Special machine tool for pattern roll lentil groove processing

A special machine tool, lentil-shaped technology, used in metal processing machinery parts, metal processing equipment, milling machines, etc., can solve the problems of difficult adjustment of workpiece and tool, unstable processing quality, poor processing stability, etc., to achieve low vibration, installation and stability. Easy maintenance and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

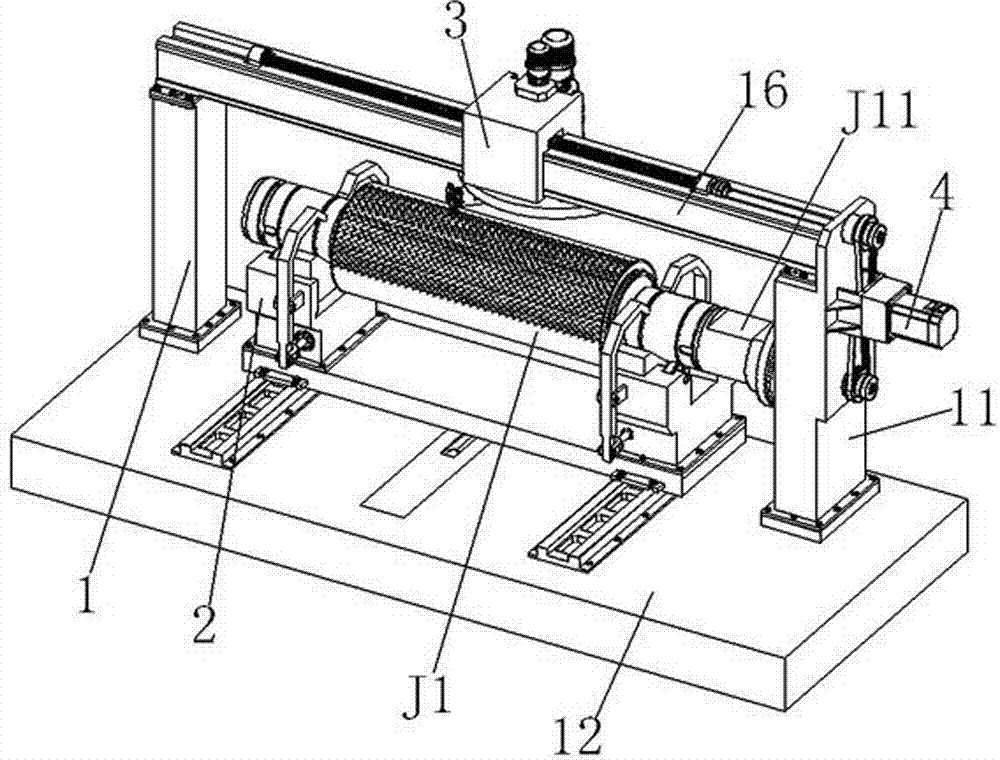

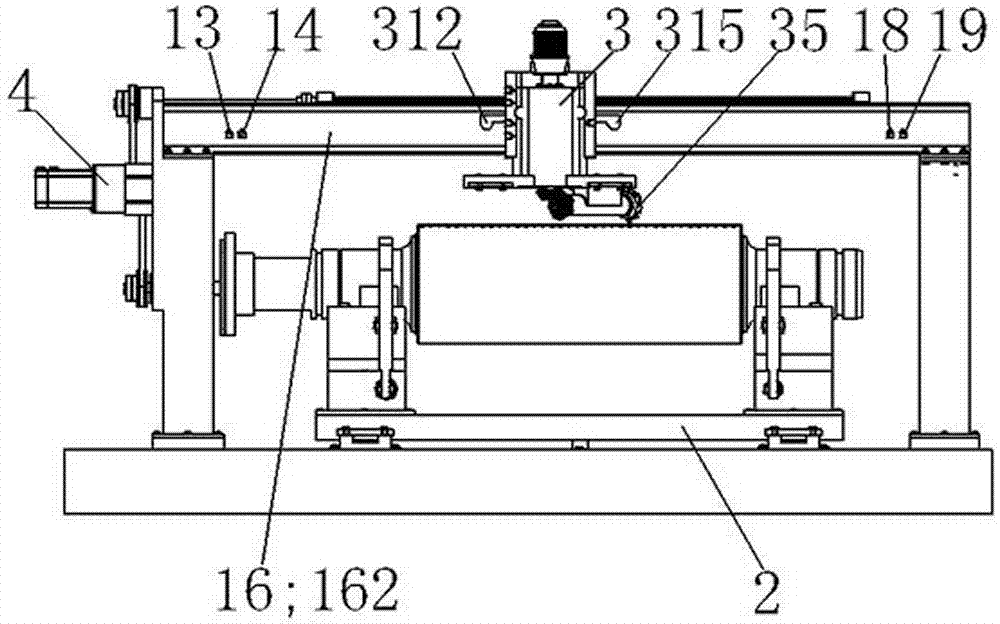

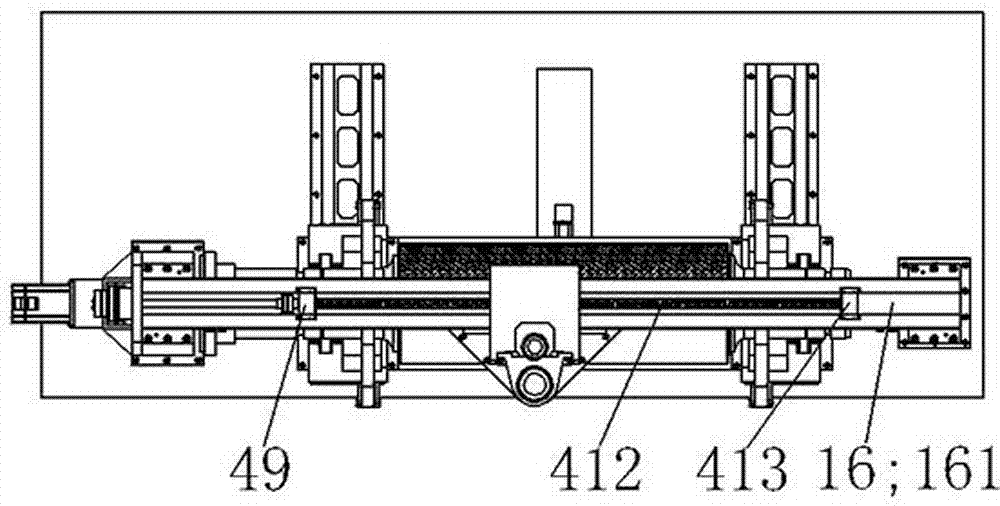

[0030] see figure 1 , figure 2 , image 3 As shown, the present invention is made up of frame assembly 1, positioning clamping device 2, power milling head device 3 and feed indexing device 4; positioning clamping device 2, power milling head device 3 and feed indexing device 4 are all arranged on the rack assembly 1.

[0031] see figure 1 , figure 2 , Figure 4 As shown, the frame assembly 1 is composed of a head leg 11, a base seat 12, a left limit travel switch 13, a left processing position travel switch 14, a cover plate 15, a beam 16, a tail leg 17, and a right processing position travel switch. 18 and the right limit travel switch 19; the head leg 11 and the tail leg 17 are placed and fixed on the base 12, the crossbeam 16 is placed and fixed on the top surface of the head leg 11 and the tail leg 17, and the crossbeam 16 1, the head leg 11 and the tail leg 17 are fixedly connected to form a gantry frame structure; the left limit travel switch 13, the left proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com