Roller-stretching-process dual-Y type rolling mill for compacted-strand steel wire rope

A technology of compacting strands and steel wire ropes, which is applied to rope-making auxiliary devices, textiles and papermaking, and textile cables, etc. It can solve the problems of multiple mold-threading processes, large mold holes, fast mold wear, etc., and achieve high product finish , its own resistance is small, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

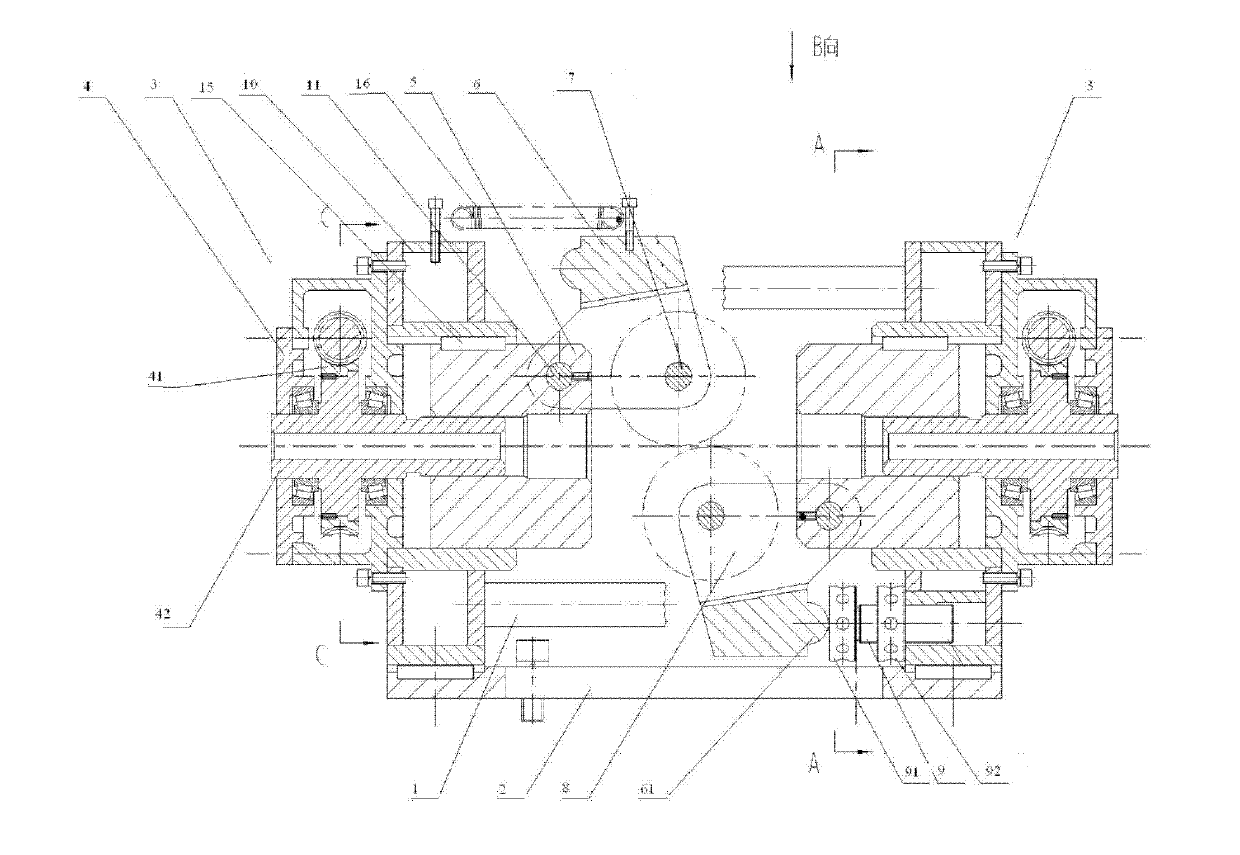

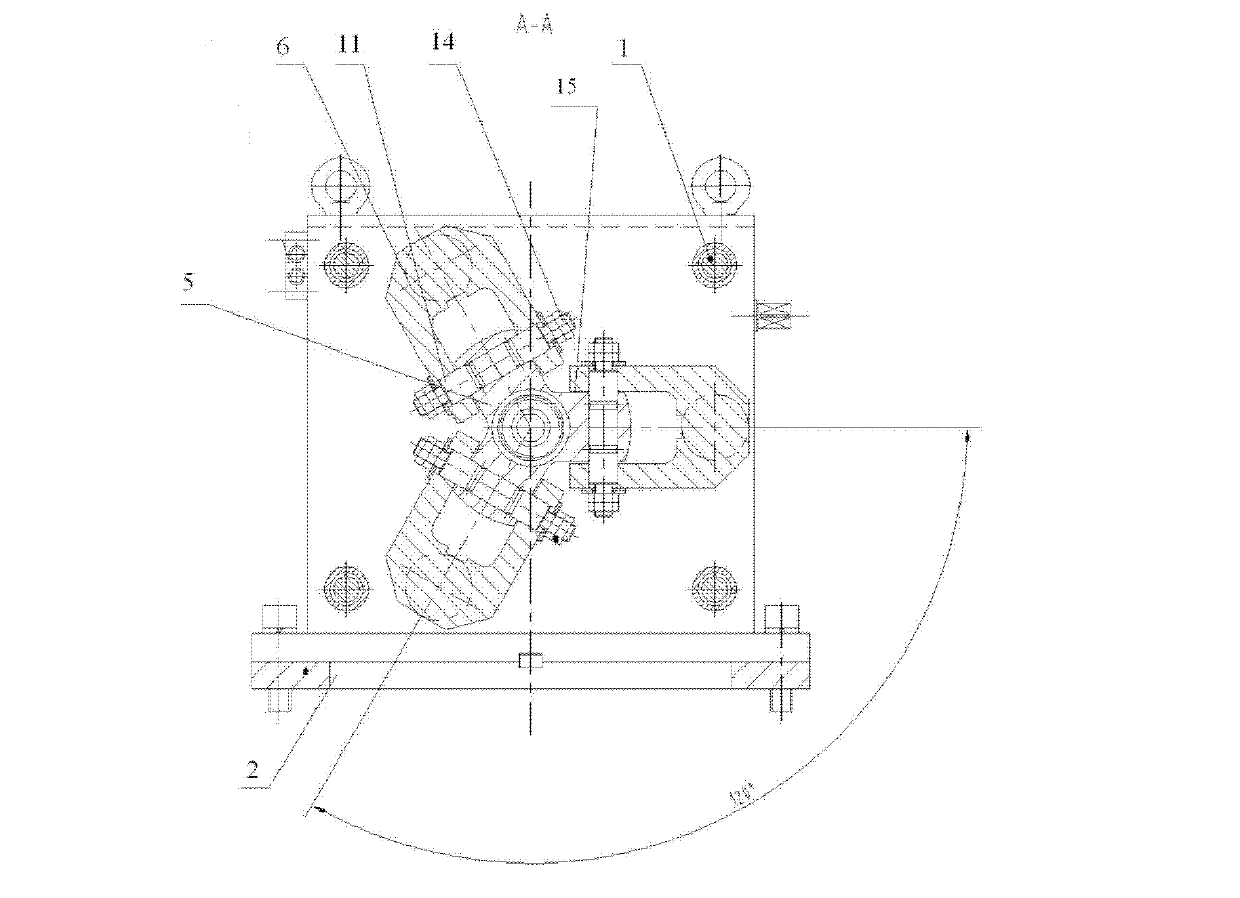

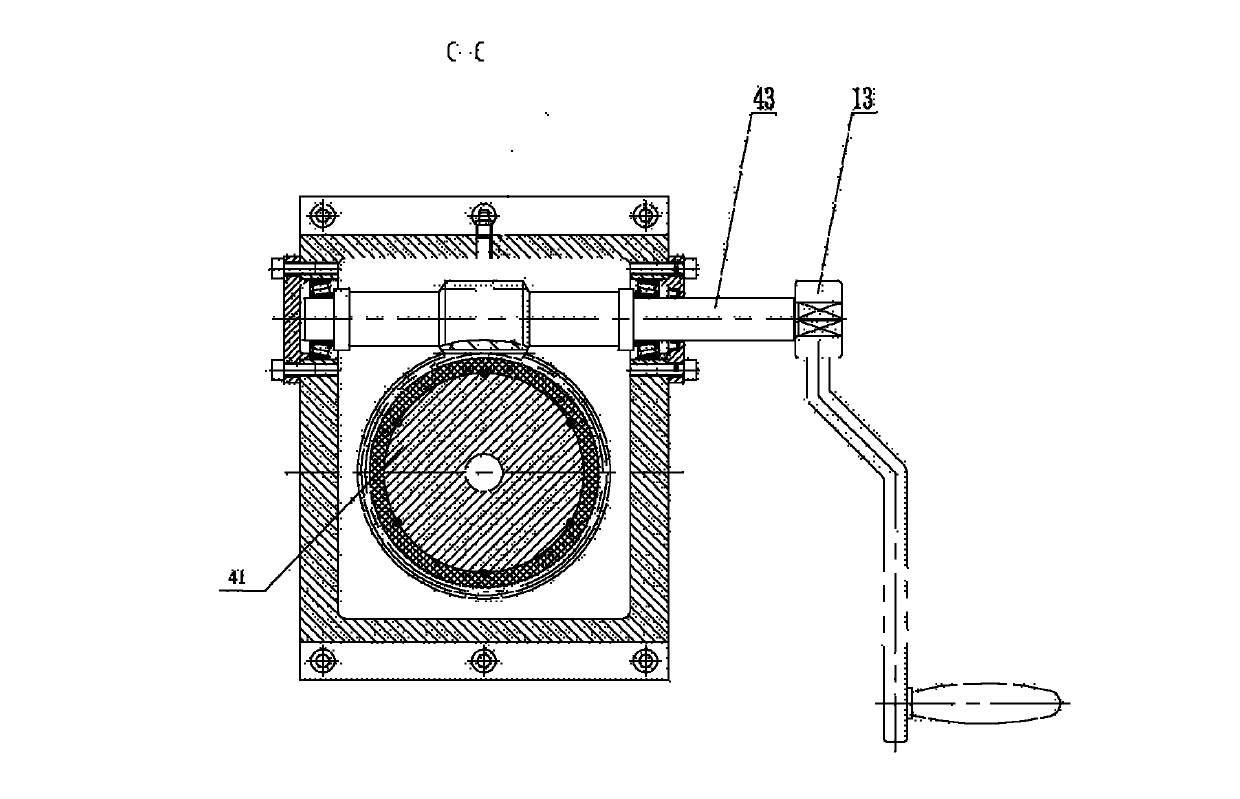

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] combined with figure 1 - attached Figure 8 Description, a roll-drawing compacted strand steel wire rope double Y-shaped rolling mill disclosed in the present invention includes a pull rod 1, a bottom plate 2 and two roll units 3; the two roll units 3 include a worm gear box assembly 4, a mounting head 5, fork head 6, roll core 7, roll plate 8, tension spring 16 and frame 10; Worm gear box assembly 4 is installed on the frame 10; Worm gear 41 is installed on the worm gear shaft 42; The worm gear shaft 42 is connected, and the outer circle of the installation head 5 is connected with the frame 10; one end of the fork 6 is installed on the installation head 5, and the other end of the fork 6 is connected with the roller core 7; the roller sheet 8 is installed on the roller core 7 ; One end of the tension spring 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com