A brushless double stator motor for hybrid electric vehicle

A hybrid and brushless technology, applied in the direction of motors, electric vehicles, synchronous machines, etc., can solve the problems of reducing device reliability and transmission efficiency, increasing mechanical wear and maintenance costs, and difficulty in heat dissipation of inner rotor windings, etc., to achieve Improve the efficiency and reliability of electromechanical energy conversion, enhance the ability to adjust the air gap magnetic field, and solve the effect of difficult adjustment of the main magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

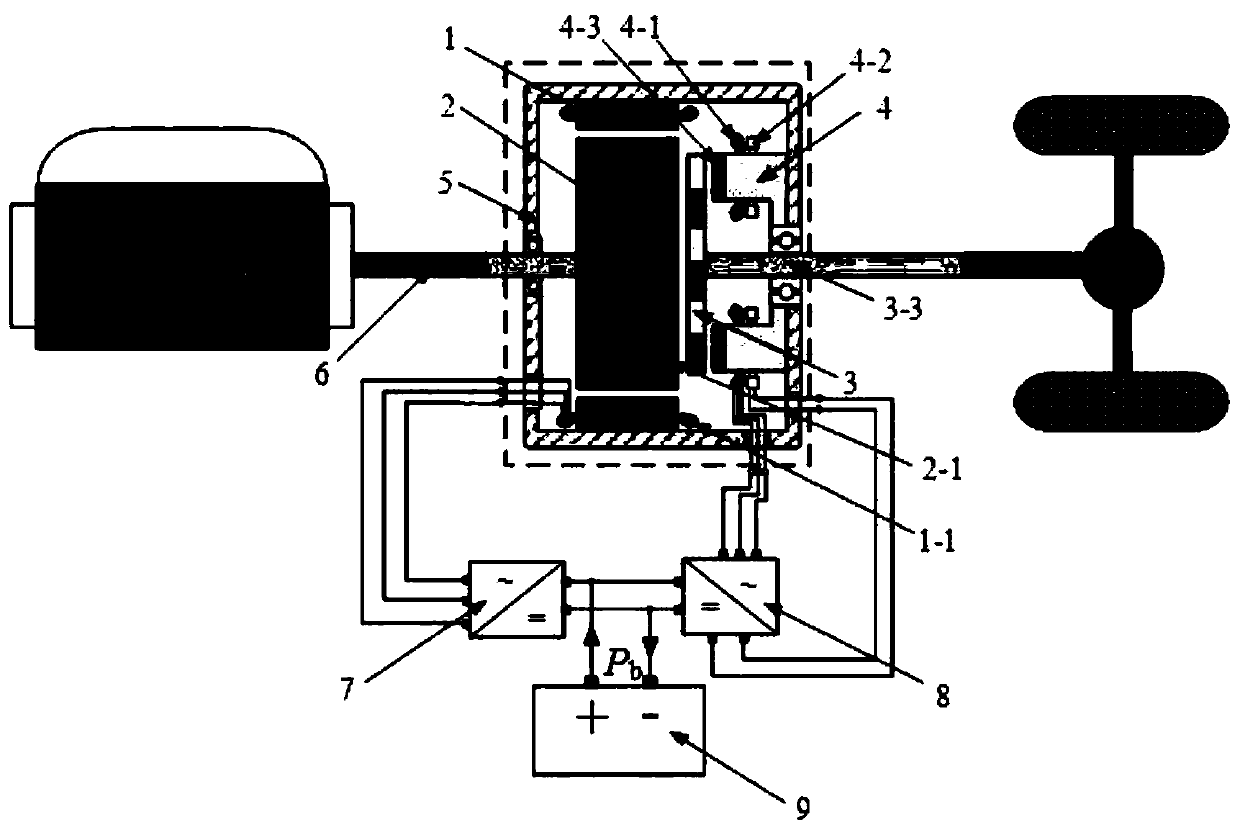

[0023] Such as figure 1 As shown, the present invention includes a motor casing 5, a first stator 1, a magnetic modulation ring 3 and a second stator 4 arranged in sequence from left to right in the motor casing 5, and the inner rotor 2 is located inside the first stator 1;

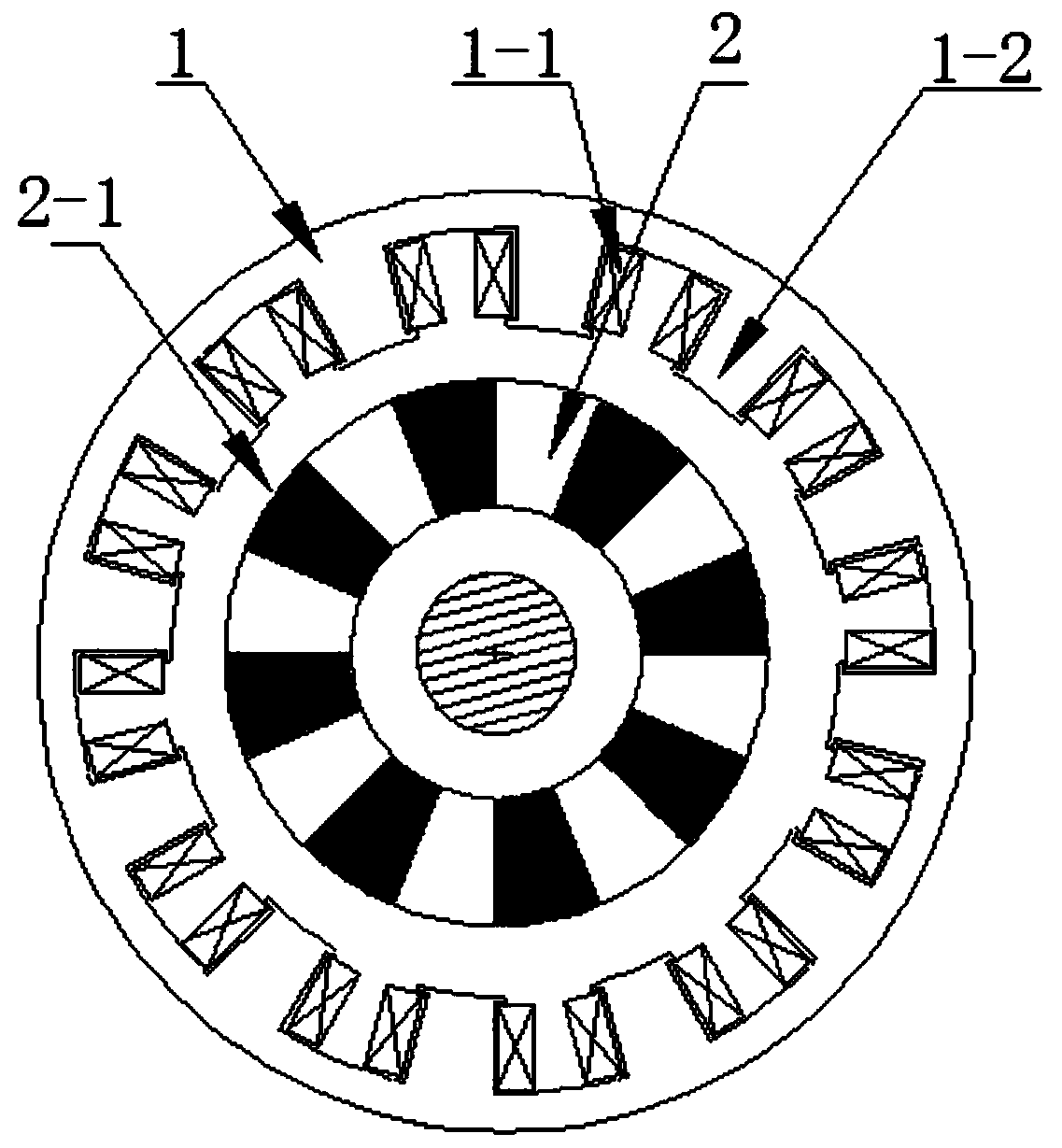

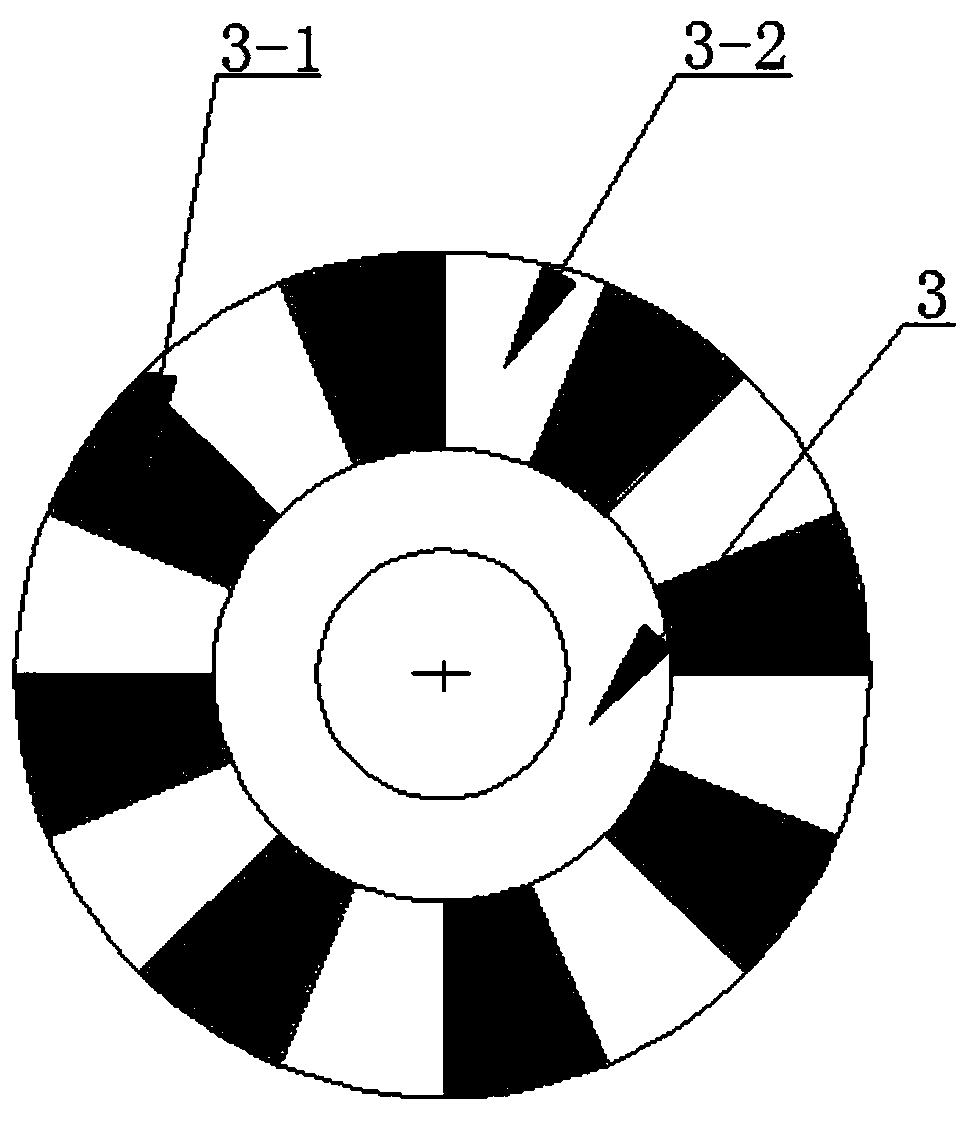

[0024] Such as figure 2 with image 3 As shown, the inner surface of the first stator 1 has twelve salient poles 1-2, and the three-phase concentrated winding 1-1 is embedded in the tooth slots on the inner surface of the first stator; the inner rotor 2 is evenly embedded in the circumferential direction Eight permanent magnets 2-1; the right side of the inner rotor 2 is the magnetic adjustment ring 3, and the magnetic adjustment ring 3 is a circular structure composed of eight magnetic conductors 3-1 and eight non-magnetic conductors 3-2 alternately arranged ; The second stator 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com