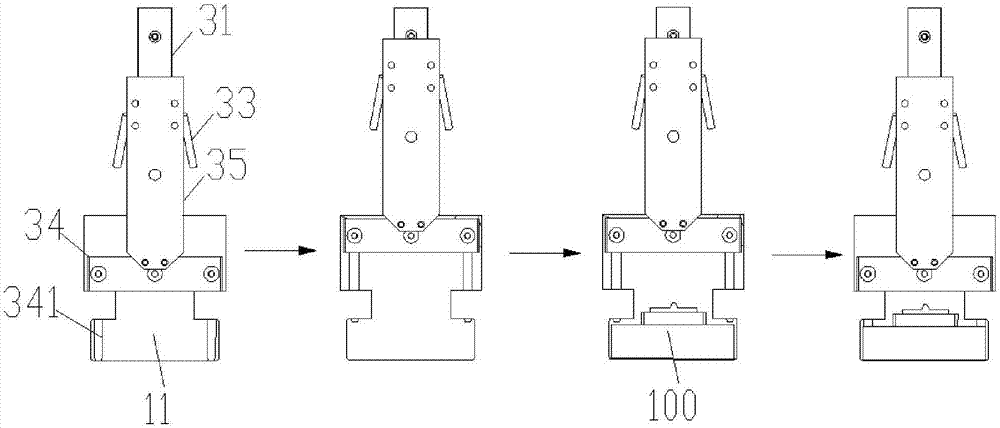

Flexible machining clamp for automobile hub

PendingCN112692622AImprove processing efficiencyReduce use costWork clamping meansPositioning apparatusStructural engineeringMechanical engineering

The invention discloses a flexible machining clamp for an automobile hub. The clamp comprises a clamping jaw, a clamping jaw driving seat and a clamping jaw disc, the clamping jaw driving seat is movably arranged in the hollow position of the middle of the clamping jaw disc, and a plurality of driving grooves which are obliquely formed in the axial direction of the clamping jaw disc are evenly distributed in the outer wall of the clamping jaw driving seat. The clamping jaws are connected to the clamping jaw disc in a sliding mode in the radial direction of the clamping jaw disc, a sliding arm is arranged on each clamping jaw, each clamping jaw is connected with the corresponding driving groove in a sliding fit mode through the corresponding sliding arm, and arc clamping jaw grooves distributed in a multi-step mode are formed in each clamping jaw and used for being matched with hubs of various sizes. Each clamping jaw is provided with a plurality of arc clamping jaw grooves distributed in a step shape, hubs of different sizes can be clamped without disassembly, the machining efficiency is improved, and the use cost is reduced. The designed clamping jaw driving seat structure adopts a hexahedron structure, so that the indexing is more accurate.

Owner:JIANGSU SLD PRECISION TECH

Drying cylinder seal head circumference face threaded hole machining indexing method and machining device

The invention discloses a drying cylinder seal head circumference face threaded hole machining indexing method. A drying cylinder is arranged and clamped on a machine tool, a pulse encoder is placed on a spindle of the machine tool, and the pulse sum of the pulse encoder is evenly divided corresponding to 360-degree rotation of the spindle. One pulse corresponds to one evenly-divided circumferenceangle. During machining, the drying cylinder and the spindle synchronously rotate. A signal conversion device is used for converting pulse signals of the pulse encoder into angle signals. After a control device conducts indexing on a circumference face threaded hole in a drying cylinder seal head according to the angle signals, and the circumference face threaded hole in the drying cylinder sealhead is obtained through machining. Since the pulse encoder is adopted, the drying cylinder can be arranged and clamped on the machine tool, the pulse encoder is placed on the spindle of the machine tool, the pulse encoder is adopted for angle measurement, and therefore accurate indexing of machining of the circumference face threaded hole in the drying cylinder seal head can be achieved under thesituation that workpieces are large. The invention further discloses a drying cylinder seal head circumference face threaded hole machining device.

Owner:白城福佳科技有限公司

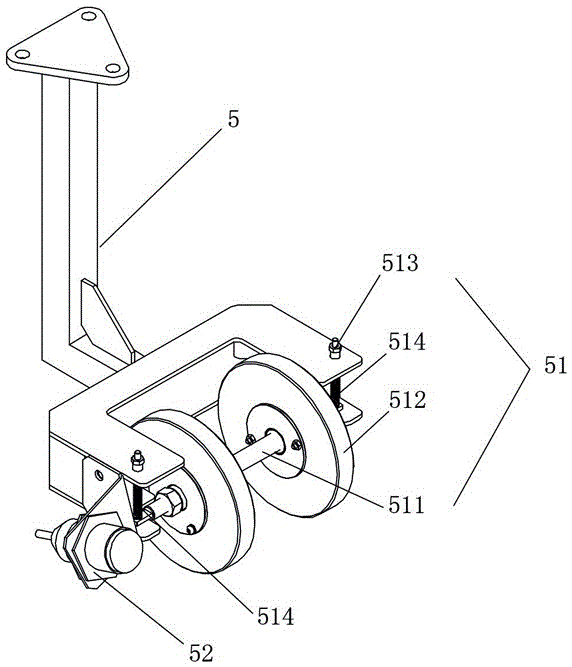

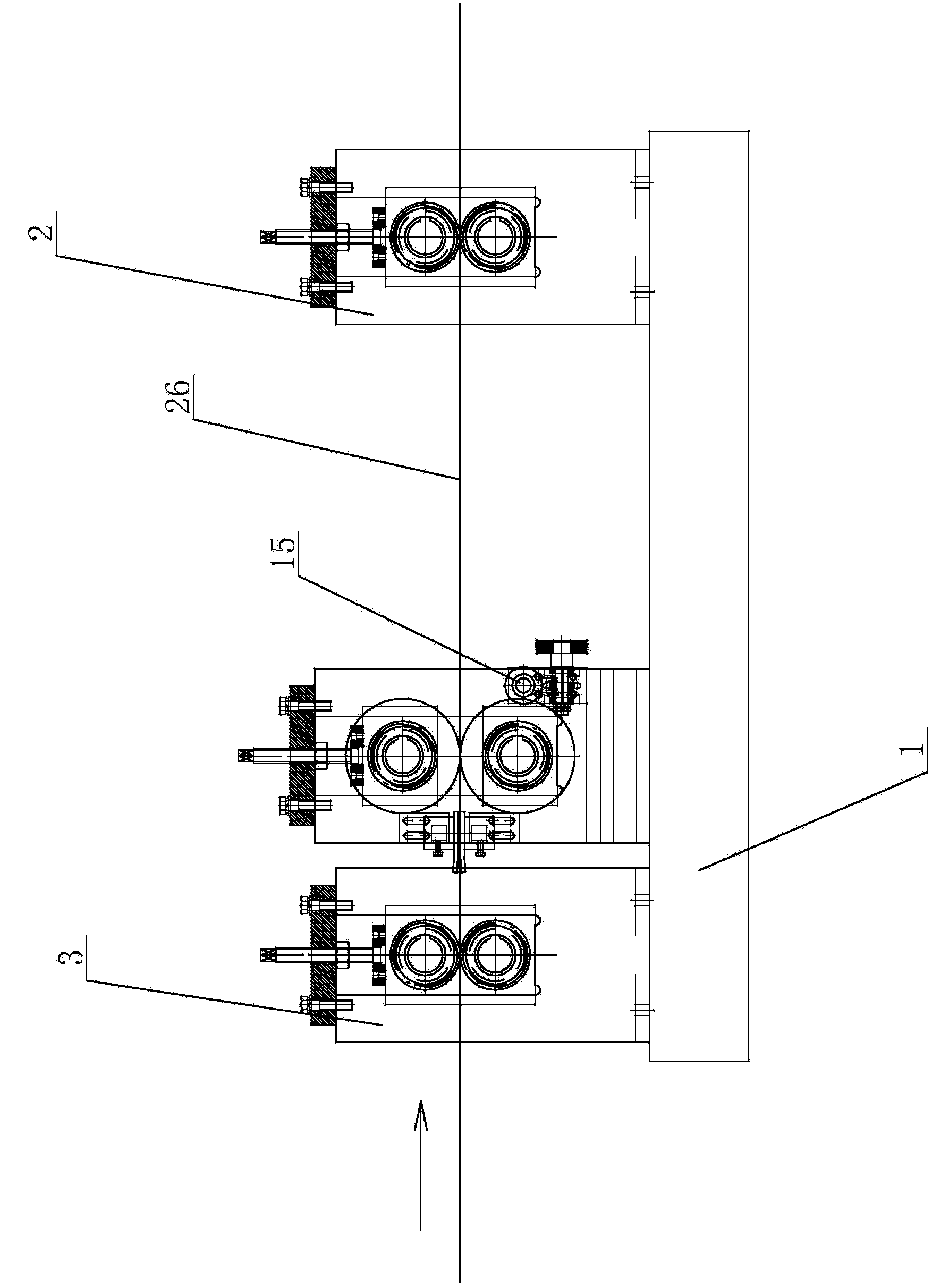

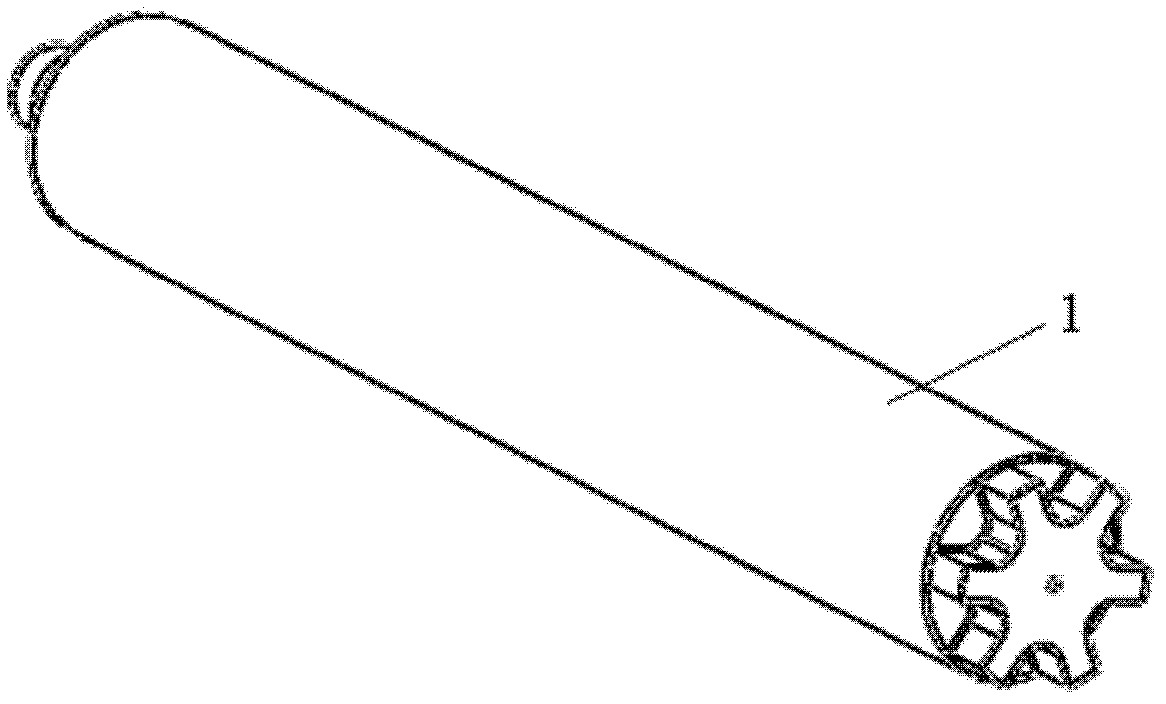

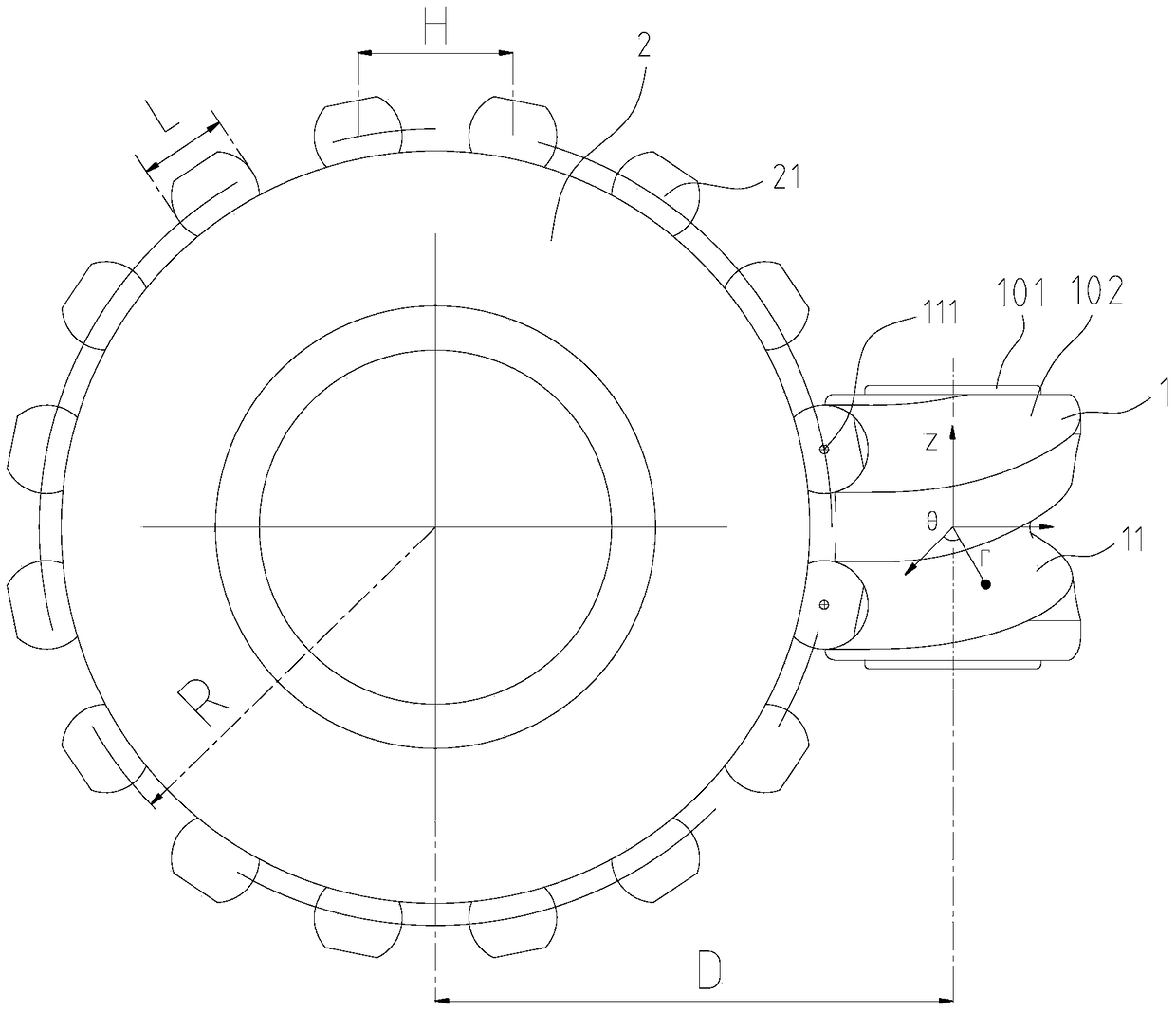

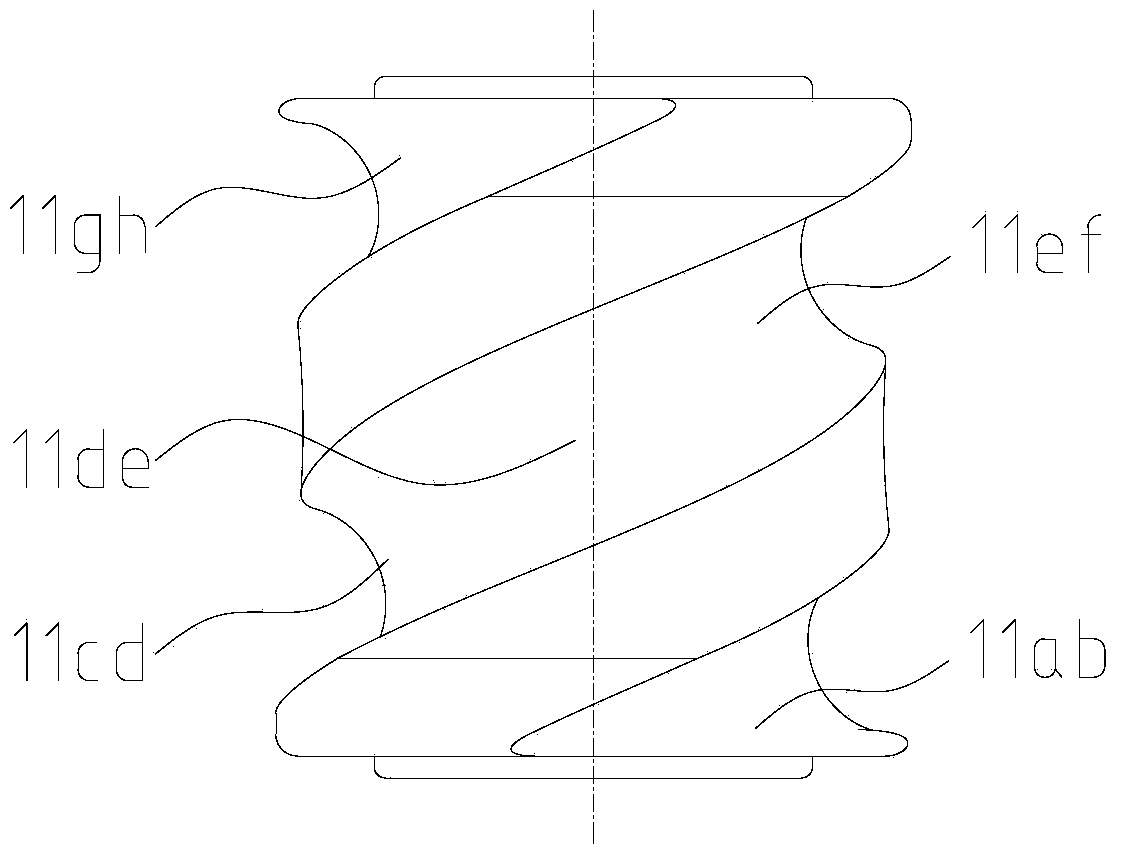

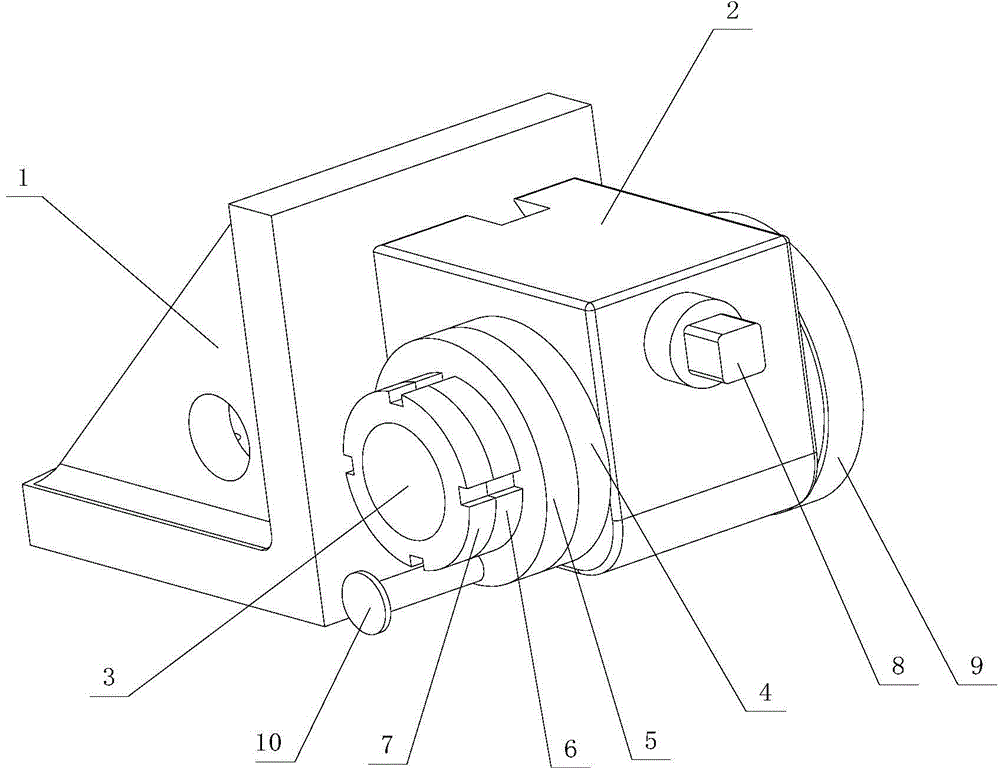

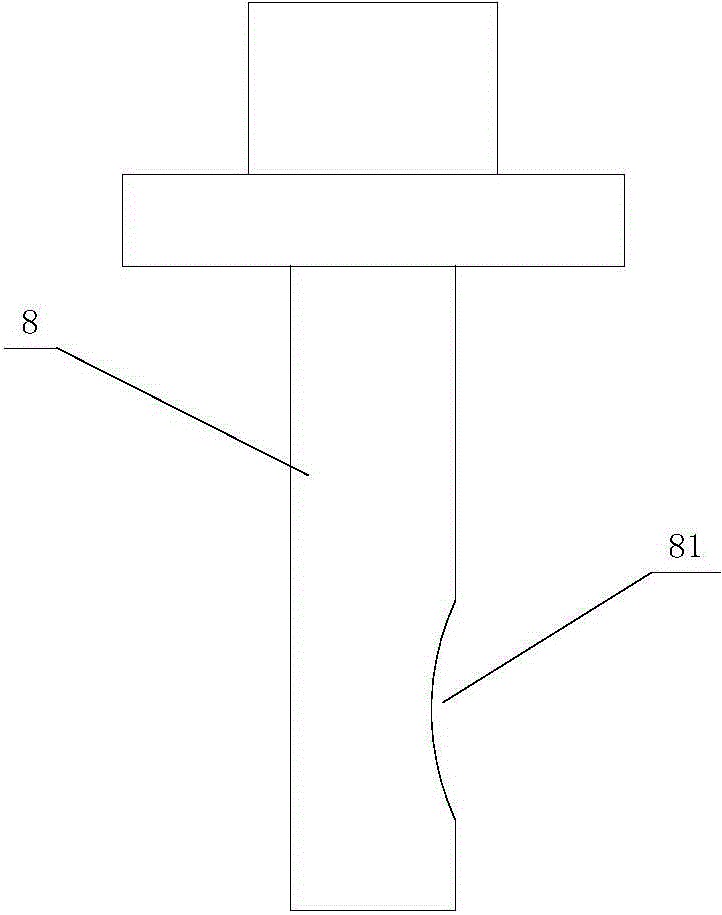

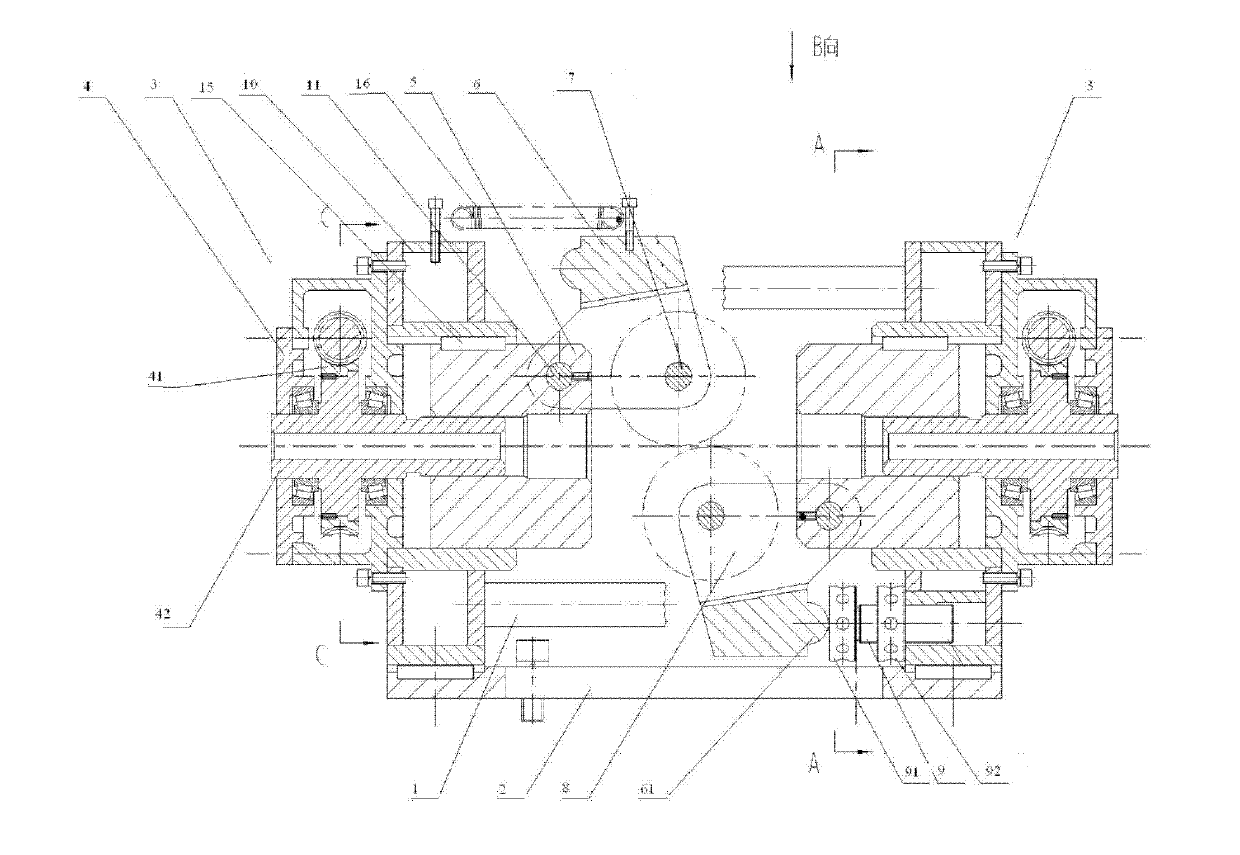

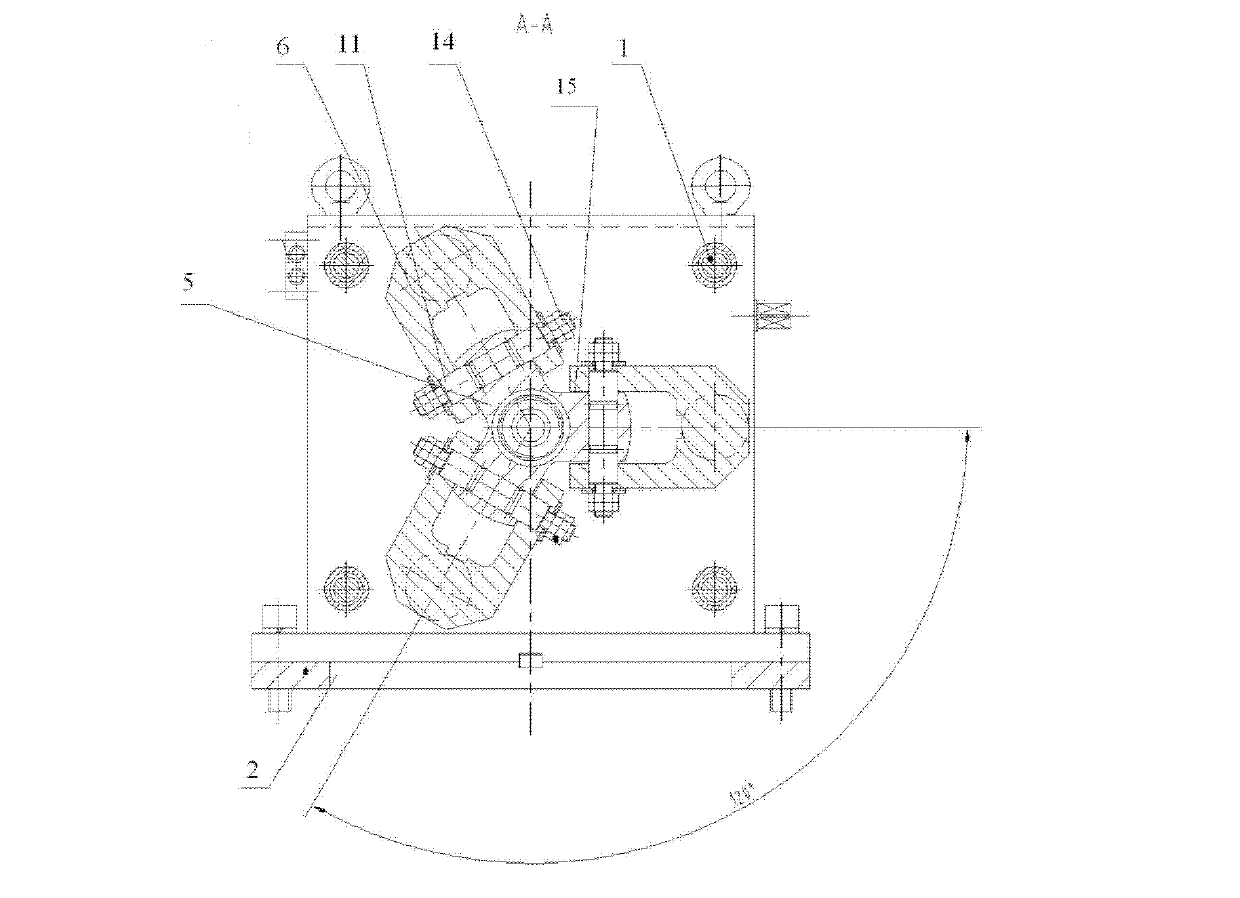

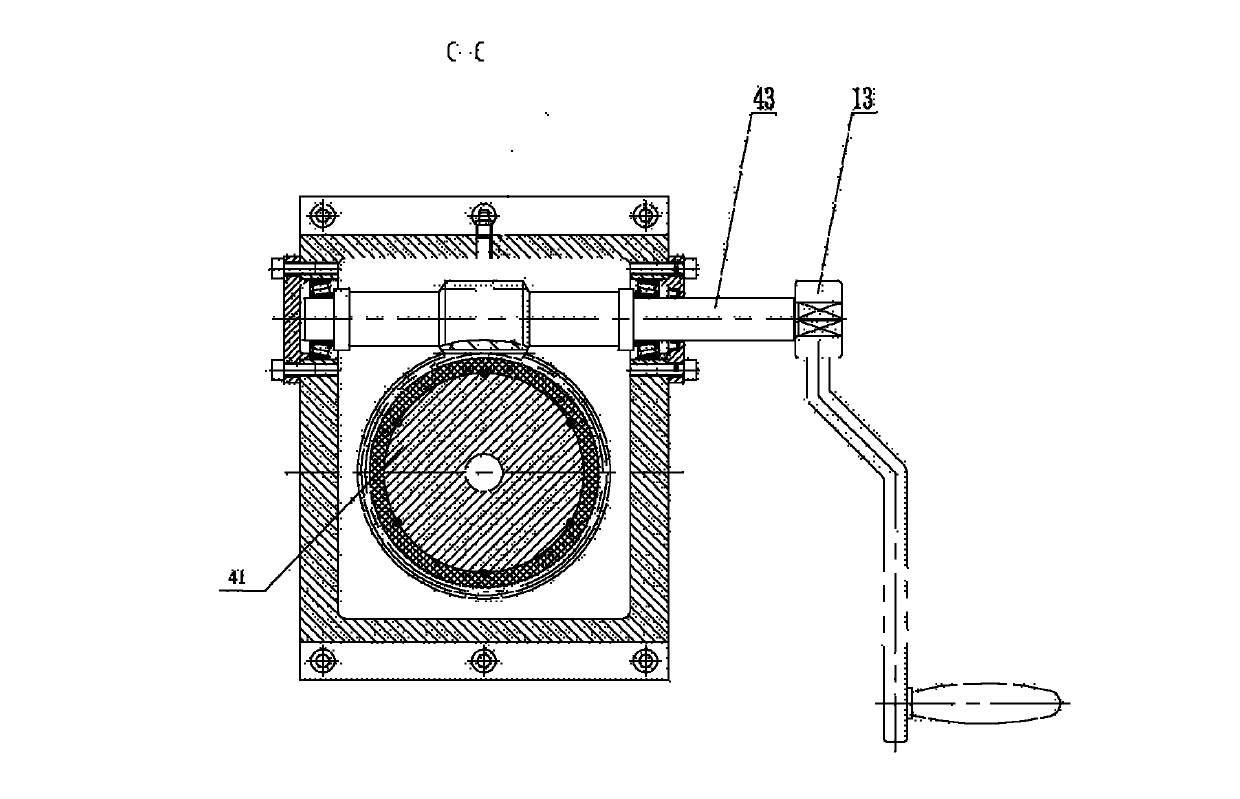

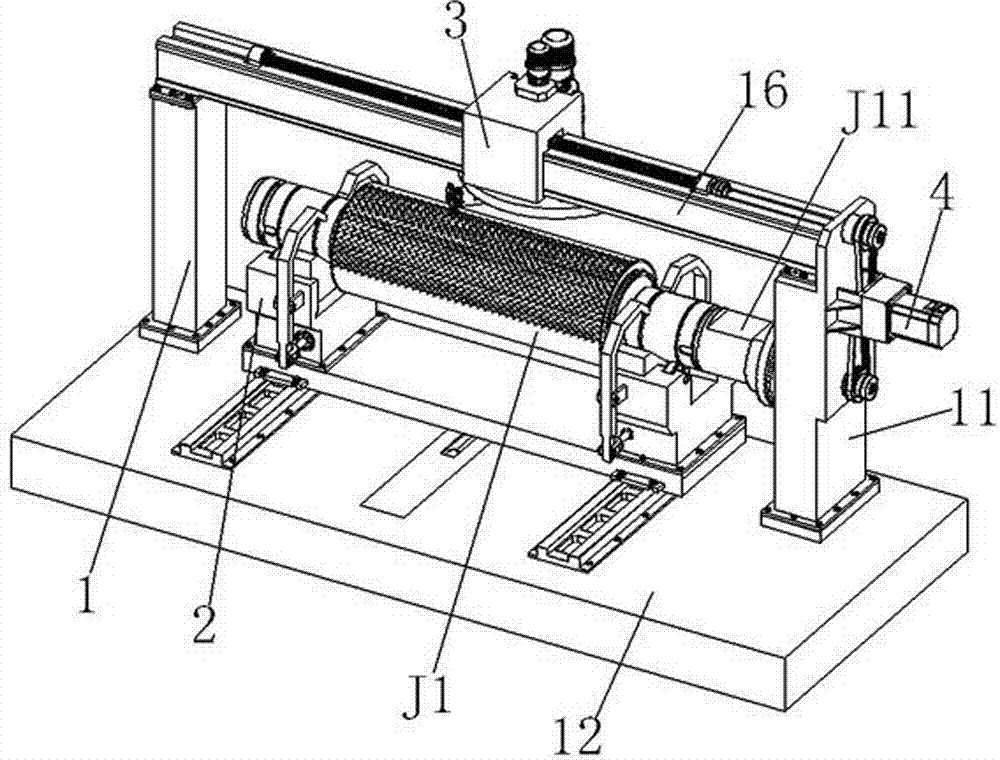

Roller-stretching-process dual-Y type rolling mill for compacted-strand steel wire rope

InactiveCN102635006AReduce resistanceExtended service lifeRope making machinesEngineeringRolling mill

The invention discloses a roller-stretching-process dual-Y type rolling mill for a compacted-strand steel wire rope. The roller-stretching-process dual-Y type rolling mill comprises draw bars (1), a bottom plate (2) and two roller units (3), wherein each roller unit (3) comprises a worm and gear box assembly (4), a mounting head (5), a fork head (6), a roller core (7), a roller sheet (8), a tension spring (16) and a stand (10); each worm and gear box assembly is arranged on the corresponding stand; worms are arranged on worm gear shafts; the inner circle of each mounting head is connected with the corresponding worm gear shaft, and the outer circle of each mounting head is connected with the corresponding stand; one end of each fork head is arranged on the corresponding mounting head, and the other end of each fork head is connected with the corresponding roller core; each roller sheet is arranged on the corresponding roller core; one end of each tension spring is arranged on the corresponding fork head, and the other end of each tension spring is arranged on the corresponding stand; the two roller units are arranged on the bottom plate; and the draw rods are connected with the two roller units. The roller-stretching-process dual-Y type rolling mill disclosed by the invention has the advantages of compact design, preciseness in scale division, convenience in adjustment, high product glossiness and long service life of the rollers.

Owner:陈吉玉

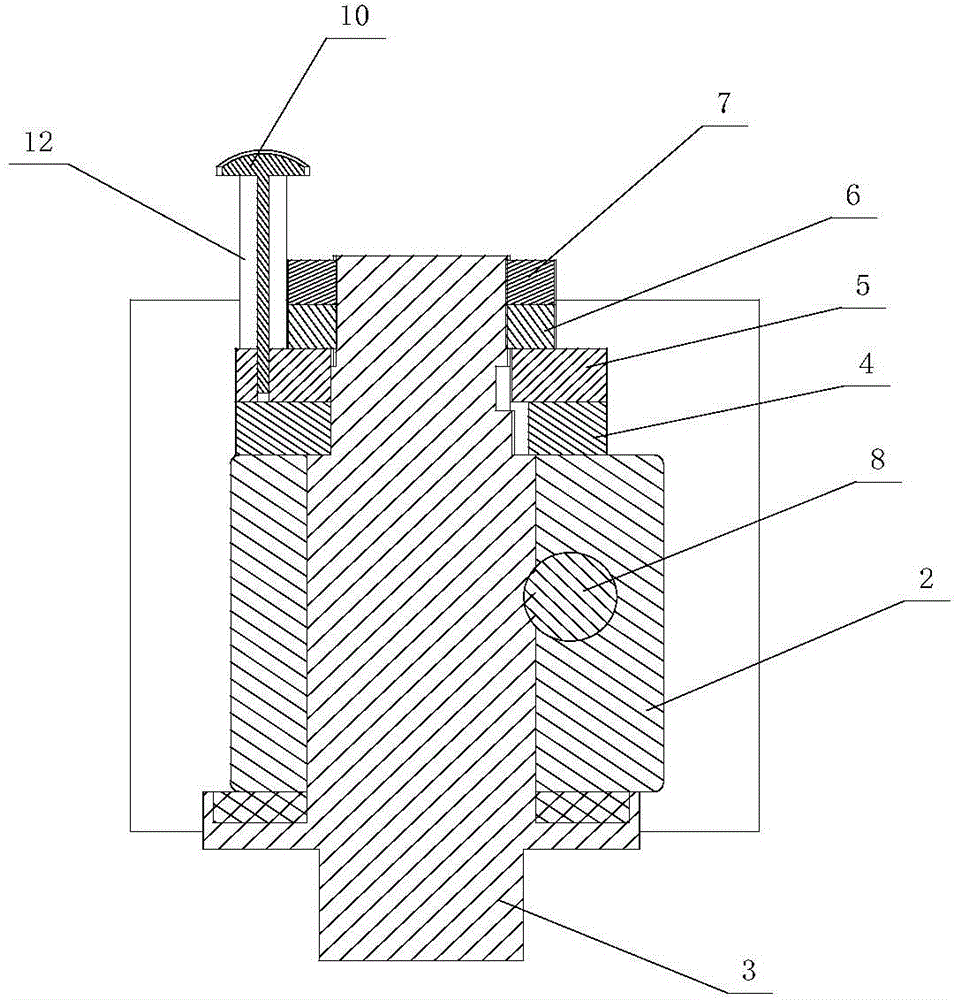

Index locating device of full-automatic small diamond saw blade double-surface edging machine

InactiveCN104551238AGuaranteed station transfer operationAccurate graduationPrecision positioning equipmentSawing tools dressing arrangementsPulp and paper industryRotating disc

The invention discloses an index locating device of a full-automatic small diamond saw blade double-surface edging machine. The index locating device is characterized by comprising a bottom plate, an index disc, an index connecting rod mechanism, a locating disc, an index air cylinder, a hinge, an index air cylinder support, a main shaft assembly, a material bearing disc and a four-station big rotating disc, wherein the main shaft assembly comprises a shaft sleeve, a main shaft and two bearings, the shaft sleeve is arranged on the bottom plate by adopting a screw, the two bearings are respectively arranged in inner holes in two ends of the shaft sleeve, and the main shaft is arranged in inner holes in the two bearings; the index air cylinder support is arranged under the bottom plate by adopting a bolt; the index air cylinder is connected with the index air cylinder support through the hinge; the index connecting rod mechanism is connected with a stretching shaft of the index air cylinder through a rotating shaft and is connected with the index disc; the index disc and the locating disc are arranged at the lower end of the main shaft. The index locating device disclosed by the invention has the advantages that the indexing is accurate, the adjusting is convenient, the working is reliable, the automation degree is high, and the service life is long.

Owner:HUANGSHI QIBANG AUTOMATION EQUIP

Six-part full-automatic assembly machine for invisible zipper puller

InactiveCN102525044BHigh degree of automationRealize automatic feedingSlide fastenersStructural engineeringMachine

The invention discloses a six-part full-automatic assembly machine for invisible zipper puller and is characterized in that a moving assembly that is connected with a power device is arranged at the table top of a frame; twelve die cavities for fixing zipper pullers are arranged at equal intervals on the margin of the division main rotor plate of the moving assembly; and a zipper puller feeding mechanism, a zipper puller detection mechanism, a zipper puller spring feeding mechanism, a spring detection mechanism, a triangular collar feeding mechanism, a triangular collar detection mechanism, a horse hooker feeding mechanism, a copper pin feeding mechanism, a copper pin detection mechanism, a puller detection mechanism, a puller detection mechanism rejected puller discharge mechanism, and a qualified product discharge mechanism are arranged on the frame and used for assembling zipper pullers. The six-part full-automatic assembly machine integrates the functions of two machines, the detection mechanisms are arranged behind the corresponding feeding mechanism to automatically identify parts in the die cavities, and the start-up or shut-down of the assembly machine is automatically controlled according to the assembly information of parts, so as to prevent defected parts from entering the next procedure or prevent idle running of the assembly machine, as a result, the rate of rejected products is reduced and the assembly machine is guaranteed to run safely and reliably.

Owner:义乌市振宏机械科技有限公司

Tire pressure sensor acceleration batch test device

InactiveCN107219038AAccurate graduationSolve the dynamic balance problemFluid pressure measurementElectric machineryTire rotation

The invention discloses a tire pressure sensor acceleration batch test device. A direct drive motor is used for directly driving a turntable, accurate scale division of the turntable can be ensured, the automobile tire rotation state can also be simulated, the structure design reduces system errors caused by a mechanical transmission reason, and the response speed and the transmission precision of the mechanism are improved. The turntable uses a horizontally-placed structure, the dynamic balance problem when the turntable rotates can be avoided, and safe and effective operation of the system can be ensured. A fixture positioning mechanism and a fixture loading / unloading device are used for automatic tire pressure sensor loading and unloading, and the whole system has a fully-automatic test function. The tire pressure sensor acceleration batch test device has the advantages of simple structure, small mechanism size, high operation efficiency and high cost performance, shackles of promotion and development of the tire pressure sensor are broken, great practical significance is realized, and the tire pressure sensor acceleration batch test device is particularly suitable for batch test on the acceleration detection function of the tire pressure sensor.

Owner:SUZHOU DINA PRECISION EQUIP

Positioning and clamping device for machining inclined hole in annular part and method of positioning and clamping device for machining inclined hole in annular part

ActiveCN111702522AEasy to slip and bendControl deformationPositioning apparatusMetal-working holdersStructural engineeringMachining

The invention discloses a positioning and clamping device for machining an inclined hole in an annular part and a method of the positioning and clamping device for machining the inclined hole in the annular part. The positioning and clamping device comprises a positioning piece, a cylinder is integrally formed on the positioning piece, a first drill hole and a second drill hole are formed in the side face of the cylinder, the first drill hole is obliquely formed away from the machining face of the positioning piece, the inclination angle between the first drill hole and the machining face of the positioning piece is equal to the inclination angle between the first inclined hole in the annular part and the placing face, the first drill hole and the second drill hole are symmetrical with respect to the central axis of the cylinder, a first datum plane and a second datum plane are arranged on the side edge of the positioning piece, the first datum plane and the first drill hole complementeach other relative to the machining face of the positioning piece, the first datum plane and the second datum plane are symmetrical with respect to the central axis of the cylinder, and a fixing andclamping device is further arranged on the positioning piece and used for fixing the annular part. According to the positioning and clamping device, the annular part circumferential positioning is accurate, the indexing mode is simple, a drill bit is not prone to slipping, the structure is reasonable and simple, and the machining requirement of the annular part inclined hole is met.

Owner:AECC AVIATION POWER CO LTD

Numerical control machine tool spindle box system with indexing mechanism

PendingCN107737952ALow costAccurate graduationPrecision positioning equipmentLarge fixed membersNumerical controlBall bearing

The invention discloses a numerical control machine tool spindle box system with an indexing mechanism. The numerical control machine tool spindle box system comprises a box body and a main shaft andfurther comprises a main shaft indexing device, a bearing sealing system, a bearing pre-tightening and anti-backlash device and a bearing lubricating system. According to the spindle box system, a driving friction wheel with the position capable of being adjusted up and down is used for driving a driven friction wheel to rotate, and the rotation angle of the main shaft is controlled through a stepping motor or an angle sensor, so that indexing is accurate, the indexing operation is simple and convenient, and the cost of an indexing device is low; the bearing sealing system of the spindle box system can play dustproof and anti-fouling roles on a bearing and also can play a role in cooling the inner ring on the bearing and the main shaft, the rigidity of the main shaft and the inner ring ofthe bearing can be improved, and the rotating precision of the main shaft can be kept; and the bearing pre-tightening and anti-backlash device can automatically eliminate a gap generated by bearing abrasion so that the rigidity of a first deep groove ball bearing and the rigidity of a second deep groove ball bearing can be greatly enhanced, the rigidity of the main shaft system can be greatly improved, and the rotating precision of the main shaft and the machining precision of machine tools can be improved.

Owner:重庆市普创长顺机械有限公司

Spherical valve core drilling machining device

PendingCN112059238AAccurate graduationImprove reliabilityAutomatic control devicesDrilling/boring measurement devicesPhysicsDrill hole

The invention relates to the technical field of spherical valve core drilling, discloses a spherical valve core drilling device, and solves the problems that a spherical valve core on the market is acore part of a certain type of flow valve body at present, the hole spacing precision on the spherical surface of the spherical valve core directly influences the product performance, but the cost isgenerally higher when the spherical valve core is machined on a five-axis linkage machine tool, and on the other hand, due to the fact that a drill bit is small and poor in strength when drilling is conducted on the spherical surface, the drill bit is prone to slipping when the drill bit makes contact with the spherical surface, the hole position deviates, and the hole spacing cannot meet the requirements for pattern design. The spherical valve core drilling machining device comprises a base, wherein an orientation frame is fixedly arranged at the top of the base; pitching shafts are fixedly arranged on the two sides of the orientation frame; the two pitching shafts are distributed with the axis of the orientation frame as the center; and two through holes are arranged in the base. According to the spherical valve core drilling device, the drilling requirements for pattern design of parts are met, the indexing is accurate, the reliability is high, the batch machining, assembling and disassembling are convenient, and the benchmark positioning is accurate.

Owner:江西中船航海仪器有限公司

Universal fast indexing and rotating device

ActiveCN109483323BGraduation realizationFast indexingPrecision positioning equipmentBlock matchComputer science

The invention discloses a universal quick indexing and rotating device, which includes an indexing mechanism, an angle rotating mechanism and a machine tool installation seat. The indexing mechanism includes a first spindle, a first rotating handle and a first base, the middle of the first spindle is provided with at least two angle indexing segments and positioning indexing blocks matched with the angle indexing segments, the angle indexing segments and the positioning indexing blocks are used cooperatively to prevent rotation of the first spindle, and the first rotating handle can drive a first dial and the first spindle to rotate together; and the structure form and working principle of the angle rotating mechanism are the same as those of the indexing mechanism, the middle of the firstspindle is installed on the front part of a second spindle through a bearing, the first spindle and the second spindle are vertically arranged, a second rotating handle can drive a second dial and the second spindle to rotate together, and the second spindle drives the indexing mechanism to tilt. According to the universal quick indexing and rotating device, indexing with various different anglescan be quickly and accurately conducted, and meanwhile, workpieces are adjusted to any inclined processing angle, so that the different processing requirements can be met by selecting the different angle indexing segments or quickly replacing the spindles.

Owner:CHONGQING STARTING POWER UNIT CO LTD

Special machine tool for pattern roll lentil groove processing

InactiveCN106001723BRealize processingClamp firmlyMilling machinesMilling equipment detailsHydraulic cylinderEngineering

The invention discloses a special machine tool for machining a pattern roller lentil-shaped groove, and aims to provide a special machine tool in the field of metallurgical machining. The machine tool is provided with a frame module, a positioning and clamping device, a power head milling device and a feed indexing device; and the positioning and clamping device, the power head milling device and the feed indexing device are all arranged on the frame module. The whole structure of the machine tool adopts a gantry vertical milling machine layout; the rigidity of a machining process system is good; the workpiece positioning and clamping are realized by using a support roller and V-shaped block combined effect; a roller is fast in rotation and reliable in clamping; the workpiece maneuvering clamping and loosening are realized by using a hydraulic cylinder to achieve the effects of labor saving and fastness; a servo motor is adopted to provide power for peripheral indexing of the roller and positioning of a multi-station feeding position; the indexing and positioning precision is high; the automatic workpiece machining can be realized through electric control; and the machine tool is used for machining workpieces, low in vibration, few in surface vibration patterns, high in machining quality, simple in structure, convenient for maintenance and low in equipment investment.

Owner:KUNMING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com