N-rail n-pin type torque suction and discharge device

A needle type, torque transmission system technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of precision, production cost increase, reliability reduction, etc., to solve the problem of torque vibration, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

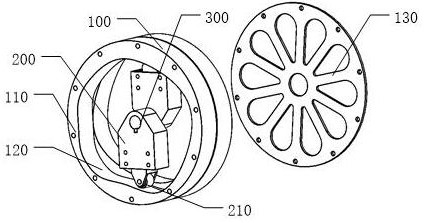

[0108] provides a figure 1 The shown double-track double-needle torque aspirator is suitable for a torque transmission system with a torque variation period of 360°. The track surface is the inner surface of the track ring, and the needle tails of the two spring pins are coaxially arranged with the track through the needle hub. And the needle tips of the two spring pins are in contact with the track surfaces of the two tracks respectively; the torque suction and discharge shaft is connected to the needle hub, and in the process of driving the spring pins to rotate, the needle tips of the two spring pins are respectively driven along their respective track surfaces. Sliding or rolling, and due to the variable diameter setting of the track, the expansion and contraction of the spring needle can be realized, and then the torque work can be sucked and exhaled in the radial direction.

Embodiment 2

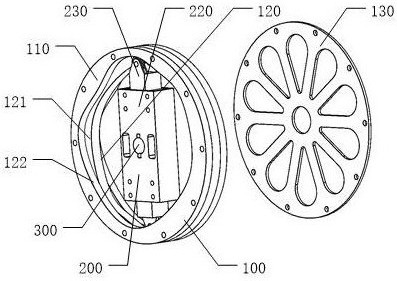

[0110] provides a figure 2 The shown double-track double-needle torque aspirator is suitable for a torque transmission system with a torque variation period of 360°. The track surface is the inner surface of the track ring, and the needle tails of the two spring needles face each other and are narrowed to only the needle ring. The needle hubs are connected together, the needle hub and the track are coaxially arranged, and the needle tips of the spring needles with branch needle tips respectively abut against the branch track surfaces on both sides, while the needle tips of the spring needles without branch needle tips It is in contact with the middle track surface in the middle; the torque suction shaft is connected with the needle ring, and in the process of driving the needle ring to rotate, the needle tip of the spring needle actively slides or rolls along the track surface, and is set due to the diameter change of the track. , to realize the expansion and contraction of t...

Embodiment 3

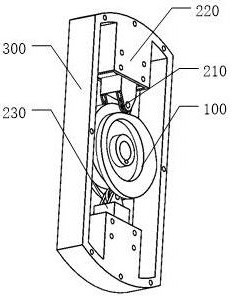

[0112] provides a image 3 The shown double-track double-needle torque aspirator is suitable for a torque transmission system with a torque variation period of 360°. The track surface is the outer surface of the track ring, and the needle tails of the two spring pins are respectively fixedly connected to the outside of the track, and On the inner surface of the needle loop coaxially arranged with the track, two elastic needles are arranged oppositely, and the needle tips of the elastic needles with branched needle tips respectively abut against the branch track surfaces on both sides, while the elastic needles without branched needle tips The needle tip of the needle is in contact with the middle track surface in the middle; the torque suction shaft drives the track to rotate through the connection with the track, so that the needle tip of the spring needle passively slides or rolls along the track surface, and due to the change of the track The radial setting realizes the exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com