Tire pressure sensor acceleration batch test device

A technology of tire pressure sensor and batch testing, which is applied in the direction of instruments, measuring devices, measuring fluid pressure, etc., can solve problems such as constraints, and achieve the effects of high operating efficiency, improved response speed and transmission accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments do not limit the present invention, and any structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0031] An embodiment of the present invention is provided below:

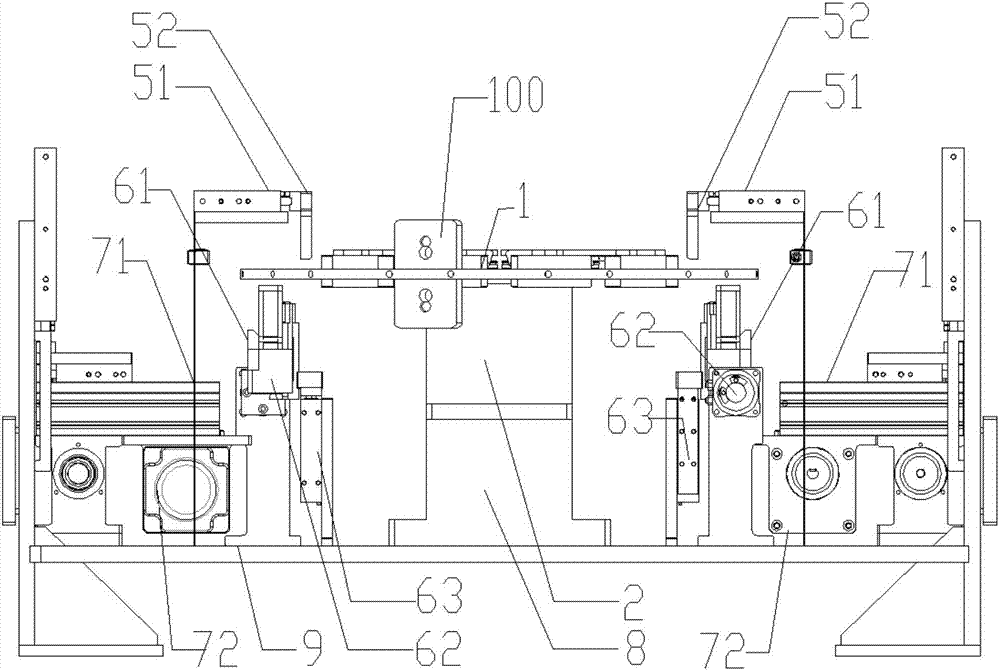

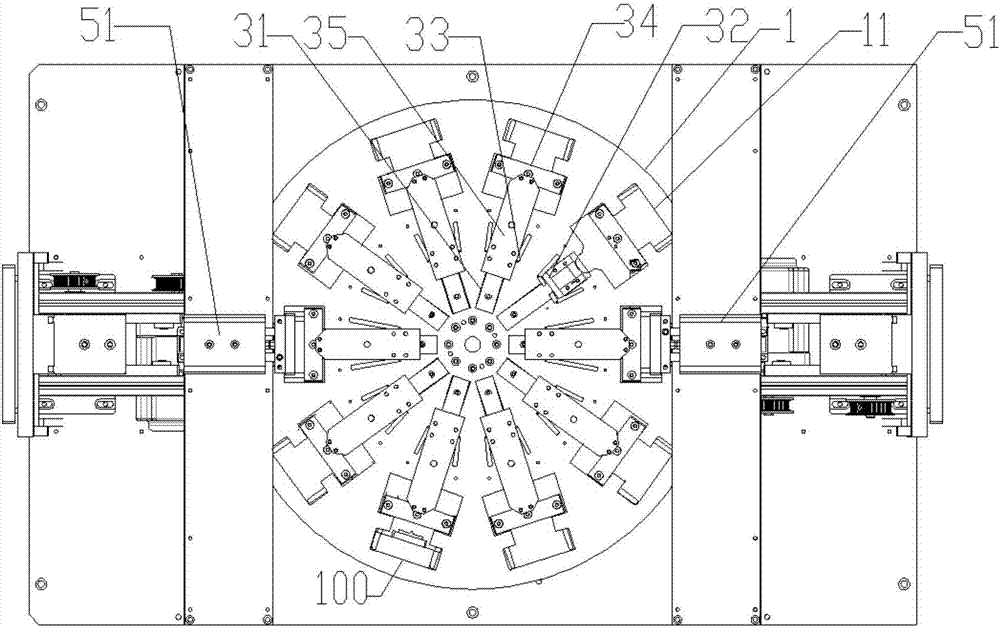

[0032] See Figures 1 to 2 , a tire pressure sensor acceleration batch testing equipment, comprising:

[0033] Turntable 1, the turntable 1 is set horizontally;

[0034] The direct drive motor 2 is arranged coaxially with the turntable 1 to drive the turntable 1 to rotate;

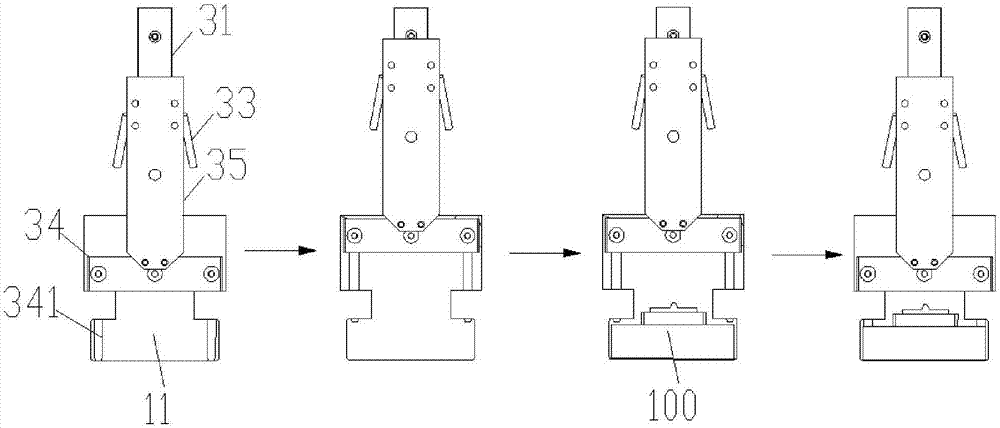

[0035] The jig positioning mechanism cooperates with the positioning port 11 provided on the turntable 1 to fix the jig 100 holding the tire pressure sensor on the turntable 1;

[0036] The jig positioning mechanism includes a slide rail 31 fixedly arranged radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com