Precision high speed chief axis power transmission connecting mechanism

A high-speed spindle and power transmission technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of spindle system manufacturing and assembly difficulties, double-key impact vibration, easy vibration, etc., to achieve compact equipment structure, Effect of reducing vibration, preventing shock vibration and stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

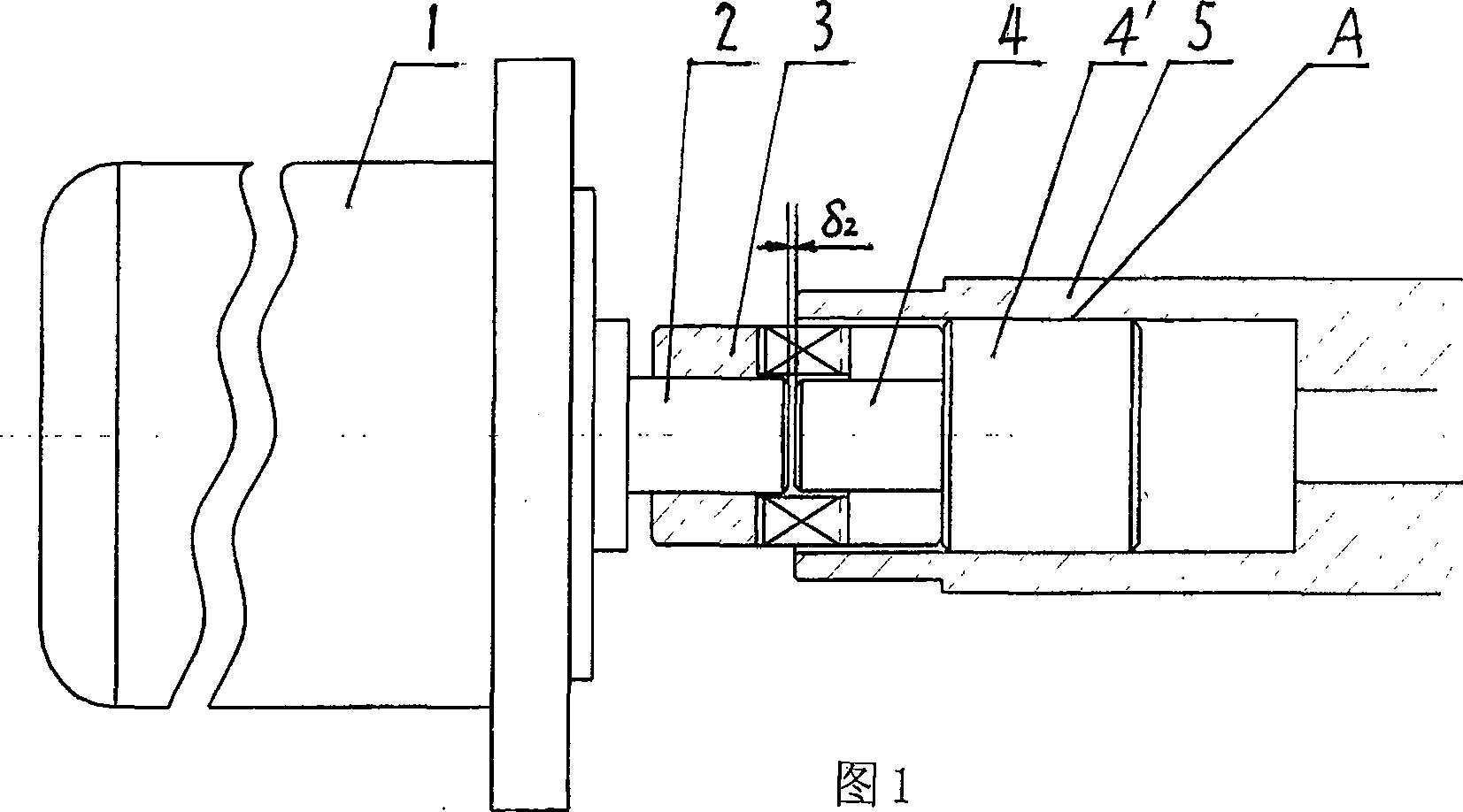

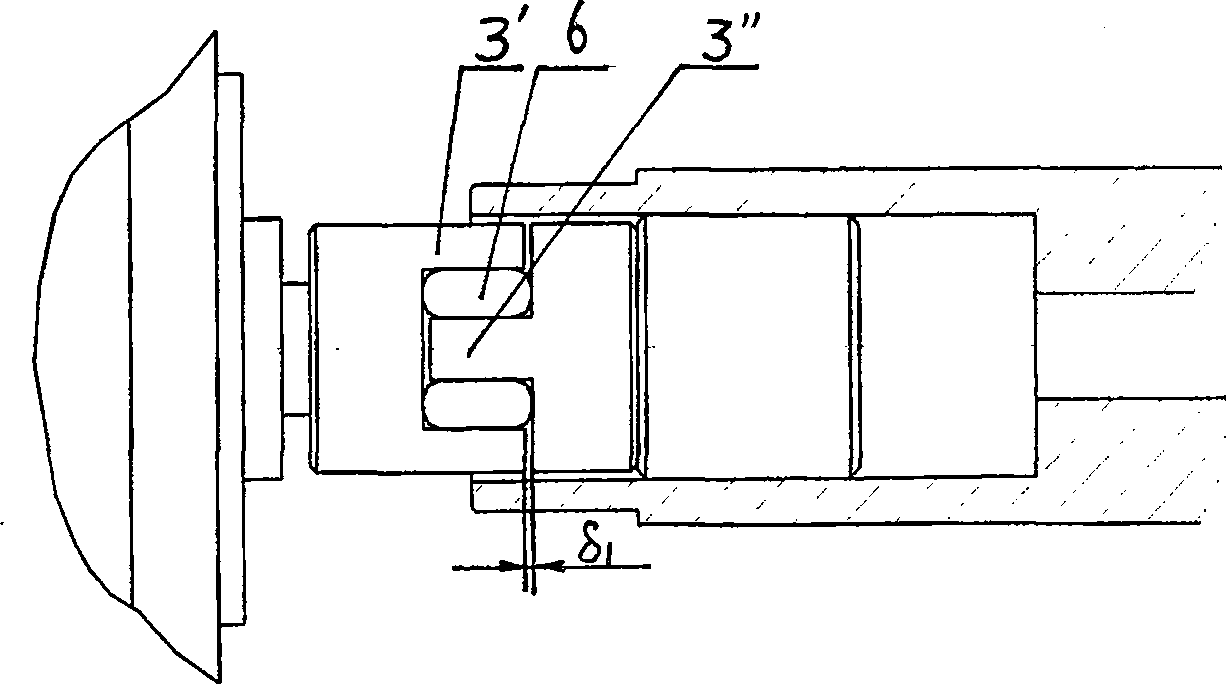

[0013] As shown in Fig. 1, the present invention is made up of high-speed motor 1, motor output shaft 2, quincunx elastic coupling 3, conical self-locking transition shaft and machine tool spindle 5. The quincunx-shaped elastic coupling 3 can be purchased directly from the market, and the ROTEX quincunx-shaped elastic coupling of KTR Trading Company in Germany is the best. The conical self-locking transition shaft needs to be designed and processed by itself. Fit the tapered self-locking transition shaft into the machine tool spindle. One end of the shaft coupling 3 is connected to the motor output shaft 2, and the other end is connected to the conical self-locking transition shaft. The conical self-locking transition shaft includes a cylindrical section 4 connected with the coupling and a conical cylindrical section 4' whose diameter is larger than the cylindrical section and can cooperate with the inner wall of the machine tool spindle to self-lock. The taper of the conical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com