Automobile starter motor stator auxiliary pole automatic welder

A technology of automatic welding machine and starter, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of low work efficiency and automation, inaccurate stator shell indexing, uneven distribution of stator auxiliary poles, etc. Achieve the effects of low labor intensity, high degree of automation, and accurate indexing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

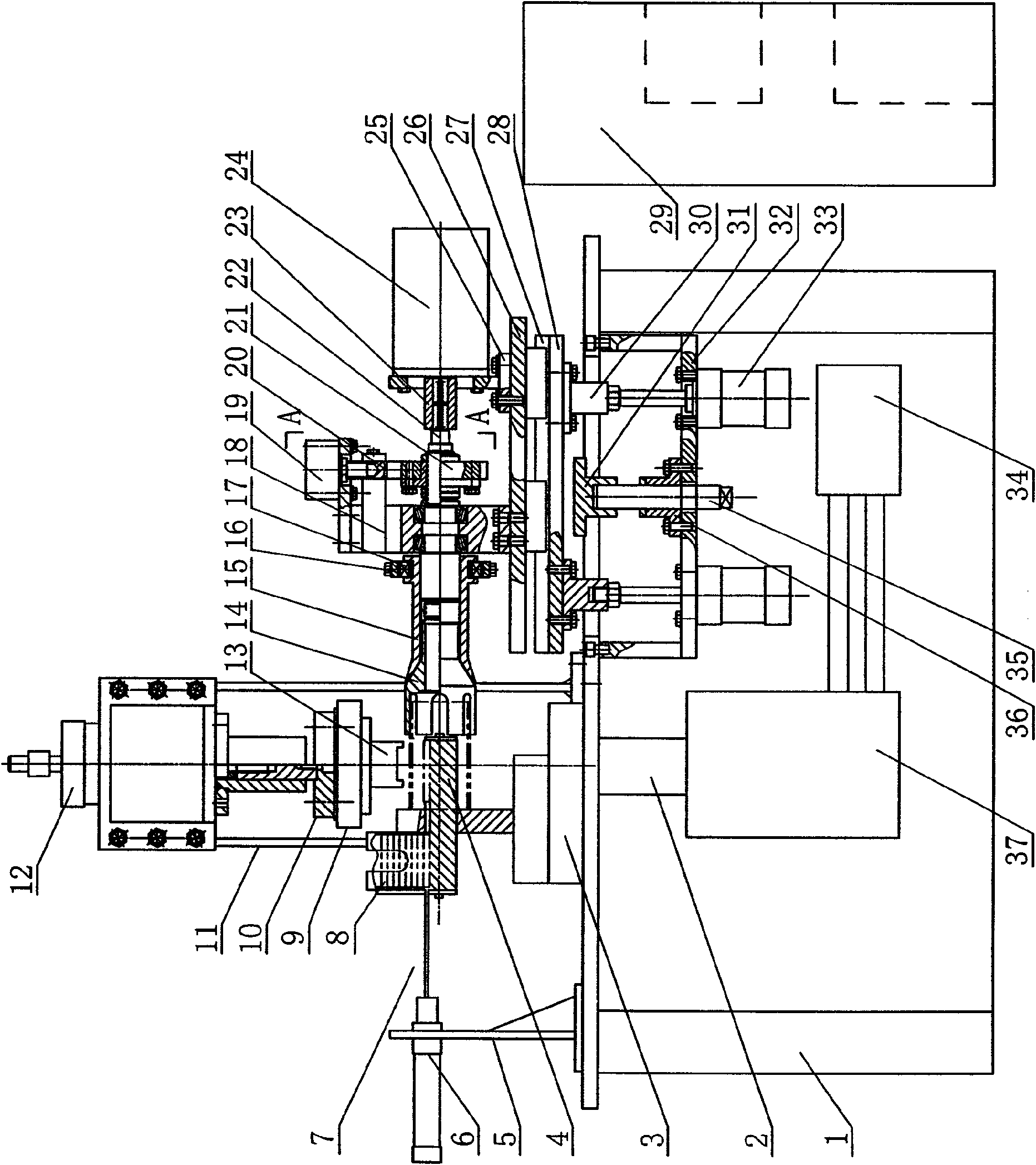

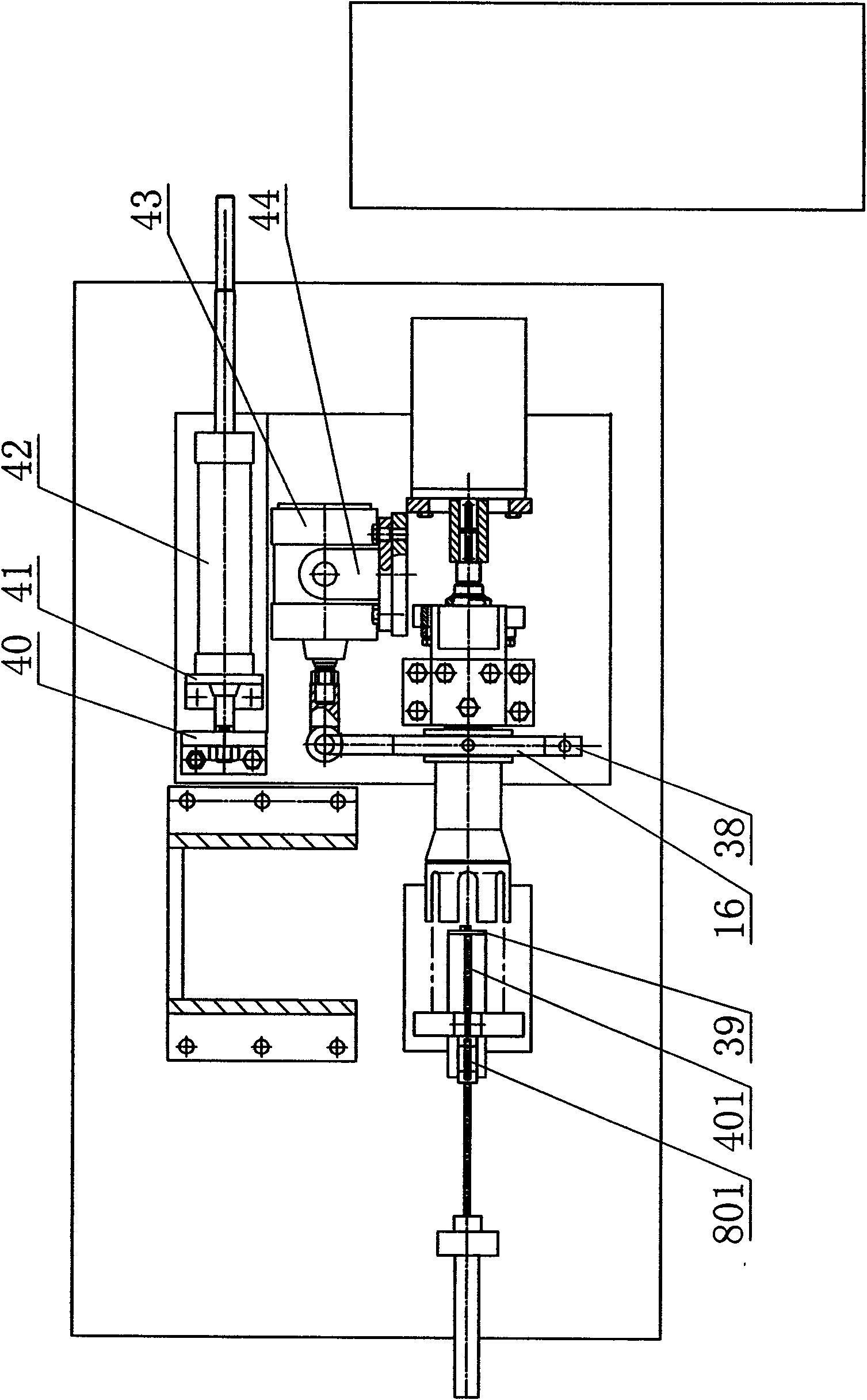

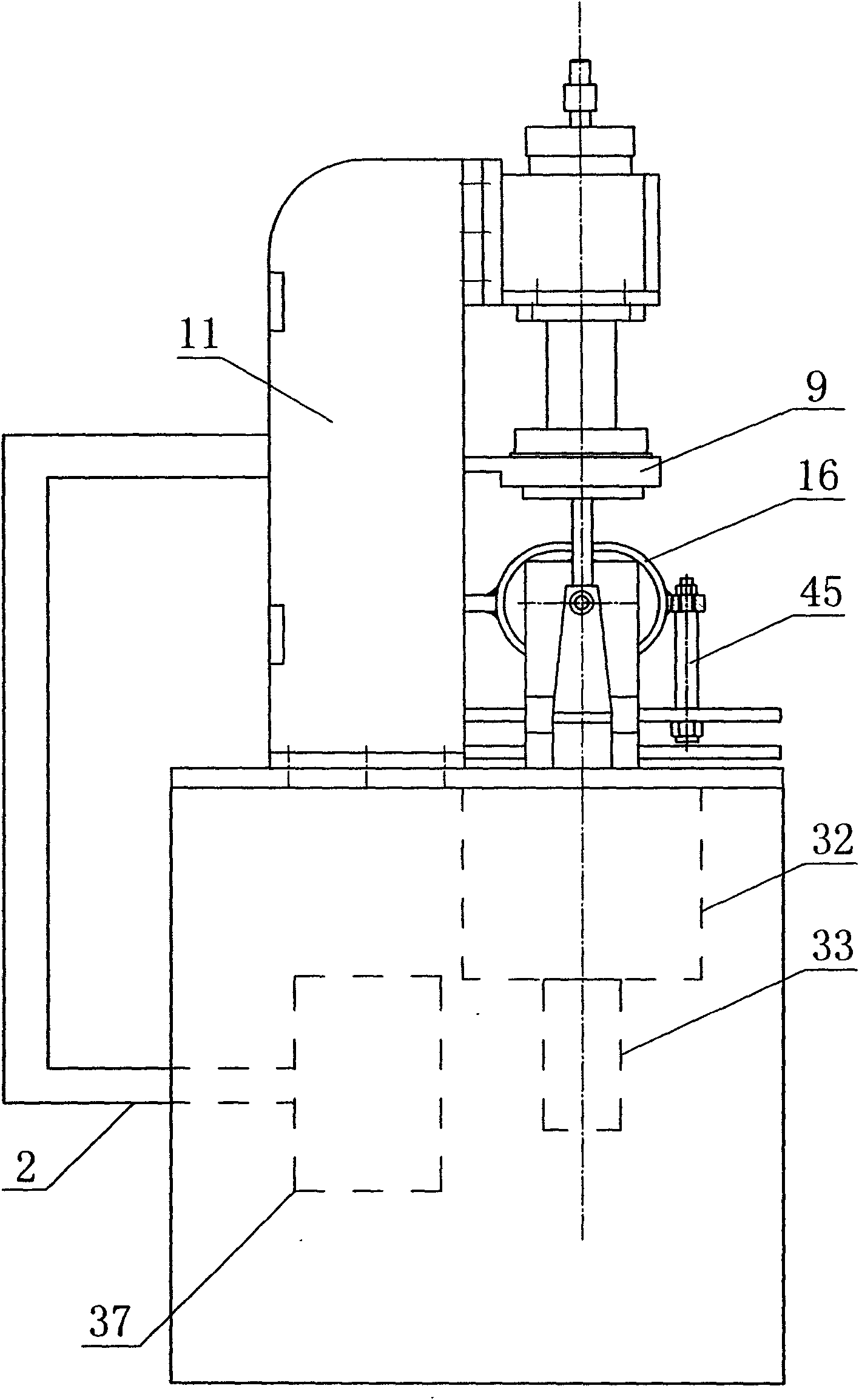

[0019] As shown in the figure, the present invention has a frame 1, on which a resistance welding machine is installed. The welding electrode cylinder 12 on the top of the support 11 is screwed to the connecting flange 10 on the cylinder rod at the lower end of the welding electrode cylinder 12, and the upper electrode seat 9 fixed on the lower surface of the connecting flange 10 by bolts is respectively fixed on the welding electrode cylinder 12 by bolts. The upper electrode 13 and the lower electrode 4 on the upper electrode holder 9 and the lower electrode holder 3, the transformer 37 and the thyristor 34 connected to each other installed in the frame 1, and the conductive strip 2 connecting the transformer 37 and the upper electrode holder 9 constitute . On the frame 1, a lifting seat plate 28 is arranged on one side of the lower electrode 4, and a reciprocating lifting mechanism is connected below the lifting seat plate 28. The reciprocating lifting mechanism is fixed sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com