Automatic dynamic balance device of direct plate setter

An automatic dynamic balancing, plate making machine technology, applied in static/dynamic balance testing, measuring device, machine/structural component testing and other directions, can solve the huge vibration of the machine, affecting the normal operation of the plate making machine and other problems, to increase the work Efficiency, solving the problem of dynamic balance of the drum, reducing the effect of working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

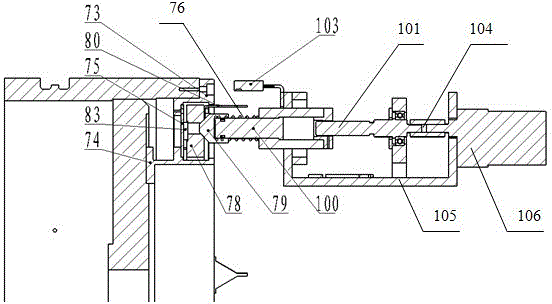

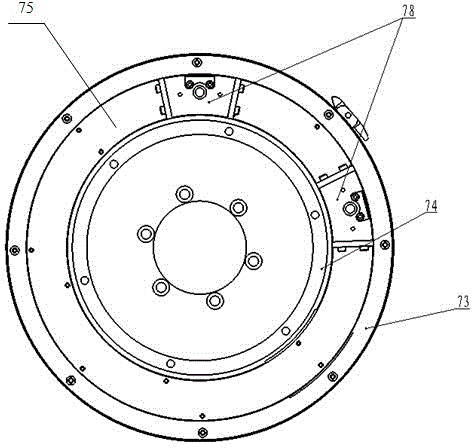

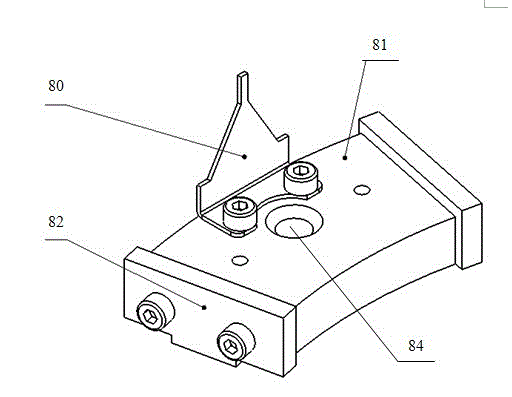

[0021] Automatic dynamic balancing device for plate-making machines, such as Figure 1 to Figure 4 As shown, it includes a roller and a balance weight support and guide device arranged on the roller. The balance weight support and guide device includes an end cover 73 and a slider support ring 74 arranged on the side of the roller. The end cover 73 and the slider support ring 74 A balance weight 78 is clamped therebetween; a balance weight drive system is also included, and the balance weight drive system includes a motor 106 and a push rod 100 . The balance drive system includes a detection optocoupler 103 for fixing and loosening the balance weight 78, a push rod 100, a push rod cap 79, a spring 76, a motor 106, and a shaft coupling 104 to form a counterweight drive system.

[0022] The balance weight driving system includes an optocoupler 103, and there are two balance weights 78. The balance weight 78 has two pieces, and by calculation, the balance weight 78 is fixed at d...

Embodiment 2

[0031] Automatic dynamic balancing device for plate-making machines, such as Figure 1 to Figure 4 As shown, it includes a roller and a balance weight support and guide device arranged on the roller. The balance weight support and guide device includes an end cover 73 and a slider support ring 74 arranged on the side of the roller. The end cover 73 and the slider support ring 74 A balance weight 78 is clamped therebetween; a balance weight drive system is also included, and the balance weight drive system includes a motor 106 and a push rod 100 .

[0032] The balance weight driving system includes an optocoupler 103, and there are two balance weights 78. The balance weight 78 has two pieces, and by calculation, the balance weight 78 is fixed at different positions for the balance of the drum. Balance weights 78 are fixed on the two end faces of the drum. The balance weights 78 are arranged in the balance weight guiding and fixing device composed of the end cover 73 and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com