Impeller fan on-site dynamic balance method

An on-site dynamic balancing, impeller fan technology, applied in static/dynamic balance testing, wind power generation, machine/structural component testing, etc. The effect of convenient measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

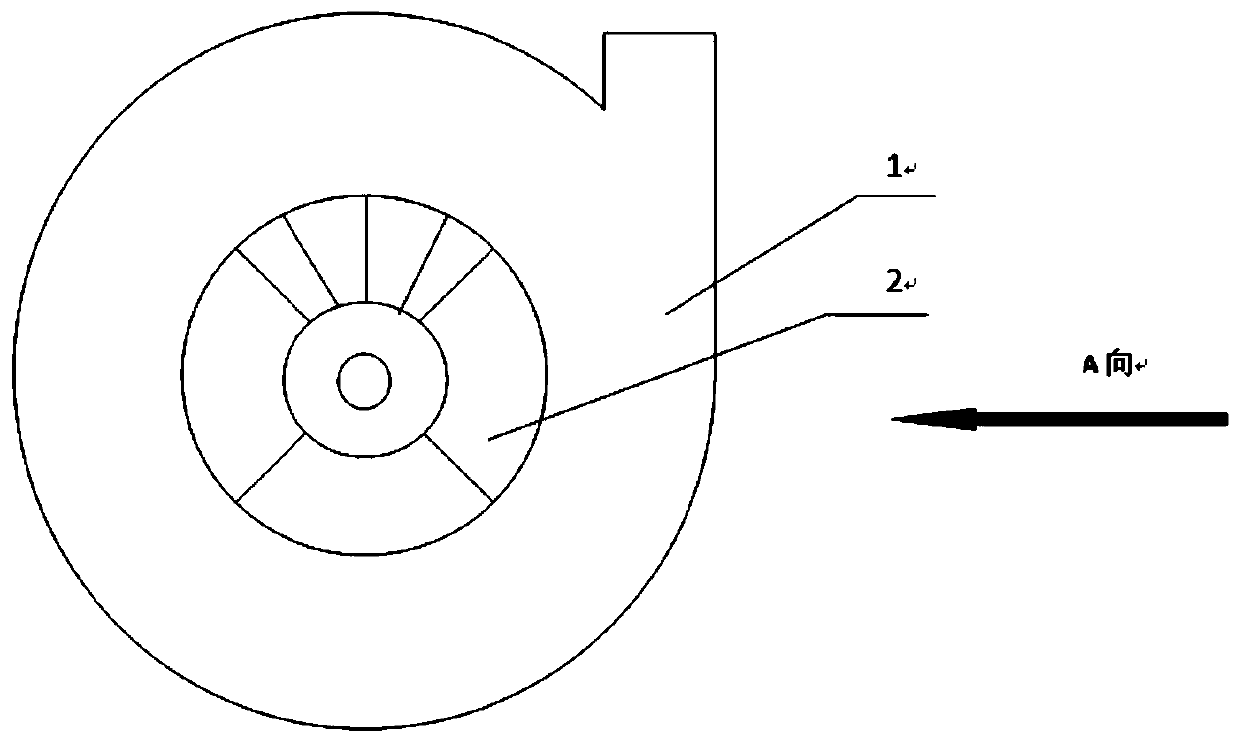

[0034] Such as figure 1 As shown, the equipment is a fan, and the measuring equipment is a vibrometer and a balance. Use a vibrometer to measure the vibration of the fan bearing seat, and use a balance to weigh the mass of the test weight 3 . The impeller fan includes a casing 1 and an impeller 2 .

[0035] Use the vibrometer to first measure the original vibration amplitude a of the equipment 0 =210um; test weight w 0 = 100g, the quality of the test weight 3 is obtained according to the field measurement of the vibration of the fan bearing seat.

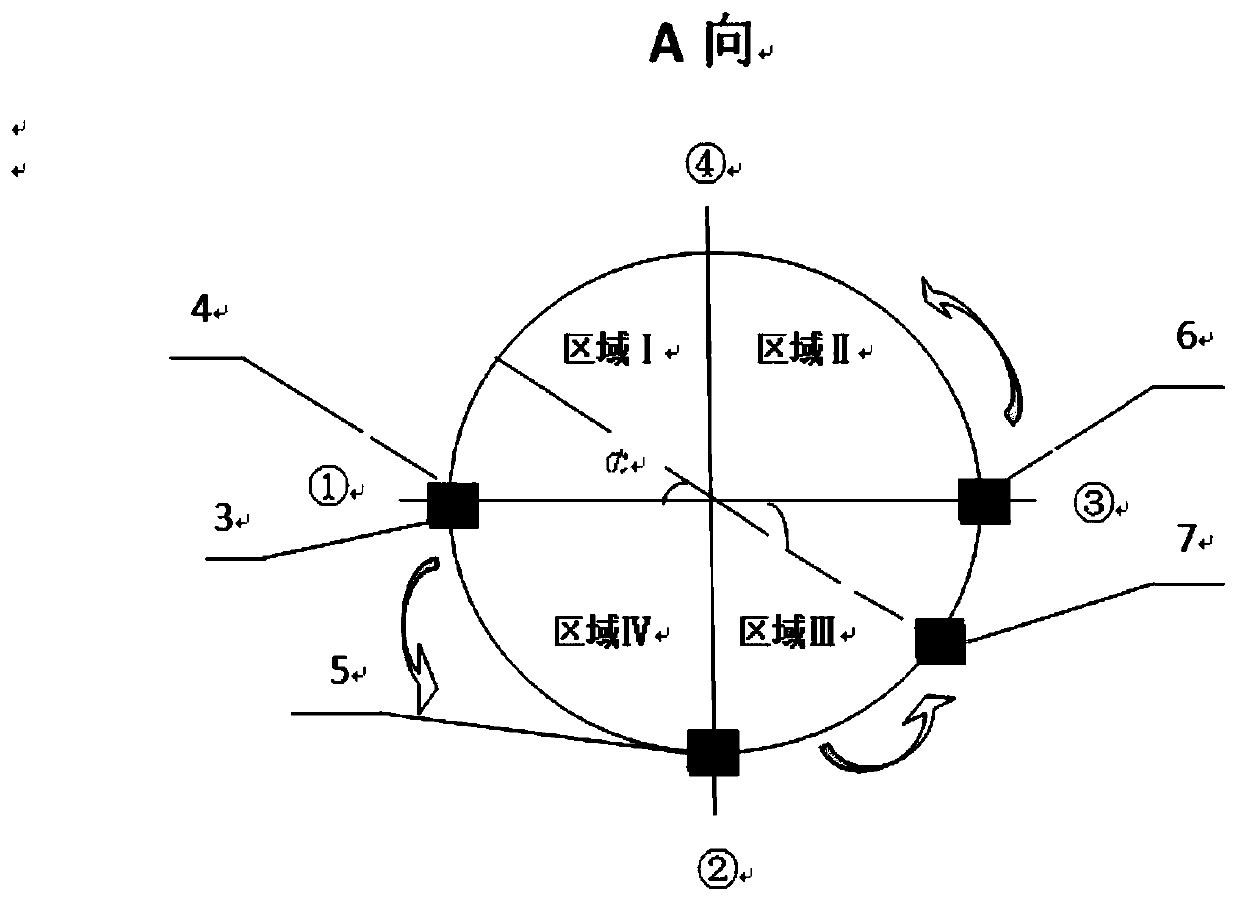

[0036] Such as figure 2 As shown, the circular area on the edge of the impeller is divided into 4 equal parts. The size of the circular area is 1000 mm in diameter of the impeller, and they are numbered 1, 2, 3, and 4 in sequence. Add a test weight at the test position 4 of the test weight at point 1, then turn on the fan or generator to measure the vibration, and record the vibration value as a 1 =290um; remove the test weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com