Spherical valve core drilling machining device

A spherical spool and processing device technology, applied in feeding devices, metal processing, boring/drilling, etc., can solve problems such as hole position offset, small drill bit strength difference, affecting product performance, etc., to achieve accurate benchmark positioning, Easy loading and unloading, accurate indexing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

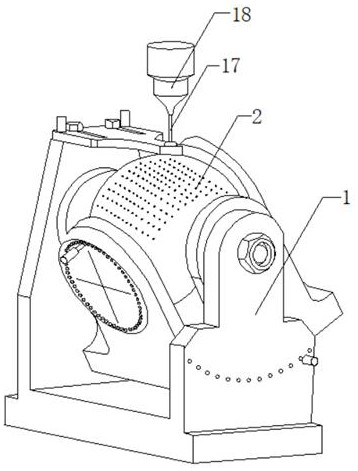

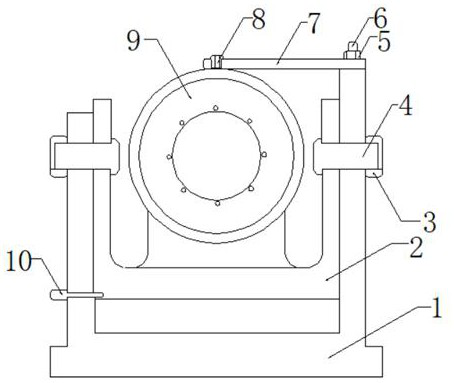

[0019] Embodiment one, by Figure 1-4 Given, the present invention includes a base 1, an azimuth frame 2 is fixedly installed on the top of the base 1, a pitch axis 4 is fixedly installed on both sides of the azimuth frame 2, and two pitch axes 4 are distributed around the axis center of the azimuth frame 2, The inside of the base 1 is provided with two through holes, and the two through holes are respectively inserted into the corresponding pitch axes 4, and one end of the two pitch axes 4 passes through the through holes and extends to the outside of the base 1. The sides are provided with several positioning holes, and several connecting holes are evenly distributed on both sides of the base 1, wherein the interior of the two positioning holes is movably inserted with a pitch positioning rod 10, and one end of the pitch positioning rod 10 is connected to the azimuth frame 2. Fixed insertion, the inside of the azimuth frame 2 is provided with a spherical valve core 9, and on...

Embodiment 2

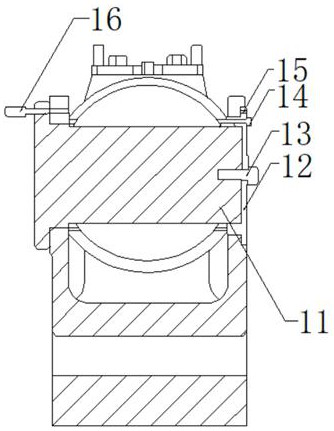

[0020] Embodiment 2, on the basis of Embodiment 1, the inside of the horizontal end cover 12 is fixedly connected with end cover screws 13 , and the horizontal shaft 11 is fixedly connected with the horizontal end cover 12 through the end cover screws 13 .

Embodiment 3

[0021] Embodiment 3, on the basis of Embodiment 1, a horizontal positioning pin 16 is movably inserted inside the base 1 , and one end of the horizontal positioning pin 16 is screwed with an anti-rotation screw 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com