Patents

Literature

38results about How to "Solve the dynamic balance problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

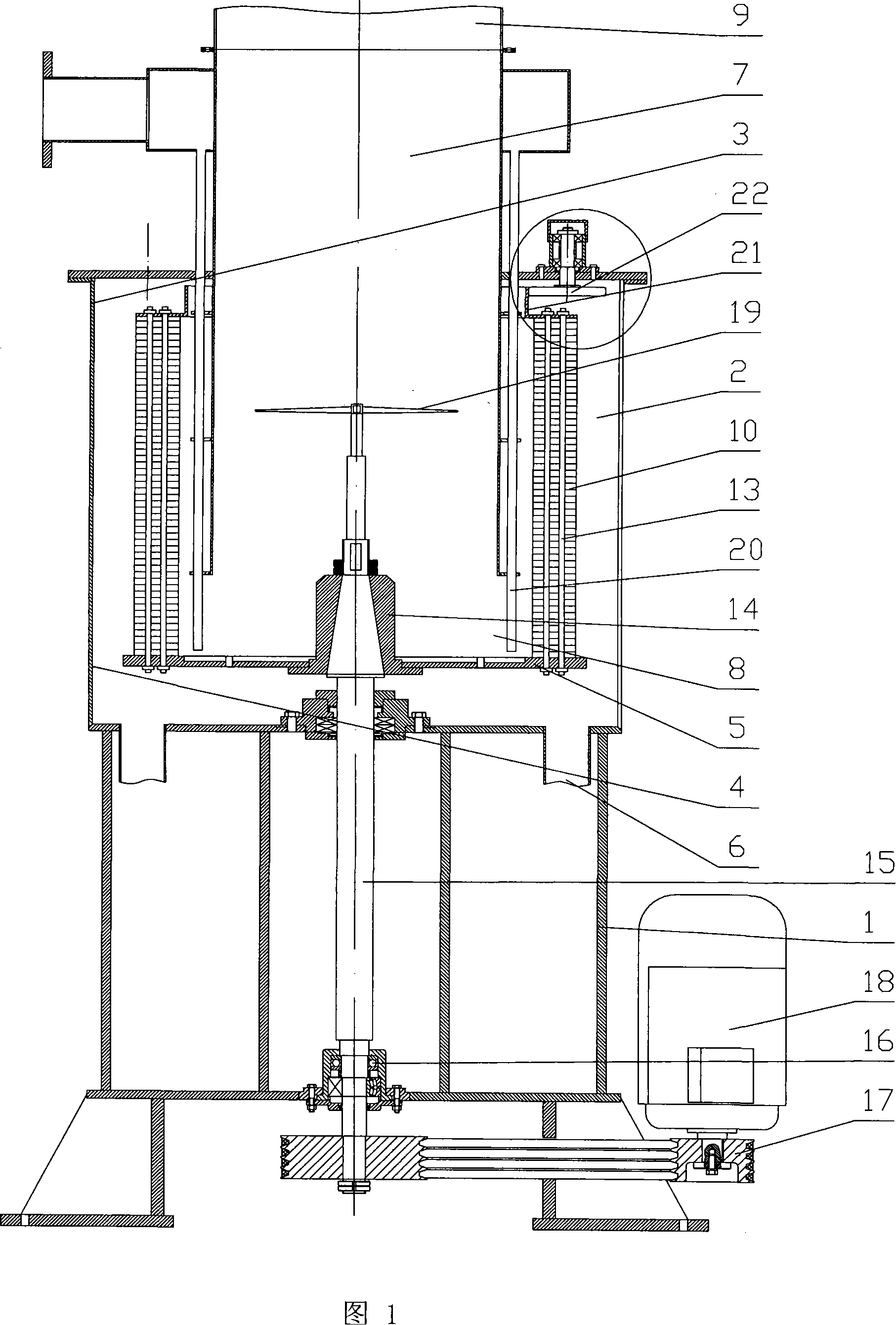

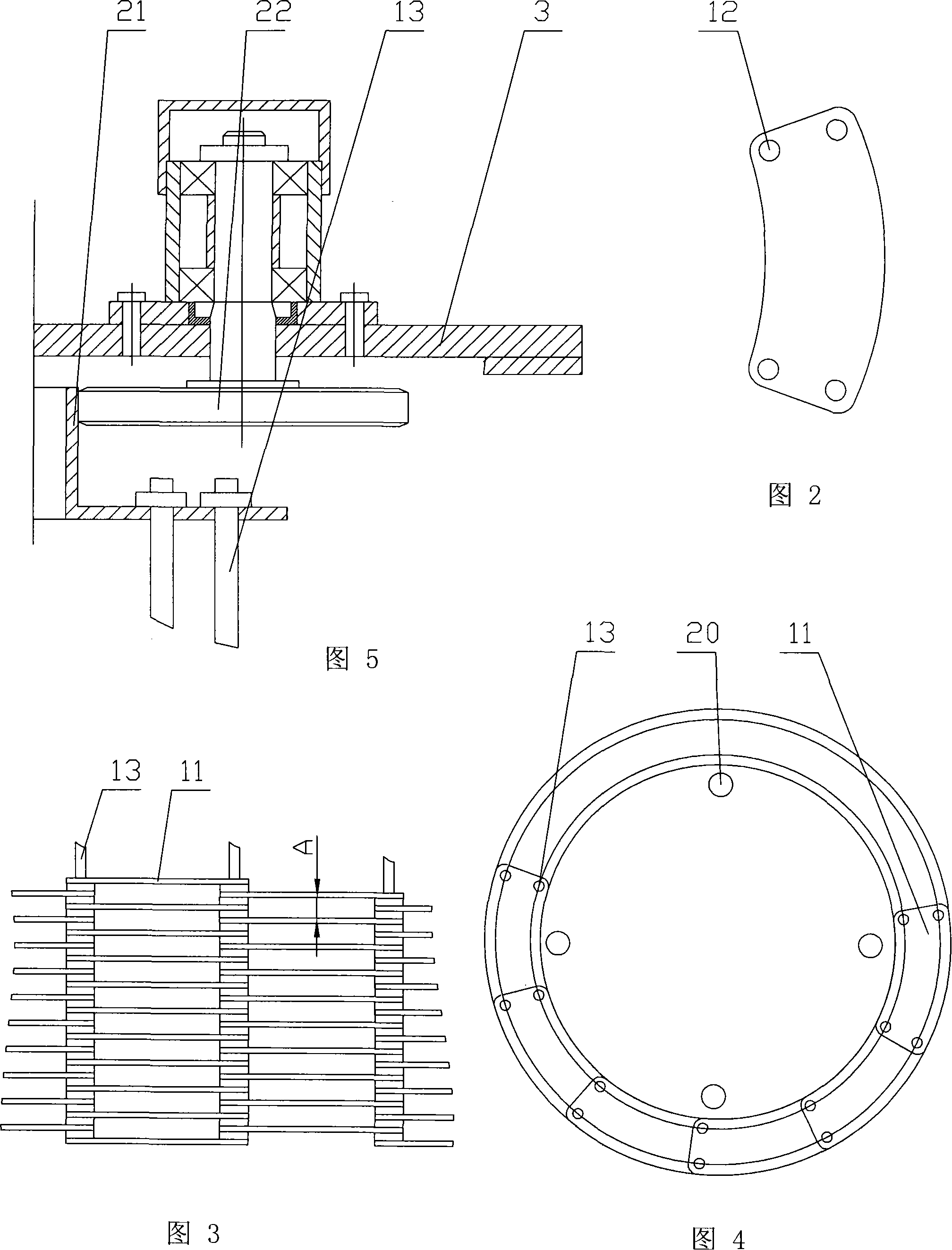

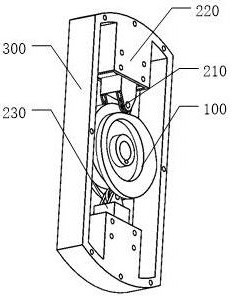

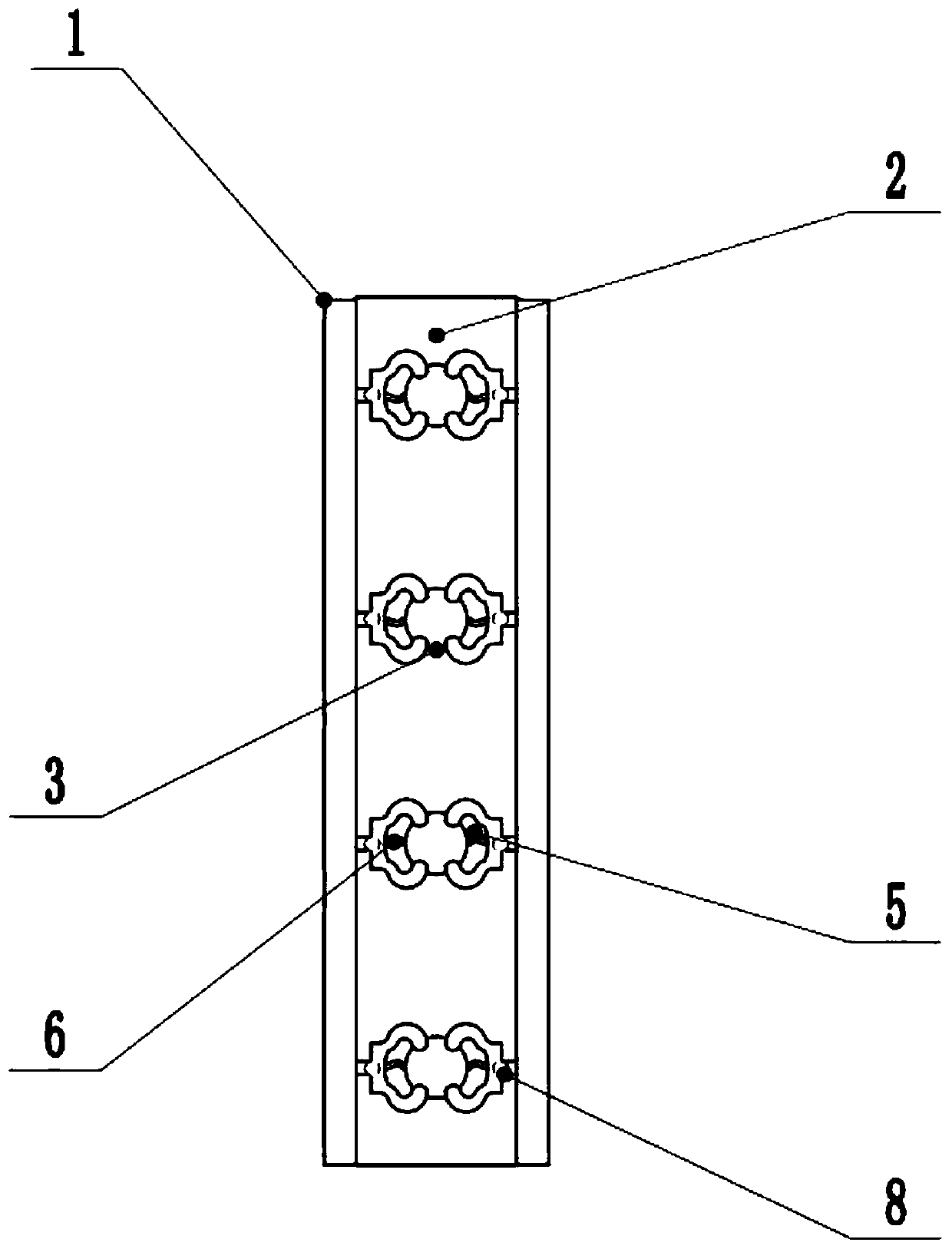

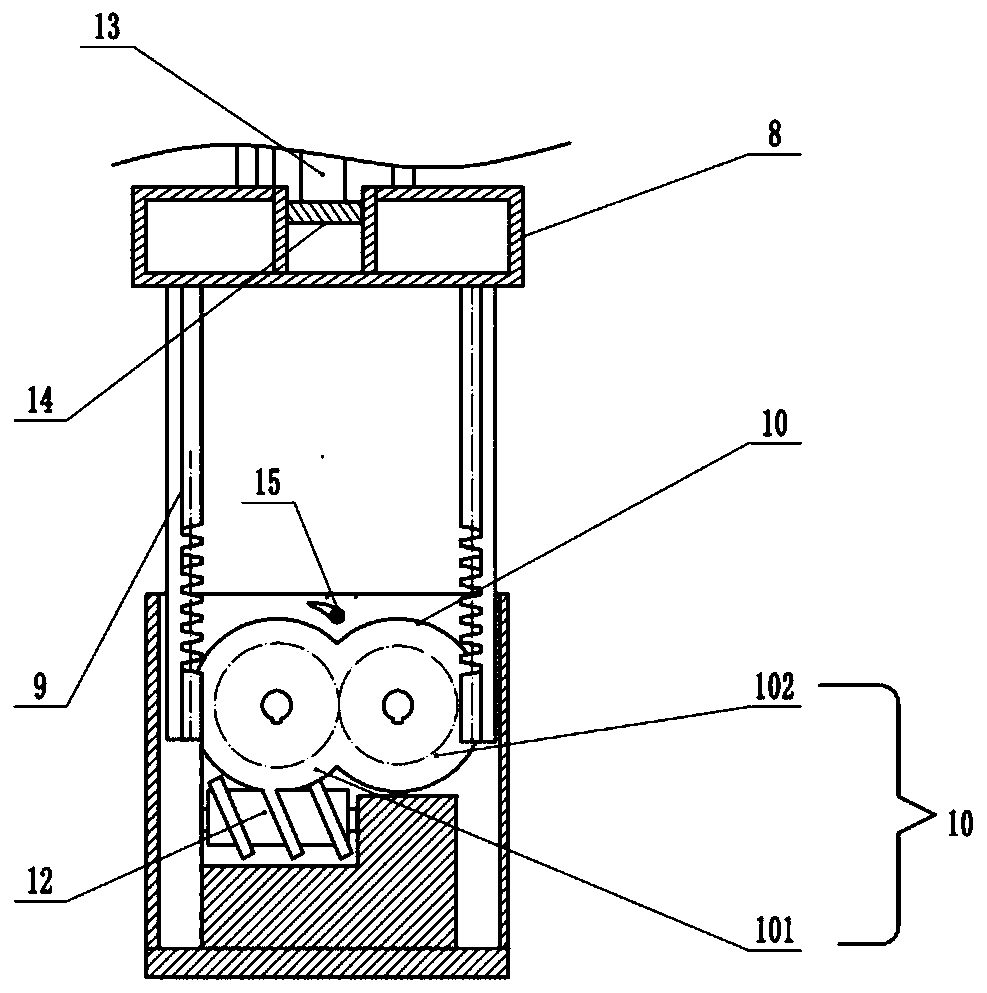

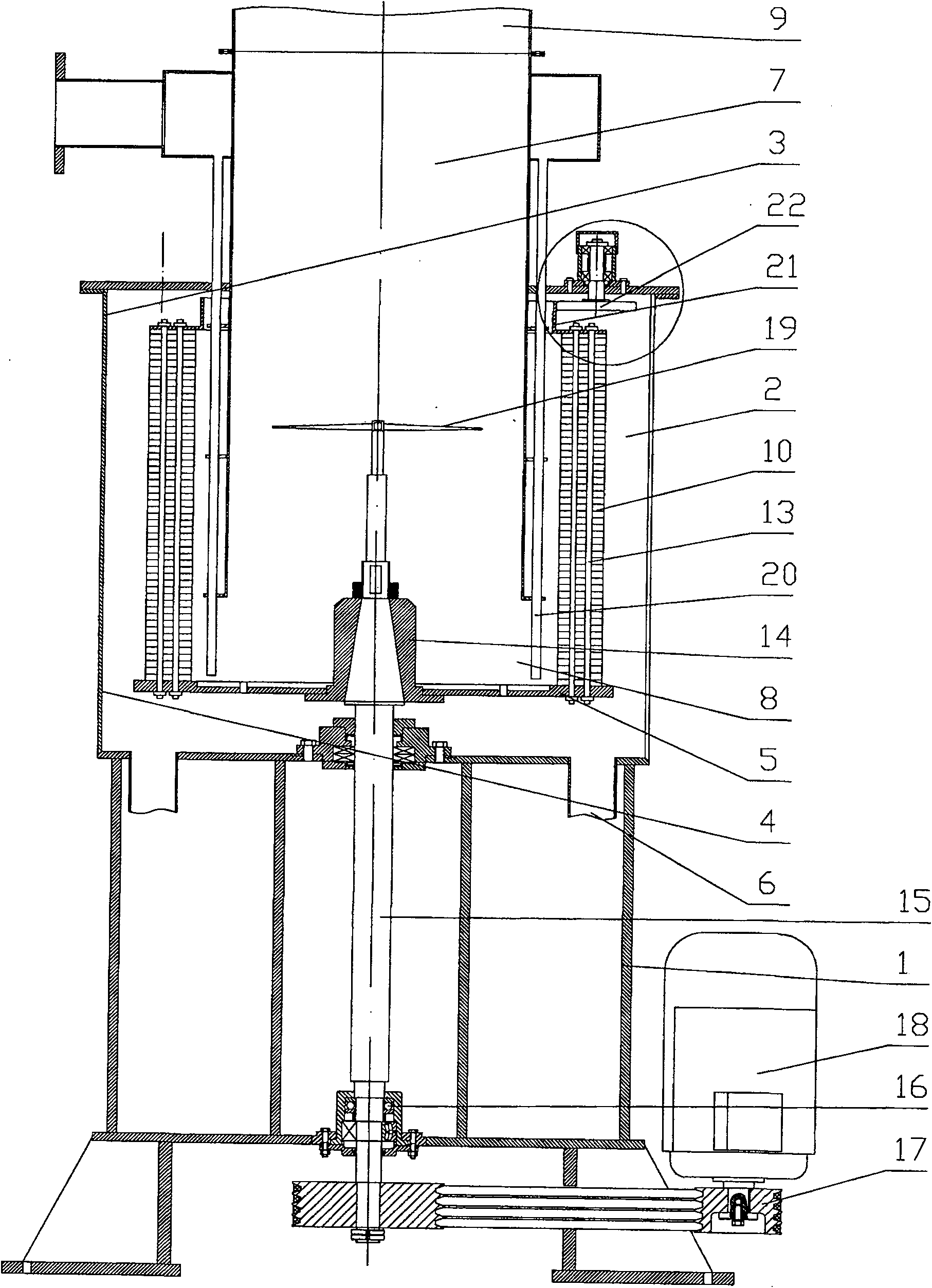

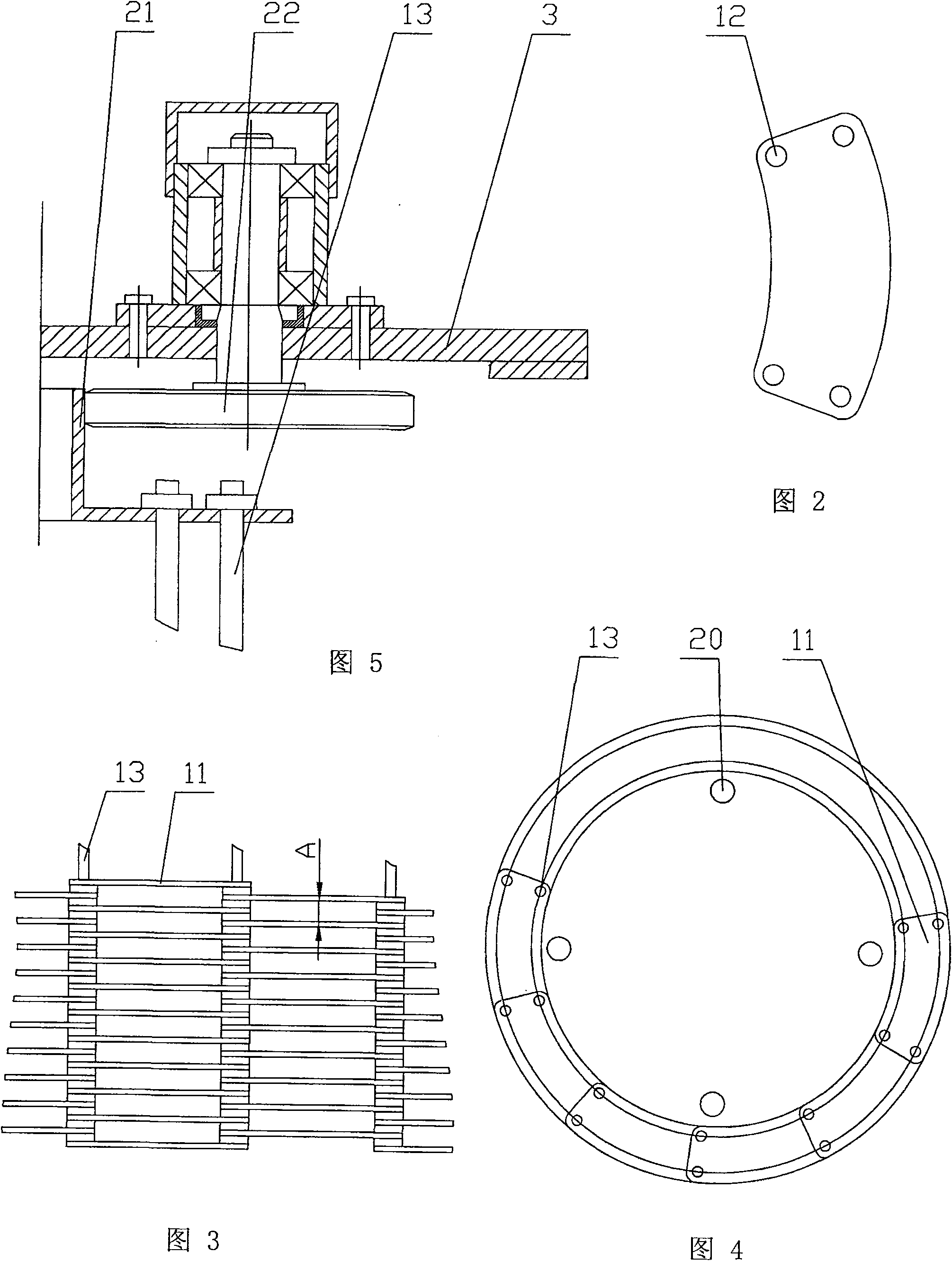

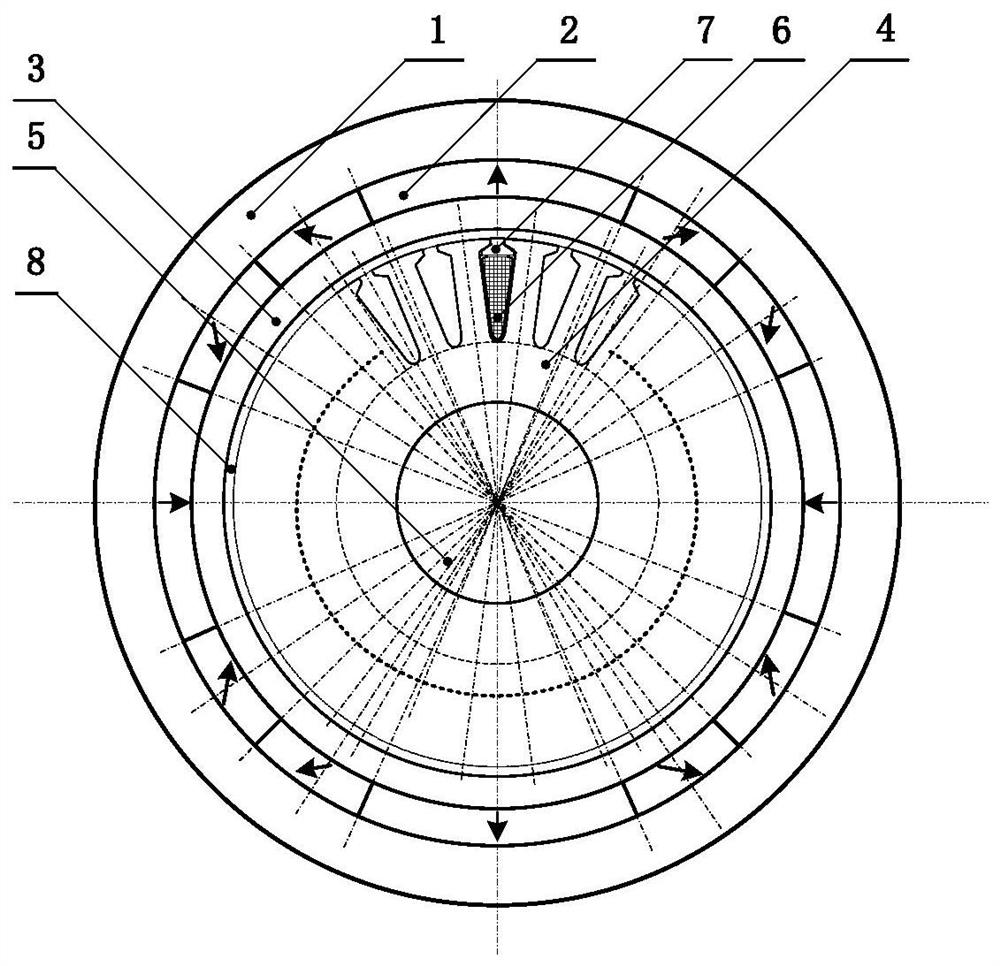

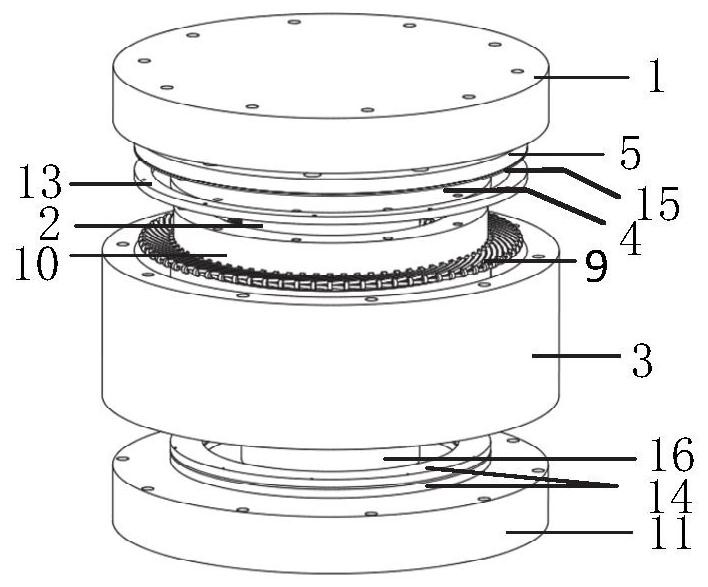

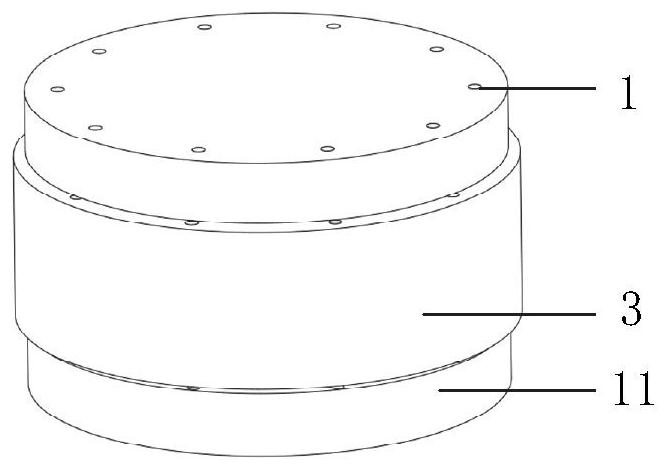

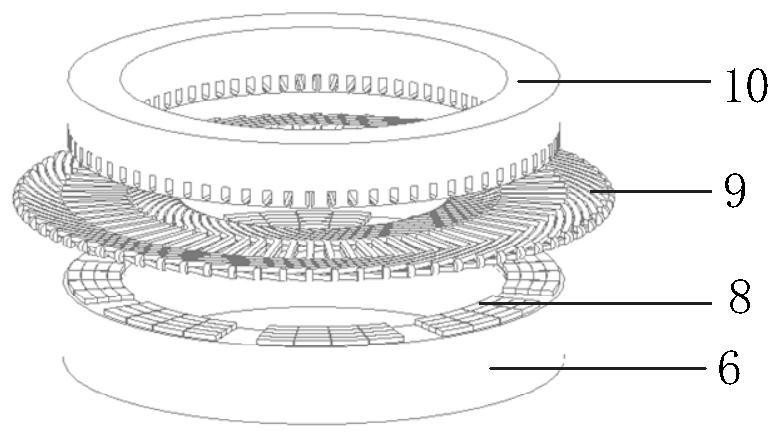

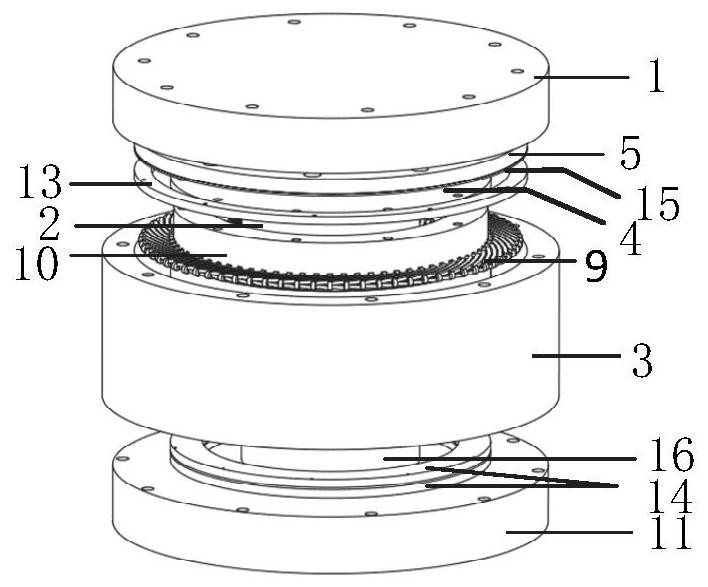

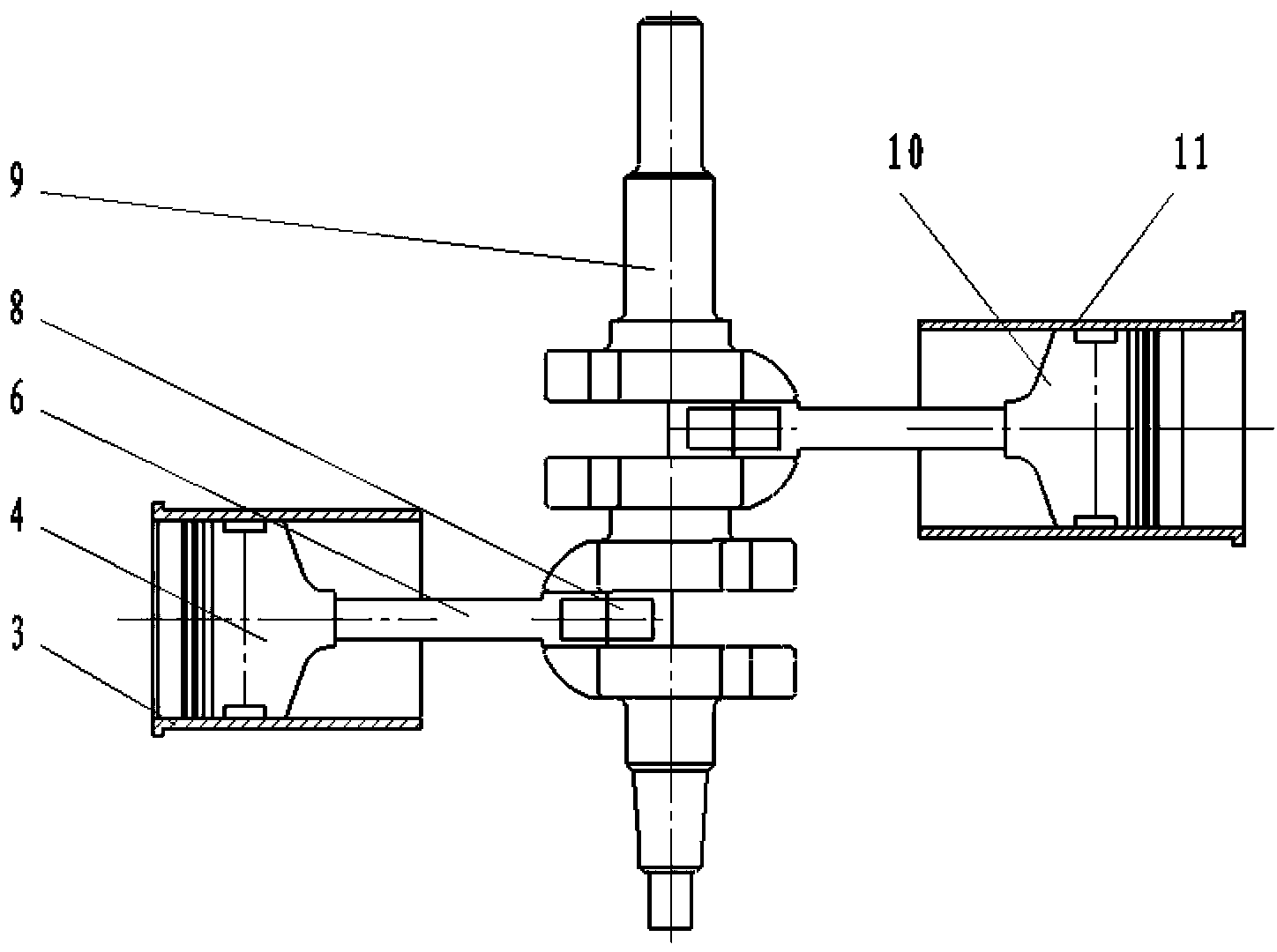

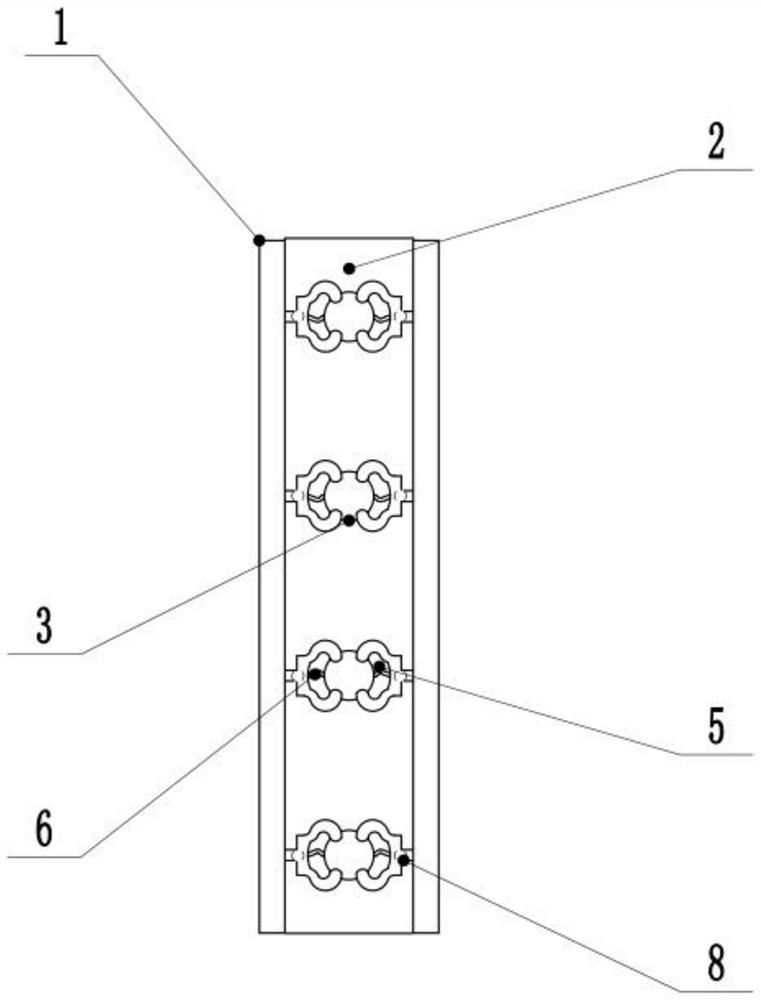

Vertical rotating bed super gravity field equipment

InactiveCN101125263ASmooth and reliable rotationReduce vibrationChemical/physical/physico-chemical stationary reactorsChemical/physical/physico-chemical moving reactorsChemical industryEngineering

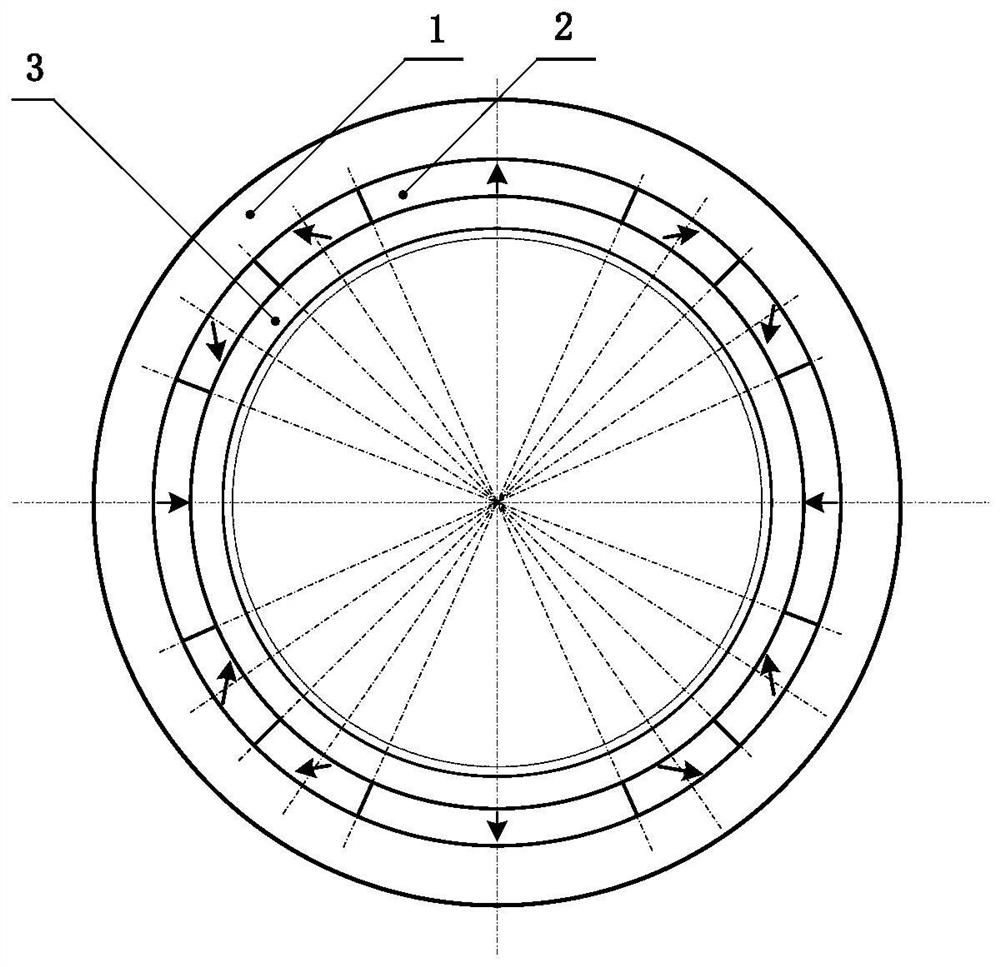

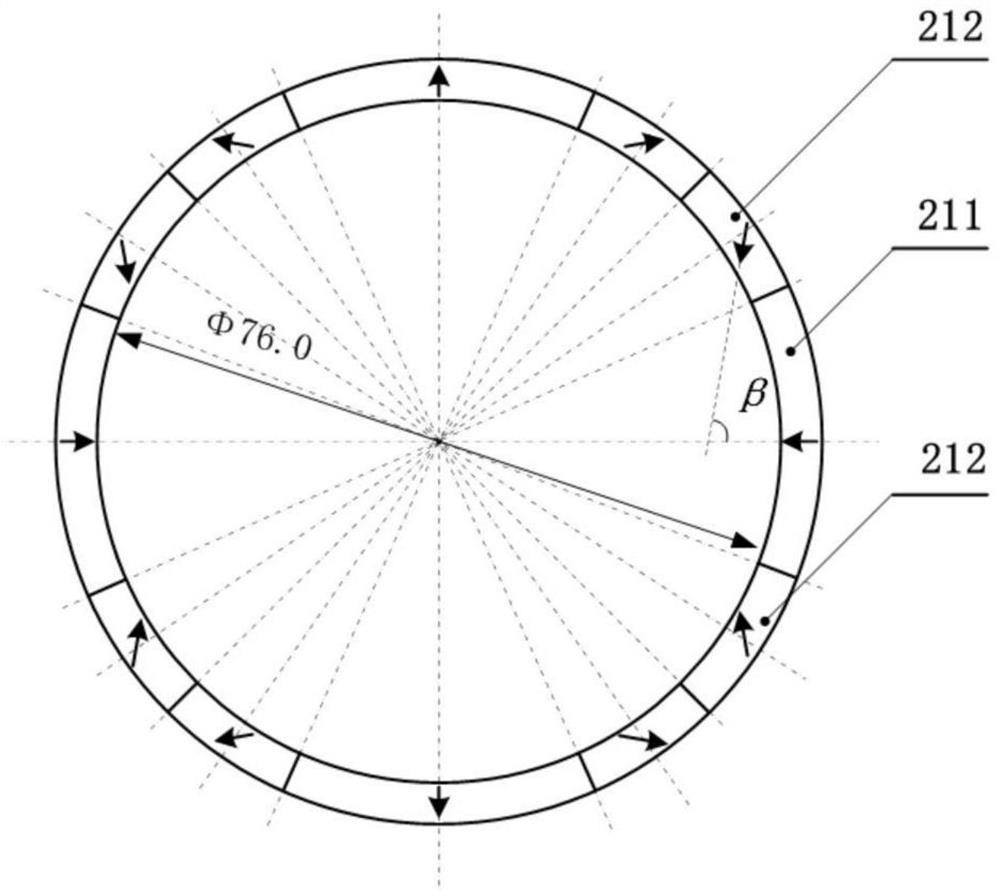

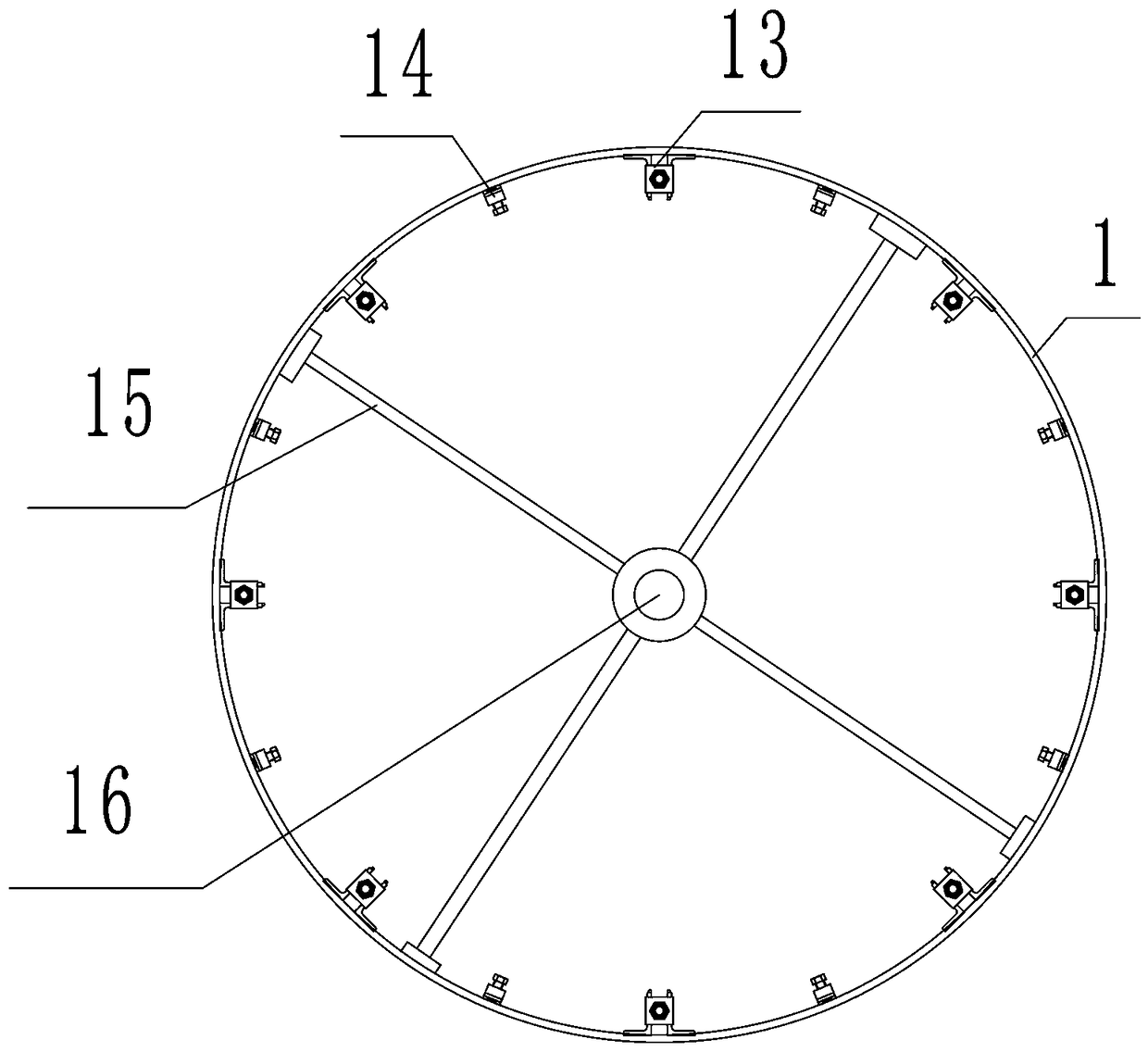

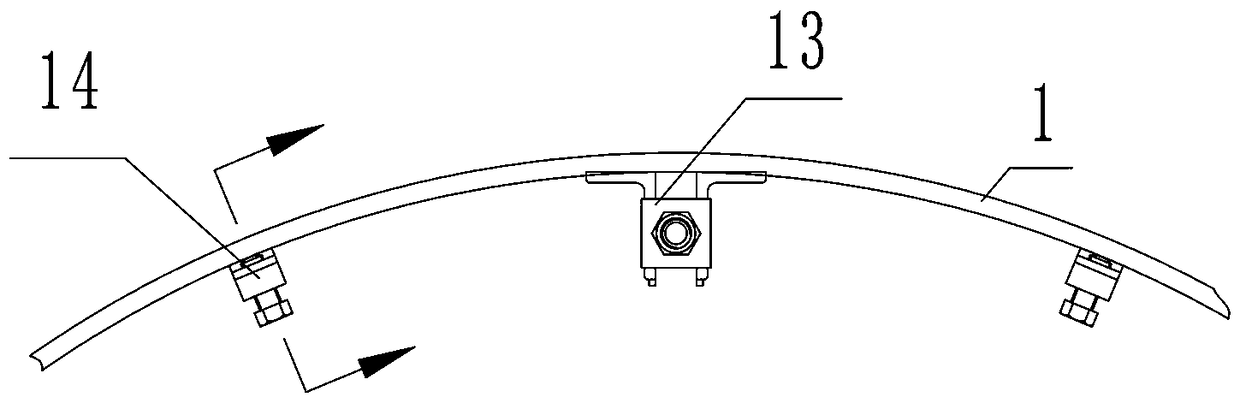

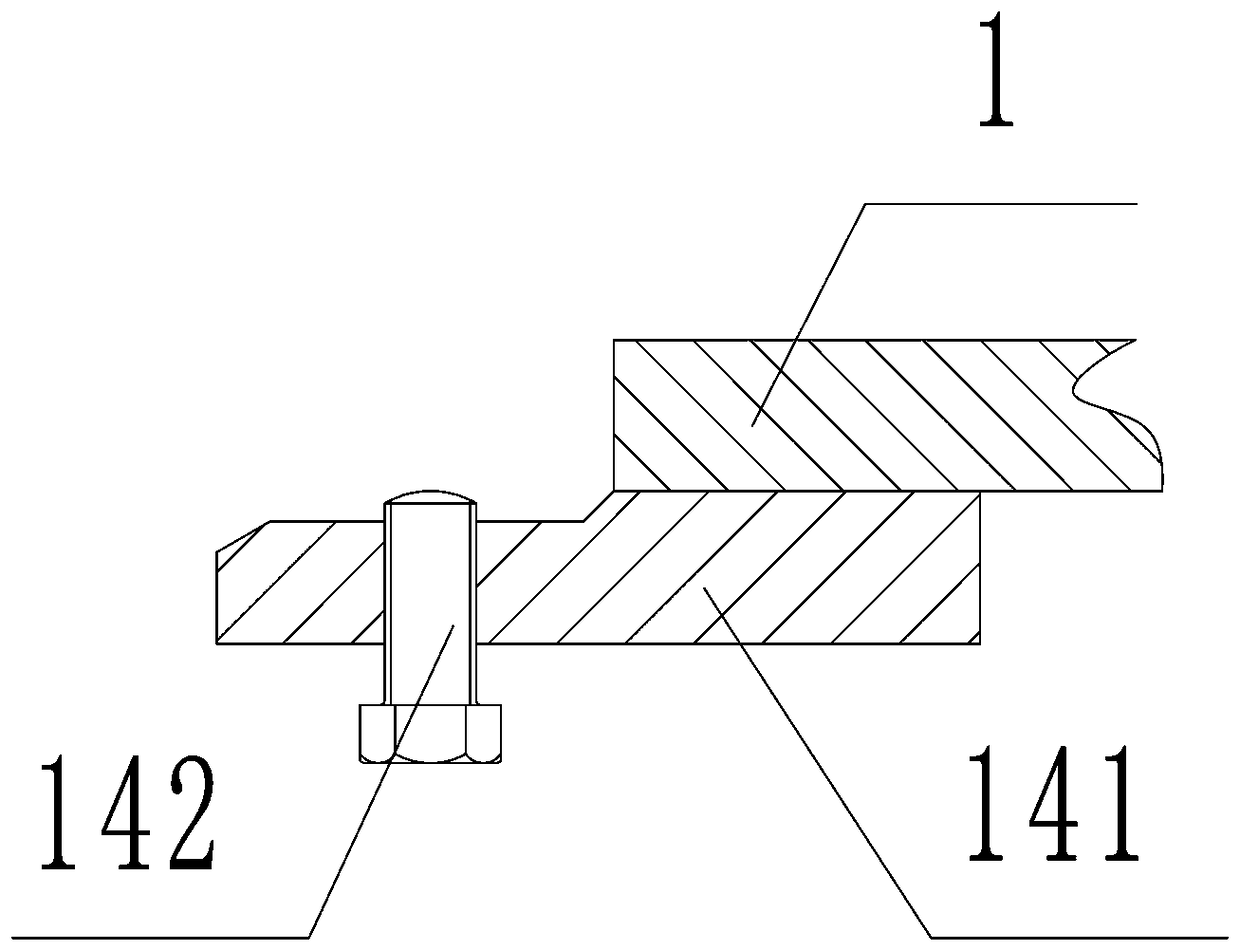

The present invention relates to a vertical rotary bed ultragravity field device, which is used for water disposing in environmental protection and for the aggrandizement of the physics and chemistry reaction in the process of atmosphere disposing. The device is also suitable to be used in the mass transfer and the reaction process of the multiphase liquid in various chemical industries. The device comprises a barrel-shaped upright shell with an air inlet arranged at the side. The middle of the shell is provided with a vertical rotating element, while the lower part of the shell is provided with a waste liquid bypass outlet. The middle of the rotating element is provided with an air guide barrel, the lower part of the air guide barrel is provided with an air inlet, while the top of the air guide barrel is connected with a demister. The side wall of the rotating element is the rotary packed bed. The whole rotating element is connected with a transmission device which provides power. The upper part of the rotating element is provided with at least three units of bearing guide pulley to form an inner inscribed circle. The rotating element rotates according to the position which is limited by the inscribed circle to bear and guide the rotation of the rotating element. As the device adopts at least three units of bearing guide pulley for supporting, both ends of the rotating element can rotate stably and reliably under the bearing, and the diameter and the volume of the rotating element can be increased. The device is used for the atmosphere disposing.

Owner:ZHEJIANG TIANYU ENVIRONMENTAL PROTECTION EQUIP

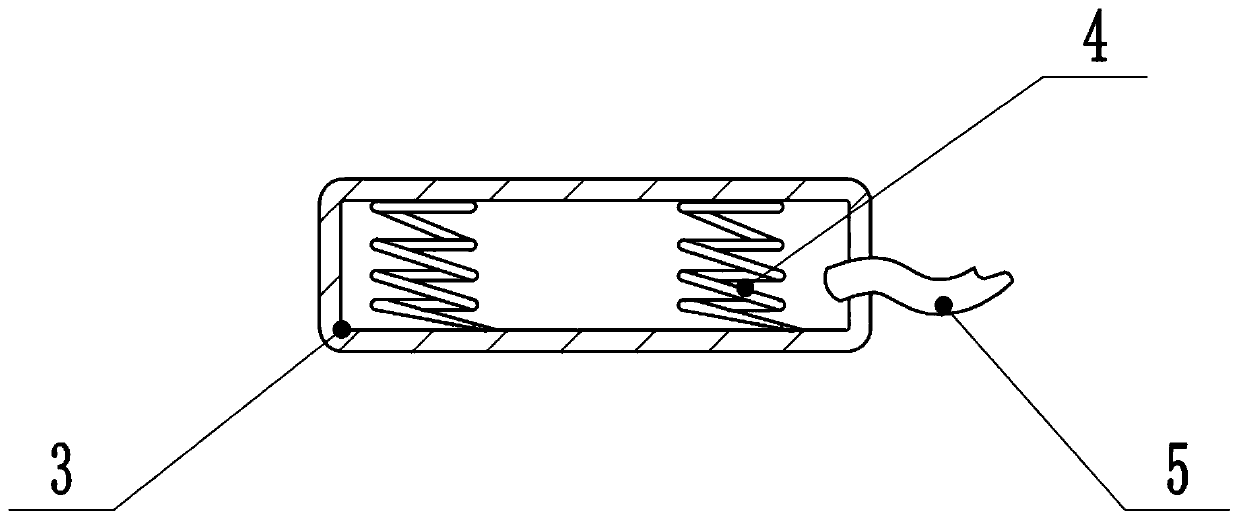

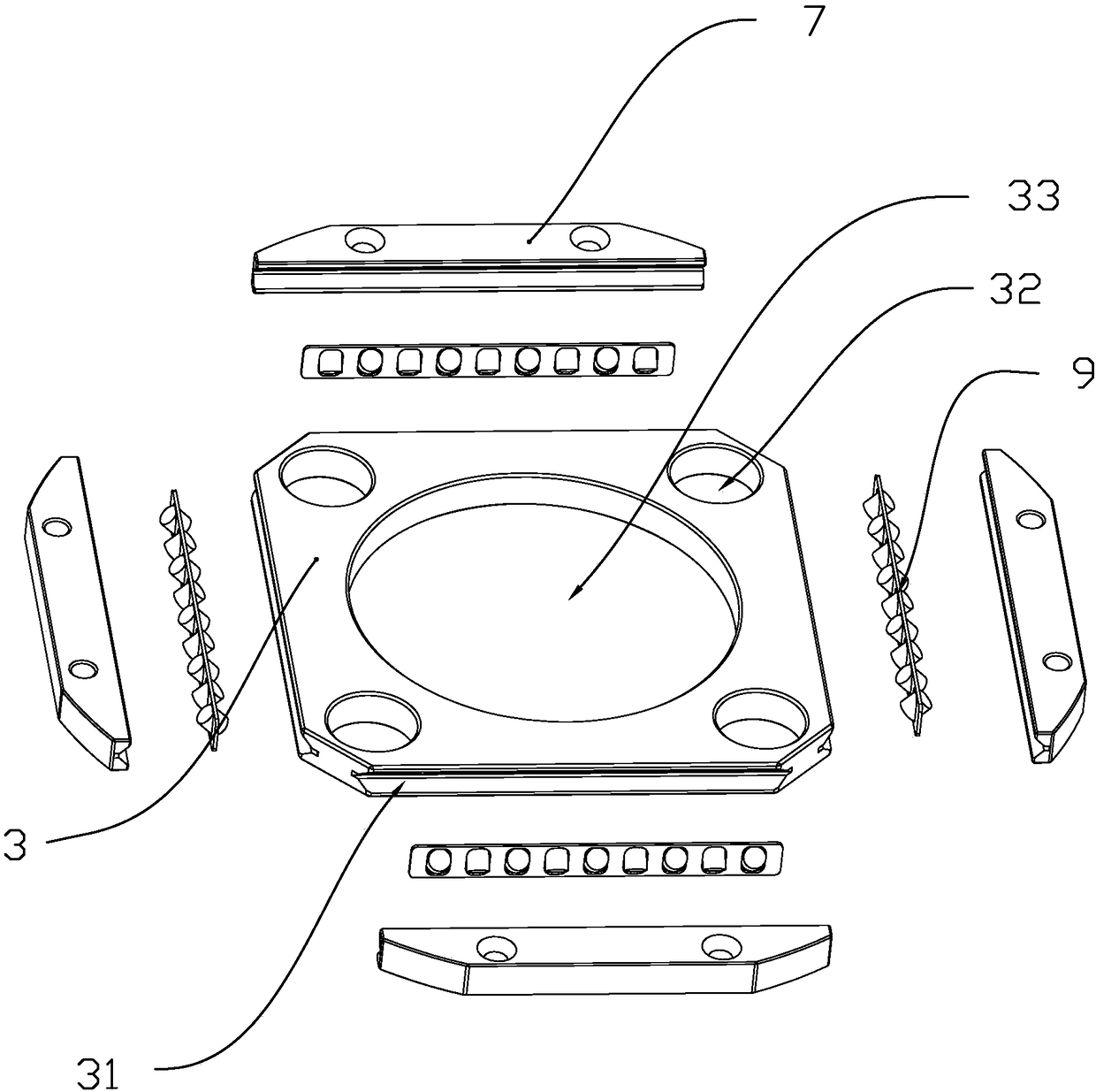

N-rail n-pin type torque suction and discharge device

ActiveCN112096827AAchieve scaleResolve instant conflictsGearingTorque transmissionMechanical engineering

The invention discloses an n-rail n-pin type torque suction and discharge device. The device comprises rails and elastic pins; the multiple rails are coaxially arranged and arranged according to 360 degrees / n equal rotation angles by taking a rail surface of the rail as the reference, and n is a natural number not less than 2 and is the number of the rails; the rail surface is a cylindrical surface or other curved surfaces formed by variable-diameter rotation, and has no rotational symmetry; the elastic pins are arranged corresponding to the number of the rails; the elastic pins inside the adjacent rails are arranged according to the 360 degrees / n equal rotation angles and are mounted coaxially or mounted on the same cylindrical surface; the elastic pins are telescopic assemblies and are arranged in the radial directions of the rails; the pin tips of the elastic pins abut against the rail surface; and either the rail or the elastic pin is fixed on a torque suction and discharge shaft in a manner of simultaneously moving with the torque suction and discharge shaft, and the other one is fixed. According to the single-rail n-pin type torque suction and discharge device, the stretchingand the retracting of the elastic pins are controlled through the cooperation of the elastic pins and the rail surface, so that the problem of instantaneous contradiction between power supply and load requirements is solved through the stretching and the retracting of the elastic pins, and the capacity of the torque transmission peak clipping and valley filling by needs is achieved.

Owner:JIANJIAN TECH (NINGBO) CO LTD

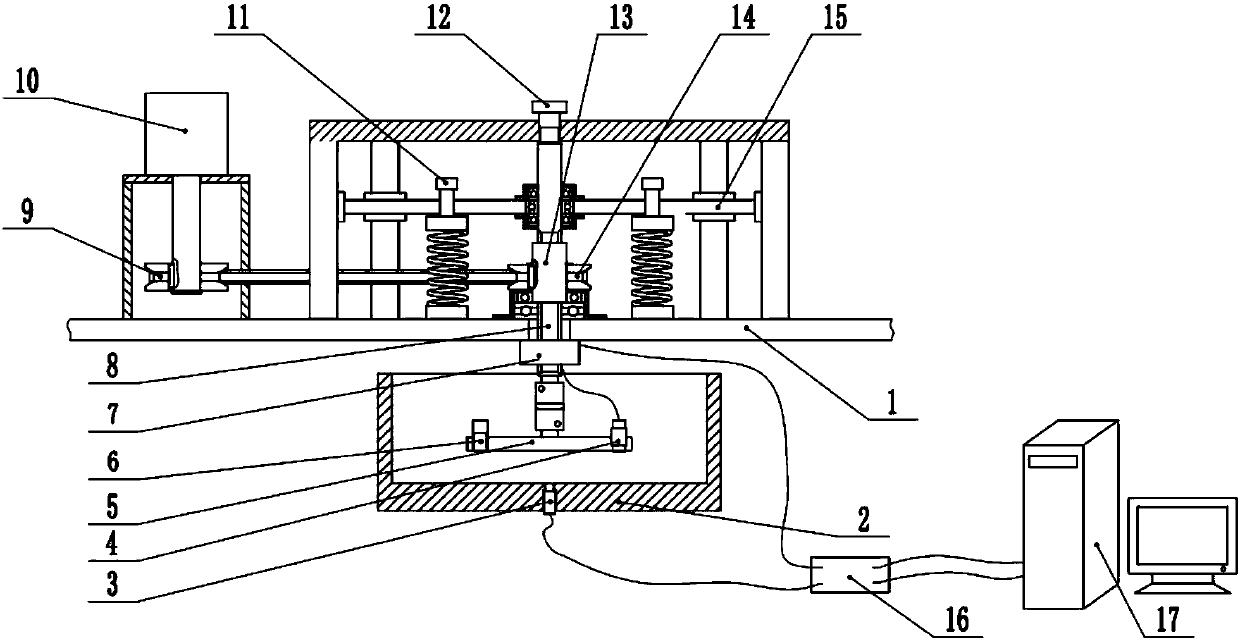

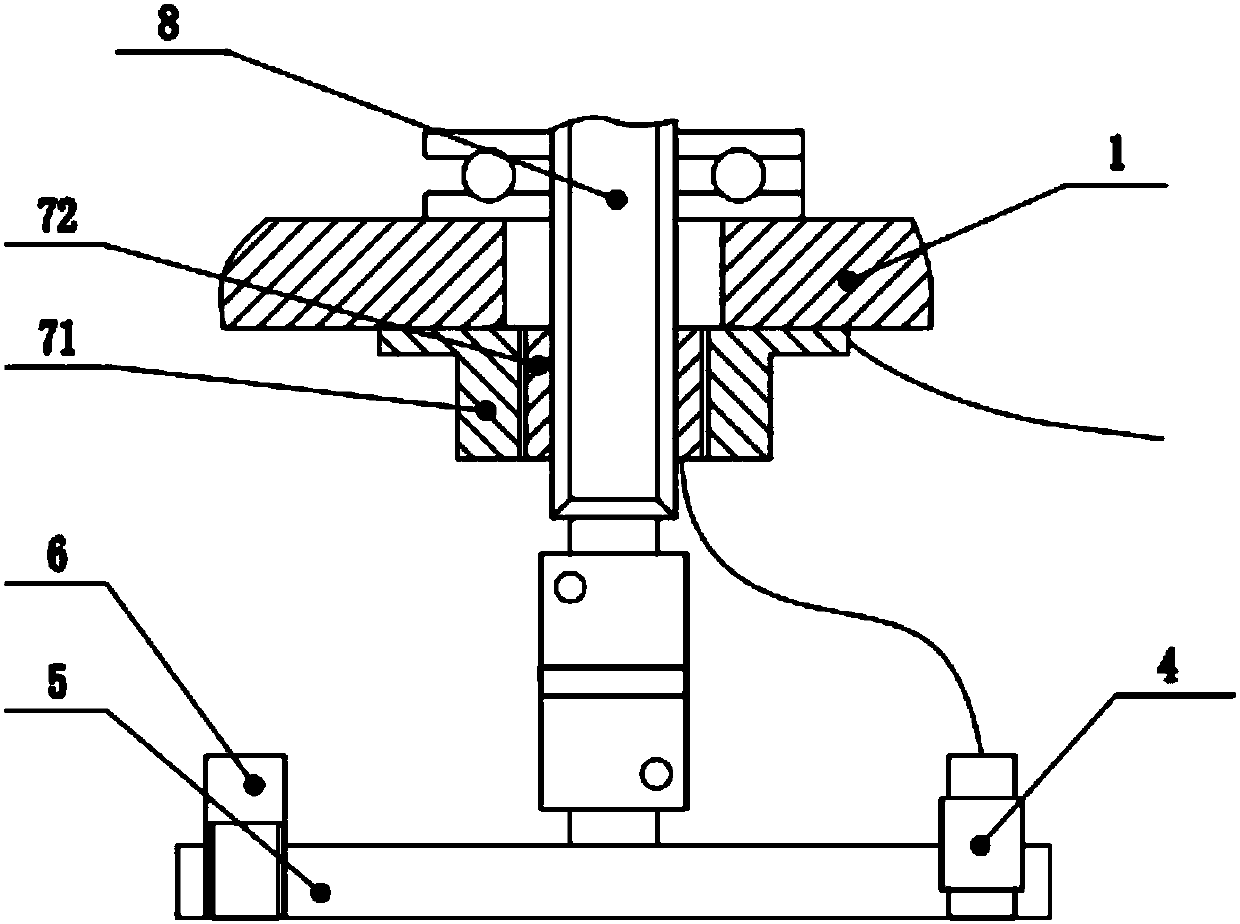

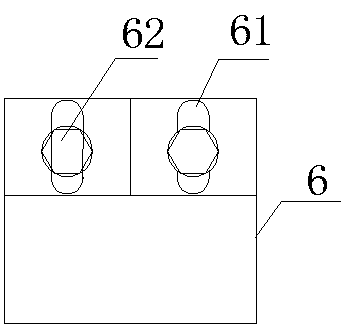

Hydraulic pressure suspension polishing fixed-point fluid pressure detecting system

PendingCN107932201AReal-time measurementSolve the problem of thread tanglingGrinding feed controlMoment of inertiaEngineering

The invention discloses a hydraulic pressure suspension polishing fixed-point fluid pressure detecting system. In a hydraulic pressure suspension polishing device, a groove is formed in the parallel area below a polishing tool disc and internally pasted with workpieces, and the polishing tool disc is mounted at the lower end of a ball spline shaft. The hydraulic pressure suspension polishing fixed-point fluid pressure detecting system comprises pressure sensors, balance adjusting studs and an electric conduction slipping ring. Holes are formed in the position of one of the workpieces and the polishing tool disc, the pressure sensors used for hydraulic pressure measuring are fixed to the position of the workpiece from top to bottom, and the balance adjusting studs are fixed to the positionsof the symmetrical sides of the workpiece in the same mode. The balance adjusting studs and the pressure sensors are equal in weight and rotary inertia. The electric conduction slipping ring is mounted on the ball spline shaft, and an inner ring of the electric conduction slipping ring is matched with the ball spline shaft. An outer ring of the electric conduction slipping ring is fixed to the bottom of a middle supporting plate. Connecting wires of the inner ring of the electric conduction slipping ring are connected with the pressure sensors, and connecting wires of the outer ring of the electric conduction slipping ring are the data output ends. According to the hydraulic pressure suspension polishing fixed-point fluid pressure detecting system, the accuracy is high.

Owner:ZHEJIANG UNIV OF TECH

Electrical spindle drived by AC permanent magnet synchronous motor

InactiveCN101013836AImprove efficiencyReduce noiseSynchronous machine detailsMechanical energy handlingLow noiseElectric machine

The invention discloses one electrical axis driven by alternating permanent simultaneous motor, which comprises outer ring stator and inner ring rotor, wherein, the rotor inside is fixed with electrical axis core; the stator outer ring is covered with cooling cover with spiral tank. The invention is of high efficiency, low noise, reliable operation and small torque.

Owner:DALIAN GUANGYANG SCI & TECH ENG CO LTD

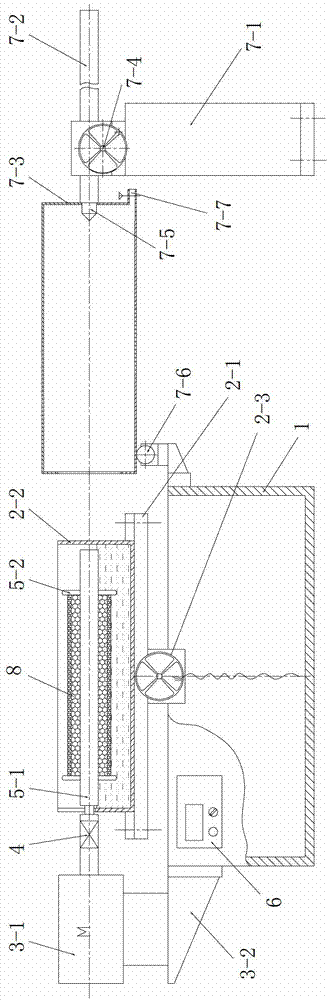

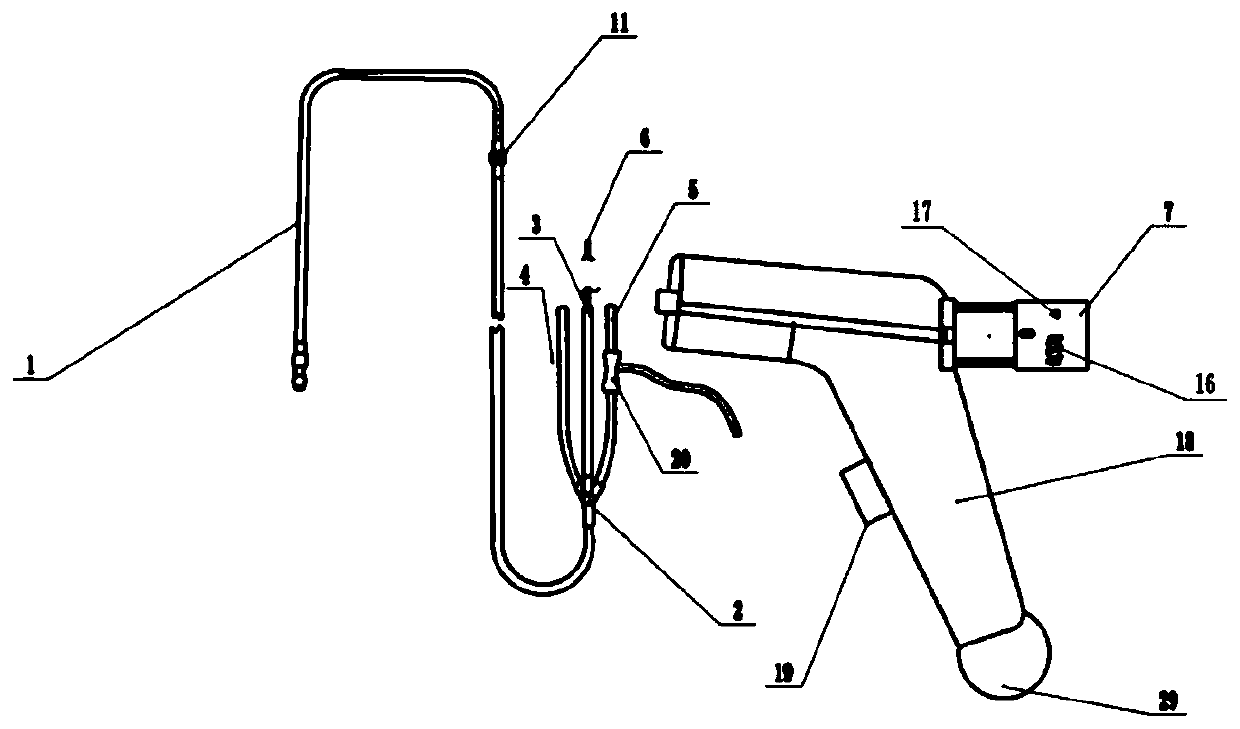

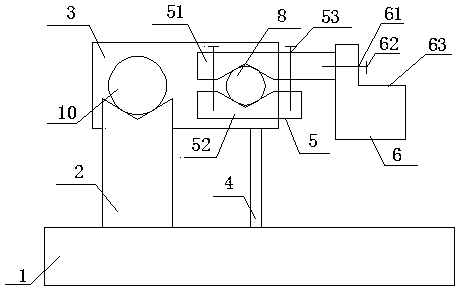

Soaking-centrifugalizing equipment

ActiveCN102962162ASimple structureEasy to operateLiquid surface applicatorsCoatingsControl systemEngineering

The invention discloses soaking-centrifugalizing equipment. The soaking-centrifugalizing equipment comprises a base, a soaking-centrifugalizing device and a slurry recovery device which is arranged at one side of the base and can move forwards and backwards in horizontal direction. The soaking-centrifugalizing device comprises a clamping tool which can continuously rotate and drive a foam filter tube precursor to synchronously rotate when rotating continuously, a soaking device which can move upwards and downwards, a rotary drive motor for driving the clamping tool to continuously rotate, and a control system for controlling and adjusting the rotation direction and the rotation speed of the rotary drive motor; the clamping tool is arranged above the base; a power output shaft of the rotary drive motor is connected with the clamping tool through a transmission mechanism; the clamping tool is arranged horizontally; and the foam filter tube precursor is horizontally arranged on the clamping tool. The soaking-centrifugalizing equipment is simple in structure, convenient to use and operate, safe and reliable in work and high in processing efficiency, realizes slurry recoverability and can be used for finishing the preparation process of various sizes of foam metal filter tubes conveniently and fast.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

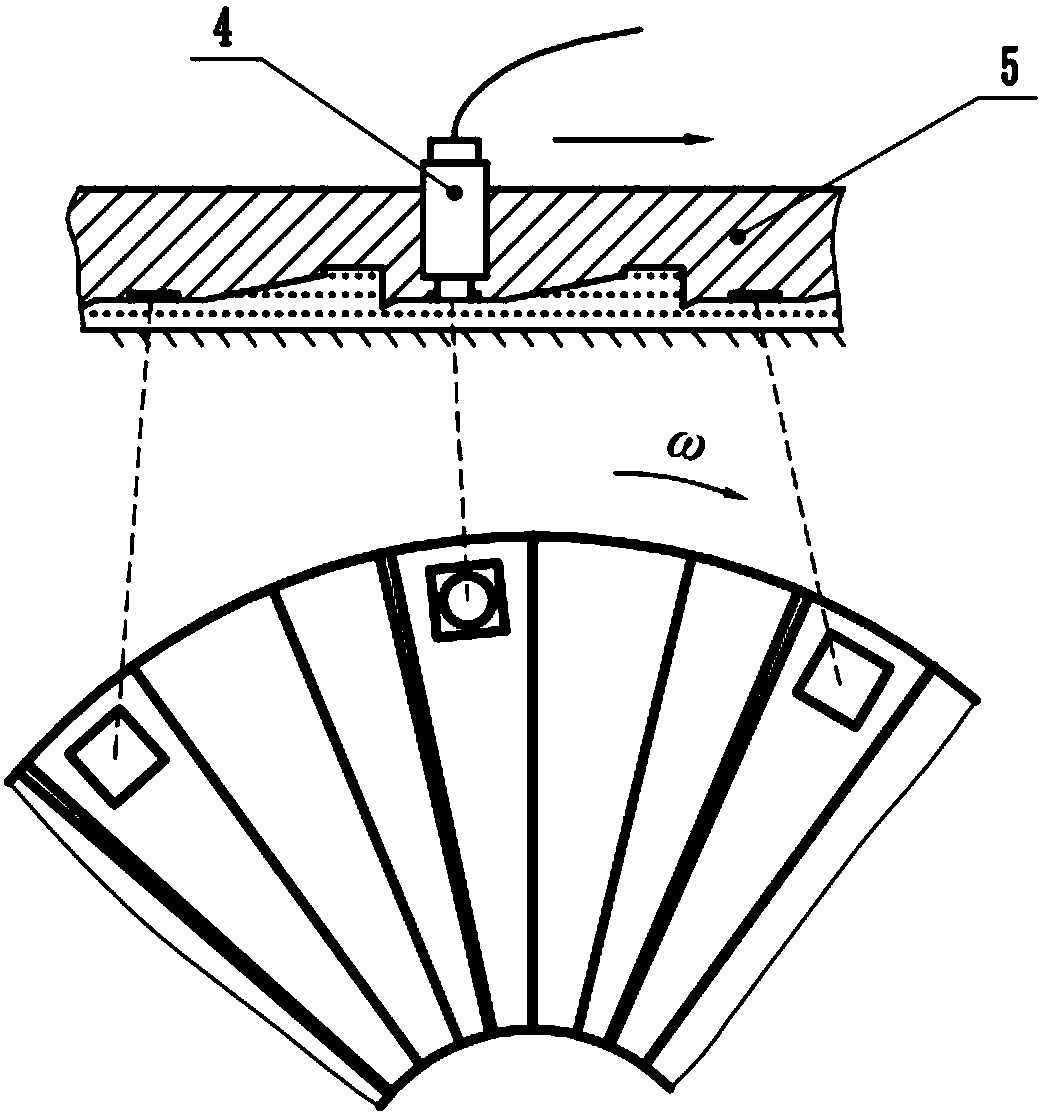

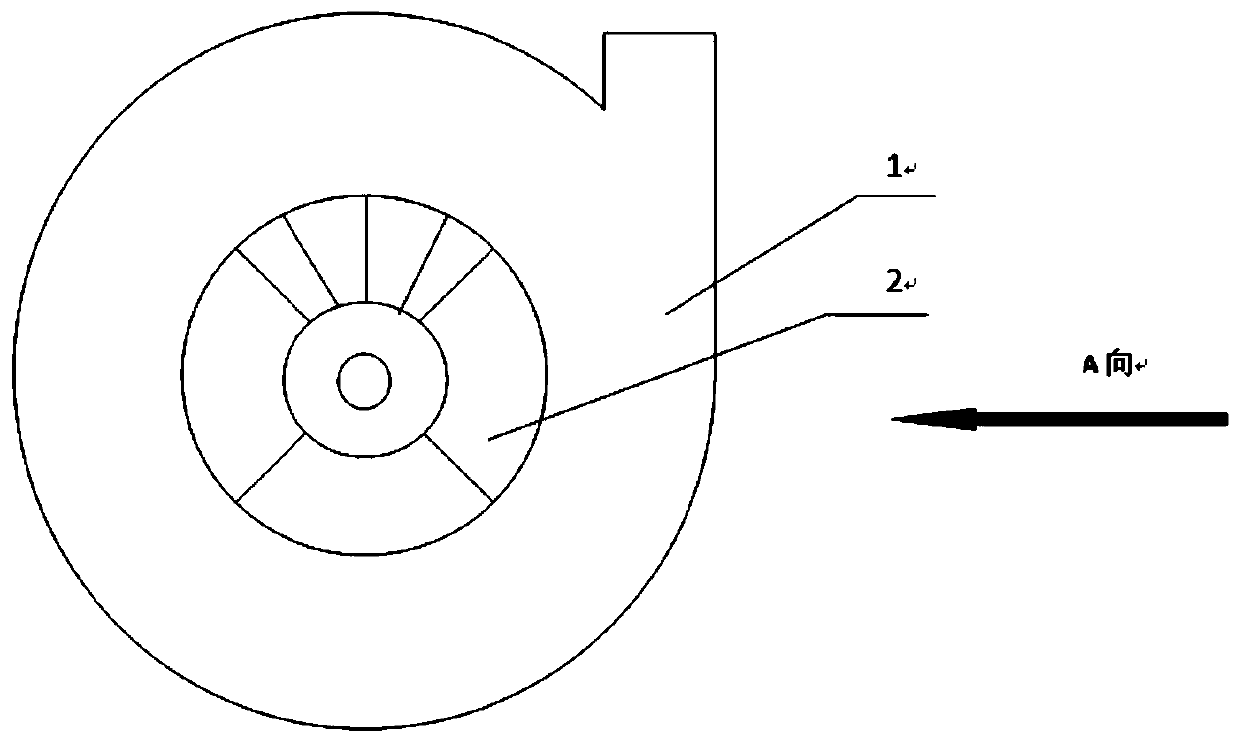

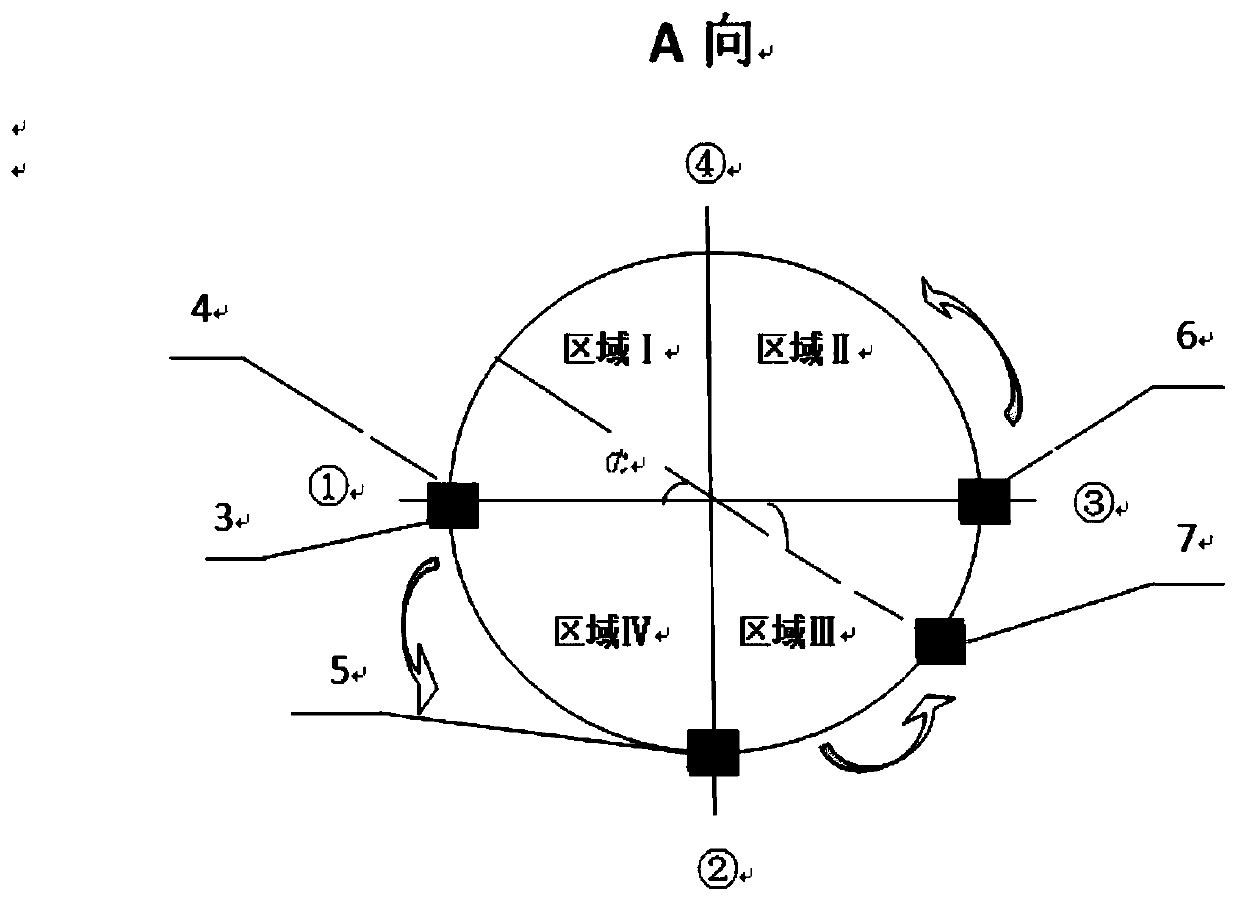

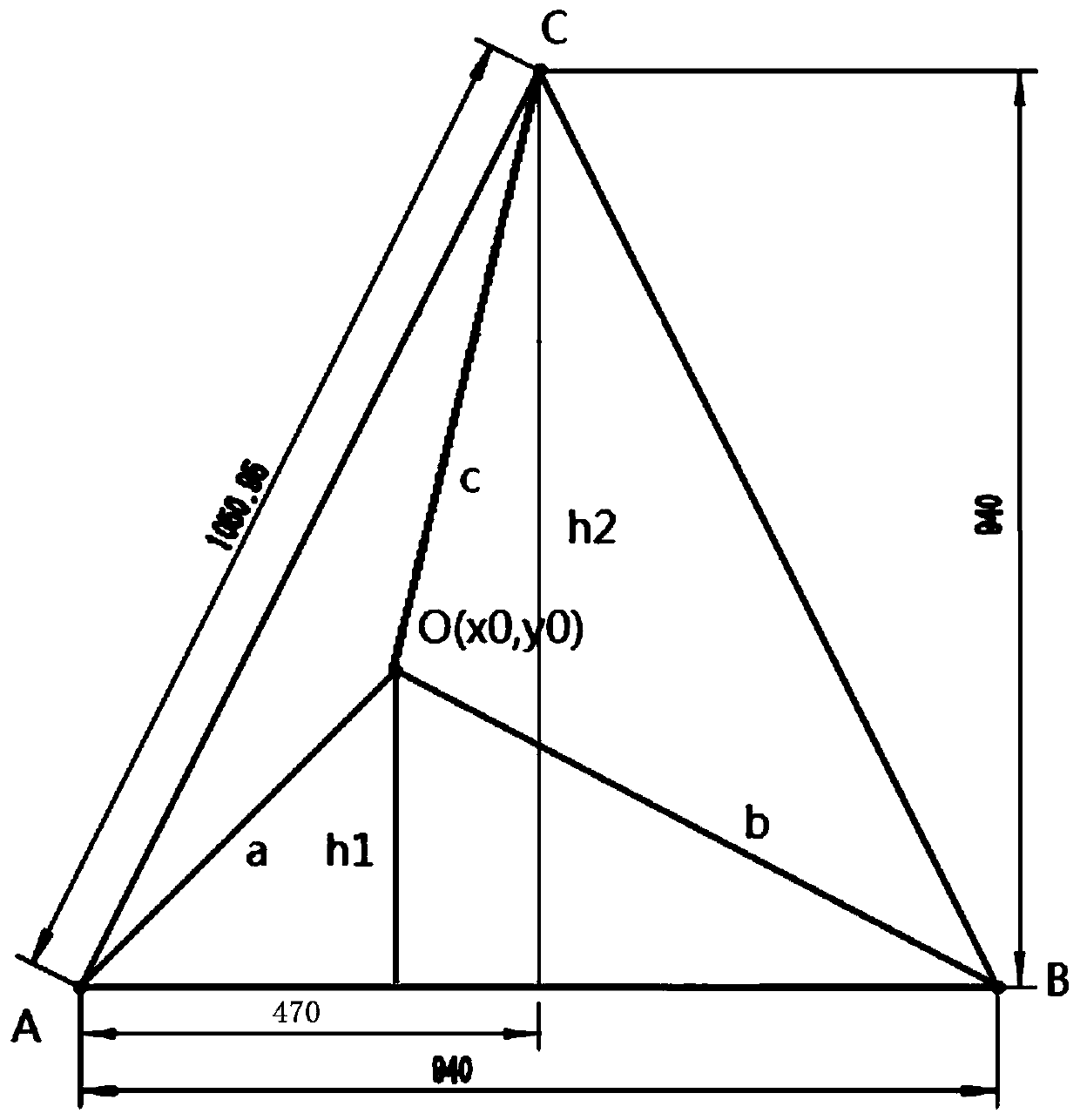

Impeller fan on-site dynamic balance method

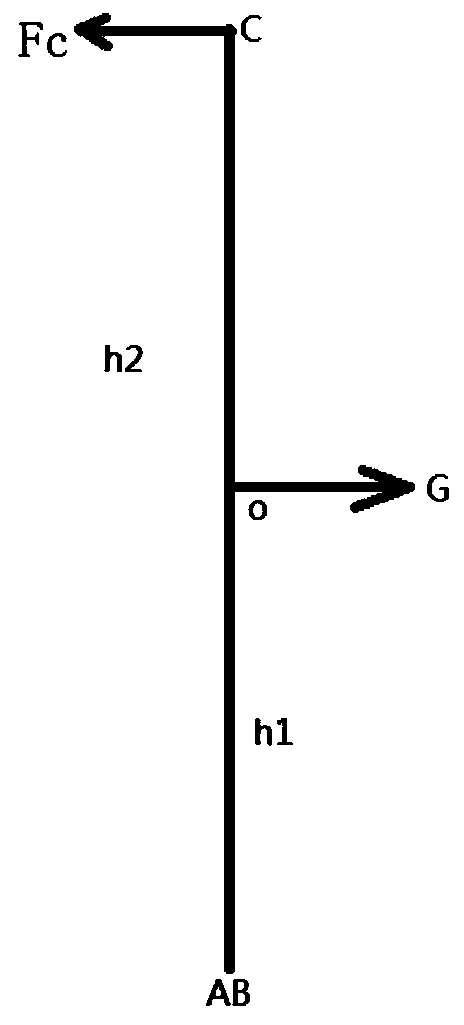

ActiveCN111024312AEasy to measureSolve the dynamic balance problemStatic/dynamic balance measurementWind energy generationImpellerVibration amplitude

The invention relates to an impeller fan on-site dynamic balance method, equipment used for measurement is a vibration meter and a weighing device, the vibration meter is used for measuring the vibration condition of a fan bearing seat, the weighing device is used for weighing the mass of a test weight block, and the test weight block is fixed at the edge of an impeller by a welding method; the original amplitude of the measuring equipment is a0; at four equal division points at the circular edge of an impeller of the impeller fan, amplitudes in the areas 1, 2 and 3 are respectively measured,wherein the amplitudes are a1, a2 and a3 respectively; the weight of the trial weight block is set to be w, the absolute amplitude excited by the trial weight block is set to be X, and the opposite direction of phi is the position needing balance weight; through the formula X2 is equal to (a12 + a32-2 * a02) / 2, x is obtained; COS phi is equal to (a12-a32) / 4X a0, wherein phi is equal to Arc COSy, and W is equal to w. a0 / X; and the opposite direction of the phi value is a counterweight position. And the counterweight point and the weight of the counterweight can be conveniently measured.

Owner:LUXI CHEM GRP

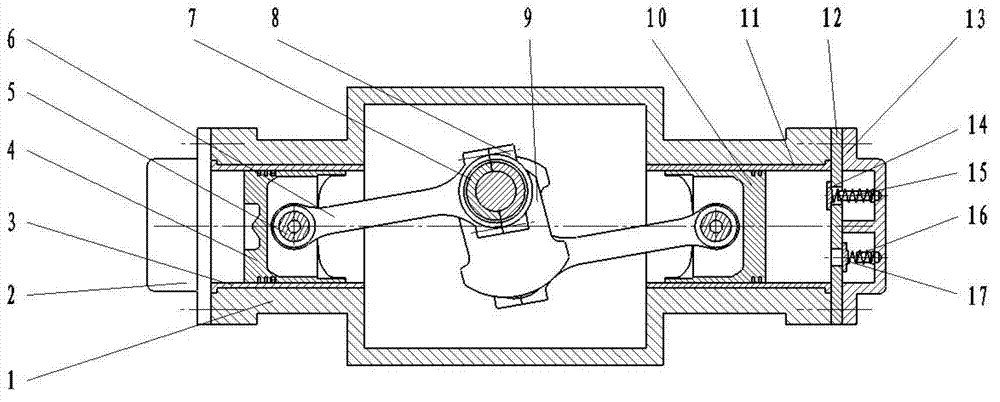

Dynamic balance type internal combustion air compressor

InactiveCN102966511ASolve the vibrationSolve the noisePiston pumpsPositive-displacement liquid enginesAir compressionExhaust valve

The invention belongs to the technical field of compressor equipment, and relates to a dynamic balance type internal combustion air compressor, wherein a power cylinder cover component and a machine body are fixedly connected; the sealing of a power piston and a power cylinder sleeve is realized through a piston ring; the power piston component and a connecting rod body are connected by a piston pin, and further constitute a revolution pair; the connecting rod bodies and a spheroidal graphite cast iron crank shaft of bearing bushes installed in the interiors of connecting rod heads constitute the revolution pairs; the connecting rod bodies and the connecting rod heads are connected into a whole body; an air compression cylinder cover component, a steel valve plate and the machine body are connected into an integral structure; an air compression cylinder sleeve and the machine body are connected; the sealing of an air compression piston component and the air compression cylinder sleeve is realized through the other piston ring; the air compression piston component and the other connecting rod body are connected by the other piston pin, and further constitute the revolution pair; and a suction valve block reset spring and an exhaust valve block reset spring are guided through the utilization of a guide shaft. In addition, the dynamic balance type internal combustion air compressor is reliable in principle, simple in structure, low in preparation cost, high energy conversion efficiency, friendly to the environment, strong in balance function and wide in application.

Owner:QINGDAO UNIV

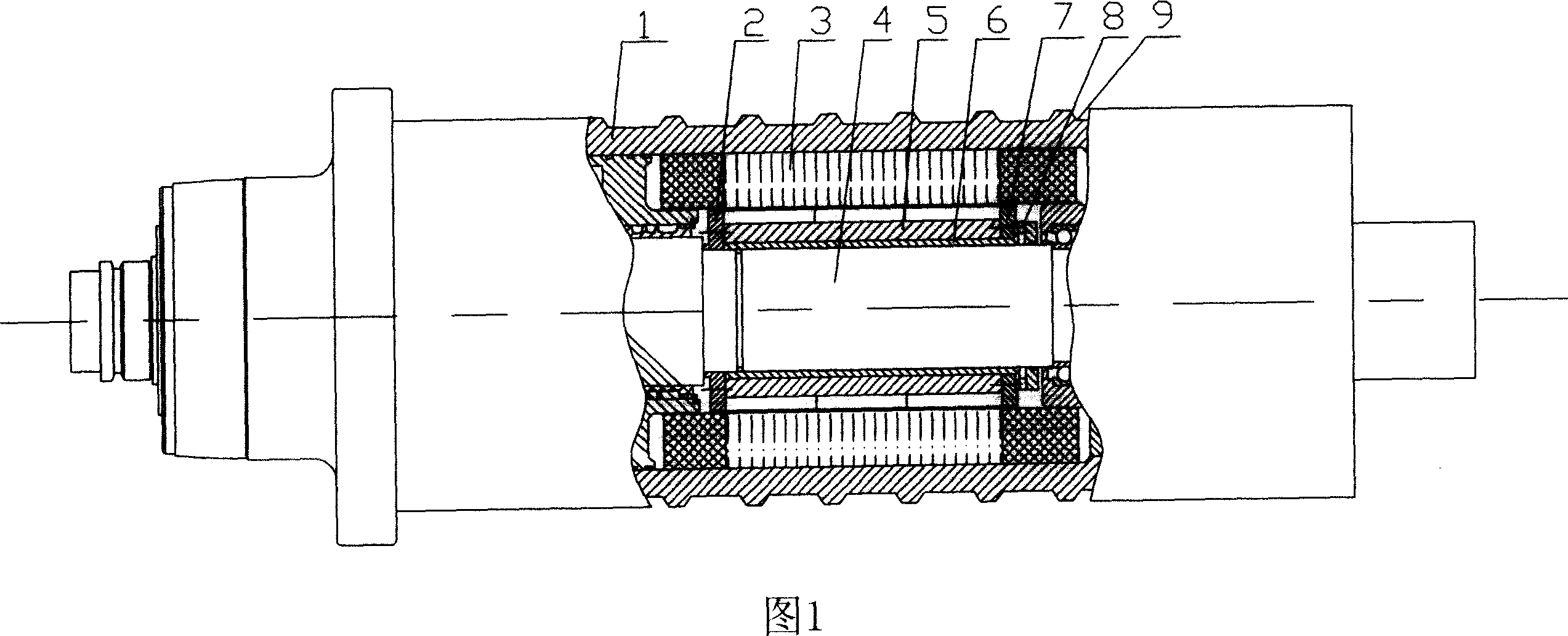

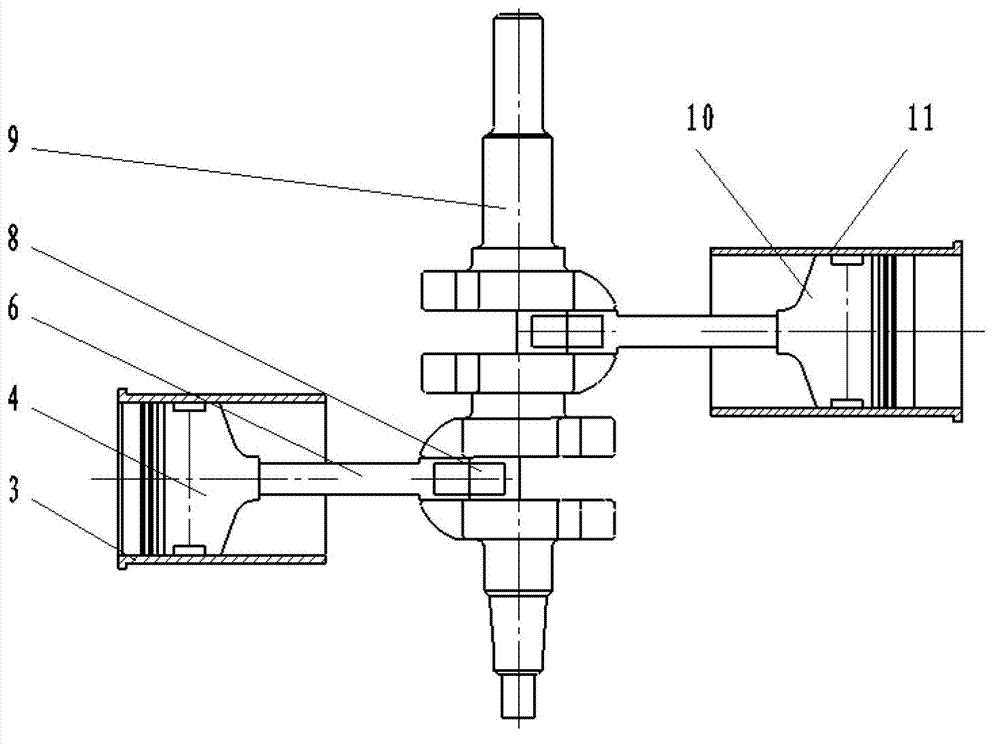

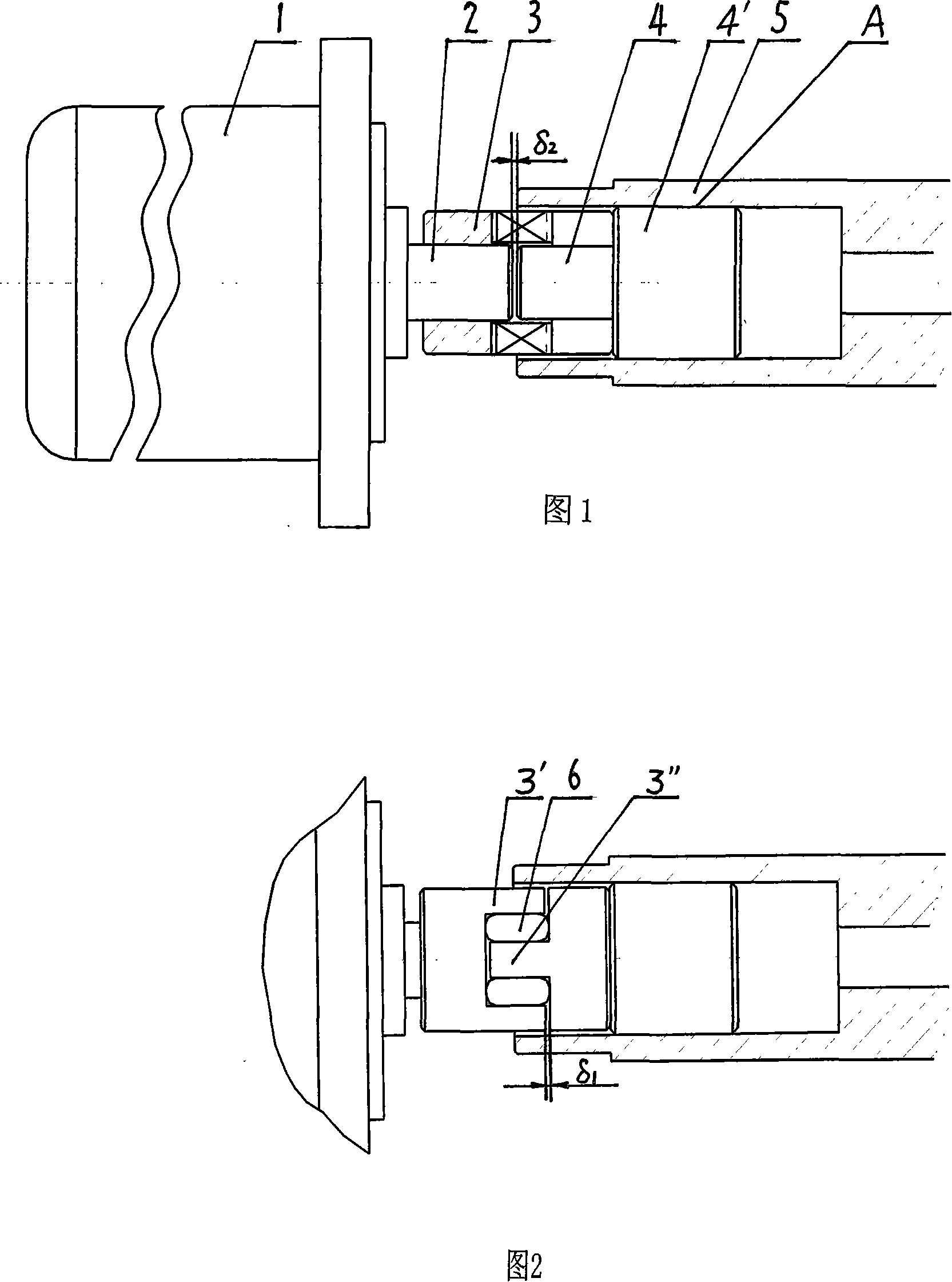

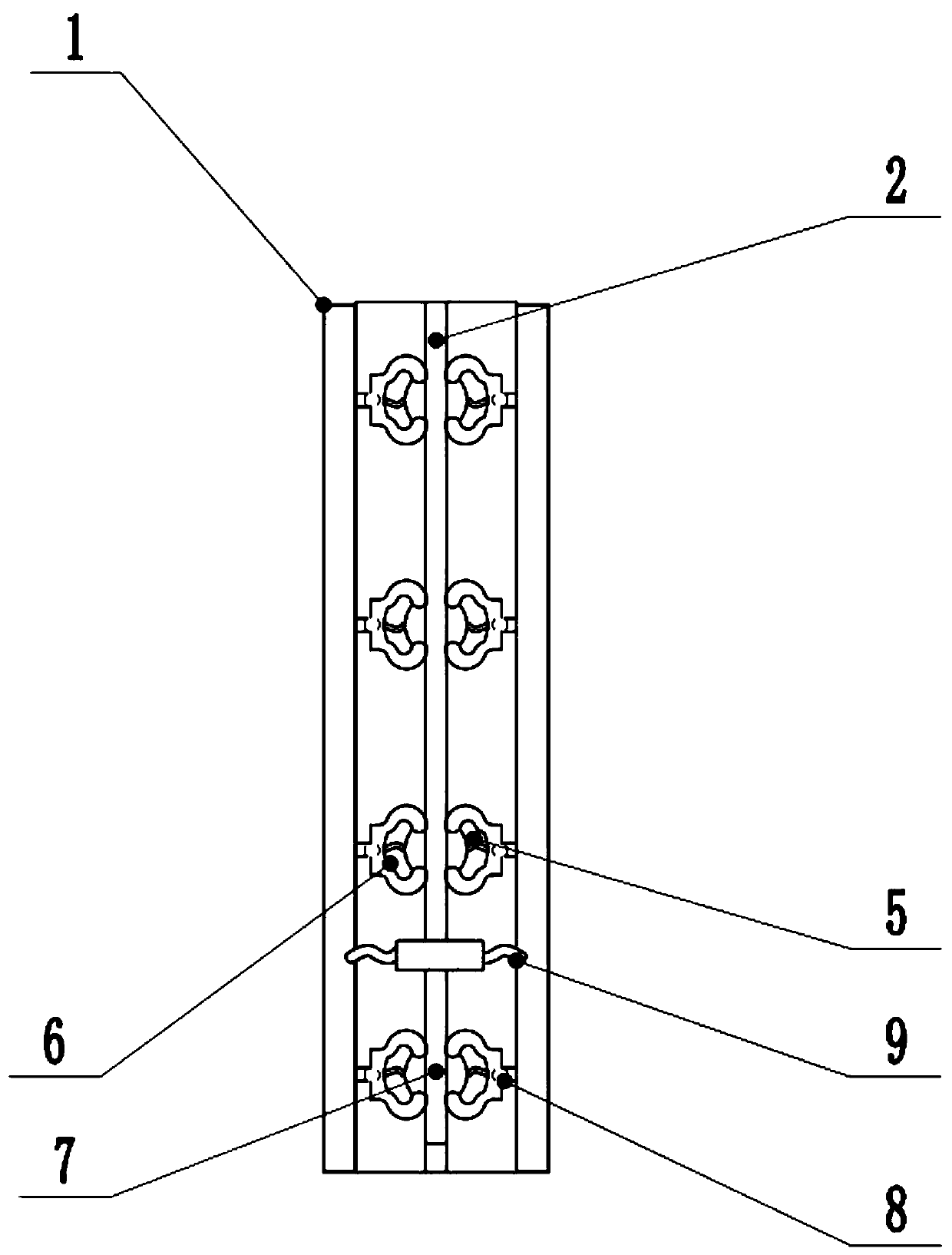

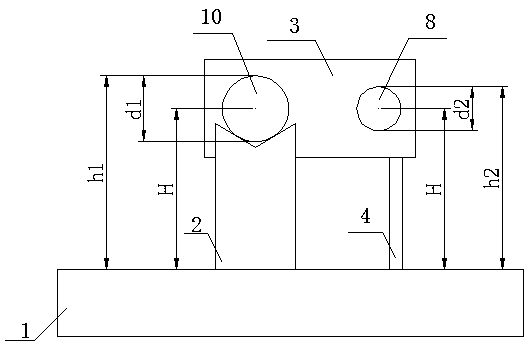

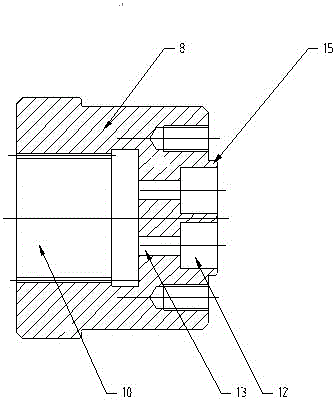

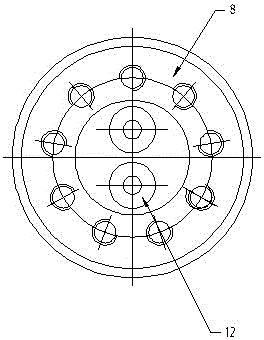

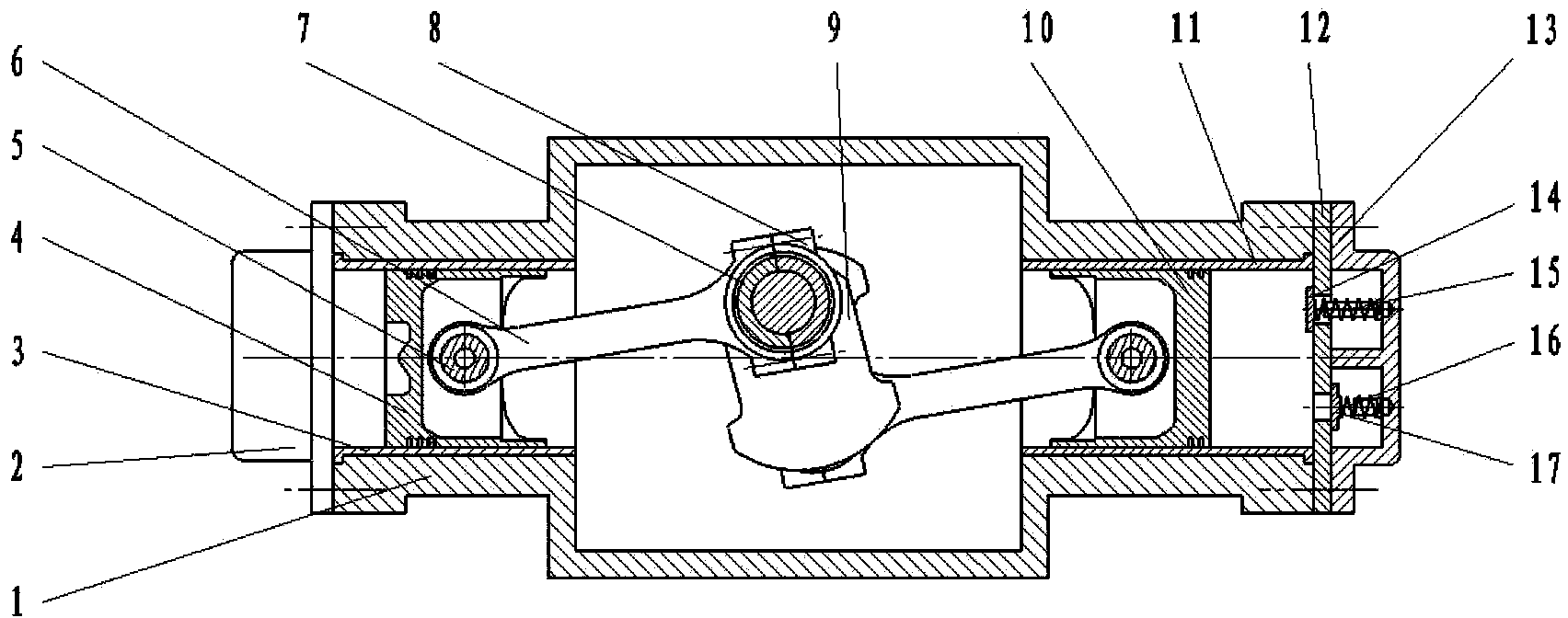

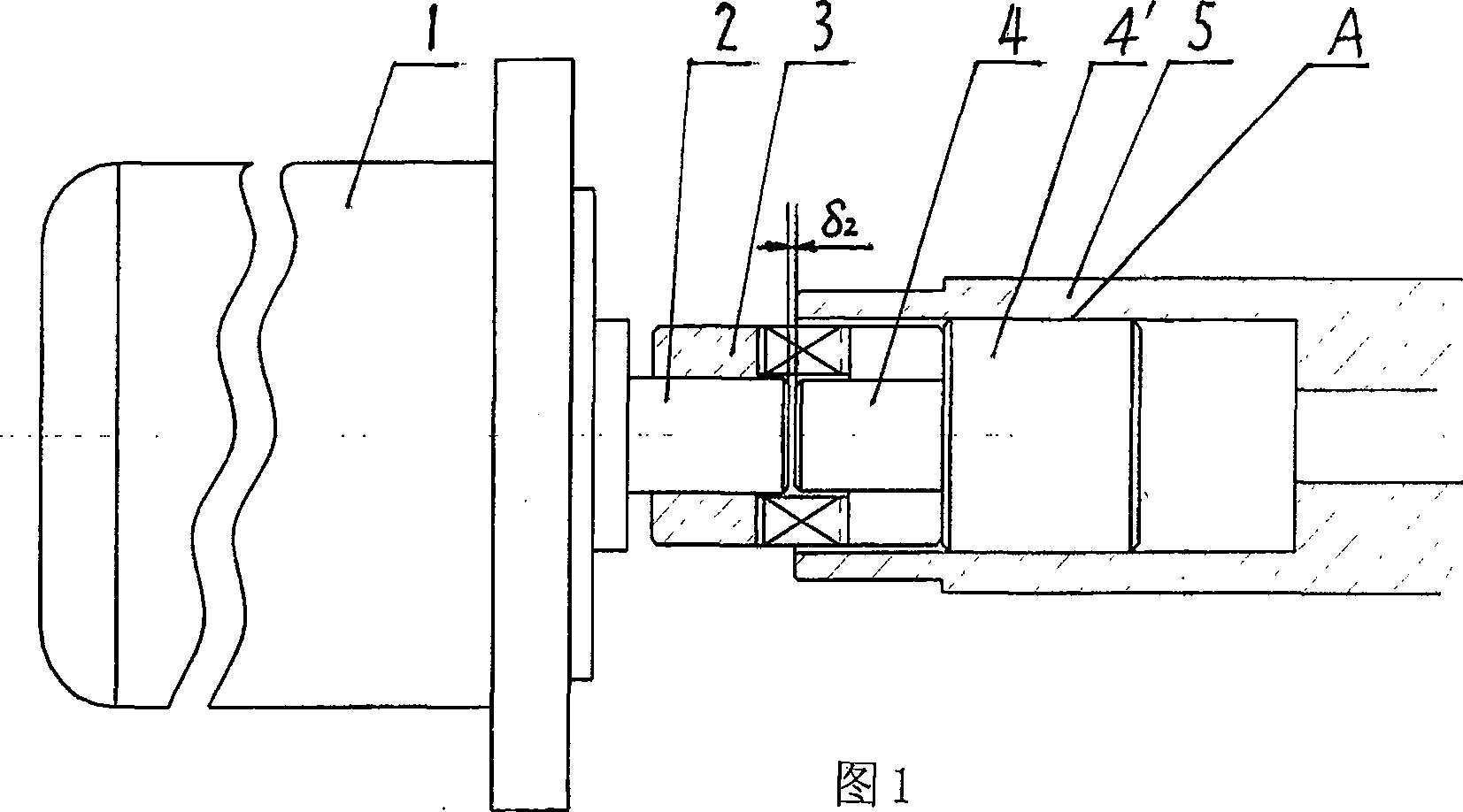

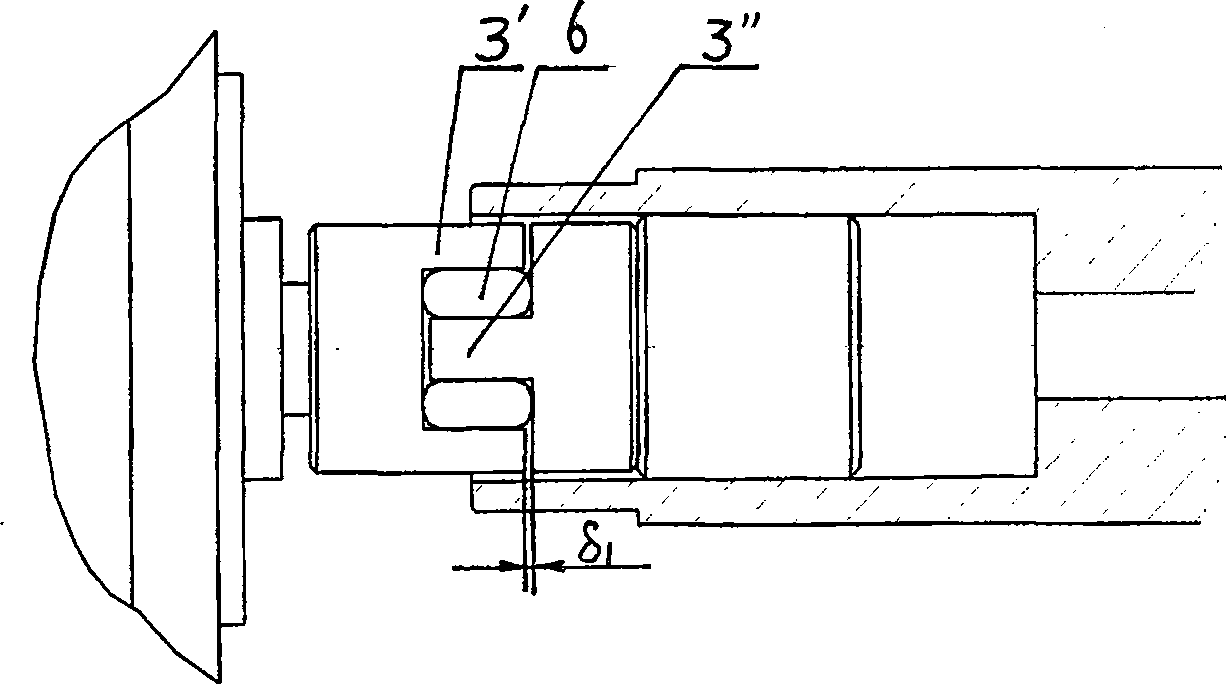

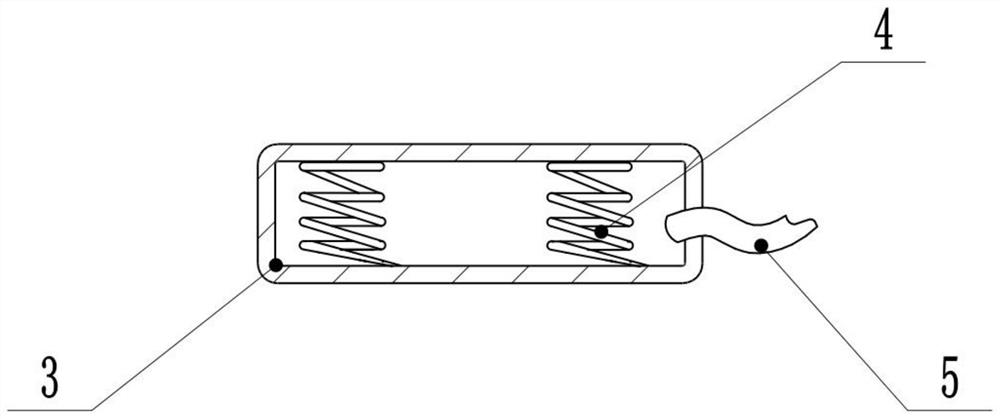

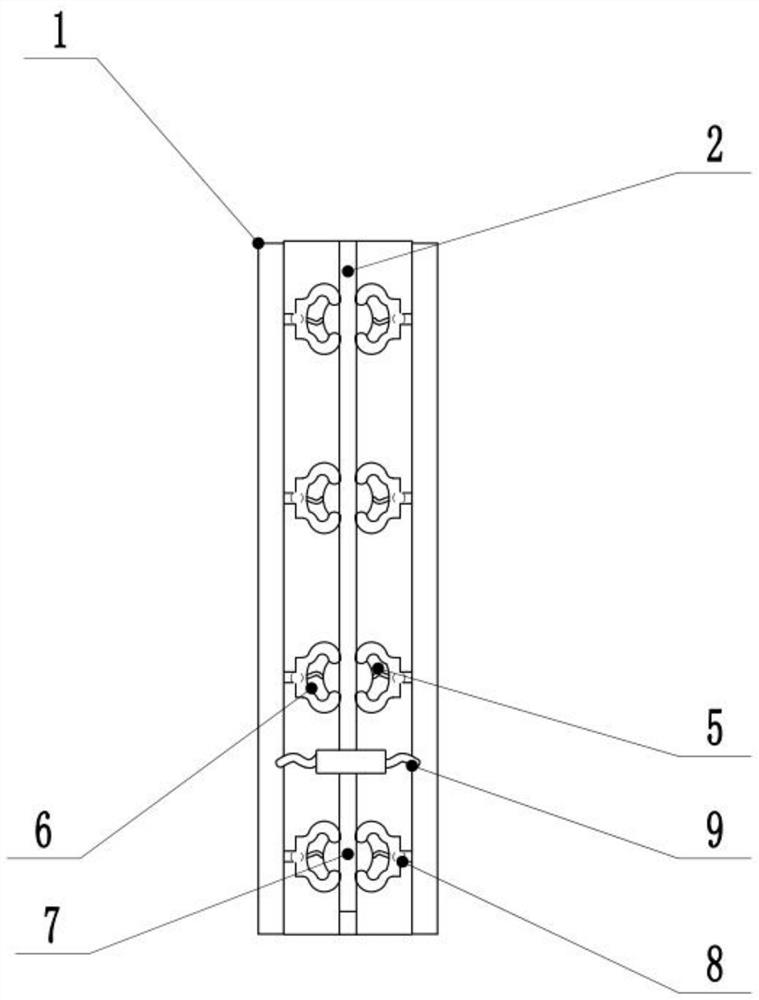

Precision high speed chief axis power transmission connecting mechanism

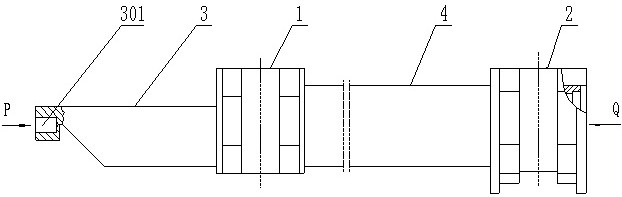

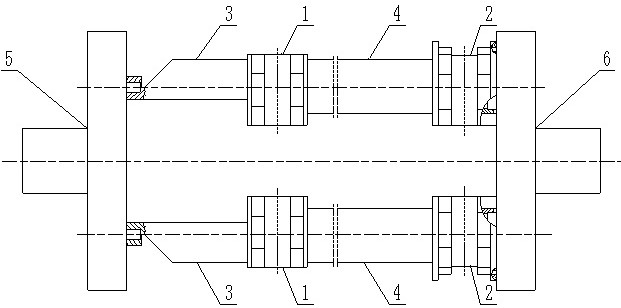

ActiveCN101140014AIncrease preloadPrevent shock vibration and stress concentrationYielding couplingEngineeringSelf locking

The invention relates to a precise high-speed main shaft power drive connecting device; wherein a coupling (3) is the coupling with elastic spider, the interior of a machine tool main shaft is provided with a coaxial conical self-locking transition shaft, and one end of the coupling (3) is connected with a motor output end (2) and its other end is connected with the conical self-locking transition shaft; the conical self-locking transition shaft comprises a cylinder section (4) connected with the coupling and a self-locking conical cylinder section (4') which has the diameter greater than that of the cylinder section and is matched with the inner wall of the machine tool main shaft, and the conicity of a conical surface (A) of the conical cylinder section (4') is 1:50 to 110. The invention can make the power drive reliable, efficient and stable under the high rotation speed, and can effectively reduce the shock produced by the power drive.

Owner:中国机械总院集团云南分院有限公司

Device for sports martial arts single-foot balance force training

The invention discloses a device for sports martial arts single-foot balance force training in the field of martial arts training equipment. The device comprises a rectangular worktable, supporting legs are arranged at the periphery of the bottom of the worktable, a rectangular groove is formed in the middle of the worktable, the width of the groove is the same as that of the foot soles of the human body, and the depth of the groove is the same as the height of the ankles of the human body; the groove is internally provided with four circular air cushions filled with air, the spacing between any two air cushions is 20-30 cm, transversely-placed covering lugs are arranged at the two radial sides of each air cushion, the covering lugs correspond to the air cushions one to one, and each covering lug is communicated with the corresponding air cushion. When a user is supported on one foot after jumping exercise, direct jumping is conducted, according to foot falling rules of jump kicking, when the user falls on the ground, the body is supported with one foot, when the foot is in contact with the air cushions, the heel of the user is stressed to be lifted, then only the foot sole is in contact with the groove, after the air cushions are stressed, the air is squeezed into the covering lugs, and after the covering lugs are inflated and expanded, the ankle of the user is clamped to be prevented from being injured.

Owner:宫拼物 +1

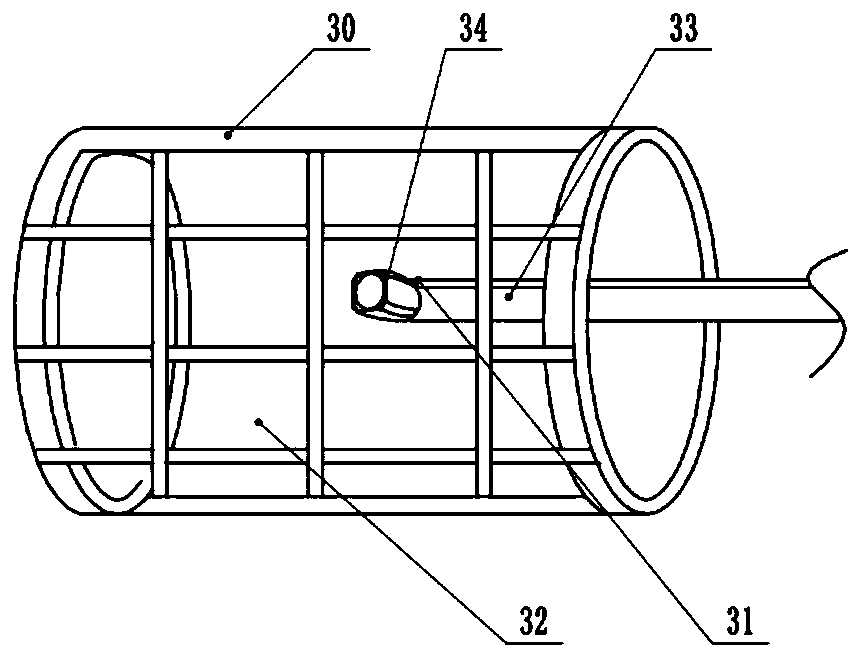

Visual pelvic floor puncture device and auxiliary equipment thereof

PendingCN110916773AGood estimateImprove flushing effectCannulasEnemata/irrigatorsInjury blood vesselPelvic diaphragm muscle

The invention discloses a visual pelvic floor puncture device and auxiliary equipment thereof in the field of medical instruments, and aims to reduce the risk that blood vessels, nerves and surrounding important organs are damaged by blind puncture in the current vaginal pelvic floor reconstruction (TVM) operation process. The device comprises a cylindrical transparent sleeve for supporting a lacuna space, an internal camera shooting component and a visual system connected with the outside for observation, wherein the outer surface of the sleeve is divided into a plurality of fine hollow grids; a mirror sheath of a visual operation kit is fixed in the center of a base in the sleeve; and the visual operation kit comprises an endoscope positioned in the mirror sheath and a high-definition display screen for displaying an endoscope image. Compared with the traditional TVM operation process, the visual pelvic floor puncture device has the advantages that blind puncture is converted into visual puncture, so that the puncture part is more accurate, the operation effect is more exact, and the risk of damage to blood vessels, nerves and surrounding important organ tissues caused by blind puncture can be greatly reduced; and the device is integrally designed, is simple and convenient to operate, does not need carbon dioxide to establish pneumoperitoneum, is low in cost and can be disinfected and repeatedly used.

Owner:重庆市妇幼保健院

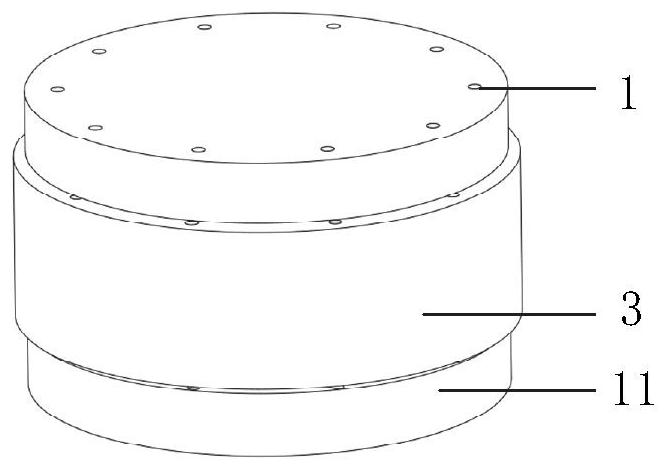

Vertical rotating bed super gravity field equipment

InactiveCN100546689CSmooth and reliable rotationReduce vibrationChemical/physical/physico-chemical stationary reactorsChemical/physical/physico-chemical moving reactorsChemical industryChemical reaction

The invention is a vertical rotating bed supergravity field equipment, which is used for strengthening physical and chemical reactions between phases in water treatment and atmospheric treatment in the environmental protection industry, and is also suitable for mass transfer of multi-phase systems in various chemical industries and reaction process. It includes a barrel-shaped upright casing with an air inlet on the side, a vertical rotating body in the middle of the casing, a waste liquid return outlet at the bottom of the casing, an air guide barrel in the middle of the rotating body, and a There is an air inlet, the top of the air guide barrel is connected with the demister, the side wall of the rotating body is a rotating packing bed, the whole rotating body is connected with the transmission device that provides power, and at least three sets of supporting guides are arranged on the upper part of the rotating body The wheels form an inscribed circle, and the rotating body rotates according to the position defined by the inscribed circle to support and guide the rotation of the rotating body. At least three sets of supporting guide wheels are used to support the rotating body to rotate stably and reliably when both ends are supported, and the diameter and volume of the rotating body can be increased for the treatment of large volumes.

Owner:ZHEJIANG TIANYU ENVIRONMENTAL PROTECTION EQUIP

Amorphous alloy high-speed outer rotor permanent magnet motor

PendingCN112953059AReduce temperature riseLow iron loss at high frequencyMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMagnetic poles

The invention discloses an amorphous alloy high-speed outer rotor permanent magnet motor, which comprises a permanent magnet outer rotor, an amorphous alloy inner stator and an air gap, wherein the outer rotor adopts a three-section Halbach array+combined magnetic pole structure, the maximum magnetic energy product of magnetic steel in the middle of a magnetic pole is larger than that of the same type of magnetic steel which is symmetrical on two sides, and the thickness, the space angle, the magnetizing angle and the coercive force of the magnetic steel are all obtained through optimization so as to ensure that the harmonic distortion rate of no-load air gap flux density of the motor is minimum, and therefore torque fluctuation of the permanent magnet motor is restrained; an iron core of the inner stator is formed by iron-based amorphous alloy strips through overlying and linear cutting so as to reduce high-frequency iron loss; and the cross section of the stator slot wedge is of a special-shaped structure, and protrusions of the cross section in the axial direction of the slot wedge are 0.1-0.2 mm higher than a notch and the parts level with the notches alternately appear, so that the amorphous alloy stator iron core is prevented from being collided by the permanent magnet outer rotor when the motor is assembled or disassembled. The outer rotor high-speed permanent magnet motor is suitable for high-efficiency, high-speed and stable operation occasions.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Machining method of wing-shaped missile shaft high-precision part

The invention provides a machining method of a wing-shaped missile shaft high-precision part. The machining method includes the following steps that a target wing-shaped part is split into welding single pieces according to the structure of the part; each welding single piece is machined; the single pieces are assembled and welded to form a missile wing assembly, and vibration is performed to relieve the stress; two missile wing assemblies are taken, an auxiliary machining device is used for clamping the two missile wing assemblies at the same time, and the two missile wing assemblies and theauxiliary machining device form a revolving body structure; and machining is performed continuously, and the auxiliary machining device is removed until a target wing-shaped part is formed. Accordingto the method, the space virtual point in the central position of the missile wing is changed into the actually-existing central axis by the aid of the auxiliary machining device, so that the arc of the missile wing forms a symmetrical and measurable circle, in-situ detection is completed, and the purpose of real-time monitoring is achieved; meanwhile, unification of the design benchmark, the process benchmark and the detection benchmark is realized, no positioning and detection errors are generated in processing and detection, symmetrical processing of the missile wing is realized, and the dynamic balance problem during machining in the grinding process is solved.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

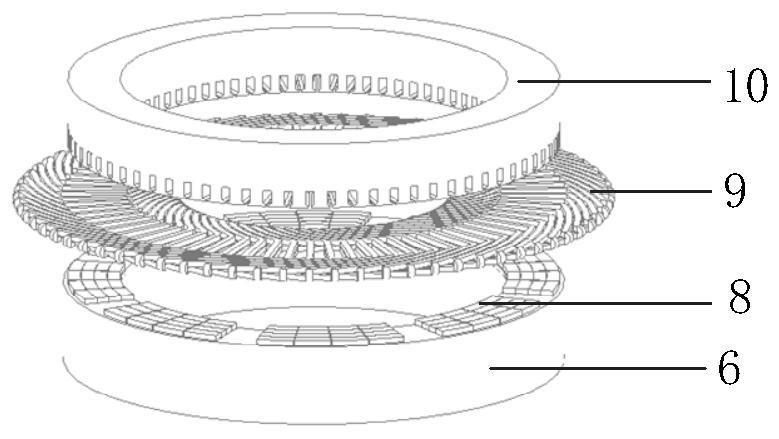

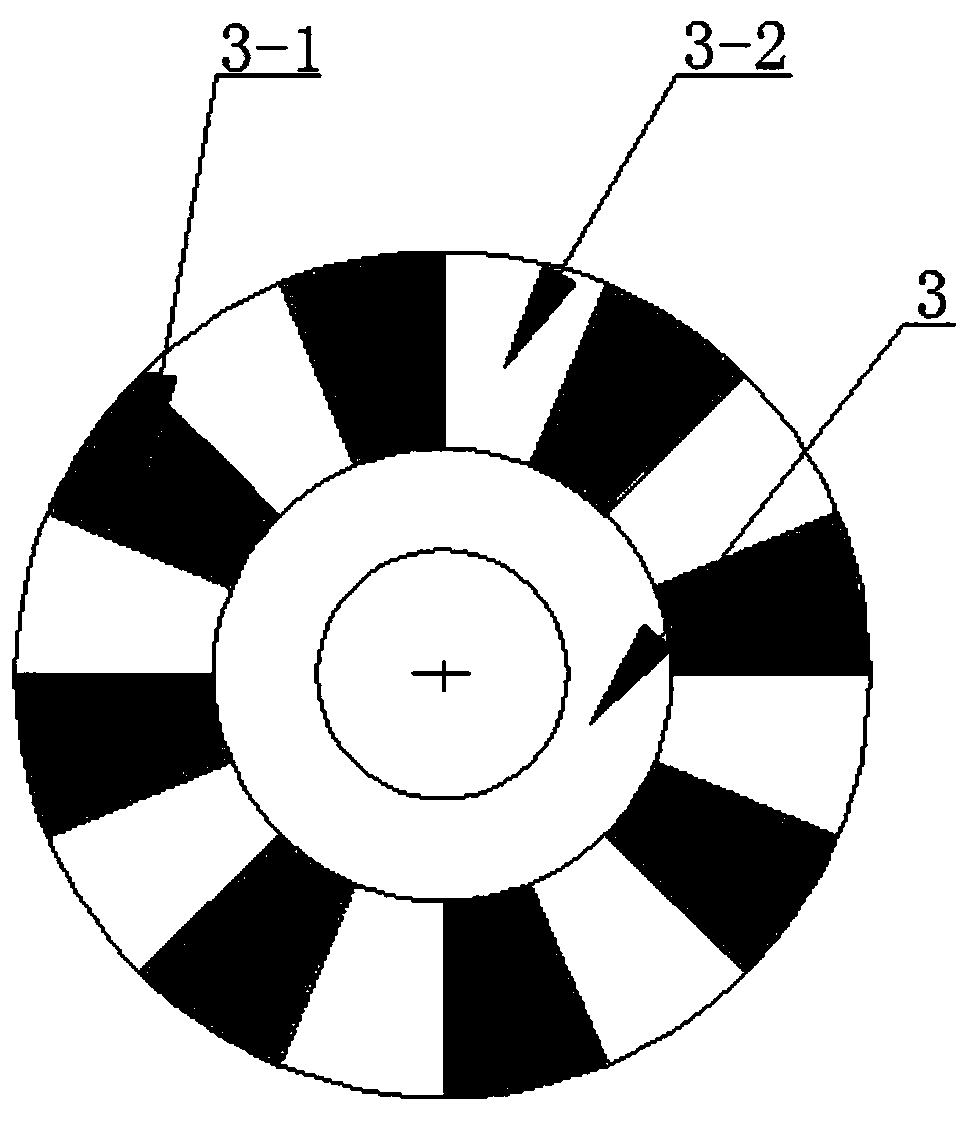

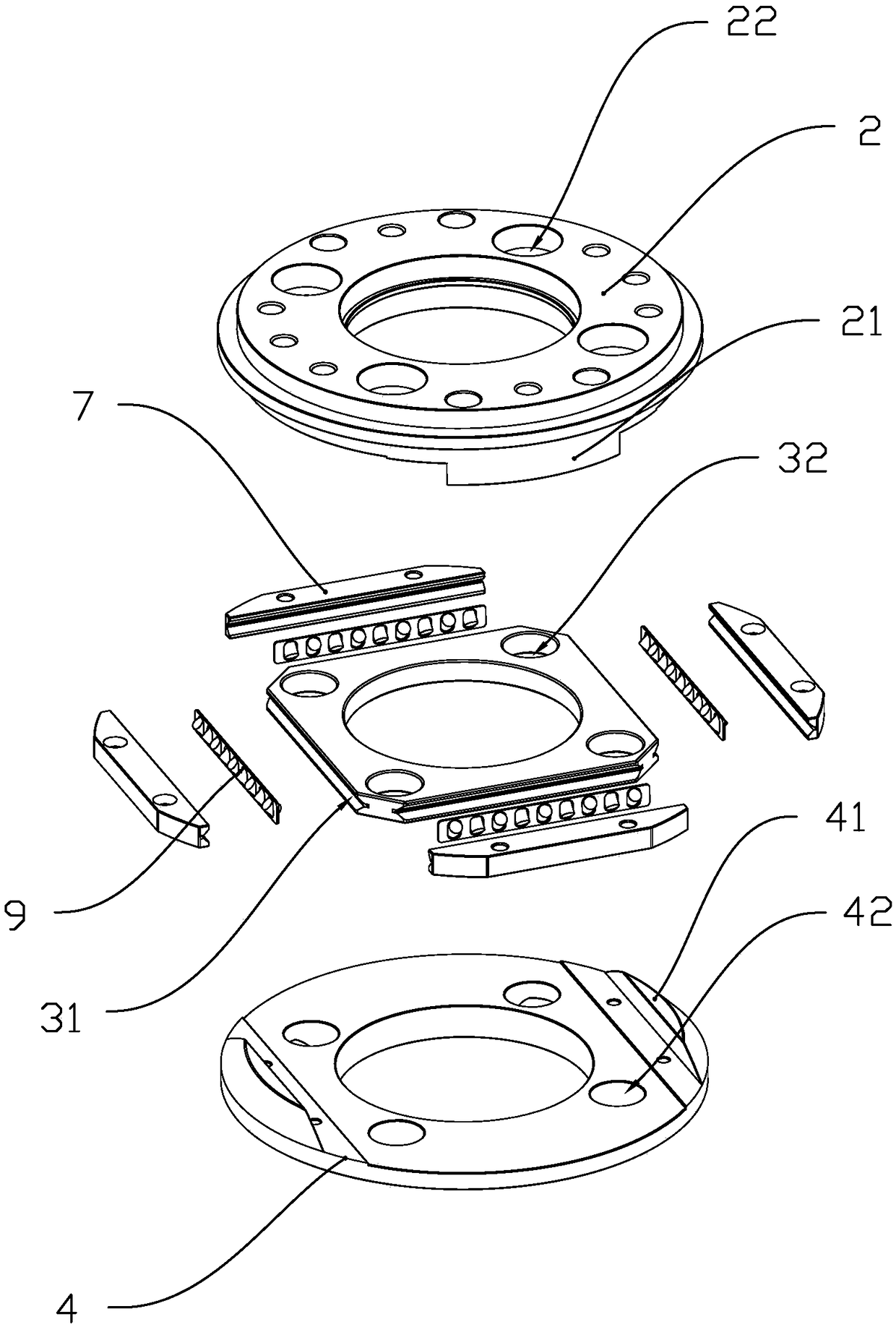

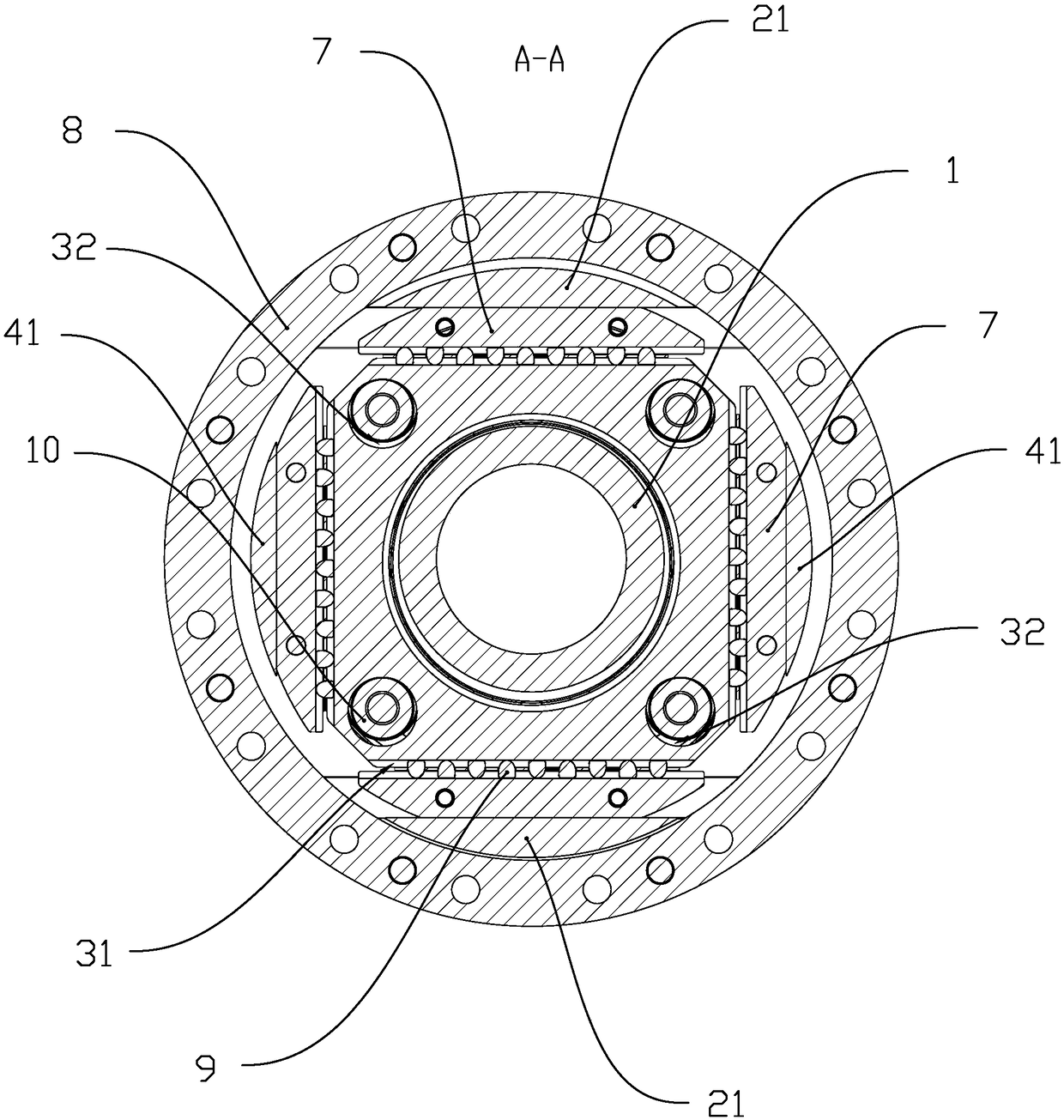

Disc type permanent magnet synchronous motor, energy storage flywheel and method

ActiveCN113131706ASolve processing problemsTo achieve the effect of complementary promotionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePermanent magnet synchronous motor

The invention provides a disc type permanent magnet synchronous motor, an energy storage flywheel based on magnetic suspension support and a method. The disc type permanent magnet synchronous motor comprises an upper stator disc and a lower rotor disc. The stator disc comprises a stator iron core, the stator iron core comprises stator teeth and a stator yoke, an armature winding is a short-moment distribution winding and is wound on the stator teeth, and winding coils are arranged in a double-layer mode in the axial direction. The rotor disc is composed of a rotor yoke disc and permanent magnets of which the N poles and S poles are arranged in a staggered manner in the circumferential direction, wherein the number of magnetic poles of the permanent magnets is uniform and the permanent magnets are embedded on the upper surface of the rotor yoke. The structure of the motor for the energy storage flywheel is optimized, the motor is an axial magnetic flux motor, the flywheel rotor serves as a magnetic conductive yoke disc of the lower rotor disc, the motor and the generator are integrated, mutual inverse operation of electric / power generation is achieved, the motor can work in an electric state and a power generation state, and the structure of a flywheel energy storage system is simplified.

Owner:SHANDONG UNIV

Alignment Tooling and Alignment Method for Multiple Crankshafts of Hybrid Fiber Multiaxial Warp Knitting Machine

ActiveCN106624766BImprove assembly accuracySolve the dynamic balance problemMetal working apparatusFiberDynamic balance

The invention relates to the technical field of crankshaft centering, in particular to a multi-crankshaft centering tool of a hybrid fiber multiaxial warp knitting machine and a centering method. The centering tool comprises a crankshaft; and the crankshaft is provided with a main shaft neck and a connecting rod shaft neck. The centering tool further comprises a flat plate, a V block, a spiral lifting device, an adjuster, an L-shaped adjusting block, a horizontal plate and a coupling; the V block is placed on the flat plate; the main shaft neck is placed on the V block; the spiral lifting device is placed on the flat plate rightly below the connecting rod shaft neck; the connecting rod shaft neck is fixedly provided with the adjuster through bolt connection; and the L-shaped adjusting block is horizontally and fixedly mounted on the adjuster through bolt connection. In consideration of difficult guarantee of the machining precision and the matching precision of a key slot and a flat key, the centering tool improves the crankshaft assembly precision, naturally solves the crankshaft dynamic balance problem caused by introduction of the key slot and the flat key, and reduces the machining cost.

Owner:中国机械总院集团江苏分院有限公司

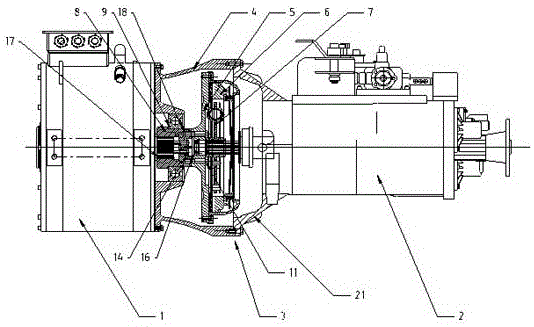

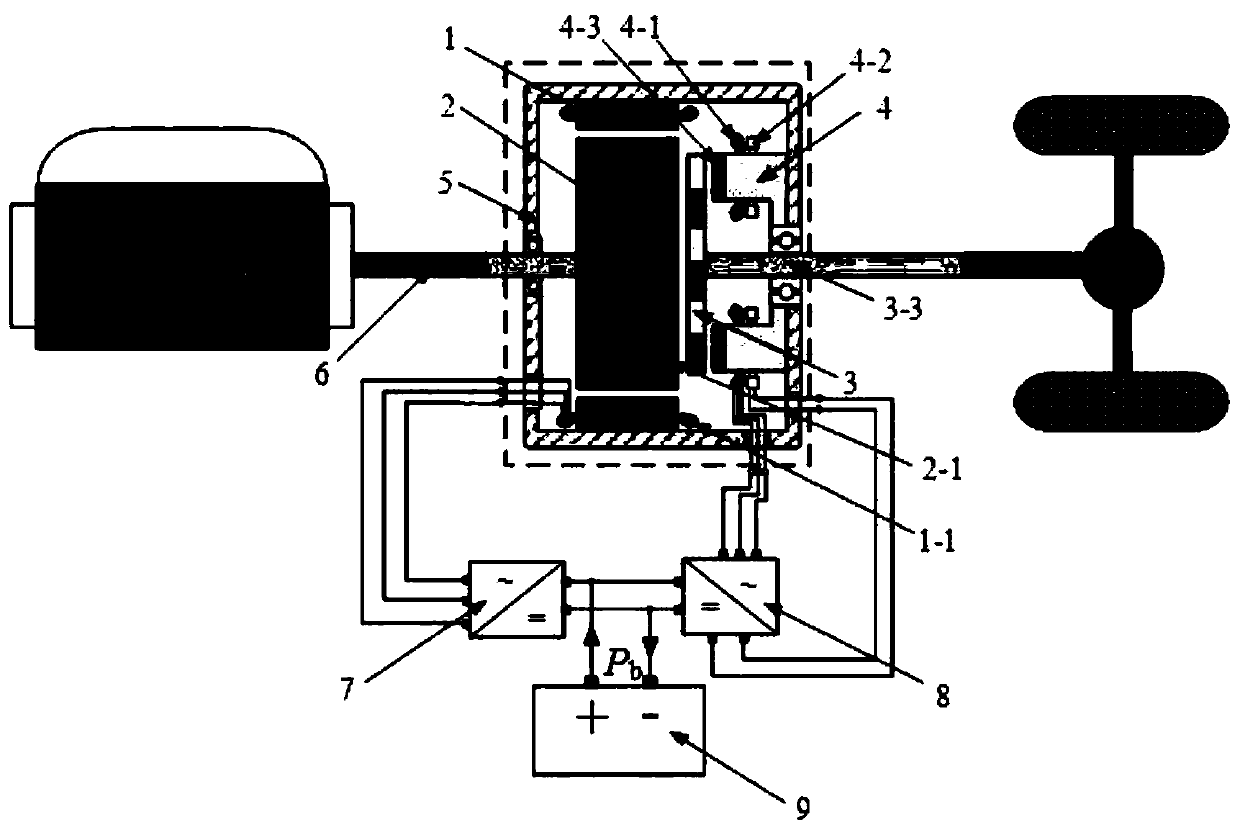

Manual clutch device for full electric vehicle

InactiveCN106274455AGuaranteed to workGuaranteed support strengthMechanical actuated clutchesControl devicesDynamic balanceEngineering

The invention relates to a manual clutch device for a full electric vehicle. The manual clutch device comprises a clutch, the two ends of the clutch are connected with a motor and a gearbox respectively, the clutch comprises a clutch outer cover and a clutch assembly installed inside the clutch outer cover, the clutch assembly comprises a flywheel panel installed on an output shaft of the motor, a friction disc and a pressure plate, the clutch outer cover and the motor are connected and positioned through a connection shaft sleeve, a support bearing is arranged between the clutch outer cover and the connection shaft sleeve, and the clutch outer cover, the connecting shaft sleeve and the flywheel panel are coaxially arranged. The manual clutch device for the full electric vehicle has the advantages that the motor and the clutch outer cover are connected by means of matching between the connection shaft sleeve and the support bearing, and therefore the support strength of the output shaft of the motor can be guaranteed, and the dynamic balance problem can be effectively prevented; in addition, the clutch outer cover, the connecting shaft sleeve and the flywheel panel are coaxially arranged, assembling is convenient, and meanwhile it can be guaranteed that the clutch works normally.

Owner:NANTONG GAOYE HEAVY IND CO LTD

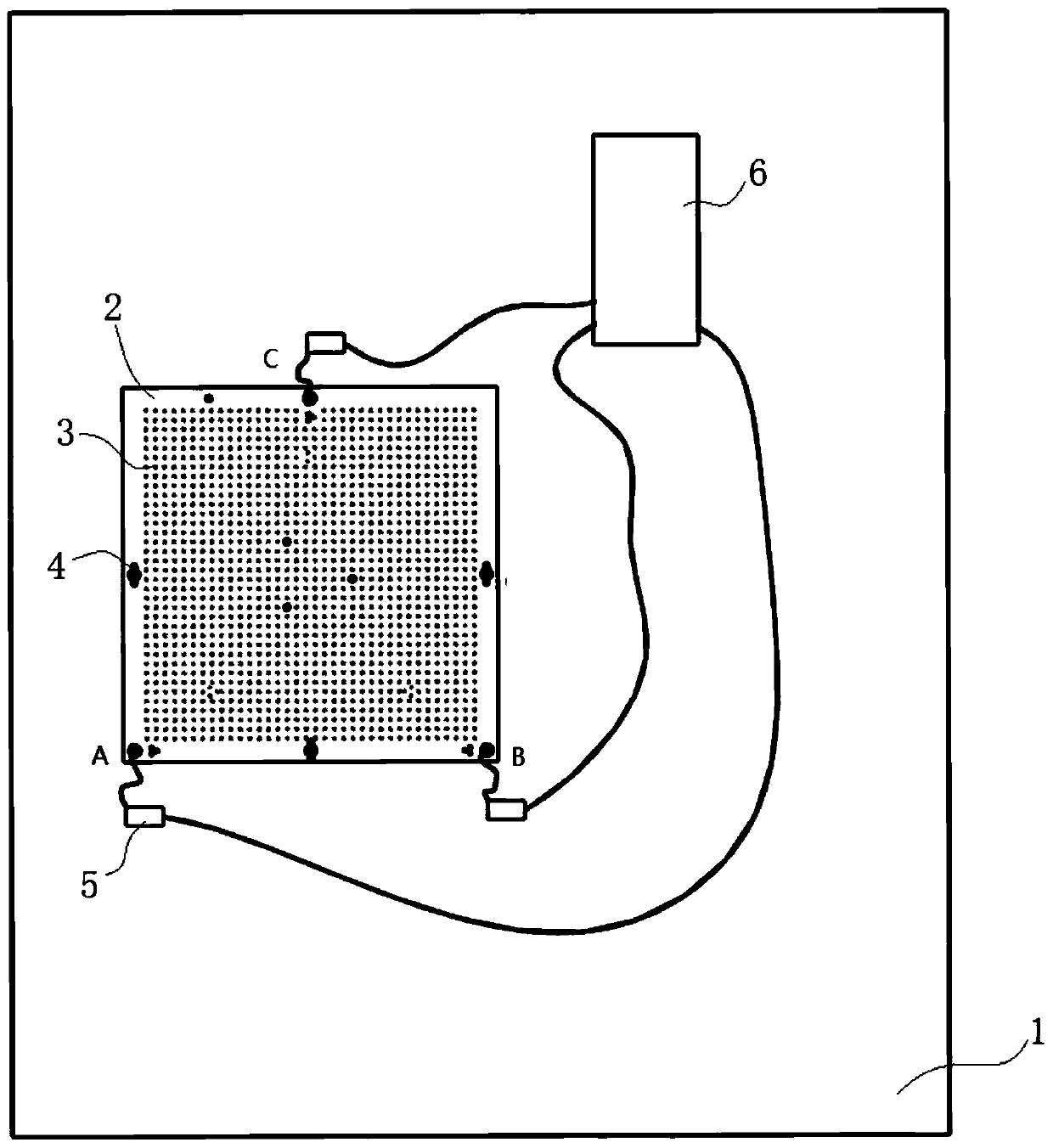

Method for testing gravity center of mechanical part

ActiveCN111207886ASolve test problemsSolve the dynamic balance problemStatic/dynamic balance measurementDynamic balanceRectangular coordinates

The invention discloses a method for testing the gravity center of a mechanical part. The method comprises steps of supporting a testing platform on a cast iron platform through a supporting column, enabling three sensors to be respectively installed at positions, close to an edge, of a lower surface of the testing platform, and enabling connecting lines of the three sensors to form a triangle; screwing bolts into the threaded holes, and then taking away the supporting column; unscrewing the bolts to take down the testing platform, pressing cylindrical heads of the sensors on a cast iron platform, and reading the initial pressure of the three sensors; horizontally placing and fixing the tested part, and obtaining the gravity G of the tested part; taking one of the sensors as an origin of coordinates, establishing a rectangular plane coordinate system, and calculating coordinate values X0 and Y0 of the center of gravity of the tested part when the tested part is horizontally placed; andhorizontally placing and fixing the tested part, calculating coordinate values X1 and Y1 of the gravity center of the tested part when the tested part is vertically placed , and the gravity center coordinates of the part are X0, Y0 and Y1. The method is advantaged in that accurate test data can be provided for solving a dynamic balance problem of a large rotary machine.

Owner:NANJING ANKE MEDICAL TECH CO LTD

Tire pressure sensor acceleration batch test device

InactiveCN107219038AAccurate graduationSolve the dynamic balance problemFluid pressure measurementElectric machineryTire rotation

The invention discloses a tire pressure sensor acceleration batch test device. A direct drive motor is used for directly driving a turntable, accurate scale division of the turntable can be ensured, the automobile tire rotation state can also be simulated, the structure design reduces system errors caused by a mechanical transmission reason, and the response speed and the transmission precision of the mechanism are improved. The turntable uses a horizontally-placed structure, the dynamic balance problem when the turntable rotates can be avoided, and safe and effective operation of the system can be ensured. A fixture positioning mechanism and a fixture loading / unloading device are used for automatic tire pressure sensor loading and unloading, and the whole system has a fully-automatic test function. The tire pressure sensor acceleration batch test device has the advantages of simple structure, small mechanism size, high operation efficiency and high cost performance, shackles of promotion and development of the tire pressure sensor are broken, great practical significance is realized, and the tire pressure sensor acceleration batch test device is particularly suitable for batch test on the acceleration detection function of the tire pressure sensor.

Owner:SUZHOU DINA PRECISION EQUIP

Method for improving furnace body dynamic balance of horizontal type converting furnace for non-ferrous metal metallurgy

The invention provides a method for improving furnace body dynamic balance of a horizontal type converting furnace for non-ferrous metal metallurgy. The method particularly comprises the steps of endsocket cutting, pre-positioning, pre-aligning, fine-aligning and welding. The process steps are simple, scientific and reasonable; the position and supporting mode of a supporting body are reasonablyset under the condition of lengthening the length of the furnace body, thereby effectively ensuring the purpose of the dynamic balance of the furnace body after lengthened, ensuring normal and stablerunning of the furnace body, increasing the yield, being capable of reducing the cost of repurchasing a second-stage supported bottom-blowing furnace, shortening the construction period, and effectively improving the economic benefits of enterprises.

Owner:洛阳玉冶机械设备有限公司

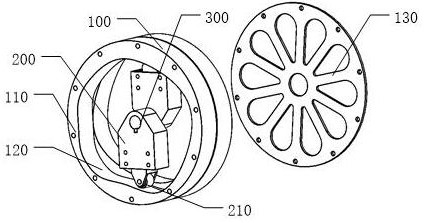

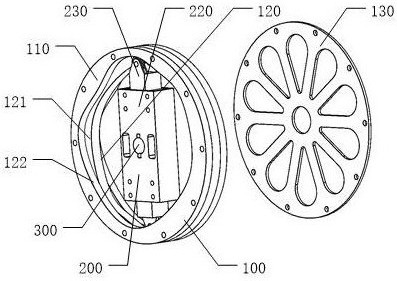

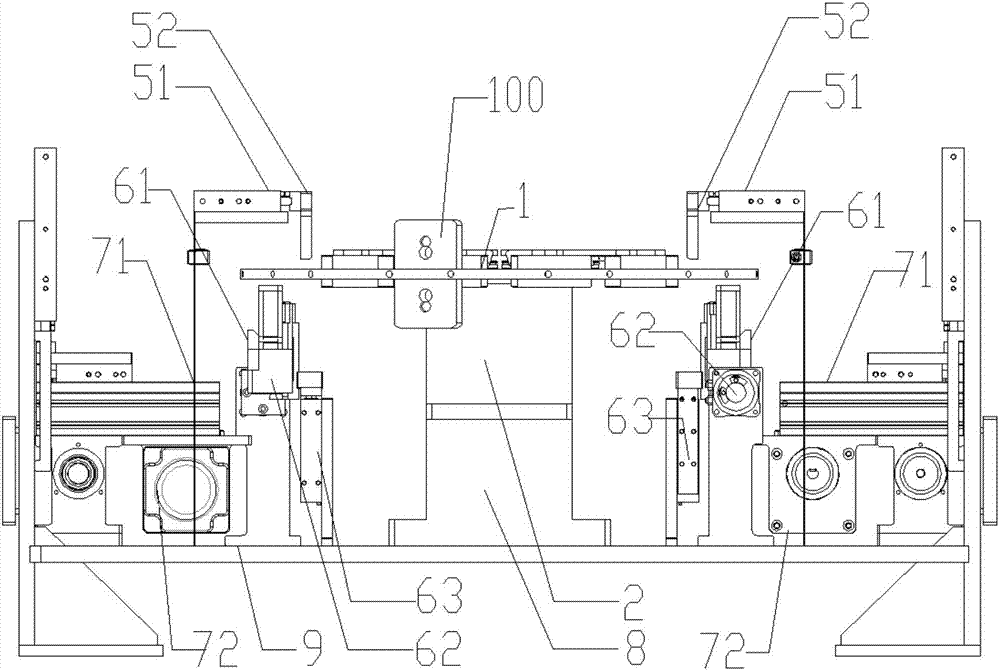

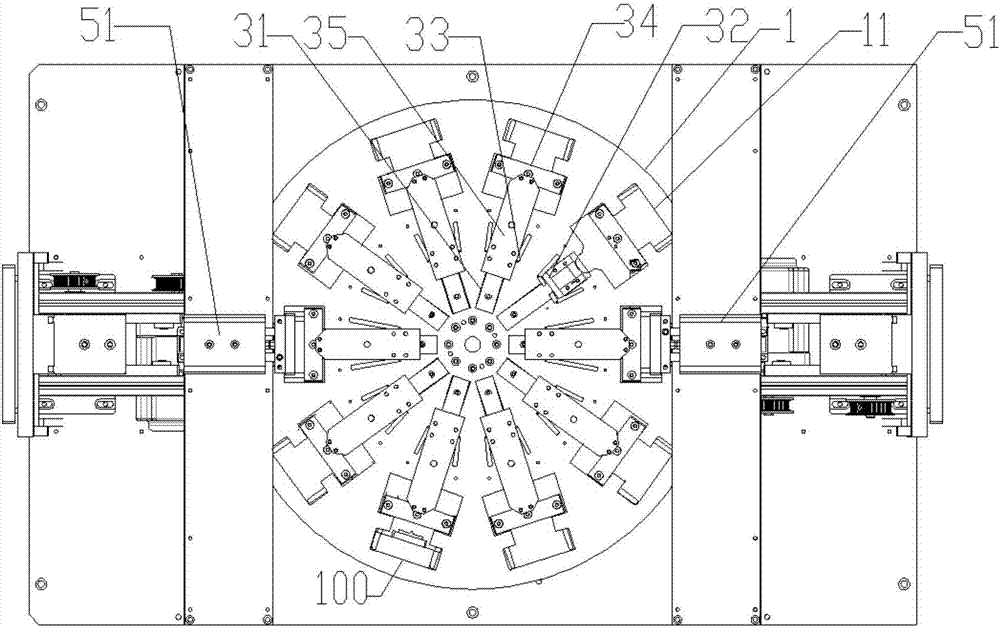

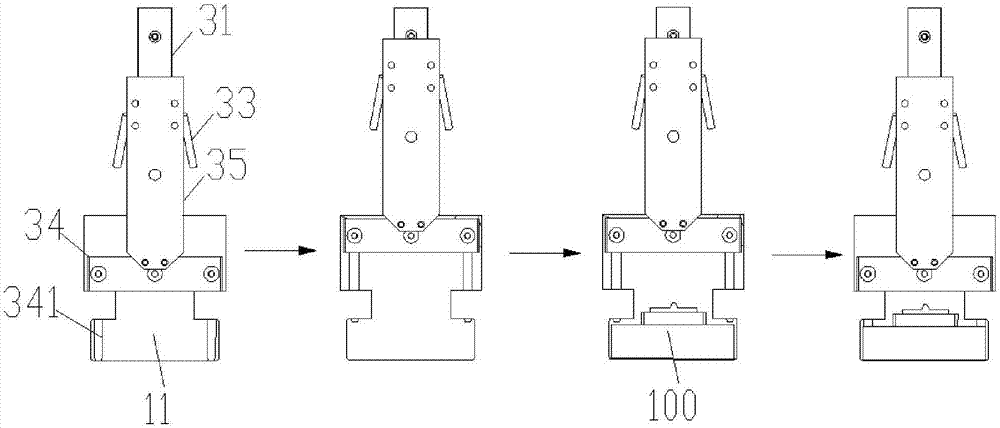

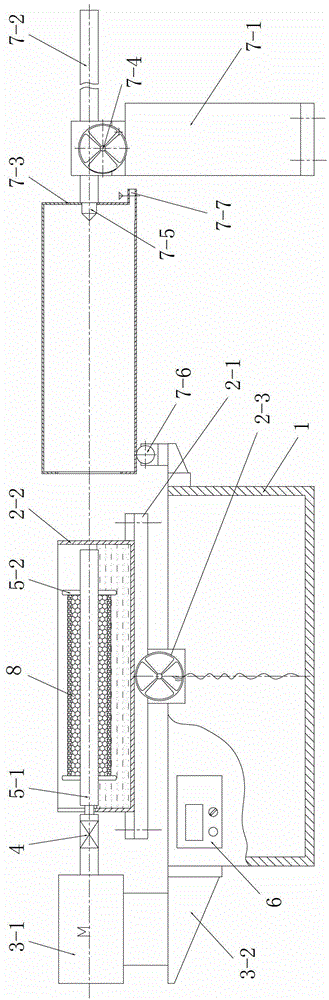

Soaking-centrifugalizing equipment

ActiveCN102962162BSimple structureEasy to operateLiquid surface applicatorsCoatingsControl systemSlurry

The invention discloses soaking-centrifugalizing equipment. The soaking-centrifugalizing equipment comprises a base, a soaking-centrifugalizing device and a slurry recovery device which is arranged at one side of the base and can move forwards and backwards in horizontal direction. The soaking-centrifugalizing device comprises a clamping tool which can continuously rotate and drive a foam filter tube precursor to synchronously rotate when rotating continuously, a soaking device which can move upwards and downwards, a rotary drive motor for driving the clamping tool to continuously rotate, and a control system for controlling and adjusting the rotation direction and the rotation speed of the rotary drive motor; the clamping tool is arranged above the base; a power output shaft of the rotary drive motor is connected with the clamping tool through a transmission mechanism; the clamping tool is arranged horizontally; and the foam filter tube precursor is horizontally arranged on the clamping tool. The soaking-centrifugalizing equipment is simple in structure, convenient to use and operate, safe and reliable in work and high in processing efficiency, realizes slurry recoverability and can be used for finishing the preparation process of various sizes of foam metal filter tubes conveniently and fast.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

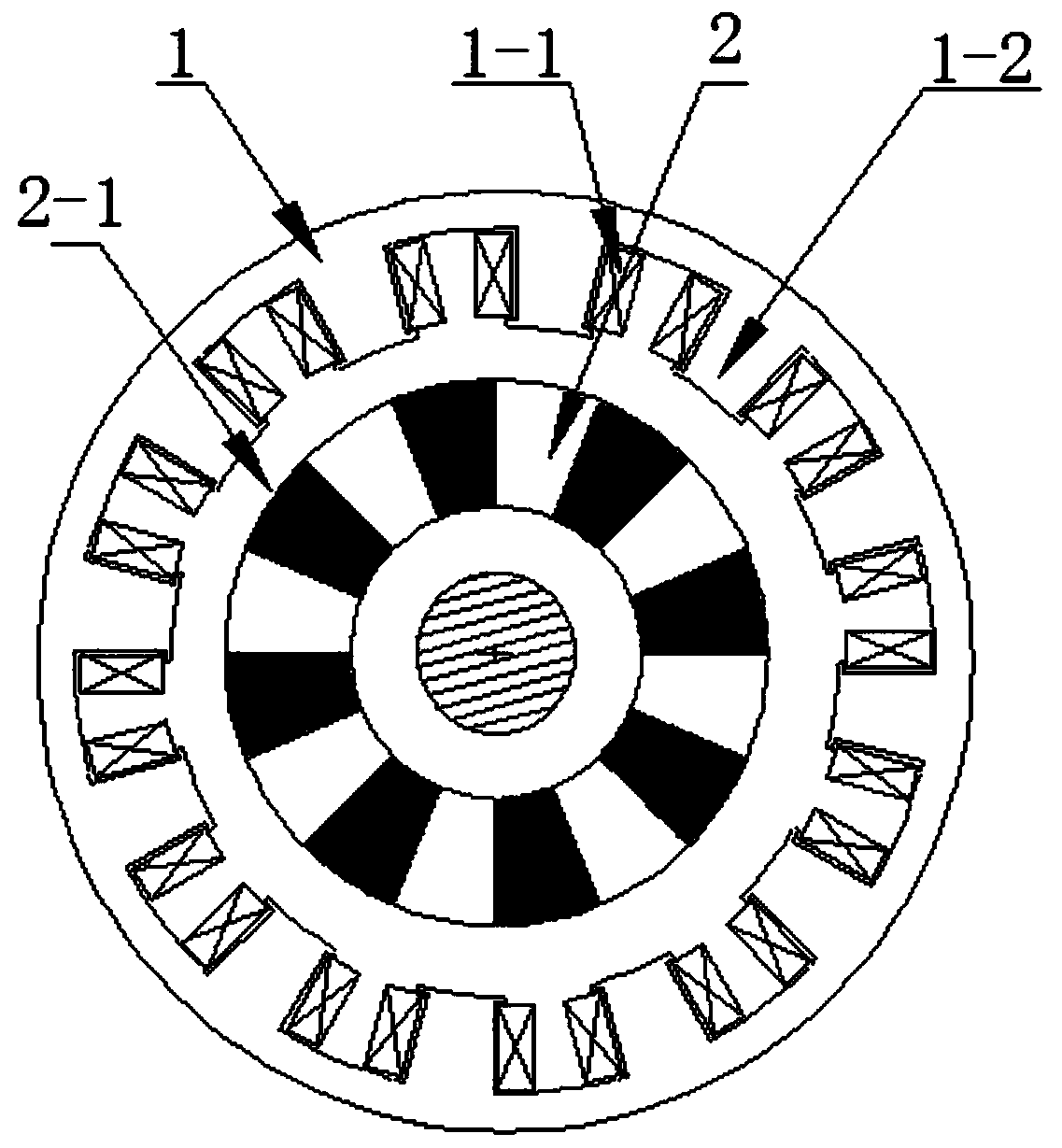

A brushless double stator motor for hybrid electric vehicle

InactiveCN107026545BAchieve brushlessSimple structureSynchronous machine detailsElectric machinesElectric machineReduction drive

Owner:CHONGQING UNIV

Disk type permanent magnet synchronous motor, energy storage flywheel and method

ActiveCN113131706BSimple structureCompact structureMagnetic circuit stationary partsMechanical energy handlingElectric machinePermanent magnet synchronous motor

The present disclosure proposes a disc-type permanent magnet synchronous motor, an energy storage flywheel based on magnetic suspension support and a method, including: an upper stator disc and a lower rotor disc; the stator disc includes a stator core, and the stator core includes stator teeth and a stator yoke Two parts, the armature winding is a short moment distribution winding, which is wound on the stator teeth, and the winding coils are arranged in double layers along the axial direction; the rotor disk is composed of a rotor yoke disk and permanent magnets arranged alternately with N poles and S poles along the circumferential direction. The number of magnetic poles of the permanent magnets is evenly embedded on the upper surface of the rotor yoke. The structure of the motor for the energy storage flywheel is optimized. The motor is an axial flux motor, and the flywheel rotor is used as the magnetic yoke disk of the lower rotor disk. The motor and generator are integrated to realize the reciprocal operation of electric power generation / power generation, and can work in There are two states of electric and power generation, which simplifies the structure of the flywheel energy storage system.

Owner:SHANDONG UNIV

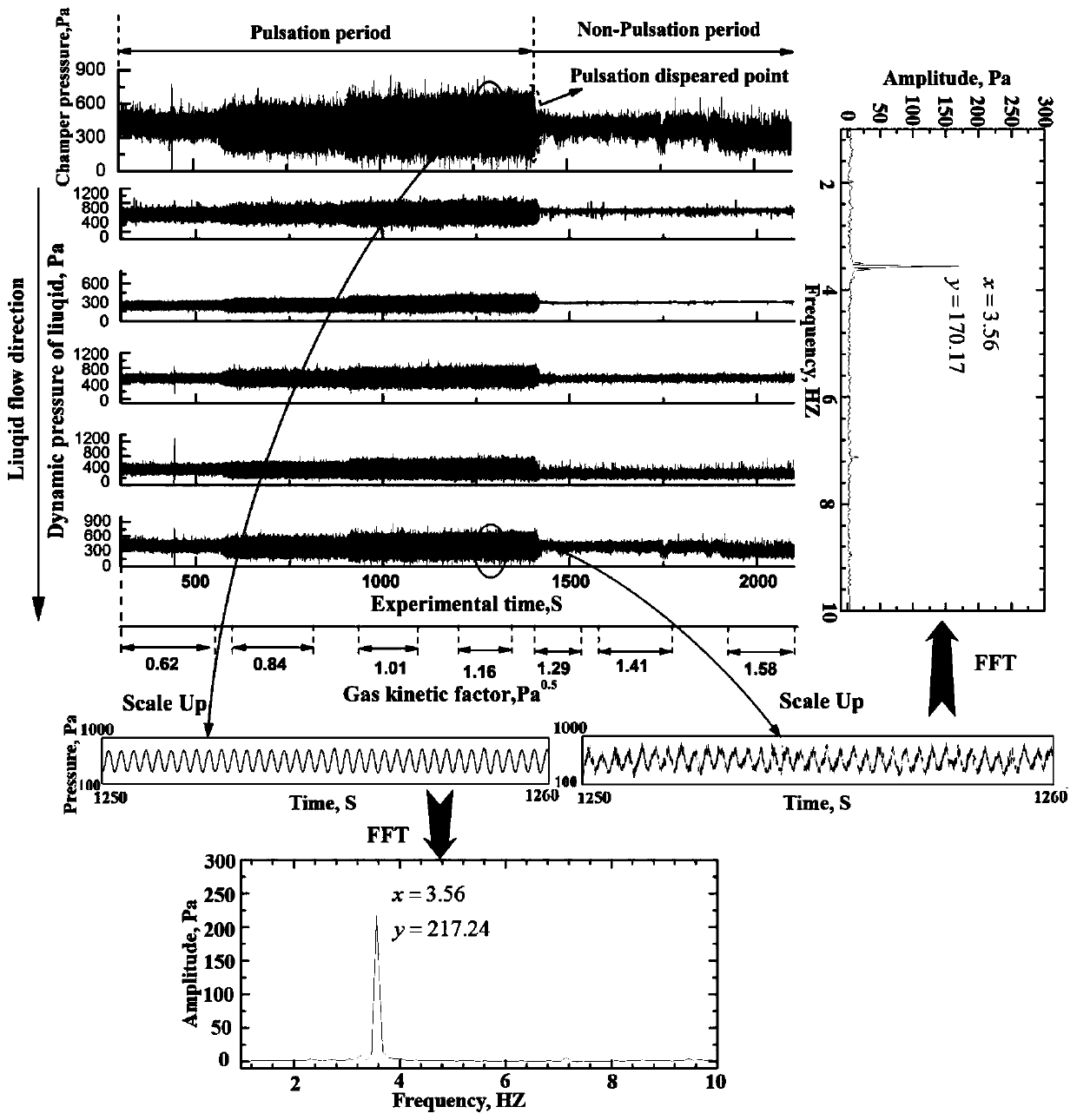

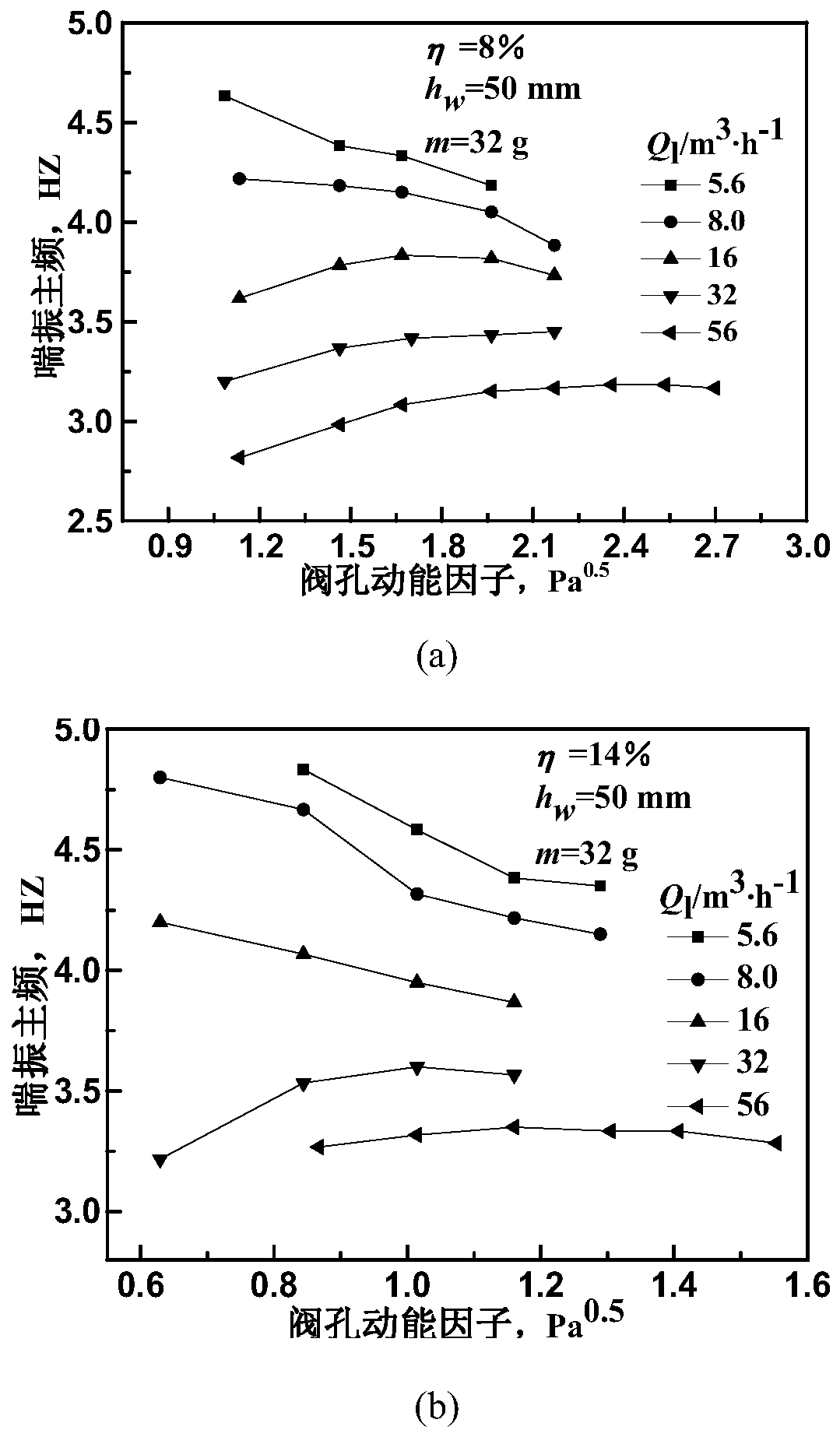

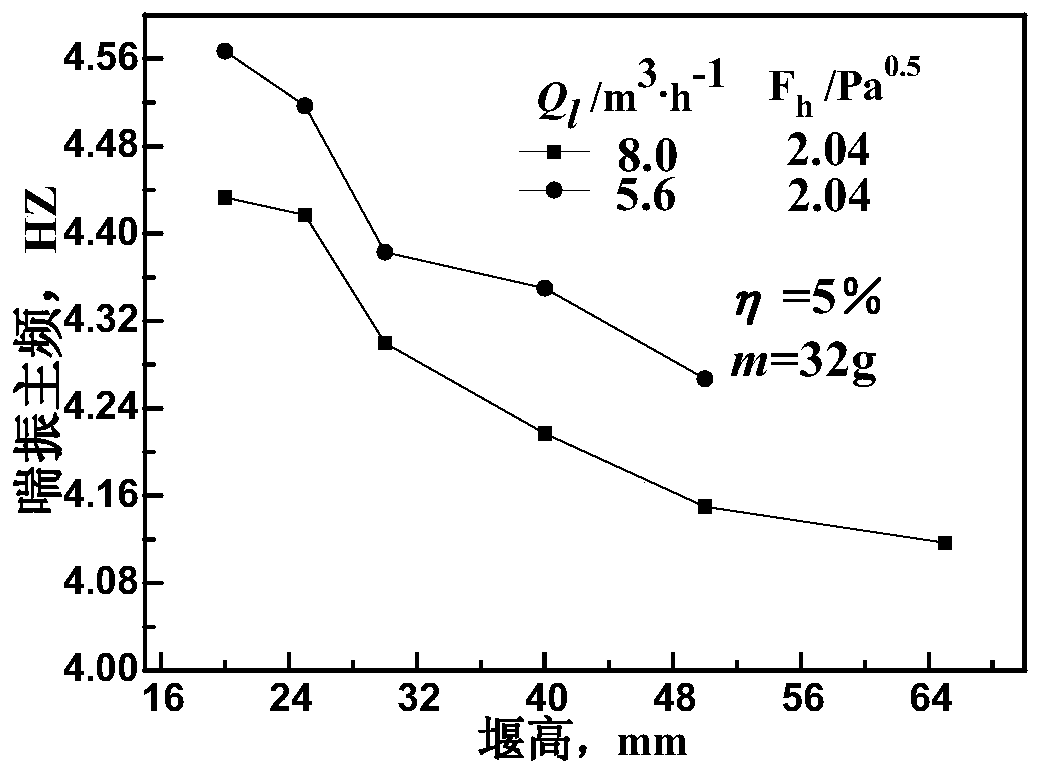

A gas-liquid surge mixing method

ActiveCN107998909BFix the leakAvoid heat leak problemsTransportation and packagingMixing gases/vapours with liquidsFluid phaseEngineering

The invention relates to a gas-liquid surge mixing method. The method uses the valve tower as a surge tower mixer to realize gas-liquid mixing. Multi-layer trays are installed in the valve tower, float valves are installed on the trays, and downcomers are arranged between the trays. The method includes the following steps: Steps: The liquid phase is fed from the upper part of the valve tower, and after feeding, it flows along the horizontal direction on the valve tray, and then is guided to the lower tray by the downcomer; the gas phase is fed from the lower part of the valve tower, and is fed by the The bottom of the tray rises through the opening of the tray in the form of pulse bubbling, driving the float valve on the tray to move up and down, so that the gas phase, liquid phase and float valve above the tray form a periodic vertical pulsation with a certain vibration frequency; The vibration frequency is the same or close to the first natural frequency or the second natural frequency of the float valve tower, which produces a surge phenomenon and realizes the mixing of the gas phase and the liquid phase. When the resonance occurs, the vibration amplitude of the float valve and the gas-liquid vibration is very high and the vibration is uniform, so that the gas phase and the liquid phase can be fully mixed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

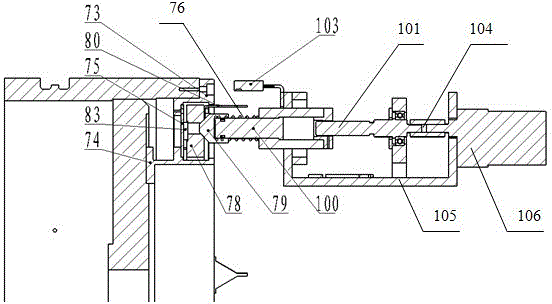

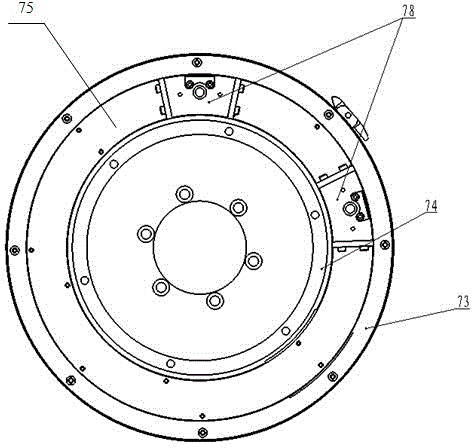

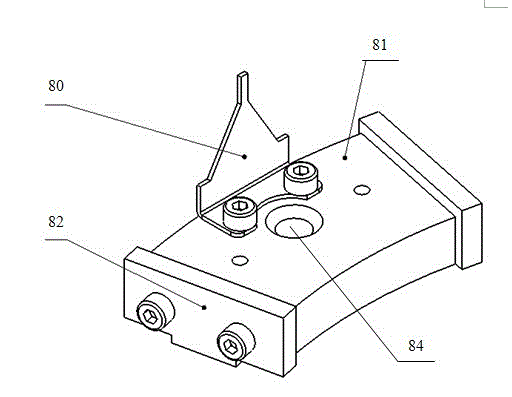

Automatic dynamic balance device of direct plate setter

ActiveCN102853969BSolve the dynamic balance problemReduce vibrationStatic/dynamic balance measurementForme preparationVibration amplitudeDynamic balance

The invention refers to a dynamic balance adjusting device of a rotary drum for plates with different sizes of a direct plate setter. The invention discloses an automatic dynamic balance device of a direct plate setter. The automatic dynamic balance device comprises a rotary drum and a balance block supporting and guiding device arranged on the rotary drum; the balance block supporting and guiding device comprises an end cover (73) arranged at the side face of the rotary cylinder and a slide block supporting ring (74); and balance blocks (78) are clamped between the end cover (73) and the slide block supporting ring (74). The automatic dynamic balance device further comprises a balance block driving system, comprising an electric motor (106) and a push rod (100). Through fixing the balance blocks on two end faces of the rotary drum, the problem of dynamic balance of the rotary drum caused by the plates with different sizes is solved, so that the vibration amplitude of the rotary drum in the high-speed rotation is reduced; and due to the fact that the dynamic balance is automatically realized, the work time is decreased, and the working efficiency of the direct plate setter is increased.

Owner:杭州东信光电科技有限公司

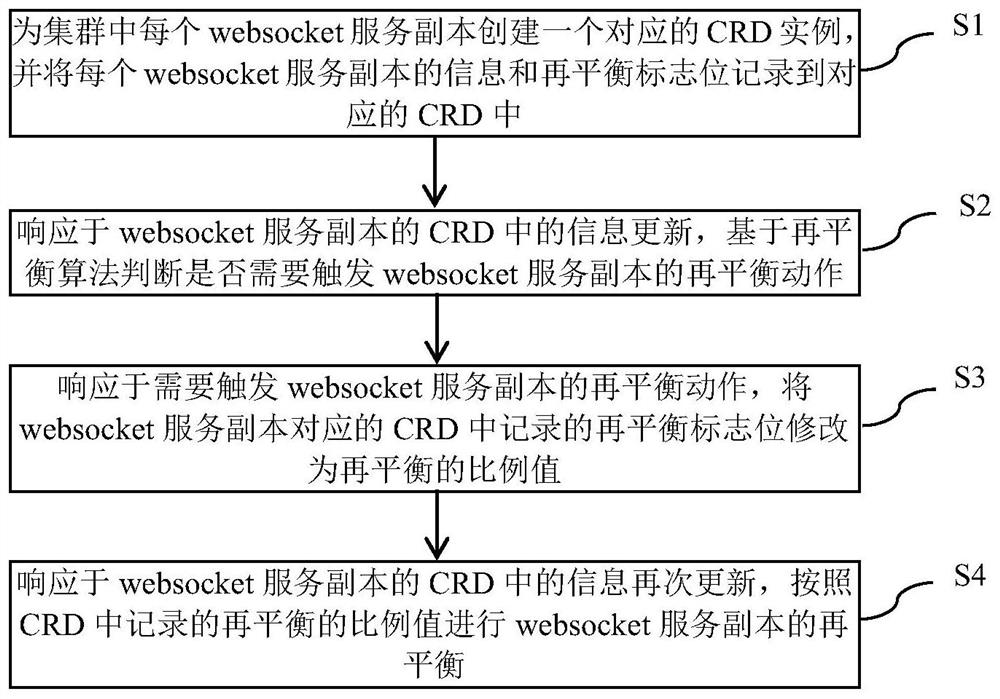

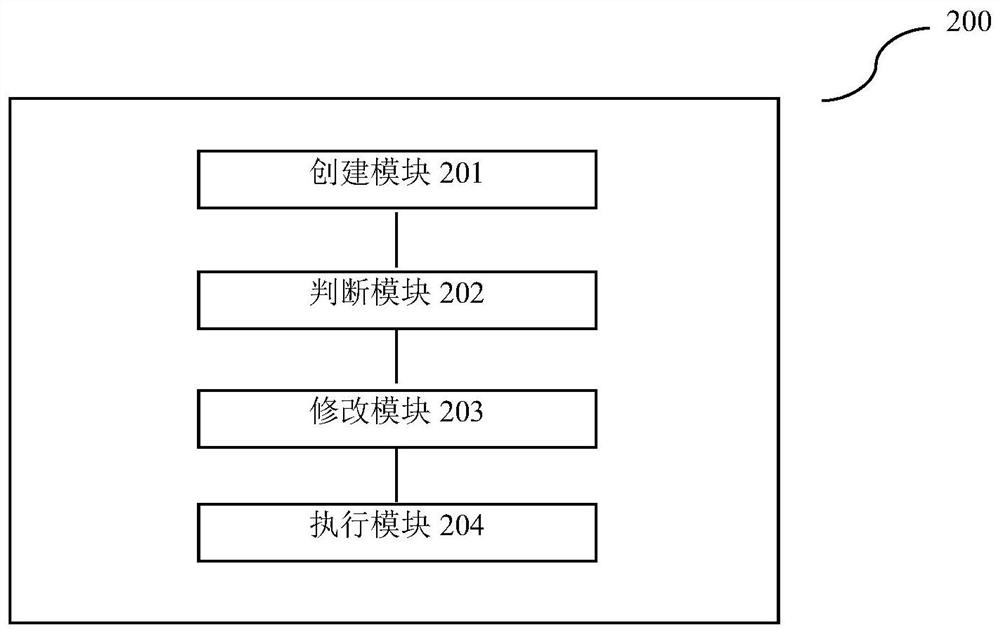

Cluster websocket service load balancing method and device, equipment, and readable medium

The invention provides a cluster websocket service load balancing method and device, equipment, and a readable medium. The method comprises the following steps: creating a corresponding CRD instance for each websocket service copy in a cluster, and recording the information of each websocket service copy and a rebalance flag bit into the corresponding CRD; in response to information update in the CRD of the websocket service copy, judging whether a rebalance action of the websocket service copy needs to be triggered or not based on a rebalance algorithm; in response to a rebalance action needing to trigger the websocket service copy, modifying the rebalance flag bit, recorded in the CRD corresponding to the websocket service copy, into a rebalance proportion value; in response to re-updating of information in the CRD of the websocket service copy, performing rebalancing of the websocket service copy according to the rebalancing proportion value recorded in the CRD. By using the scheme provided by the invention, the problem of dynamic balance of the workload between the multi-copy websocket servers in the k8s cluster can be solved, and the coping capability of the websocket servers in a traffic emergency scene is improved, so that the practical value is very high.

Owner:济南浪潮数据技术有限公司

Dynamic balance type internal combustion air compressor

InactiveCN102966511BSolve the vibrationSolve the noisePiston pumpsPositive-displacement liquid enginesAir compressionExhaust valve

The invention belongs to the technical field of compressor equipment, and relates to a dynamic balance type internal combustion air compressor, wherein a power cylinder cover component and a machine body are fixedly connected; the sealing of a power piston and a power cylinder sleeve is realized through a piston ring; the power piston component and a connecting rod body are connected by a piston pin, and further constitute a revolution pair; the connecting rod bodies and a spheroidal graphite cast iron crank shaft of bearing bushes installed in the interiors of connecting rod heads constitute the revolution pairs; the connecting rod bodies and the connecting rod heads are connected into a whole body; an air compression cylinder cover component, a steel valve plate and the machine body are connected into an integral structure; an air compression cylinder sleeve and the machine body are connected; the sealing of an air compression piston component and the air compression cylinder sleeve is realized through the other piston ring; the air compression piston component and the other connecting rod body are connected by the other piston pin, and further constitute the revolution pair; and a suction valve block reset spring and an exhaust valve block reset spring are guided through the utilization of a guide shaft. In addition, the dynamic balance type internal combustion air compressor is reliable in principle, simple in structure, low in preparation cost, high energy conversion efficiency, friendly to the environment, strong in balance function and wide in application.

Owner:QINGDAO UNIV

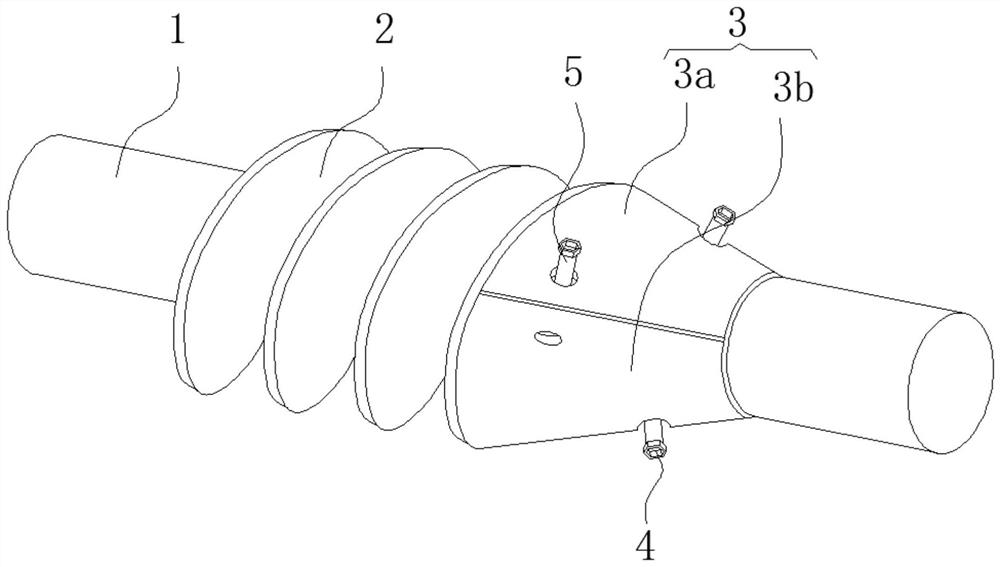

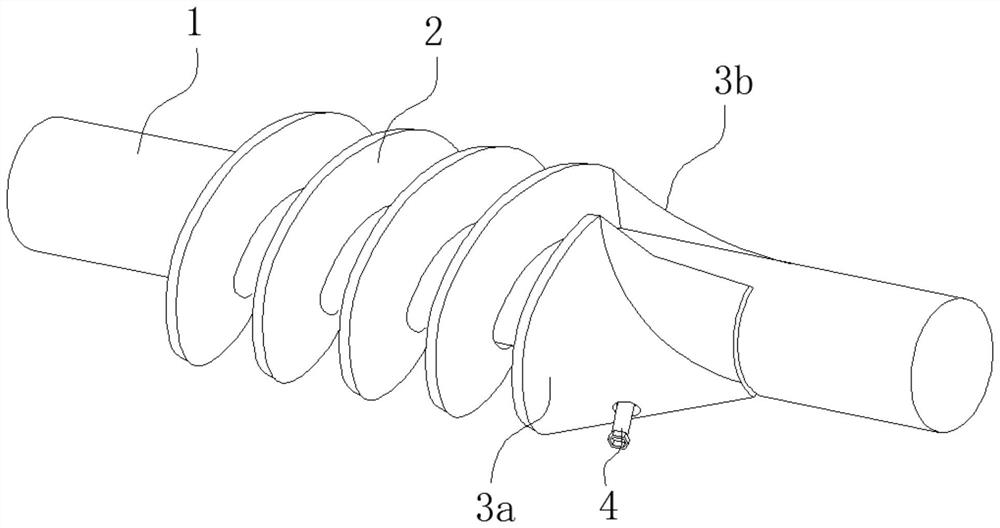

An auger for a screw extrusion solid-liquid separator

ActiveCN110253931BReduce adverse bending moment effectsEffective protectionPressesMechanical engineeringBending moment

The invention relates to the technical field of solid-liquid separators, and discloses an auger for a screw extruding solid-liquid separator, comprising a twisted shaft and a helical twisted blade fixedly sleeved outside the twisted shaft, the front end of the twisted shaft and A pressure-bearing mechanism is provided at the end surface of the spiral twisted blade, the end of the pressure-bearing mechanism fits the end helical surface of the spiral twisted blade, the side surface of the pressure-bearing mechanism is a tapered surface, and the pressure-bearing mechanism It consists of a front pressure bearing sleeve and a rear pressure bearing sleeve. In the present invention, a pressure-bearing mechanism is installed at the end of the helical blade, and the pressure-bearing mechanism bears the axial reaction force from the extrusion of the material at the front end of the solid-liquid separator body, and the shear bolt bears the main force, thereby being able to Effectively protect the end of the helical blade, and at the same time, the setting of the conical side can push the axial reaction force component to the cylinder wall, so that a certain extrusion effect is formed between the material and the cylinder wall, and the pressure-bearing mechanism is further reduced. The unfavorable bending moment effect caused by the axial reaction force borne by itself.

Owner:ZHEJIANG RISHENG ENVIRONMENTAL PROTECTION MACHINERY

Precision high speed chief axis power transmission connecting mechanism

ActiveCN100487263CSolve the dynamic balance problemIncrease self-locking abilityYielding couplingElectric machineCoupling

The invention relates to a precise high-speed main shaft power drive connecting device; wherein a coupling (3) is the coupling with elastic spider, the interior of a machine tool main shaft is provided with a coaxial conical self-locking transition shaft, and one end of the coupling (3) is connected with a motor output end (2) and the other end is connected with the conical self-locking transition shaft; the conical self-locking transition shaft comprises a cylinder section (4) connected with the coupling and a self-locking conical cylinder section (4') with the diameter greater than that of the cylinder section and is matched with the inner wall of the machine tool main shaft, and the conicity of a conical surface (A) of the conical cylinder section (4') is 1:50 to 110. The invention can facilitate the power drive reliable, efficient and stable under the high rotation speed, and can effectively reduce the shock produced by the power drive.

Owner:中国机械总院集团云南分院有限公司

Sliding plate driving assembly with mixed movement

PendingCN108331889AReasonable cooperationSolve complexityWobble plate gearingsOblique crank gearingsSlide plateAxial rotation

The invention relates to mechanical transmission components and assemblies thereof which are suitable for apply occasions with mixed planar and rotating movement and are particularly suitable for a cycloidal speed changer to drive an output shaft. A sliding plate driving assembly with mixed movement comprises a sliding plate body, wherein the sliding plate body is provided with a clamping surfaceclamped by various driving parts and driven parts at the same time and forming radial sliding axial rotation clamping fit with the sliding plate body; and installation grooves fitting to the various driving parts and driven parts or matched guide rails and used for holding sliding pieces are formed in the clamping surface. The invention provides a new technical scheme of the sliding plate drivingassembly with mixed movement.

Owner:HSOAR GRP

A device for sports martial arts single-leg balance force training

ActiveCN109876408BAvoid ankle sprainsAvoid sprainsStiltsPhysical medicine and rehabilitationFoot supports

Owner:宫拼物 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com