Electrical spindle drived by AC permanent magnet synchronous motor

A permanent magnet synchronous motor and electric spindle technology, which is applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, electric components, etc., can solve the high technical requirements for motor rotor and stator cooling and affect the reliability of machine tools To solve the problems of safety and stability, large size of AC permanent magnet asynchronous motor, etc., to achieve the effect of good control characteristics, small torque fluctuation and easy cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

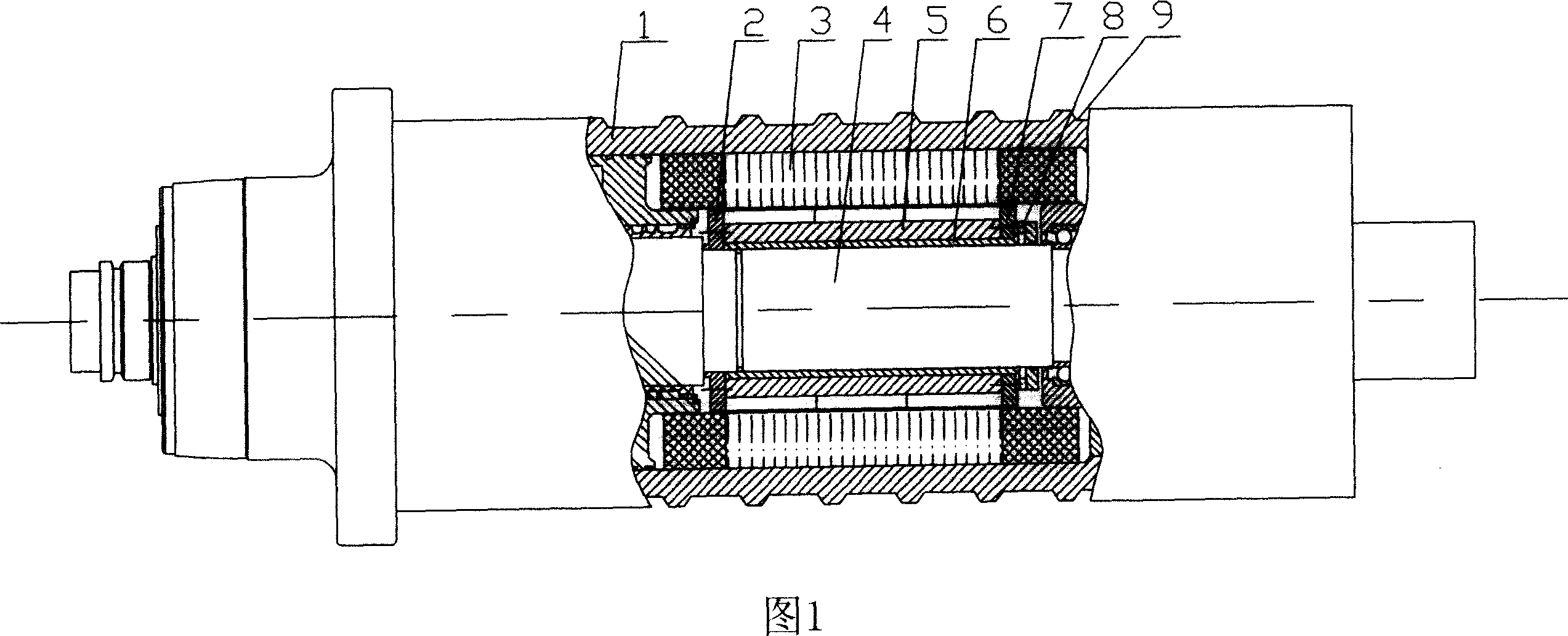

[0010] Referring to Fig. 1, the subsection diagram of the partial structure of the built-in electric spindle adopting the permanent magnet synchronous motor is illustrated. Wherein, the motor stator 3 is located outside the rotor 5 , end covers 2 and 7 are provided at both ends of the rotor, and an inner sleeve 6 is provided between the rotor 5 and the core shaft 4 of the electric spindle. The mandrel 4 is connected to the inside of the inner sleeve 6 in an interference manner, and the inner sleeve 6 is also connected to the interior of the rotor 5 in an interference manner. Also shown among the figure is an oil inlet hole 8 for dismounting.

[0011] Usually, both ends of the motor of the electric spindle are equipped with spindle bearings, and the heating of the motor will directly reduce the working accuracy of the bearings. If the heat dissipation of the motor is not solved well, it will affect the reliability and stability of the machine tool. However, for synchronous mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com