Hydraulic pressure suspension polishing fixed-point fluid pressure detecting system

A technology of fluid pressure and detection system, which is applied in the direction of grinding/polishing equipment, control of workpiece feed movement, grinding machine tool components, etc., to achieve high accuracy and solve the effect of entanglement problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

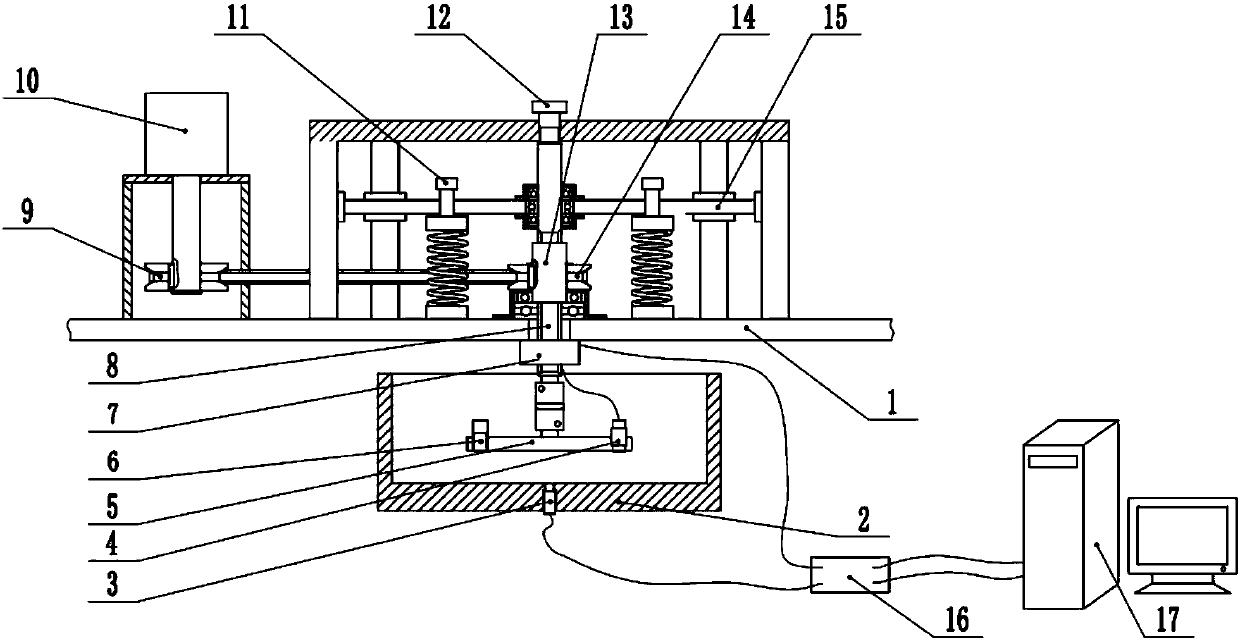

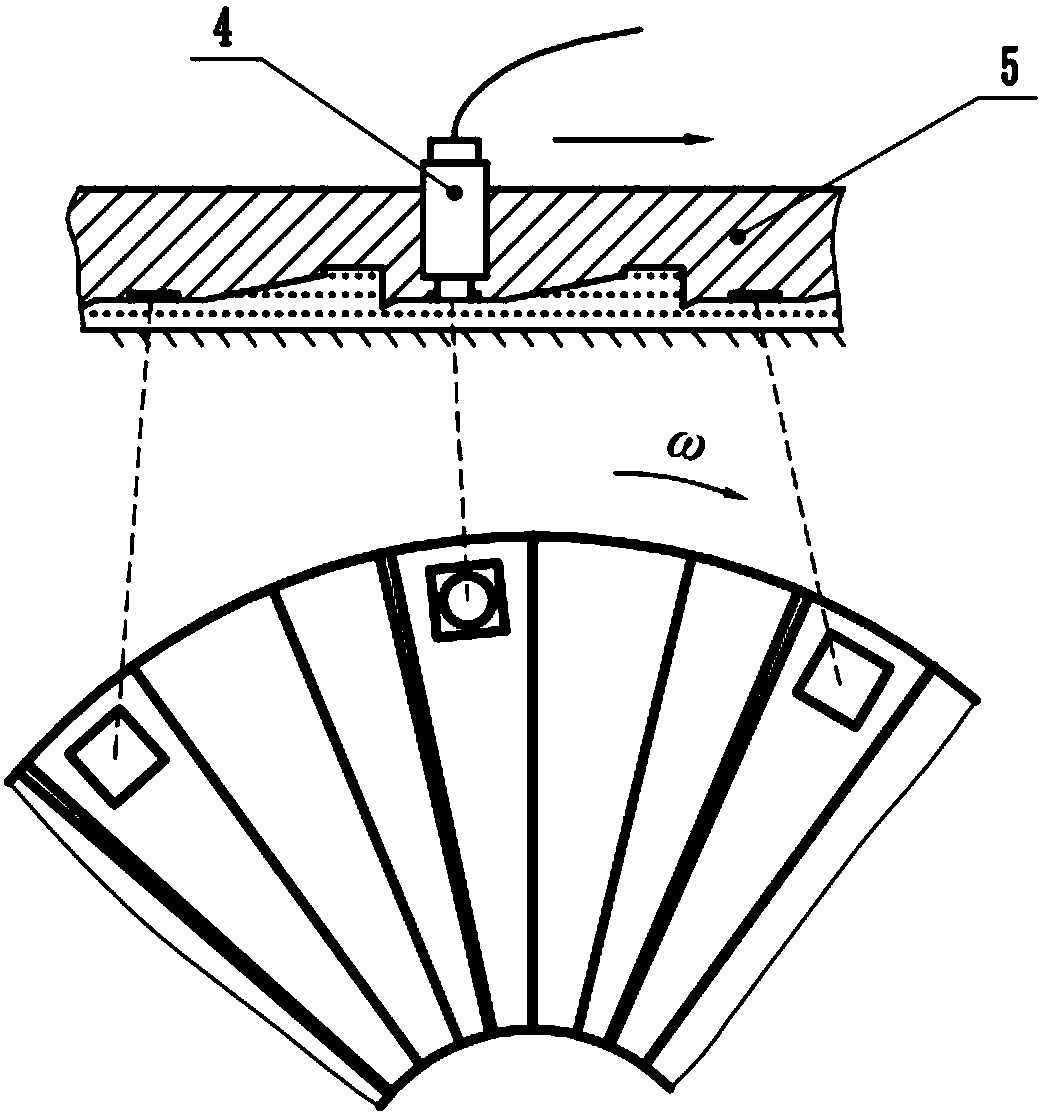

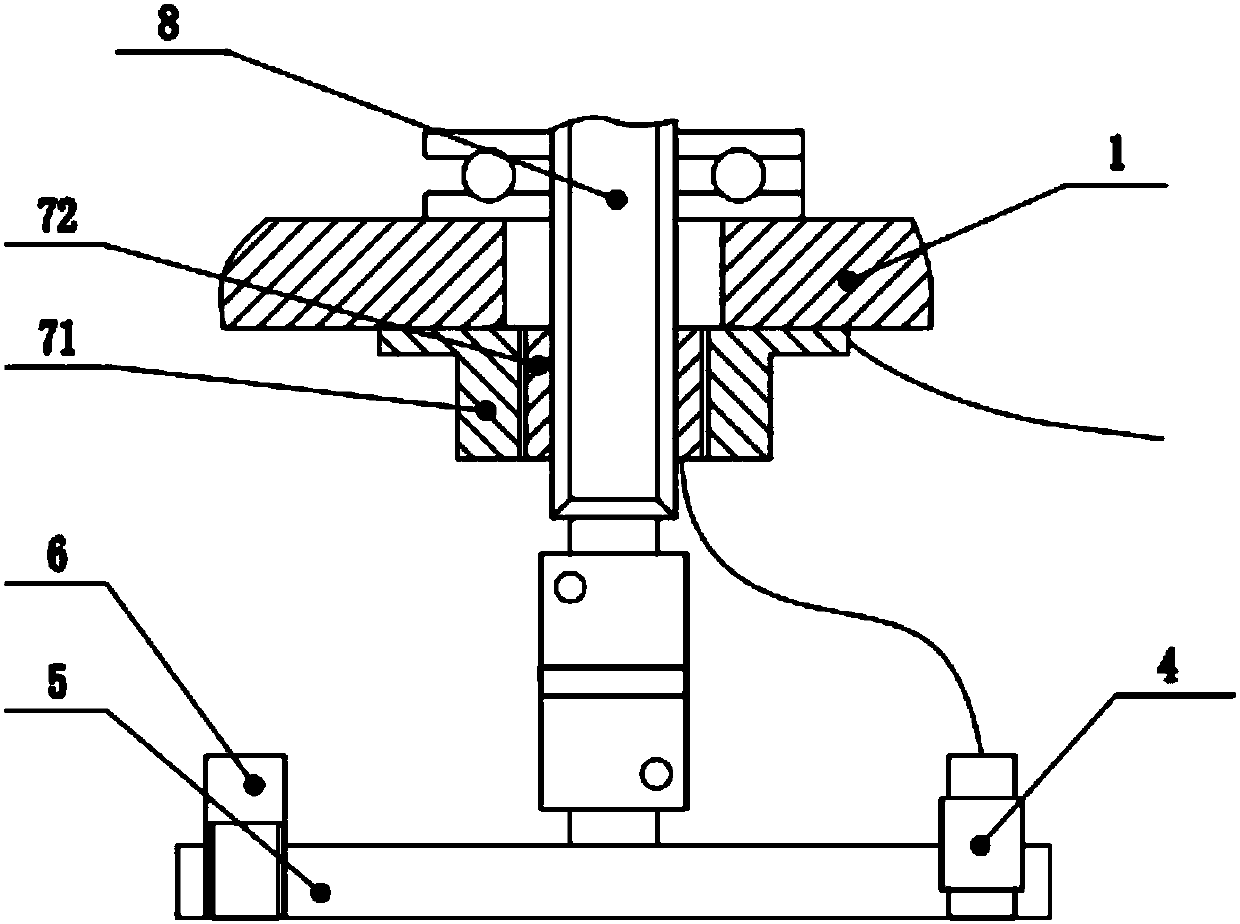

[0019] refer to Figure 1 ~ Figure 3 , a hydraulic pressure suspension polishing fixed-point fluid pressure detection system, including a pressure sensor 4, a balance adjustment screw 6, a signal conditioning amplifier, a conductive slip ring 7, an acquisition card 16 and a computer 17. The parallel area below the polishing tool disk 5 has a groove, and a workpiece is pasted in the groove. One of the workpiece positions is drilled together with the polishing tool disk 5, and the pressure sensor 4 for hydraulic pressure measurement is fixed on the workpiece drilled position from top to bottom. On the symmetrical side of the workpiece position, the balance adjustment stud 6 is fixed in the same way. The conductive slip ring 7 is installed on the ball spline shaft 8 , the inner ring 71 of the conductive slip ring cooperates with the ball spline shaft, and the outer ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com