Patents

Literature

33results about How to "Effort-saving clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

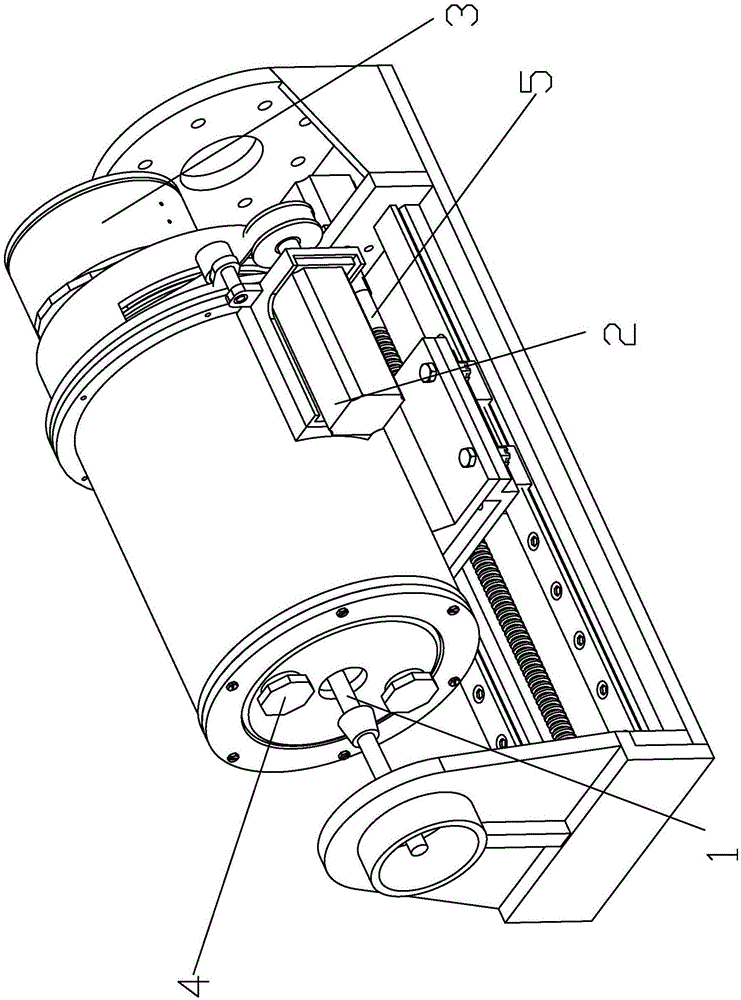

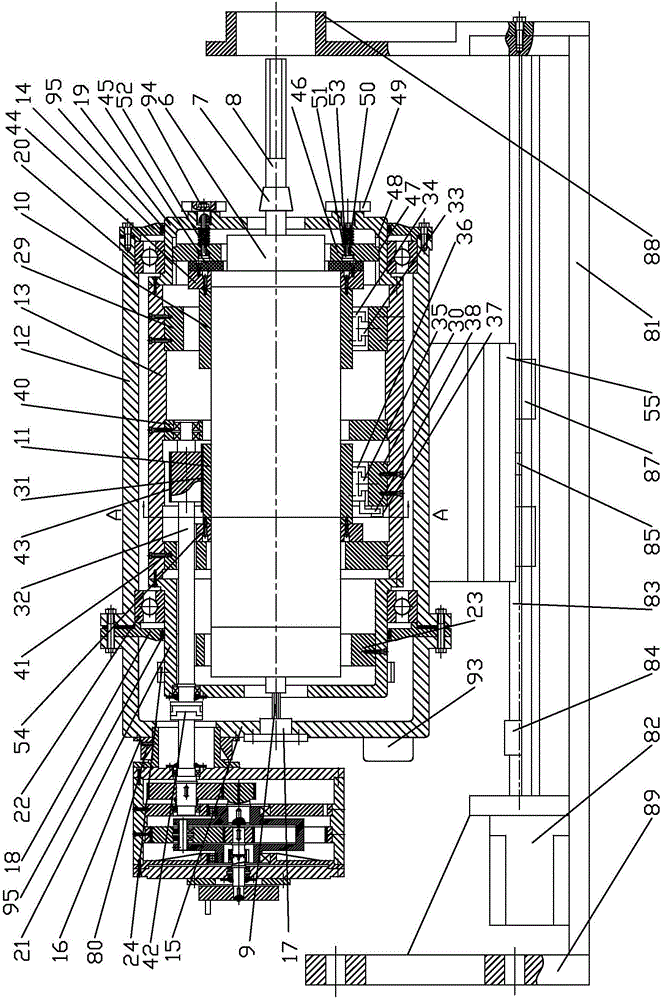

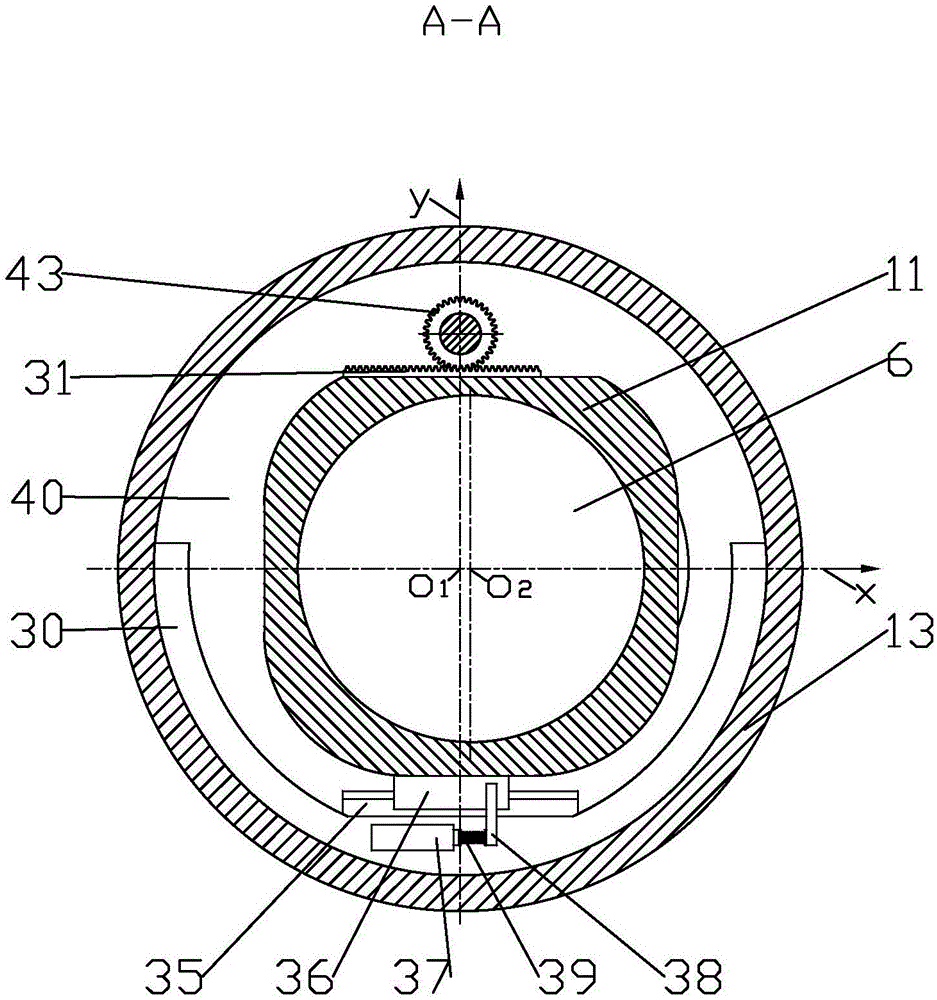

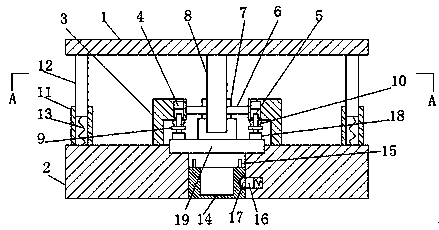

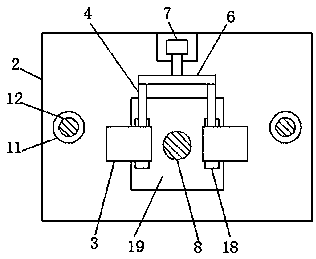

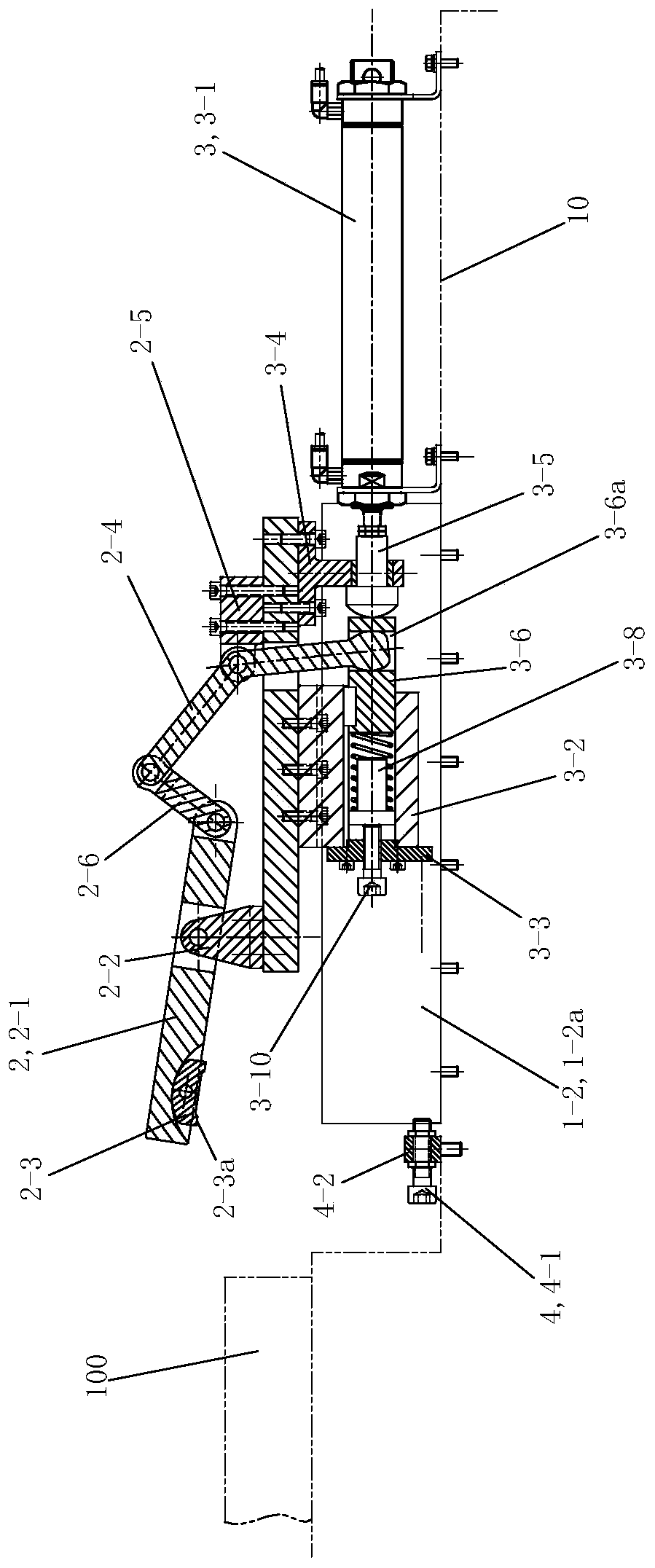

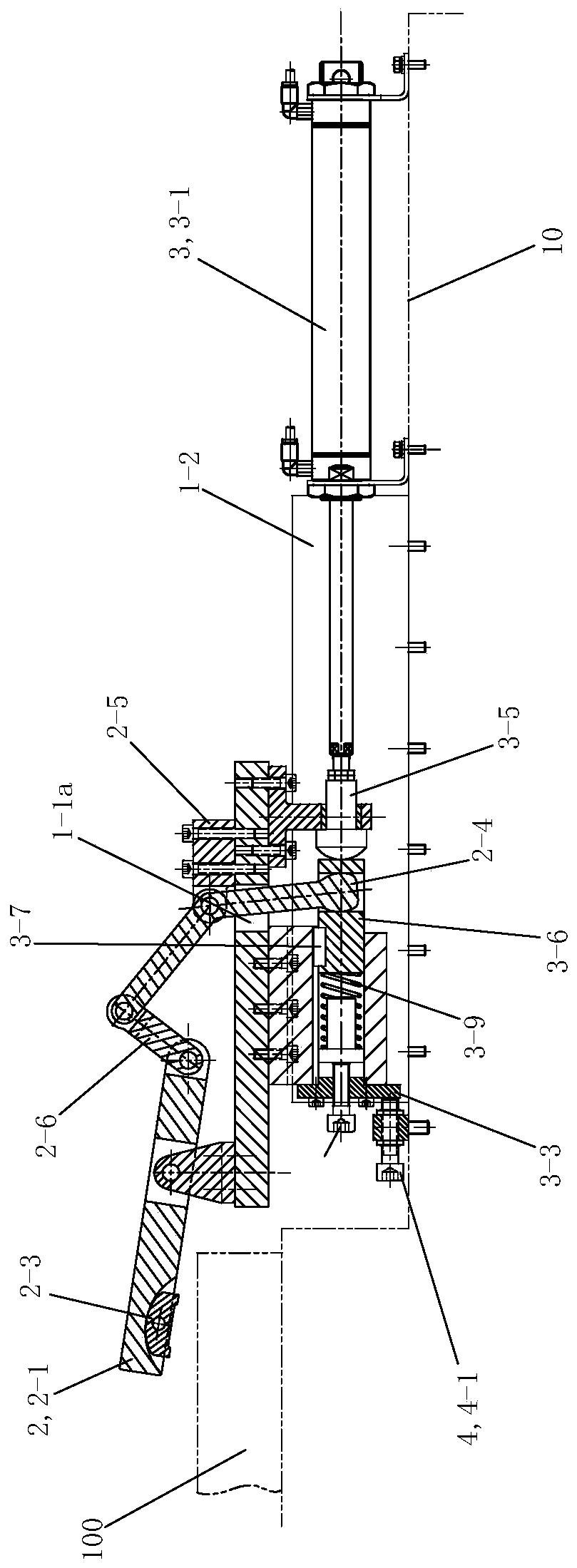

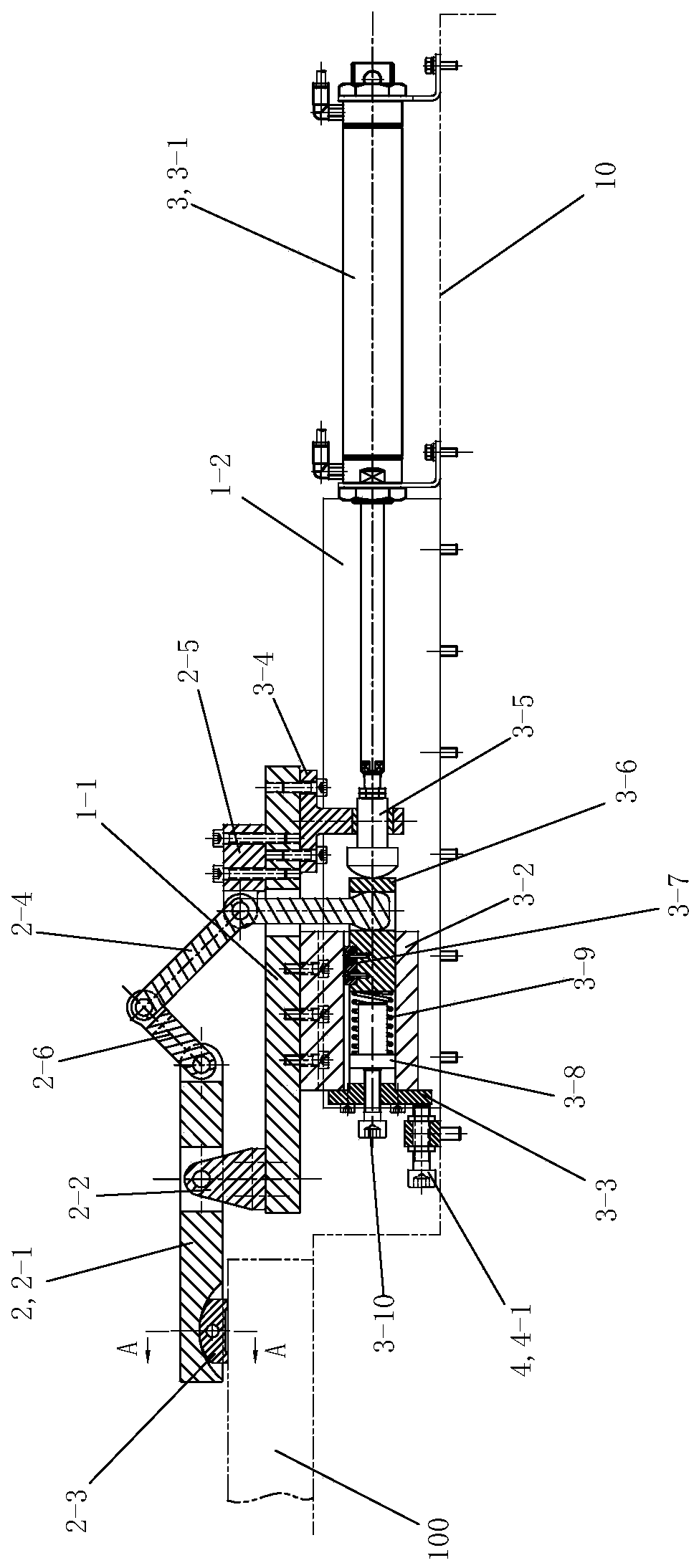

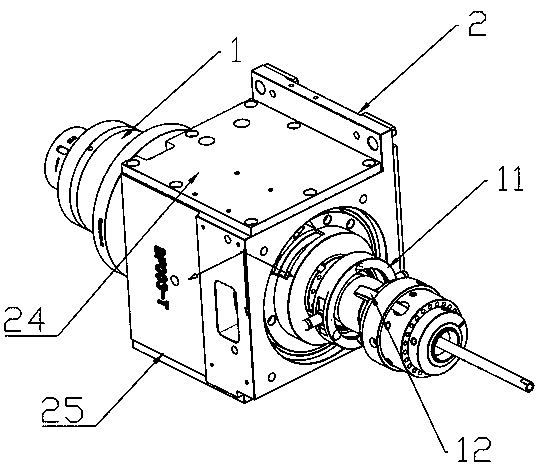

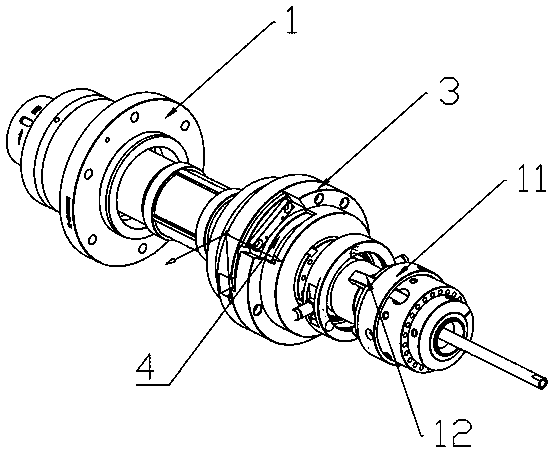

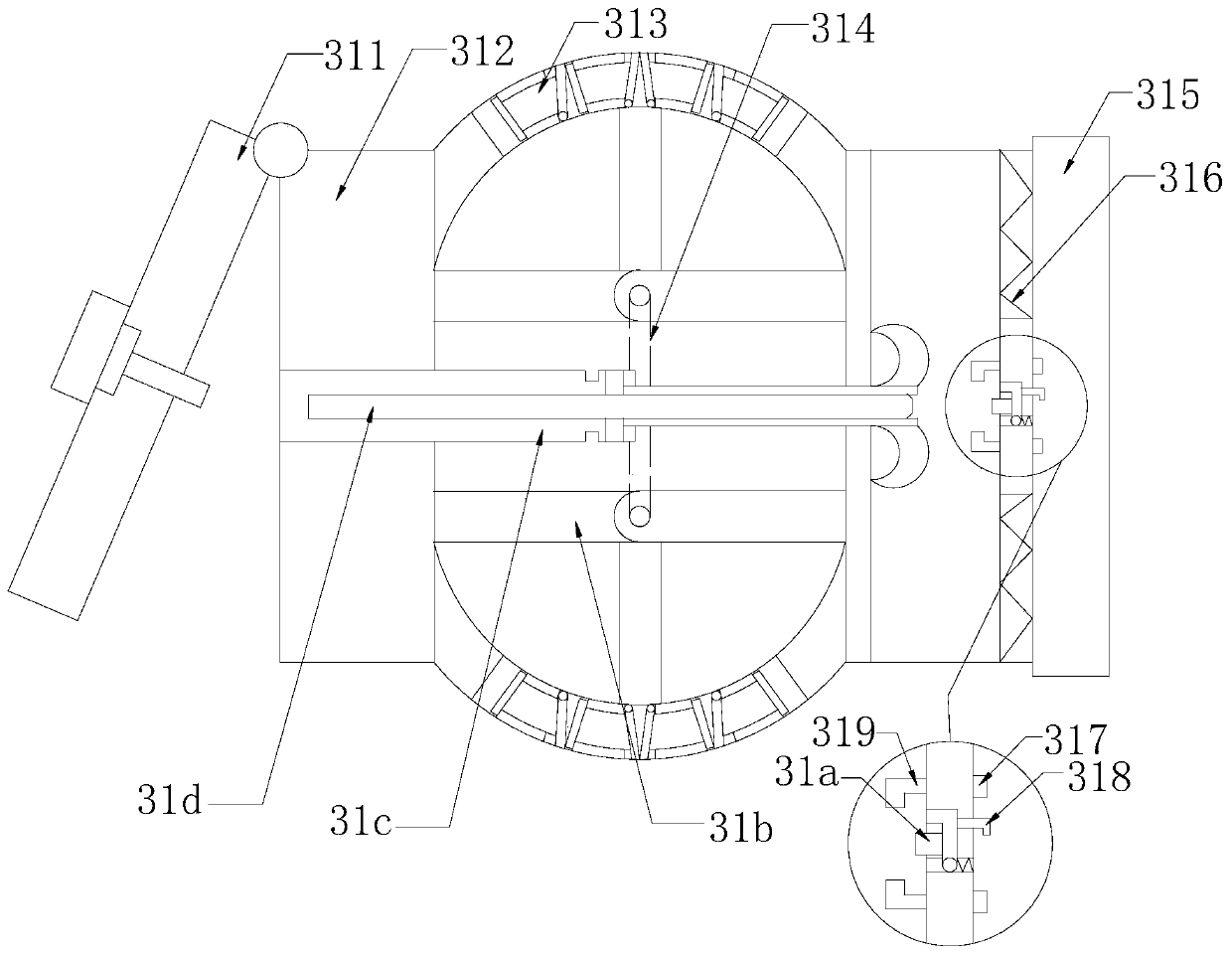

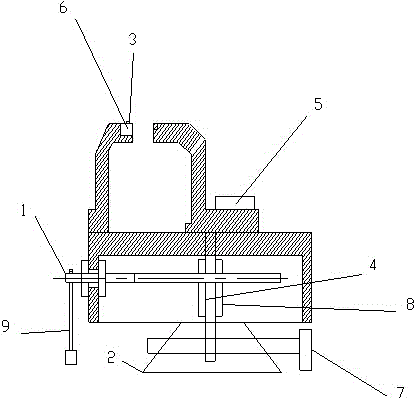

Planetary speed reduction type eccentricity-adjustable helical hole-milling device

ActiveCN106670553AReduce frictional resistanceReduce input powerFeeding apparatusLarge fixed membersSelf lockingEngineering

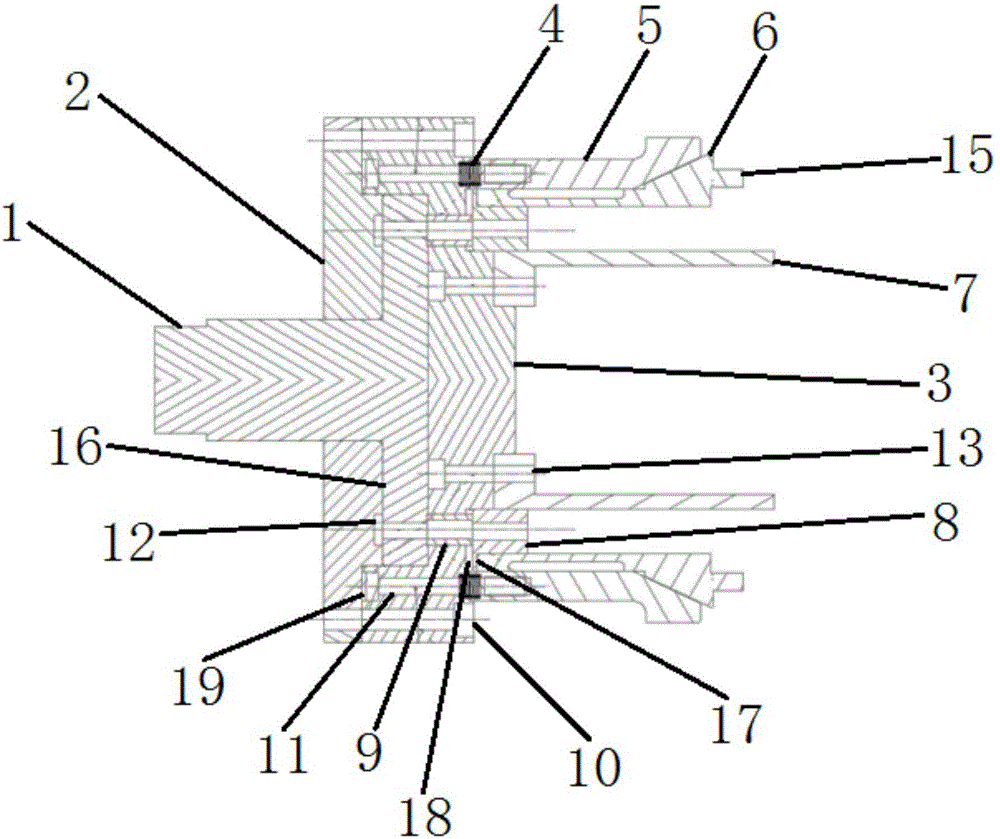

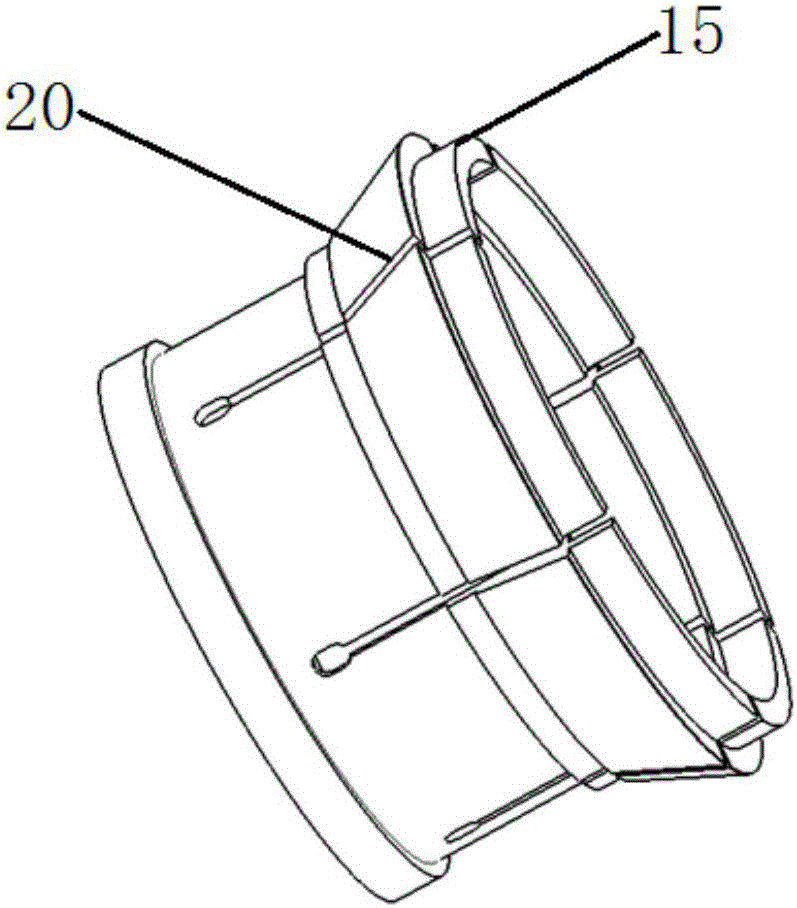

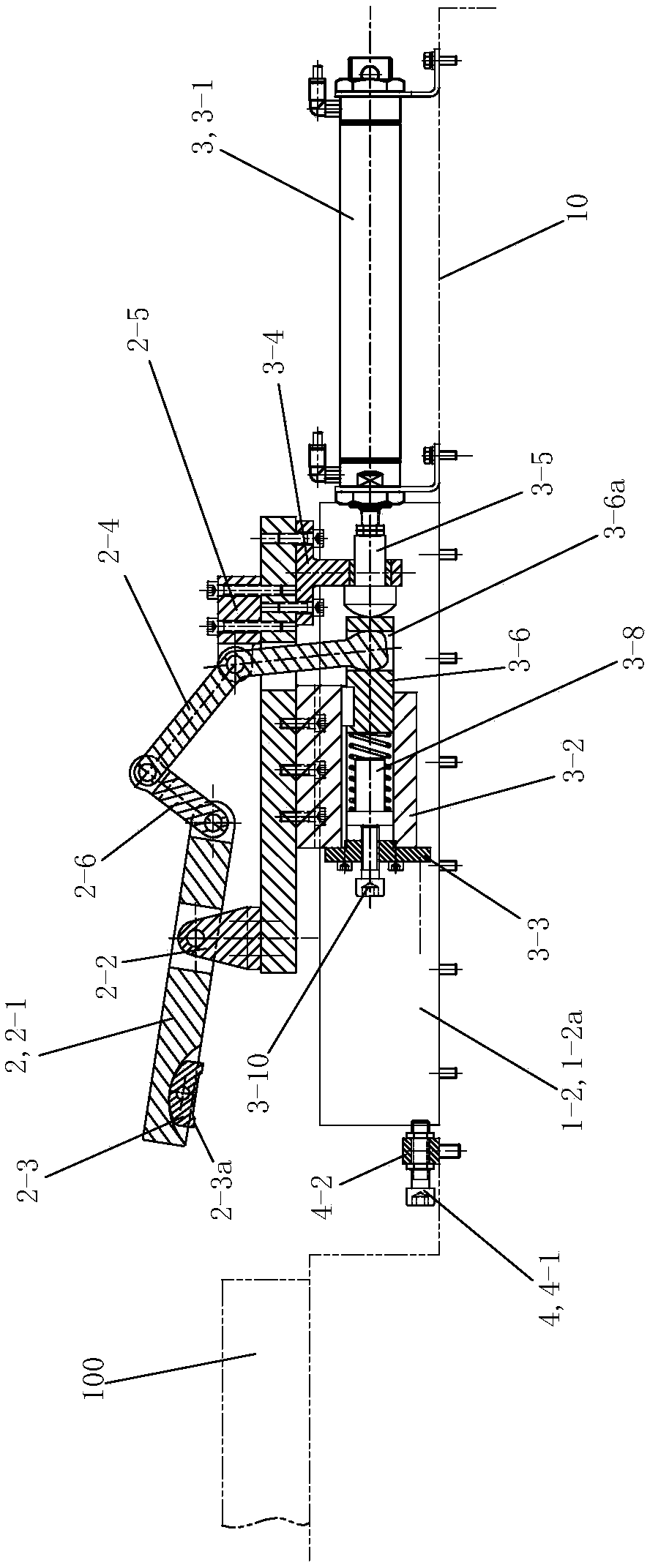

The invention discloses a planetary speed reduction type eccentricity-adjustable helical hole-milling device. The planetary speed reduction type eccentricity-adjustable helical hole-milling device is characterized by comprising a rotation system, a revolution system, a radial eccentricity adjusting system, a clamping braking system assembly and an axial feeding system. The radial eccentricity adjusting system can achieve precise trace linear eccentricity adjustment with high transmission ratio, and required input power is small. Compared with sliding block adjusting structures disclosed by existing patents, the radial eccentricity adjusting system can perform adjustment conveniently with less labor, and compared with a dual eccentric sleeve structure and an offset sliding block structure, the ratio of the size of the adjusting structure to the size of a rotation power source is greatly decreased, the occupied space is reduced, and the dead weight is reduced relatively in case of the identical material. Compared with an electromagnetic brake, the clamping braking system assembly can perform braking easily and conveniently; compared with a radial screw holding structure, the required pretightening force is small, and clamping is reliable; and compared with a worm and gear structure, self-locking never fails, and the working stability is high.

Owner:DALIAN JIAOTONG UNIVERSITY

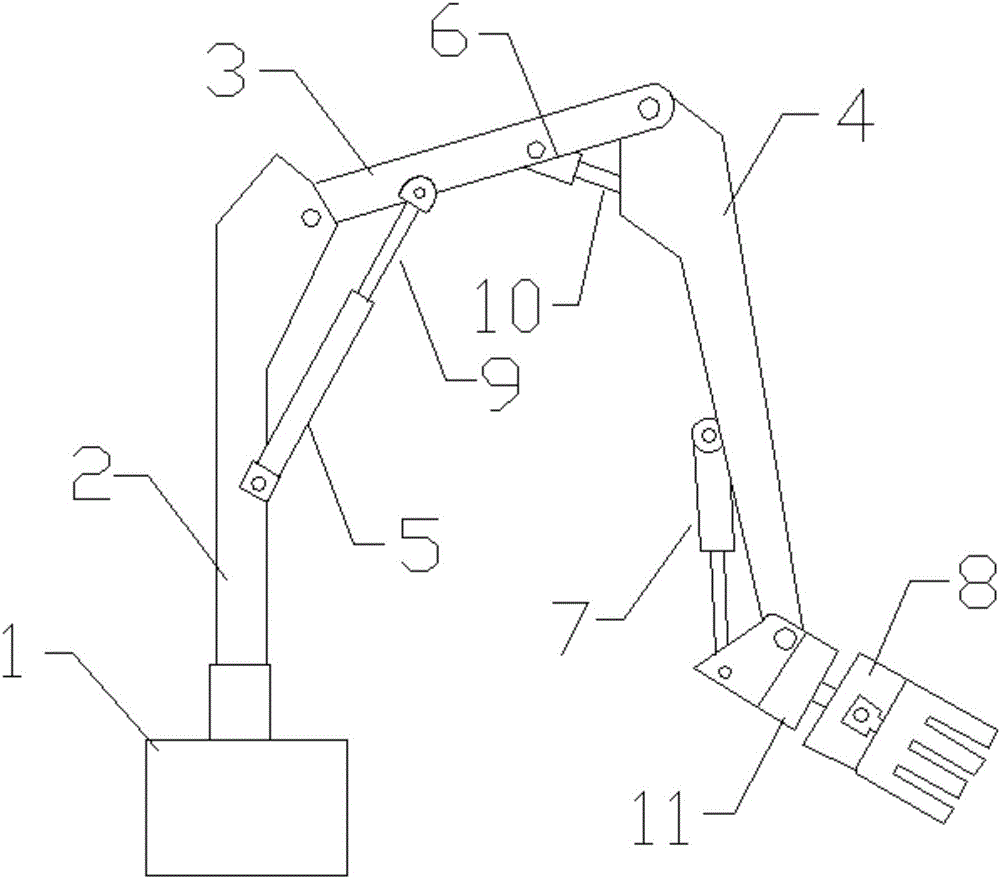

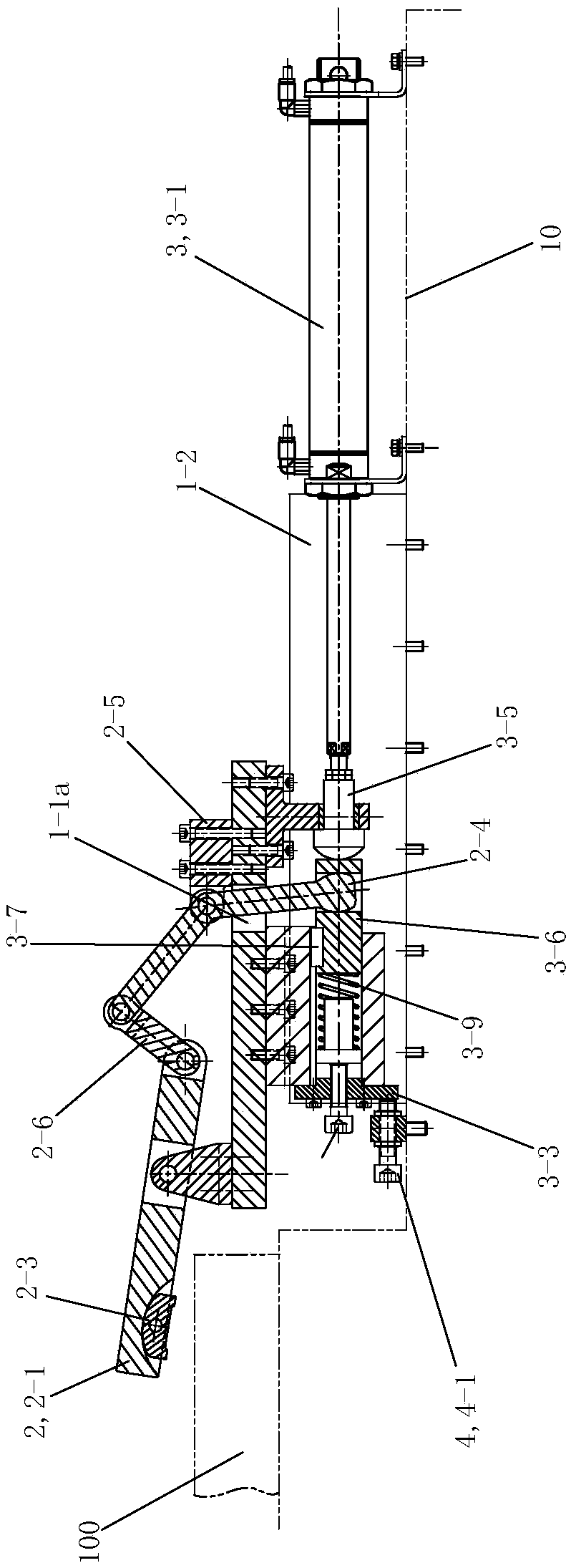

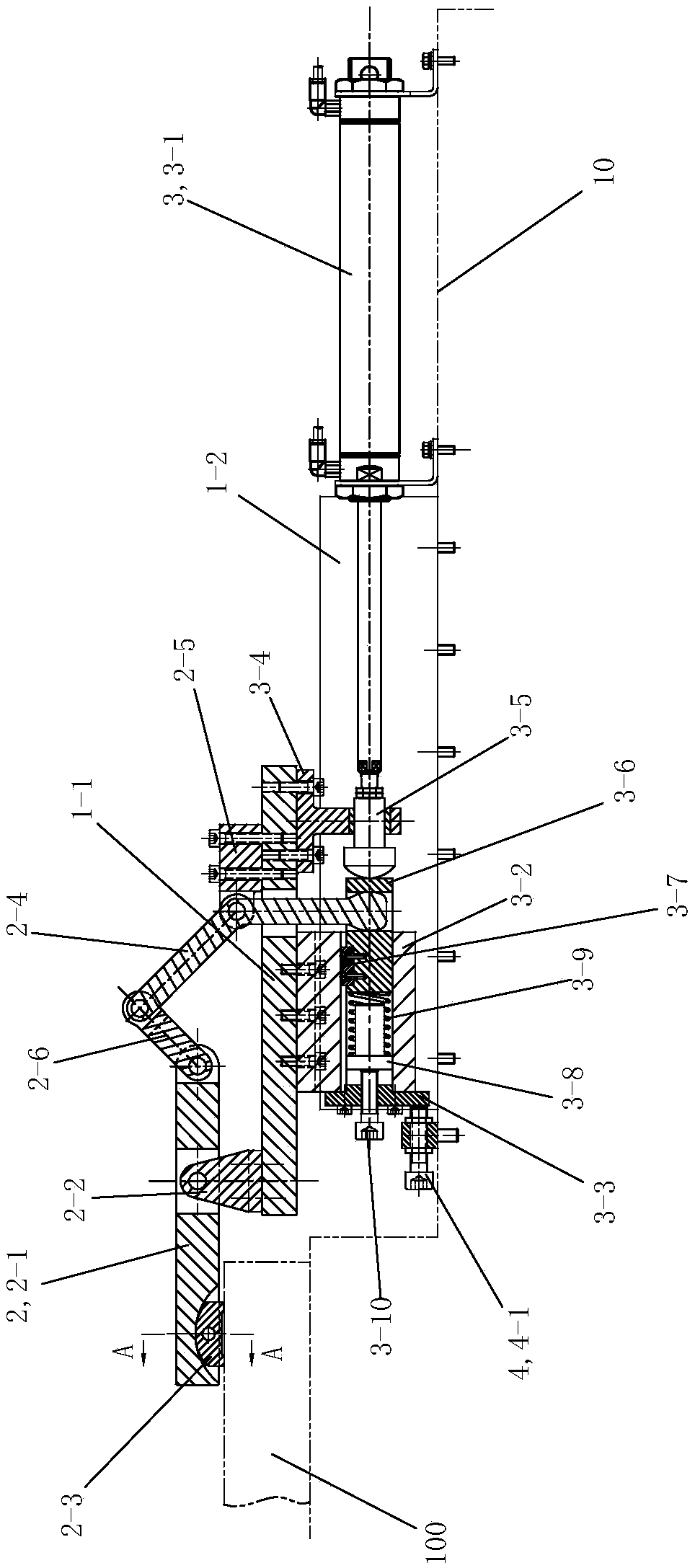

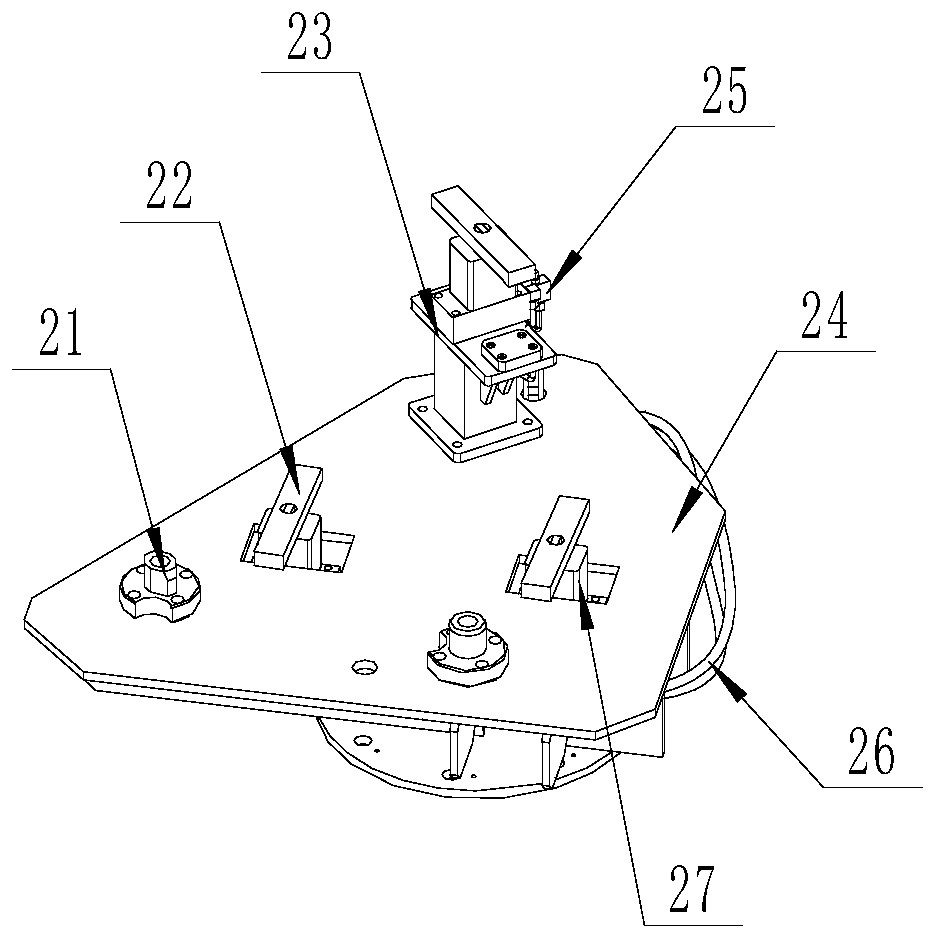

Multifunctional manipulator

InactiveCN105965502AHigh mechanical strengthImprove control effectProgramme-controlled manipulatorHydraulic cylinderEngineering

The invention discloses a multifunctional manipulator. Rubber pads are arranged in a grasper and attached to the inner walls of the grasper, friction between the grasper and goods can be increased when the rubber pads get close to each other, and the goods can be prevented from being damaged by the grasper. Bolt holes are formed in the grasper, the rubber pads are fixed to the grasper through countersunk screws so that the rubber pads can be prevented from falling off. The rubber pads have the 10-degree inclination angle, labor can be saved during clamping and reliability is achieved. Pressure sensors are arranged on the inner walls of the grasper and can know grasping force of the grasper on the goods, and strength is prevented from being too large. Hydraulic cylinders are guide rod type spiral swinging hydraulic cylinders, the grasper can rotate by 360 degrees, objects are conveniently clamped, the number of lifting hydraulic oil cylinders is two, the number of swinging hydraulic oil cylinders is two, the number of pitching hydraulic oil cylinders is two, mechanical strength of the multifunctional manipulator can be improved, and the manipulator can work for a long time. The multifunctional manipulator has the advantages of being good in control effect, high in mechanical strength and high in automation degree, and has wide market prospects.

Owner:XINXIANG UNIV

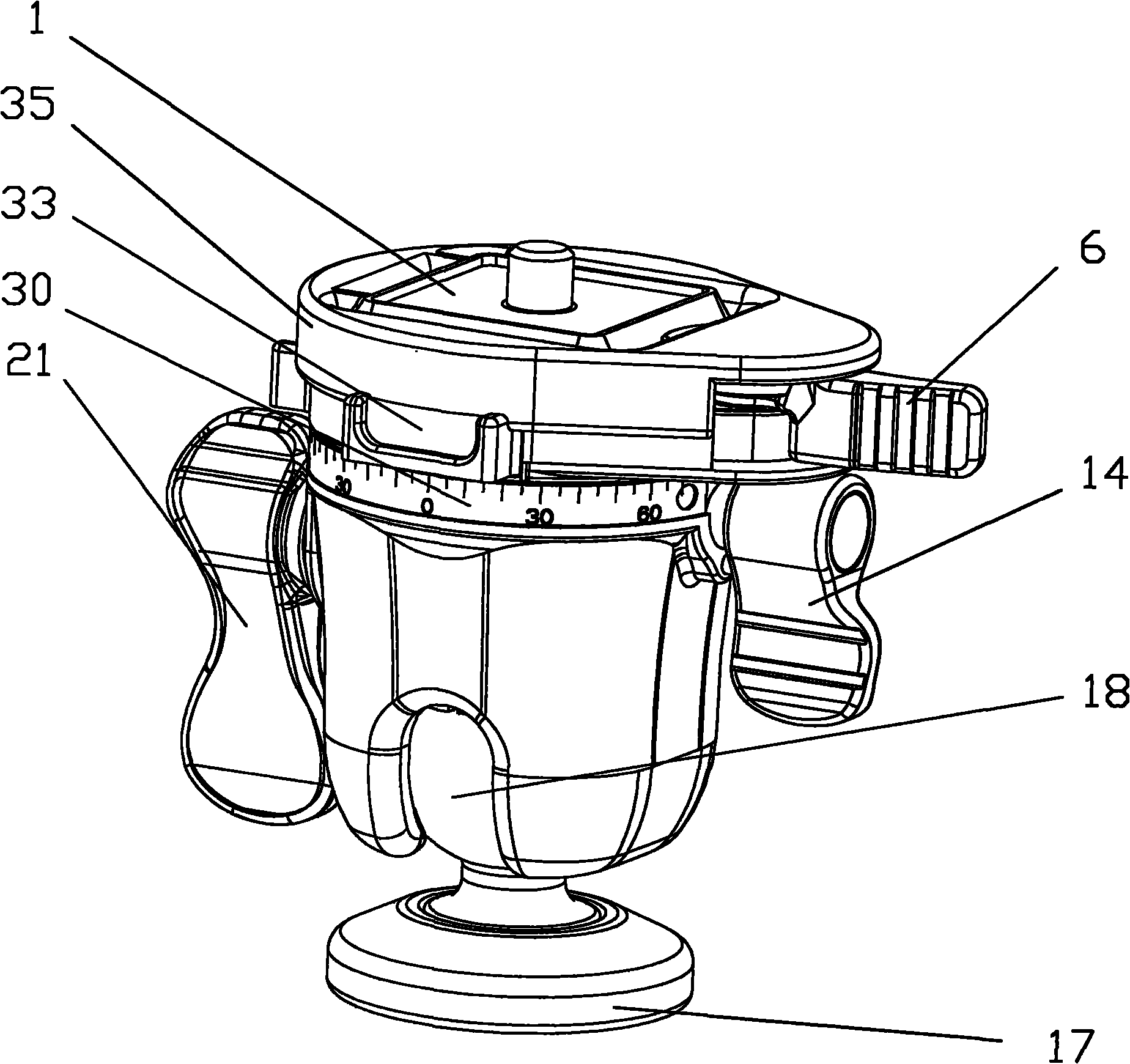

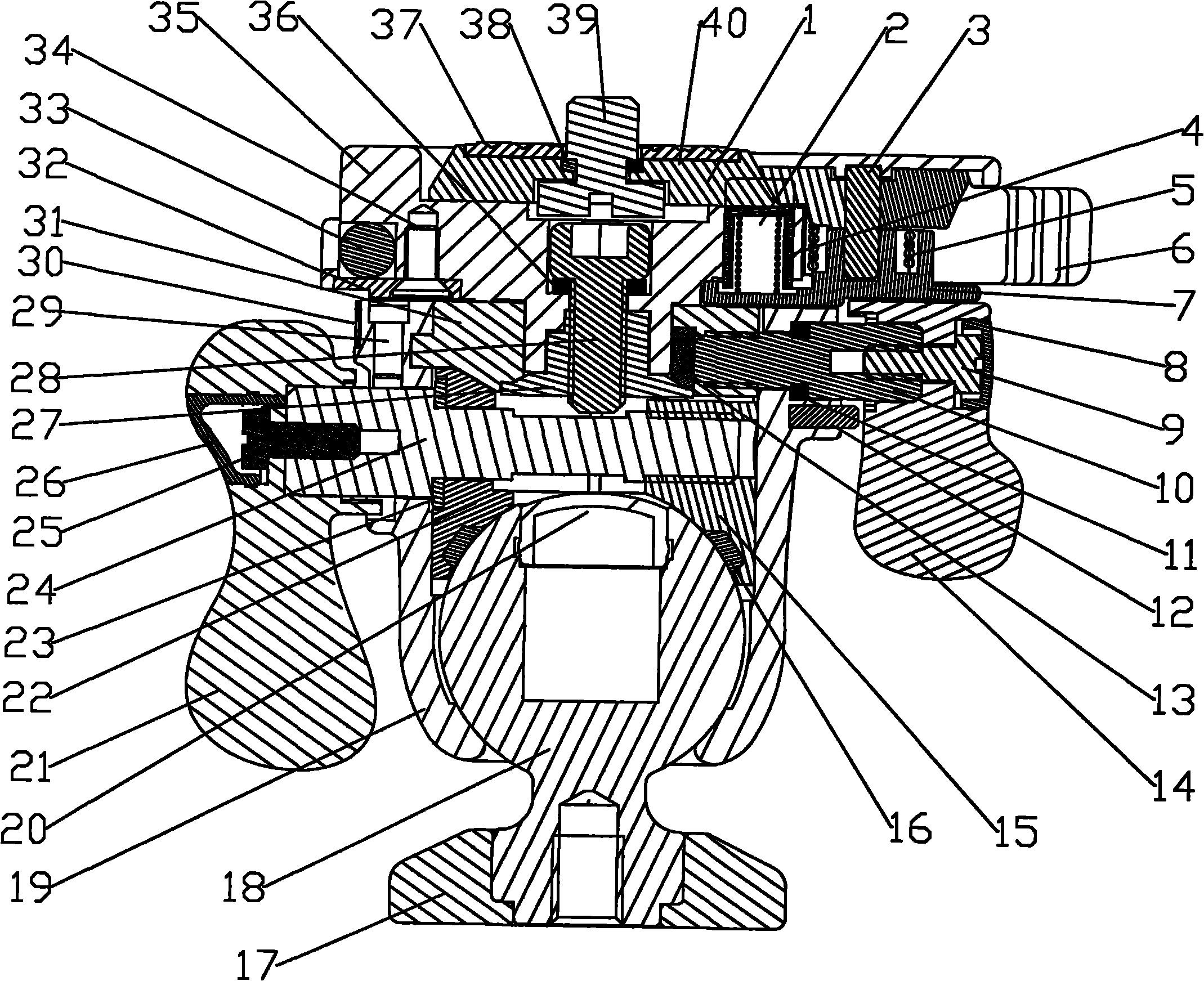

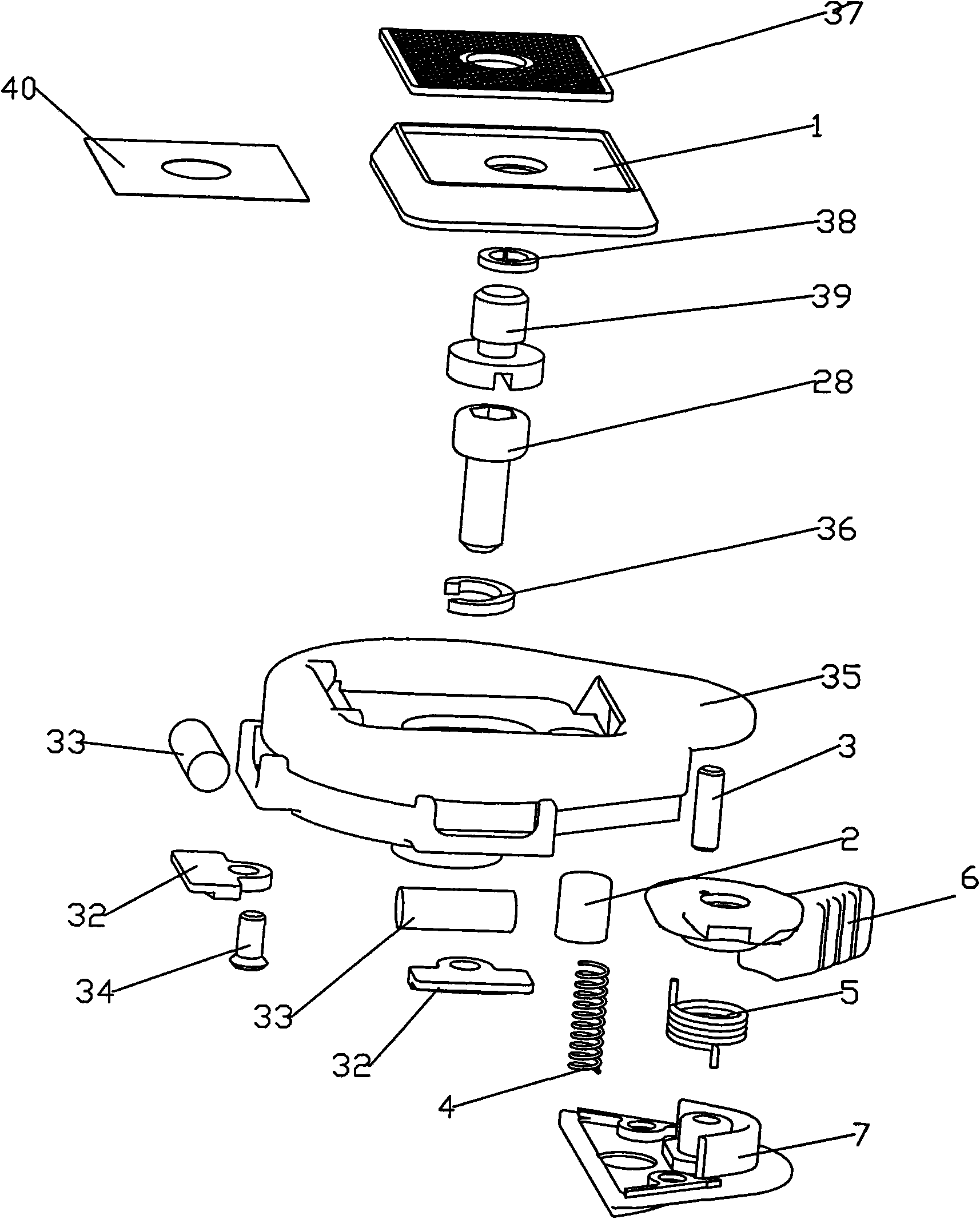

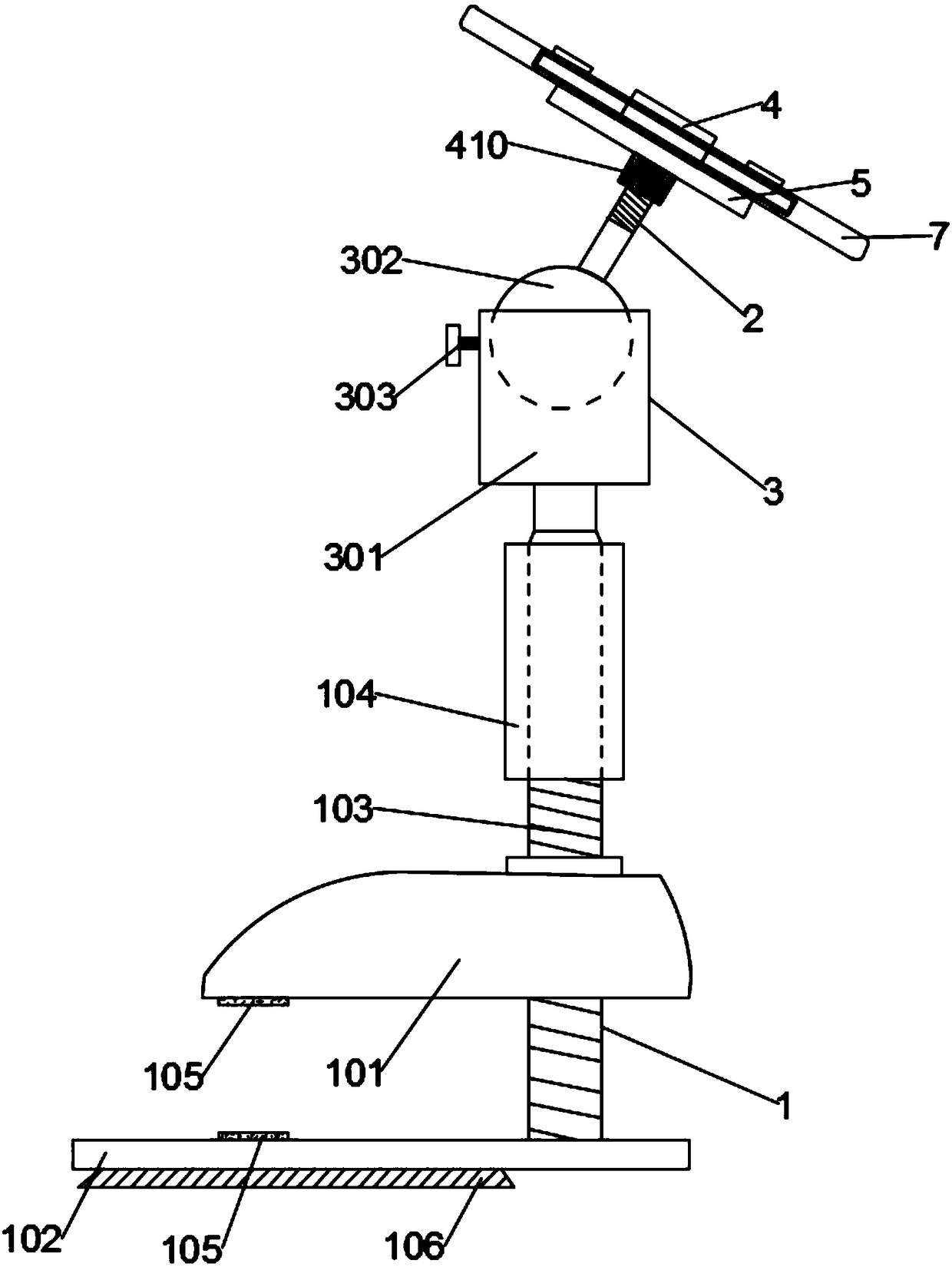

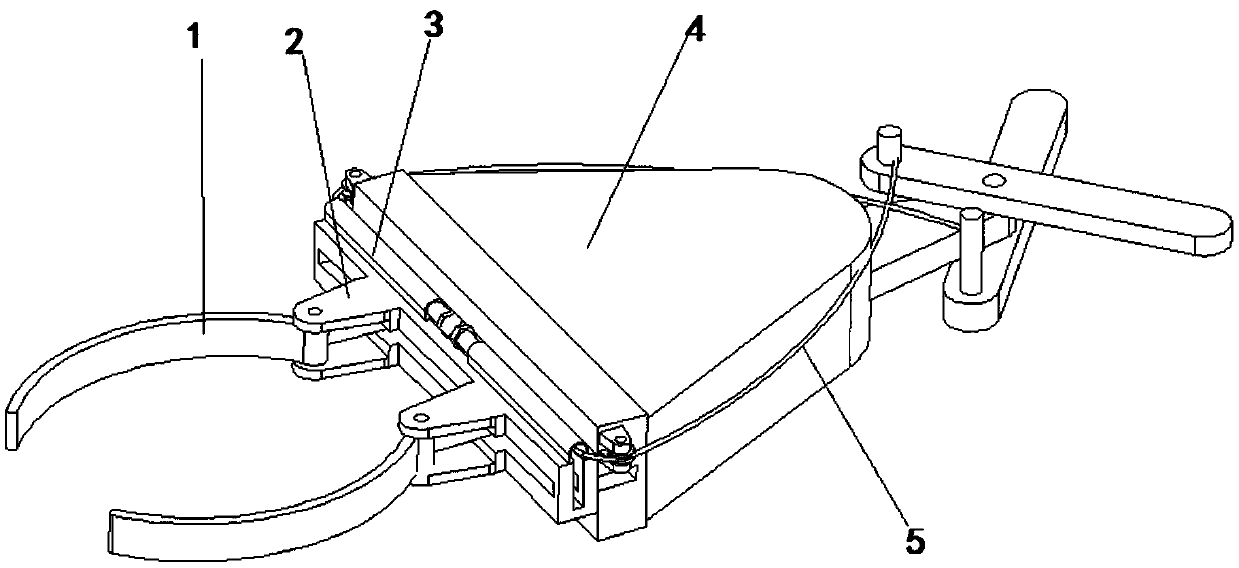

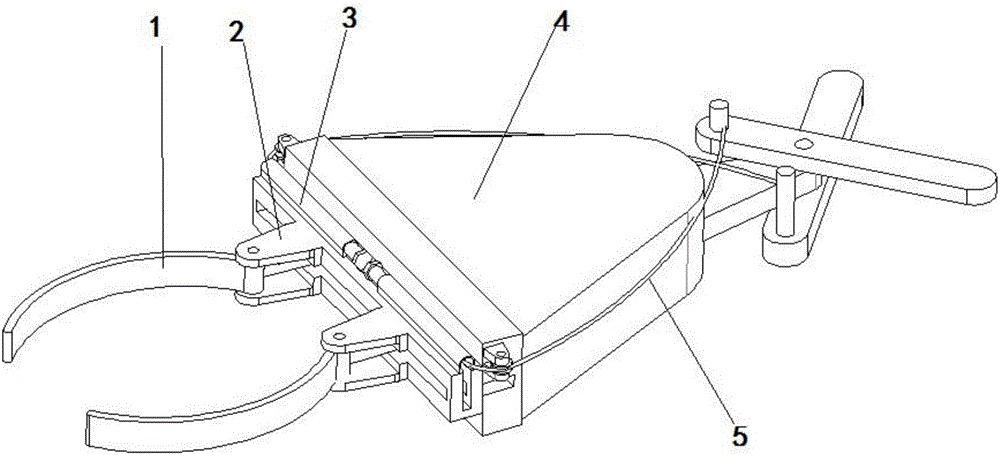

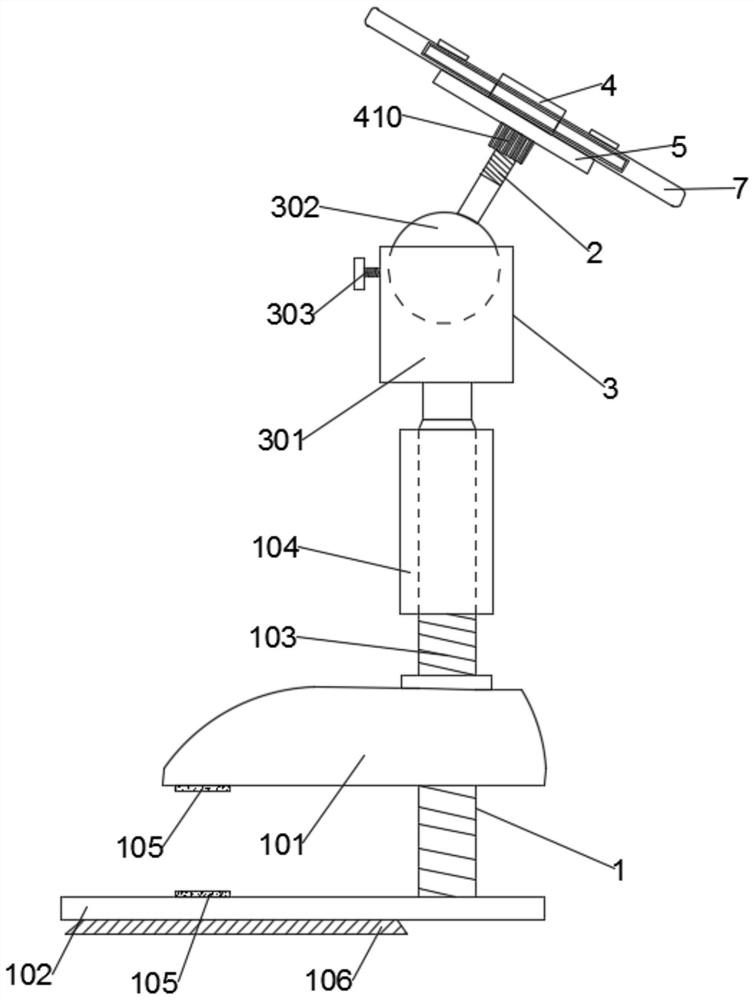

Multifunctional portable holder

InactiveCN101858476AEffort-saving clampingCompact structureStands/trestlesCamera body detailsEngineeringRotating disc

The invention relates to the photographic equipment field, in particular to a multifunctional portable holder with a holder rotating disc part which can rotate freely around a mandrel. The multifunctional portable holder comprises a holder main body. The holder main body comprises a ball seat, a ball and a ball locking device. A rotating disc and a rotating disc locking device are arranged above the holder main body. A camera connecting device is arranged on the rotating disc. The invention has the advantages that the structure is compact, the volume is small and ingenious, the multidirectional shooting function is added because the rotating disc is arranged above the holder main body, the horizontal adjustment is fast and convenient because a level meter is arranged on the rotating disc, the clamping of the ball is energy-saving because of the interactive function of the holder main body, a left clamping block, a right clamping block and a supporting ring, and the goal of easy and free use is reached.

Owner:REAPER PHOTO SUPPLY +1

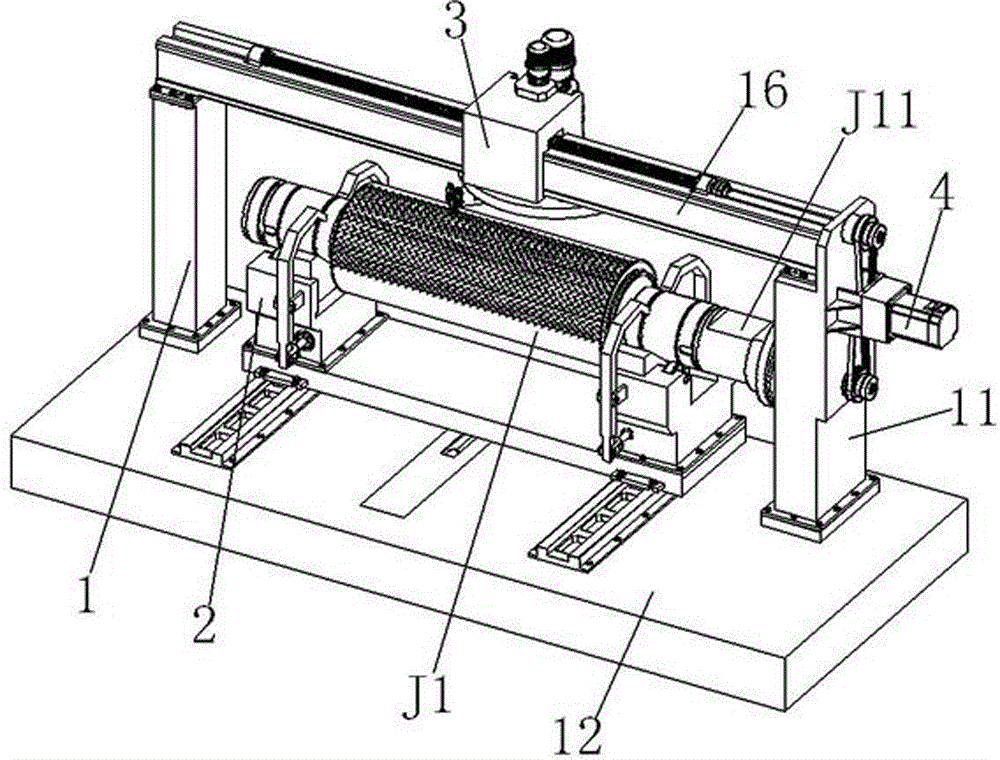

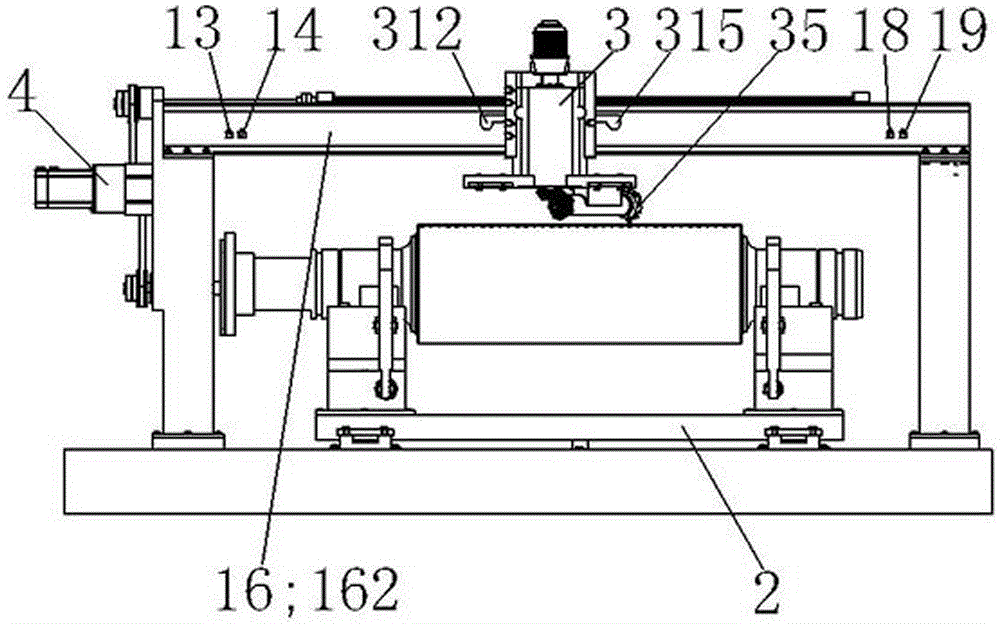

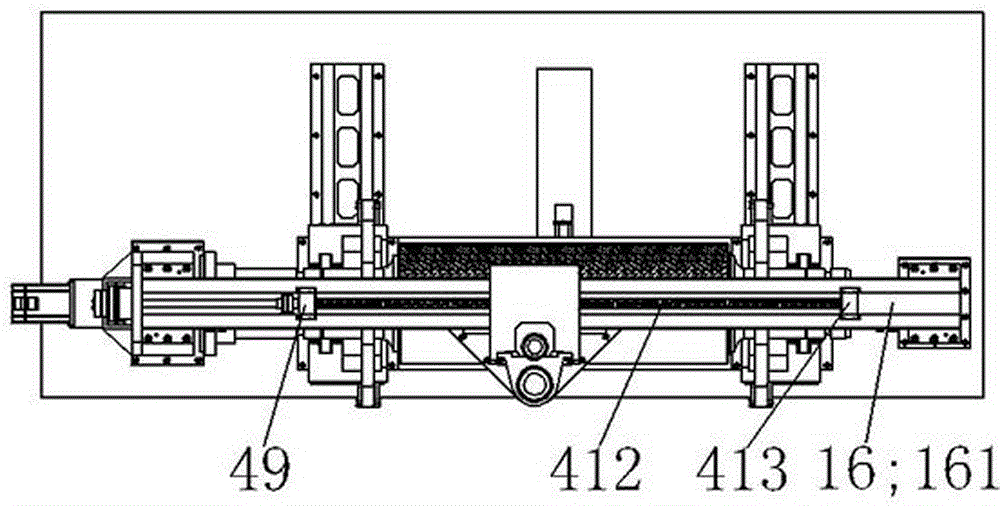

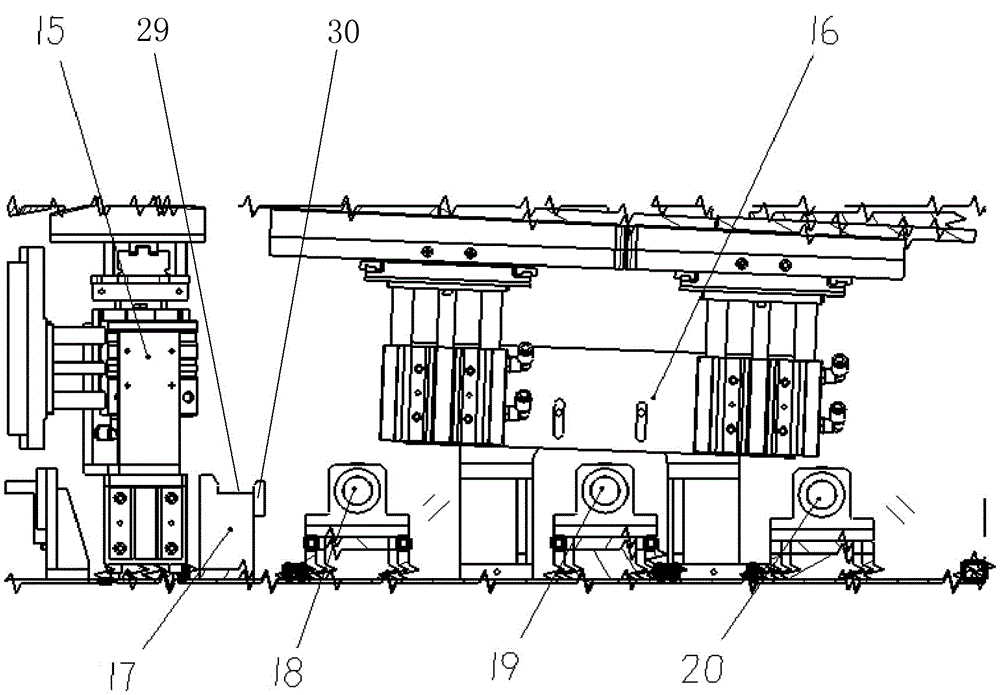

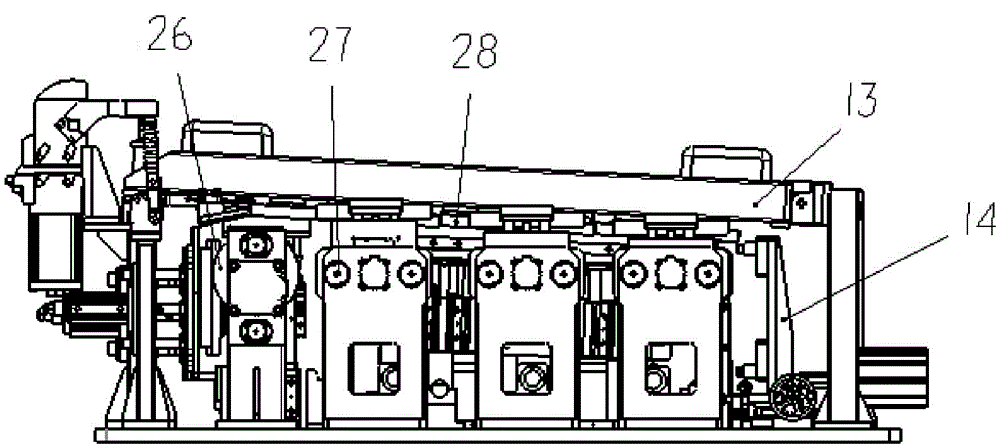

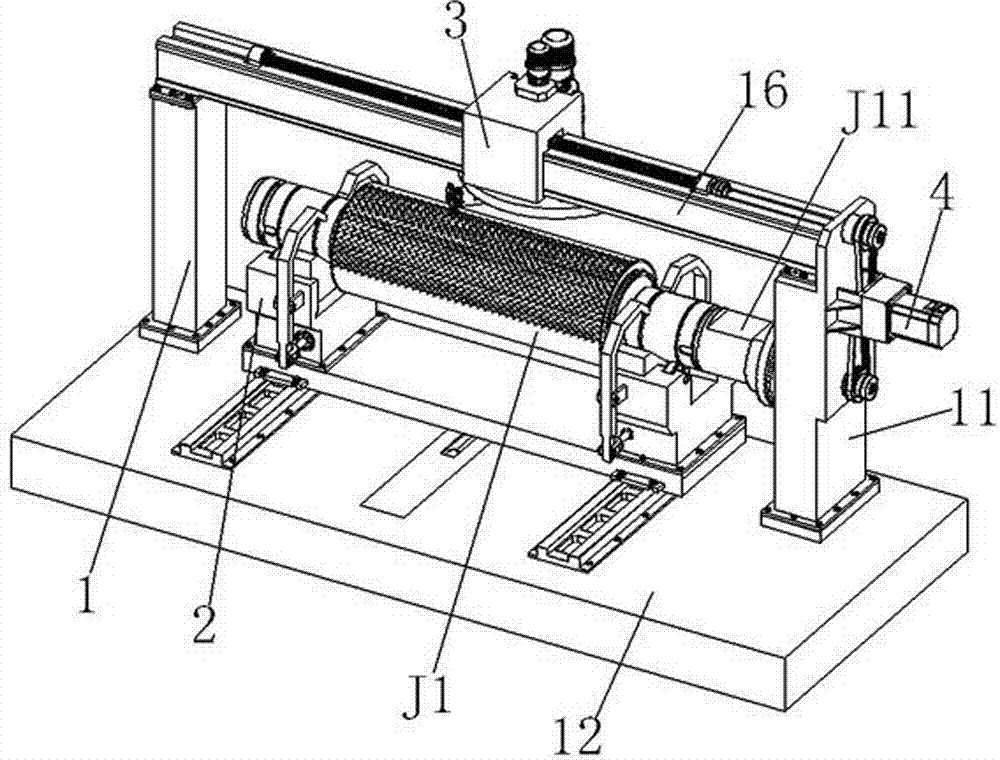

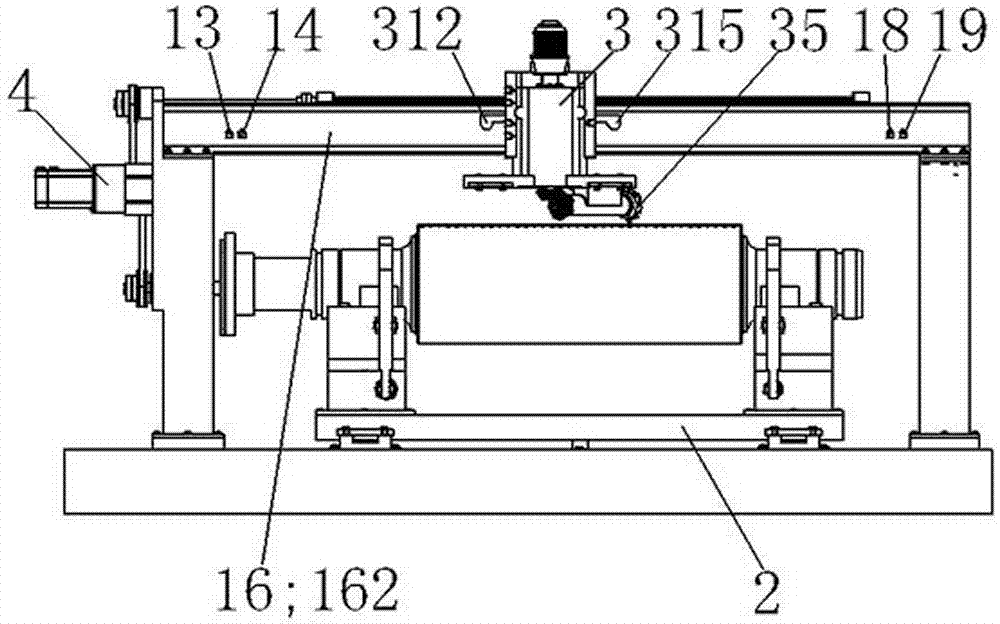

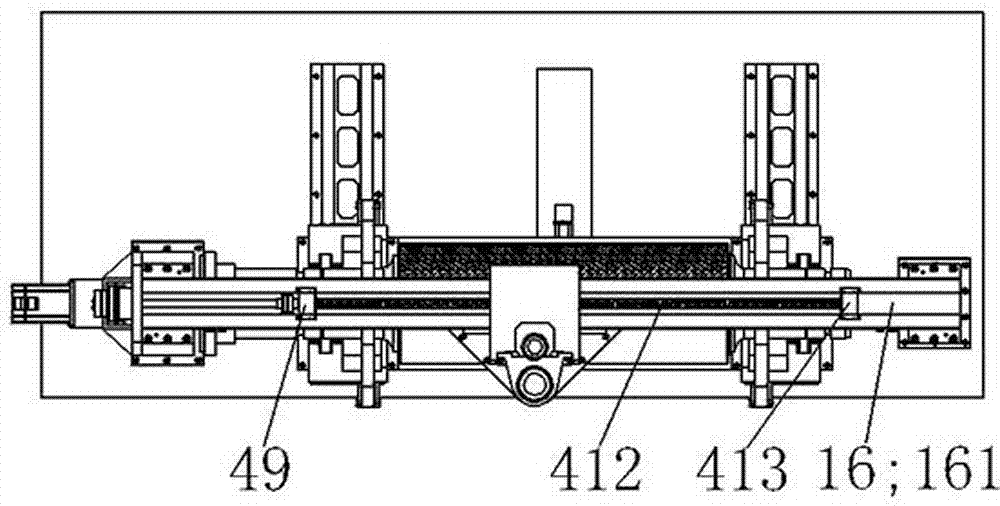

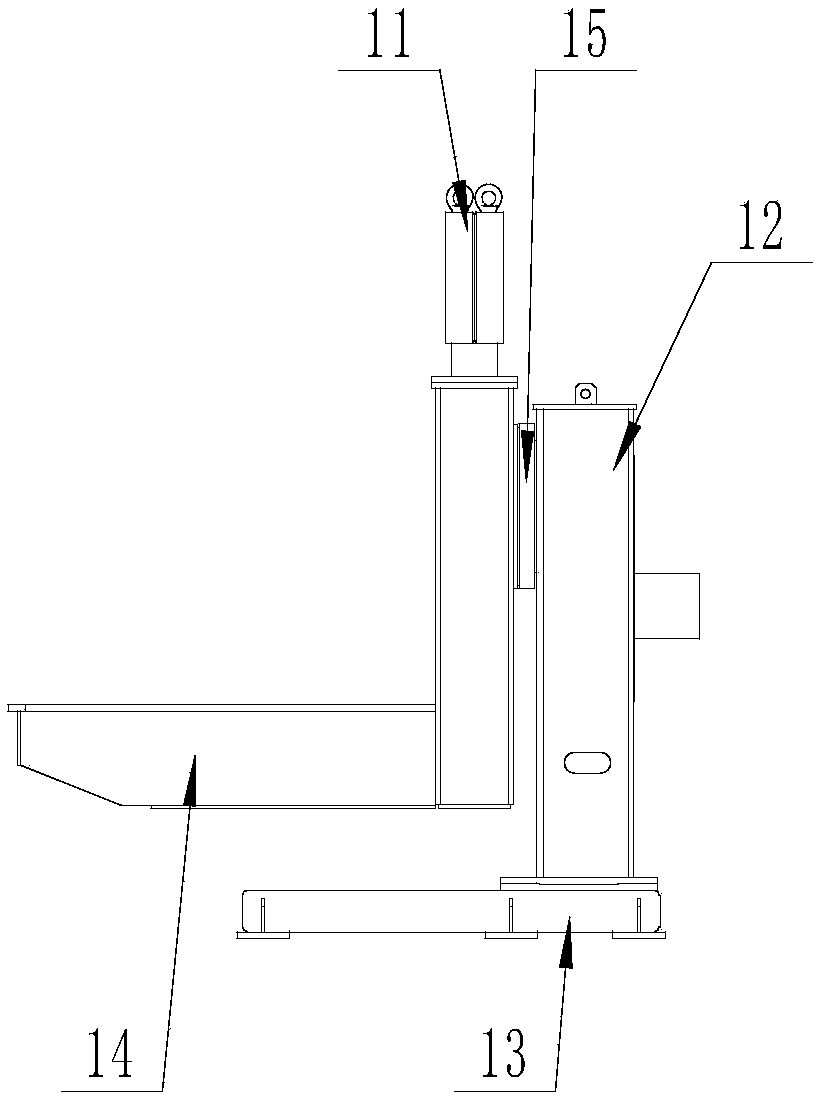

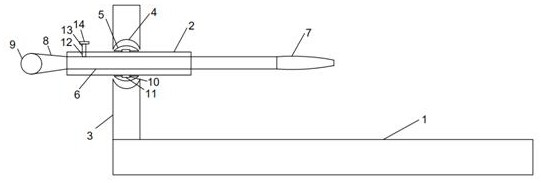

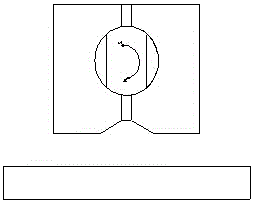

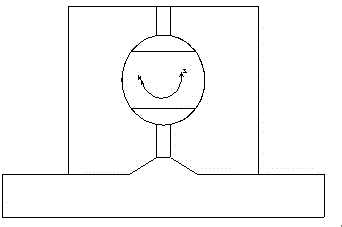

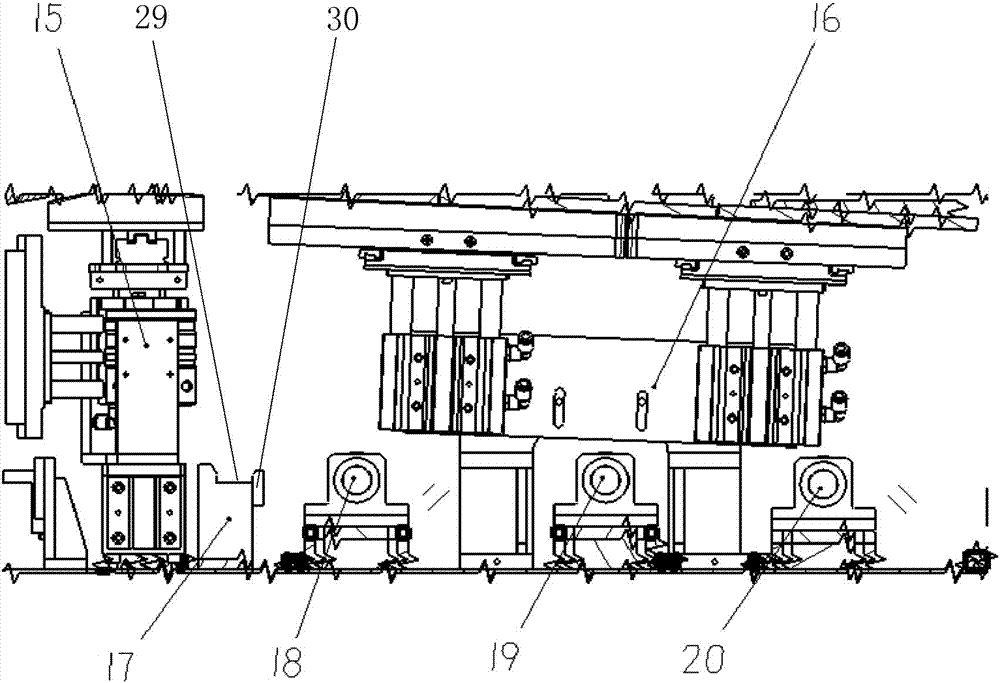

Special machine tool for machining pattern roller lentil-shaped groove

InactiveCN106001723ARealize processingClamp firmlyMilling machinesMilling equipment detailsHydraulic cylinderElectrical control

The invention discloses a special machine tool for machining a pattern roller lentil-shaped groove, and aims to provide a special machine tool in the field of metallurgical machining. The machine tool is provided with a frame module, a positioning and clamping device, a power head milling device and a feed indexing device; and the positioning and clamping device, the power head milling device and the feed indexing device are all arranged on the frame module. The whole structure of the machine tool adopts a gantry vertical milling machine layout; the rigidity of a machining process system is good; the workpiece positioning and clamping are realized by using a support roller and V-shaped block combined effect; a roller is fast in rotation and reliable in clamping; the workpiece maneuvering clamping and loosening are realized by using a hydraulic cylinder to achieve the effects of labor saving and fastness; a servo motor is adopted to provide power for peripheral indexing of the roller and positioning of a multi-station feeding position; the indexing and positioning precision is high; the automatic workpiece machining can be realized through electric control; and the machine tool is used for machining workpieces, low in vibration, few in surface vibration patterns, high in machining quality, simple in structure, convenient for maintenance and low in equipment investment.

Owner:KUNMING UNIV

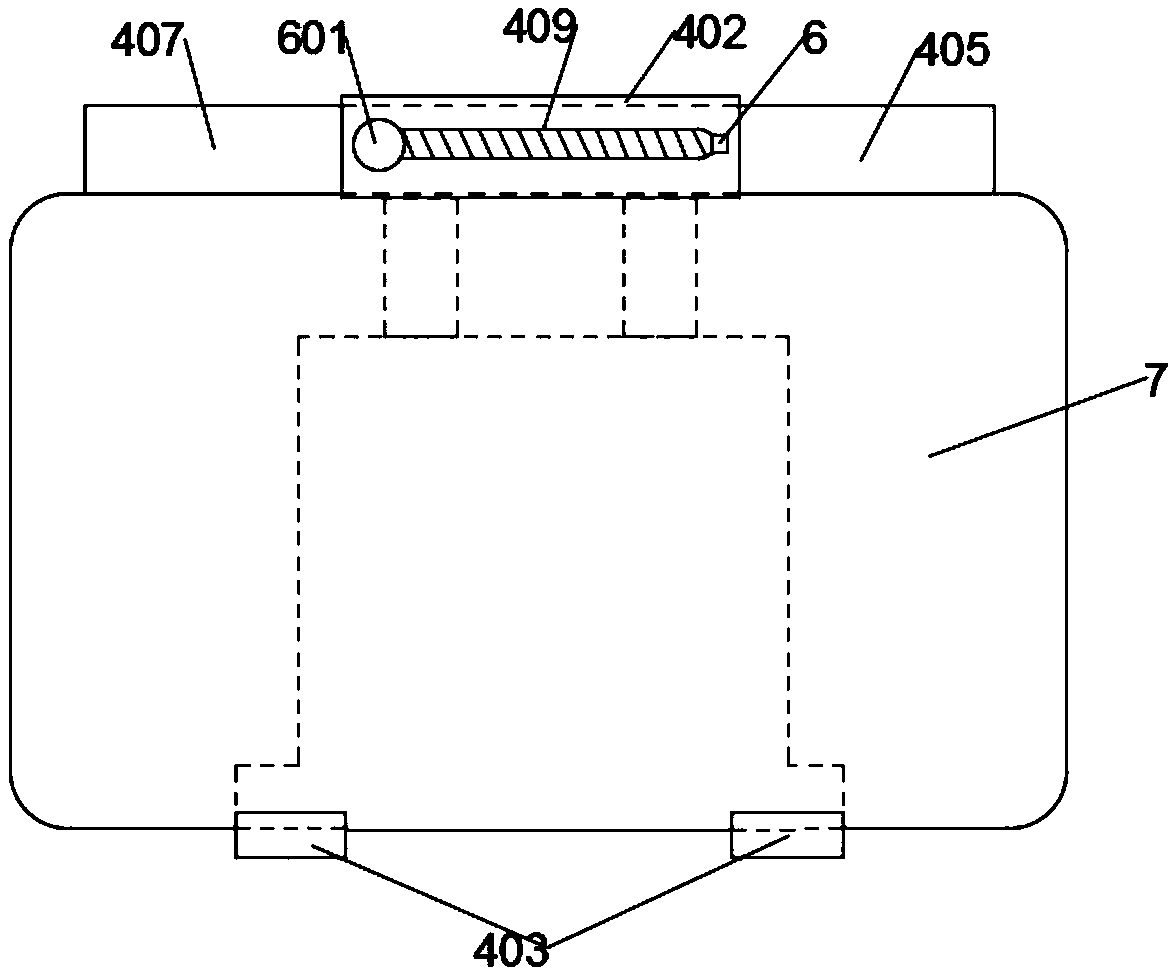

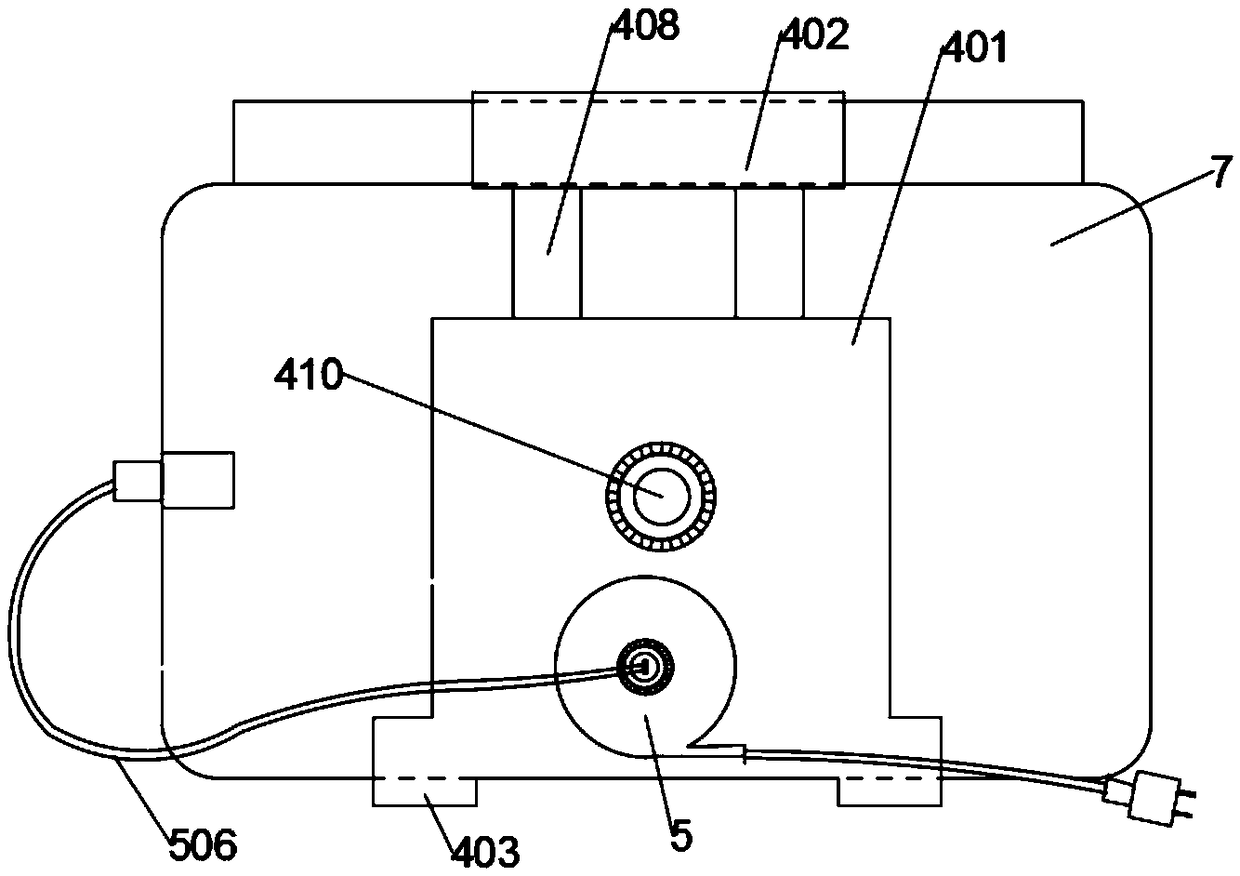

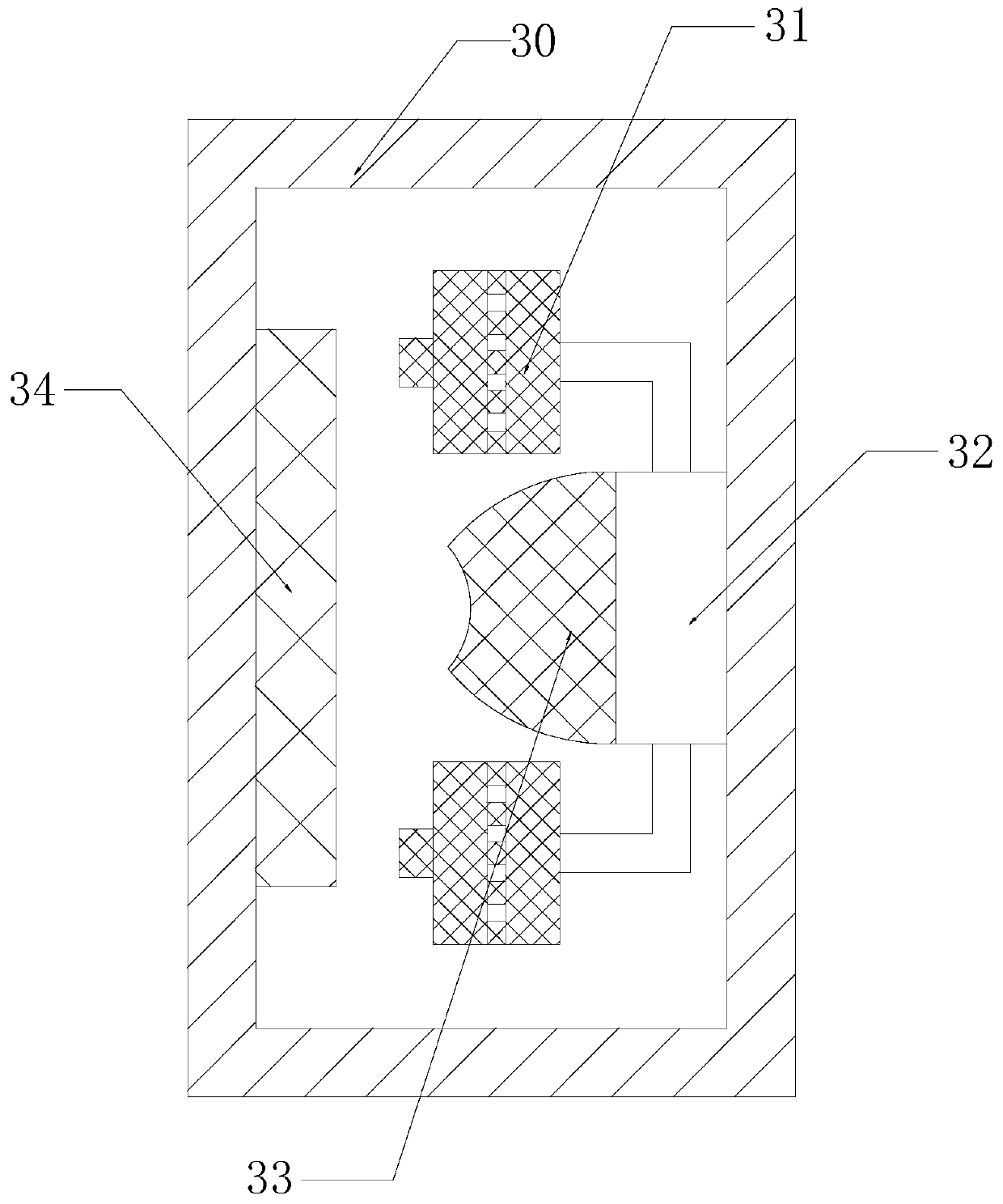

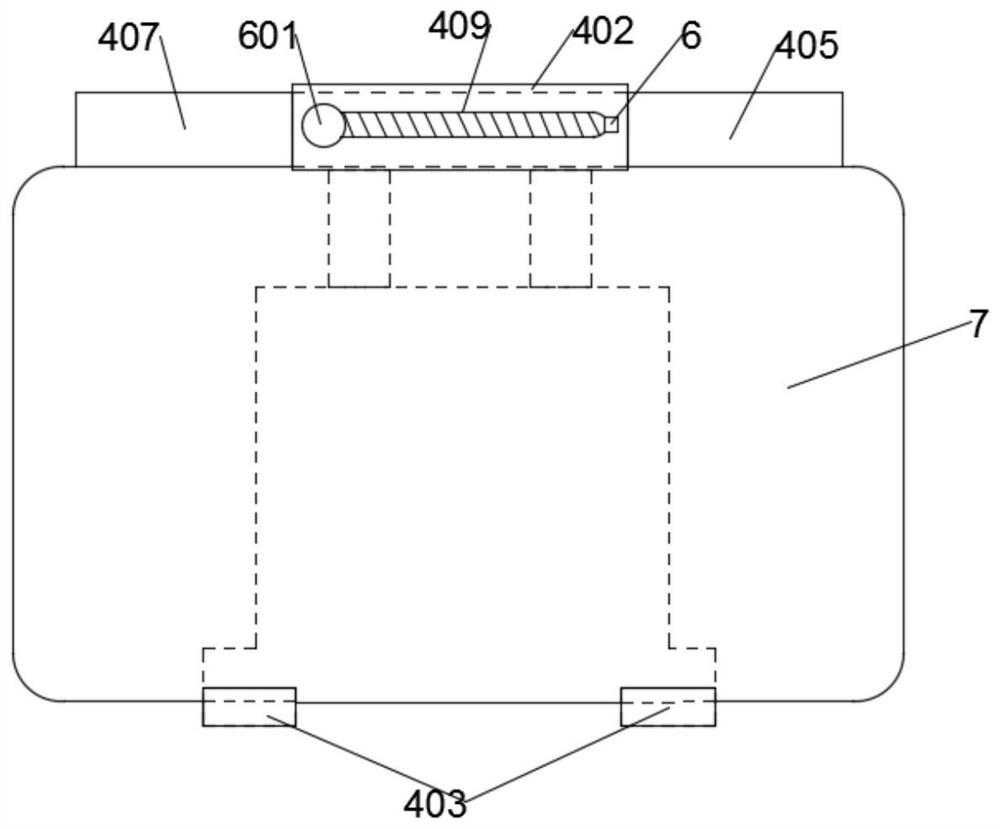

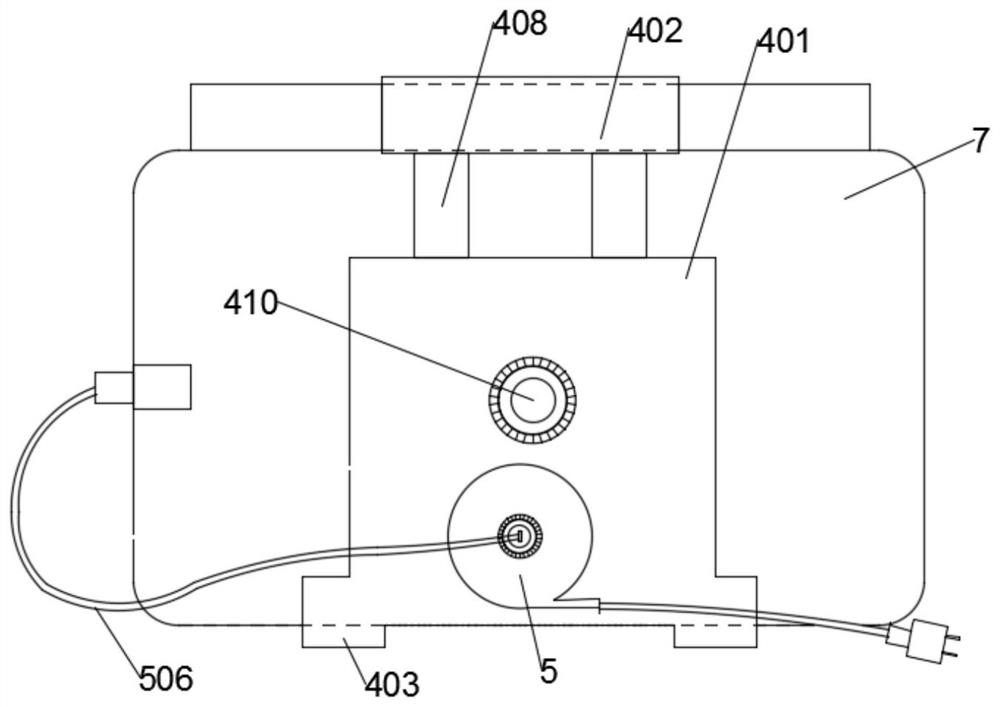

Universal multifunctional clamping equipment for digital products

ActiveCN109058732AEffort-saving clampingStand steadyFlexible article cleaningCleaning using toolsEngineeringMechanical engineering

The invention discloses universal multifunctional clamping equipment for digital products. The universal multifunctional clamping equipment comprises an angle demodulator which can rotate in all directions and a base clamping part clamped on a peripheral available clamp piece, wherein the base clamping part is fixedly mounted below the angle demodulator; a clamp supporting rod with threads on thesurface is rotationally mounted above the angle demodulator; a telescopic clamping device for clamping the digital products in different specifications is fixedly mounted on the clamp supporting rod in a sleeving manner; a wire collection box which is convenient to collect charging data lines is arranged at the back of the telescopic clamping device; and a screen cleaning device for simply cleaning a screen is arranged above the telescopic clamping device. According to the universal multifunctional clamping equipment, firm clamping can be performed with or without an external object, various digital products in different specifications can be clamped, the screens of the digital products can be quickly cleaned, the data lines of the digital products can be quickly stored and drawn for charging at any time.

Owner:束玲

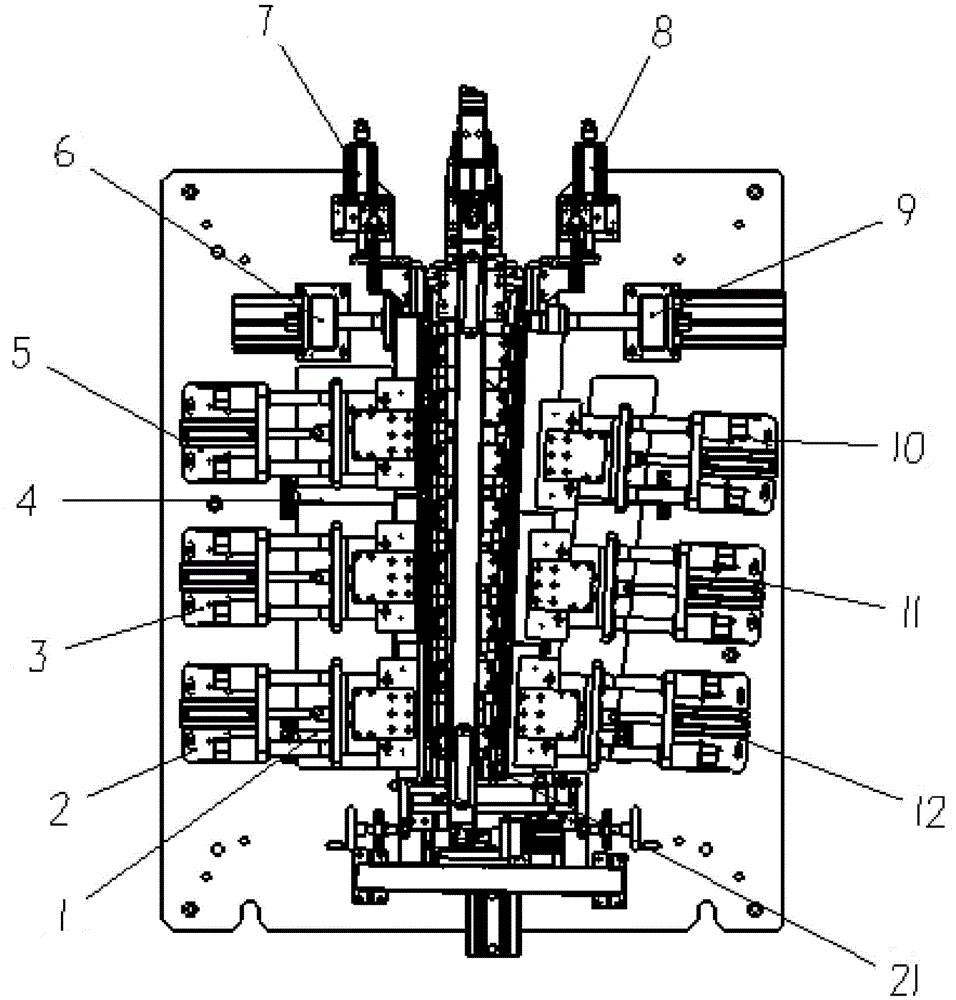

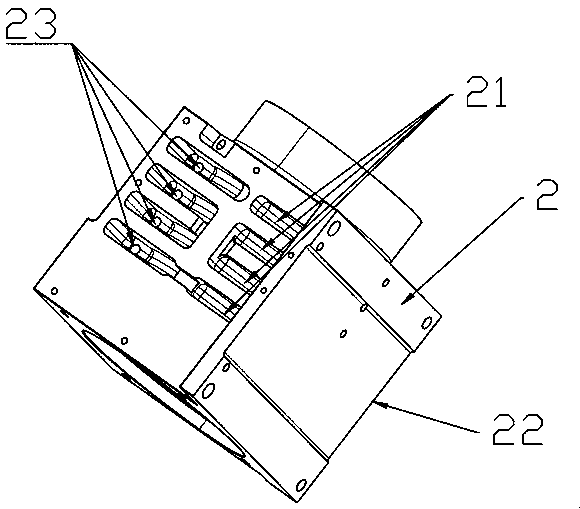

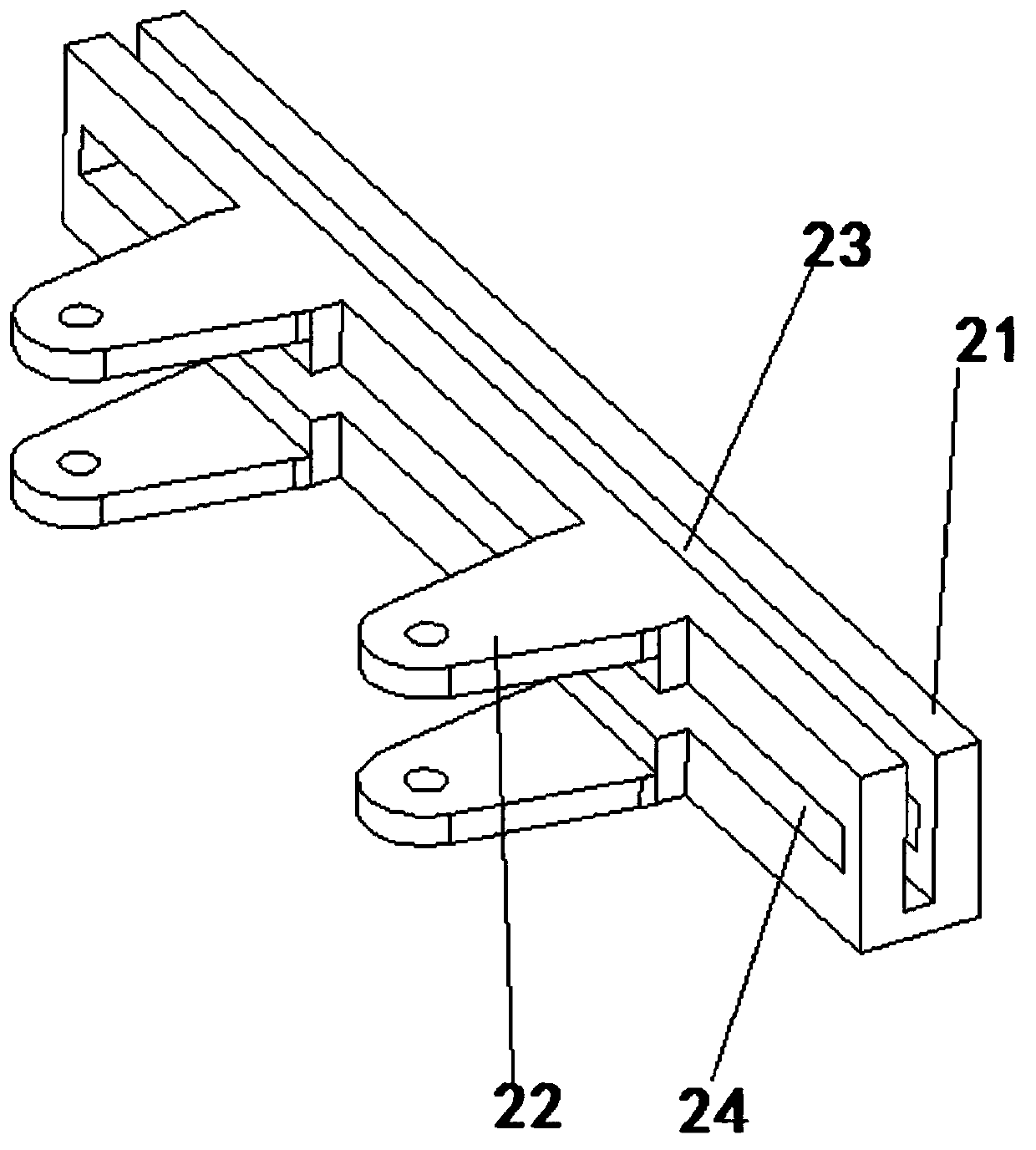

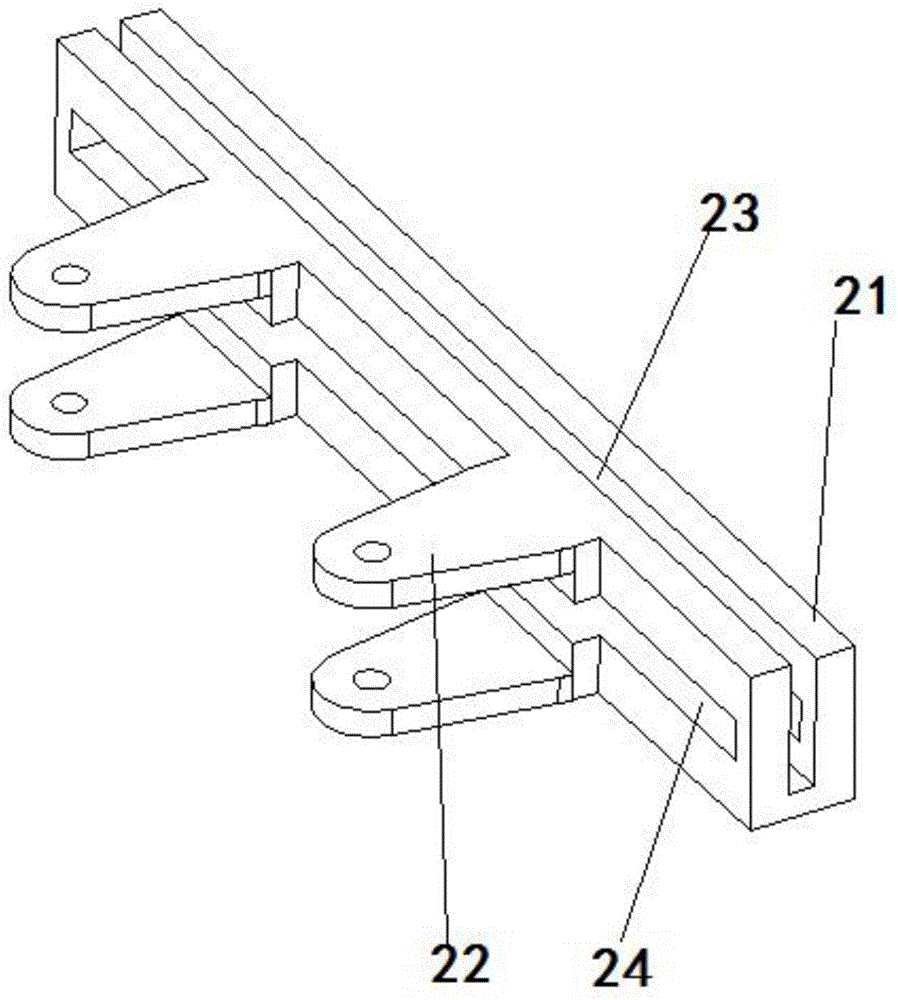

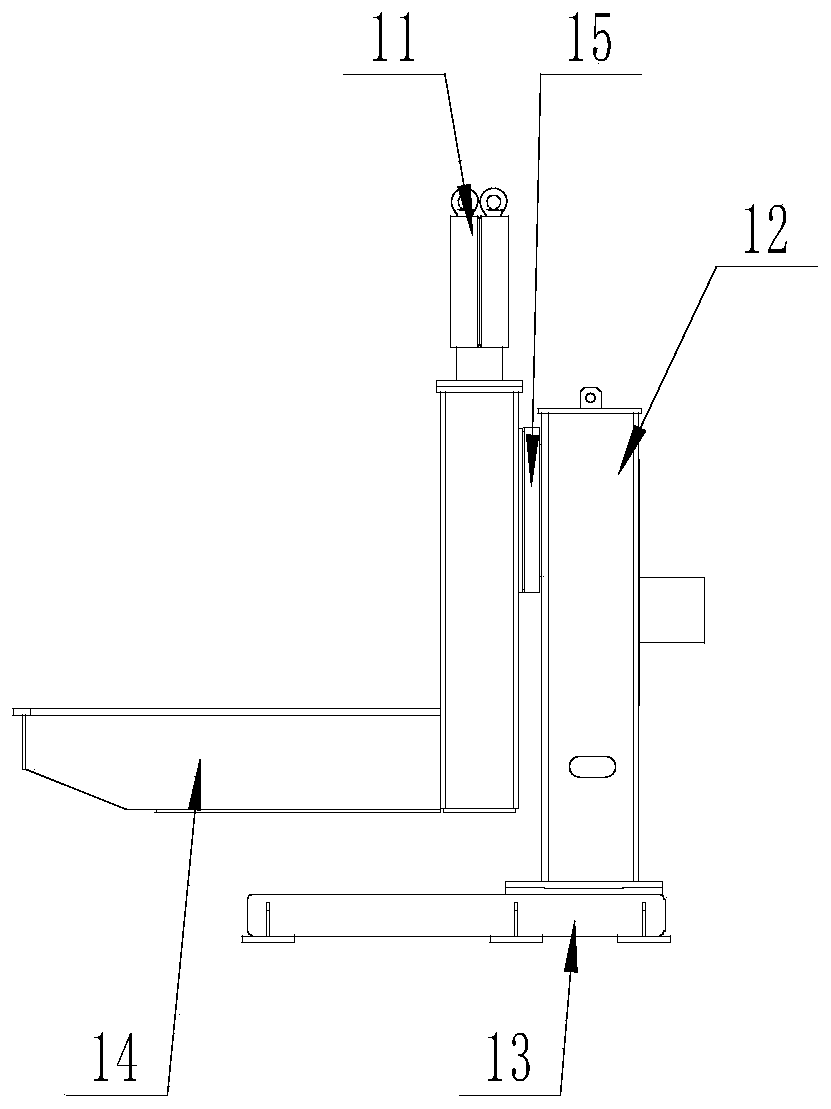

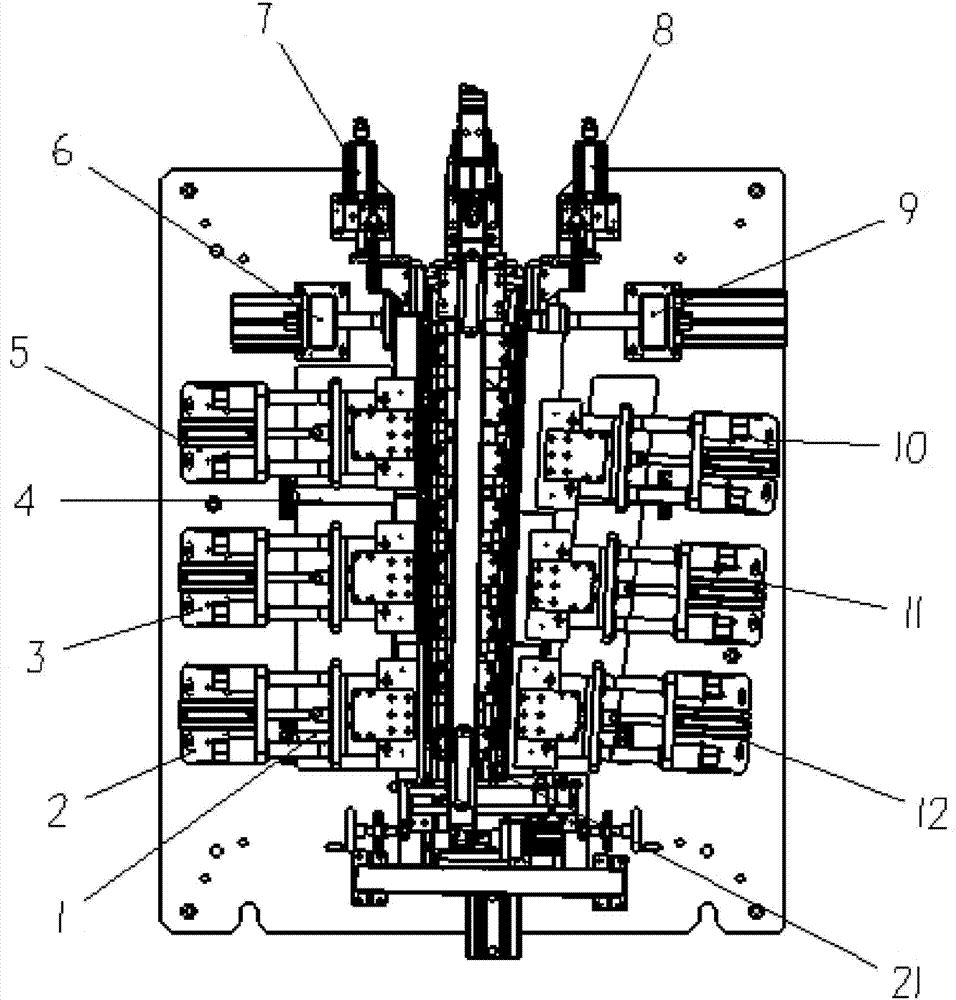

Tool clamp used for robot automatic welding

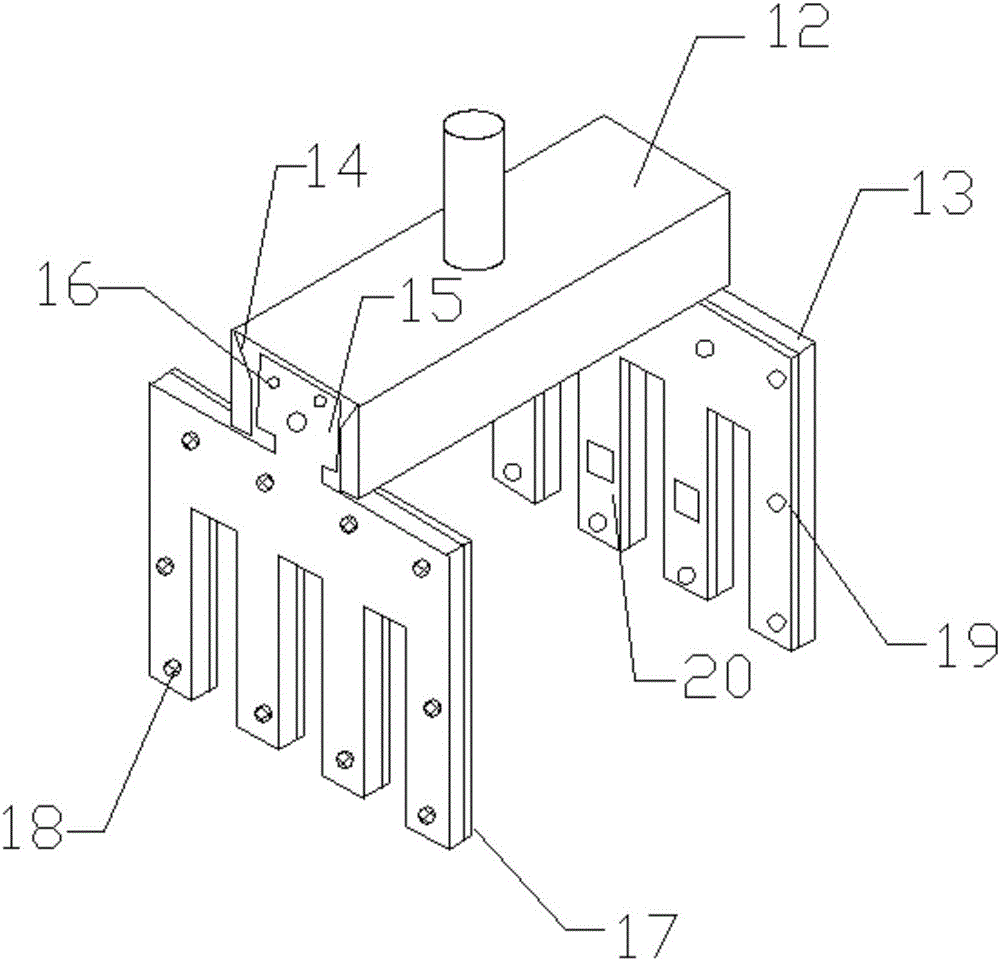

ActiveCN105598621AEasy to operateSatisfy positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThin walled

The invention discloses a tool clamp used for robot automatic welding. The tool clamp comprises a separation plate tab positioning assembly (14), shaft hole positioning assemblies (6, 9), plane plate compression assemblies (2, 3, 5), curved plate compression assemblies (10, 11, 12), side wall plate compression assemblies (7, 8), a transverse beam assembly (13), back air protective jacking mechanisms (15, 16), jacking compression mechanisms (18, 19, 20), a middle separation frame assembling component (17) and auxiliary supports (1, 4), wherein the plane plate compression assemblies (2, 3, 5) and the curved plate compression assemblies (10, 11, 12) are located on the two sides of the middle part of the transverse beam assembly (13) respectively; the side wall plate compression assemblies (7, 8) are distributed on the two sides of the front end part of the transverse beam assembly (13); the shaft hole positioning assemblies (6, 9) are further distributed on the two sides of the front end part of the transverse beam assembly (13); and the separation plate tab positioning assembly (14) is distributed at the tail part of the transverse beam assembly (13). The invention provides an automatic welding tool which is simple to operate and efficient, aiming at certain complicated thin-wall welding parts; and the requirements on tool positioning precision and clamping efficiency by robot automatic welding are met.

Owner:JIANGXI HONGDU AVIATION IND GRP

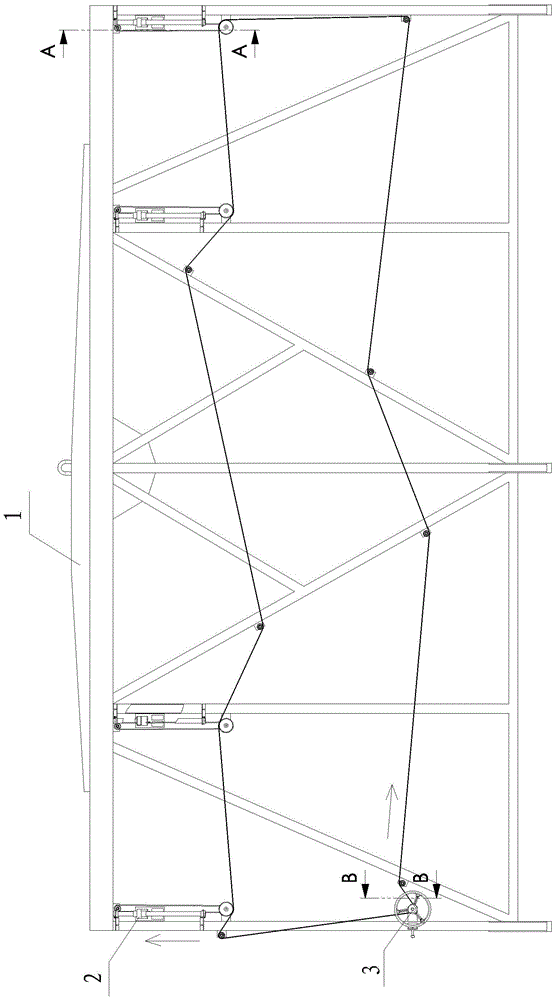

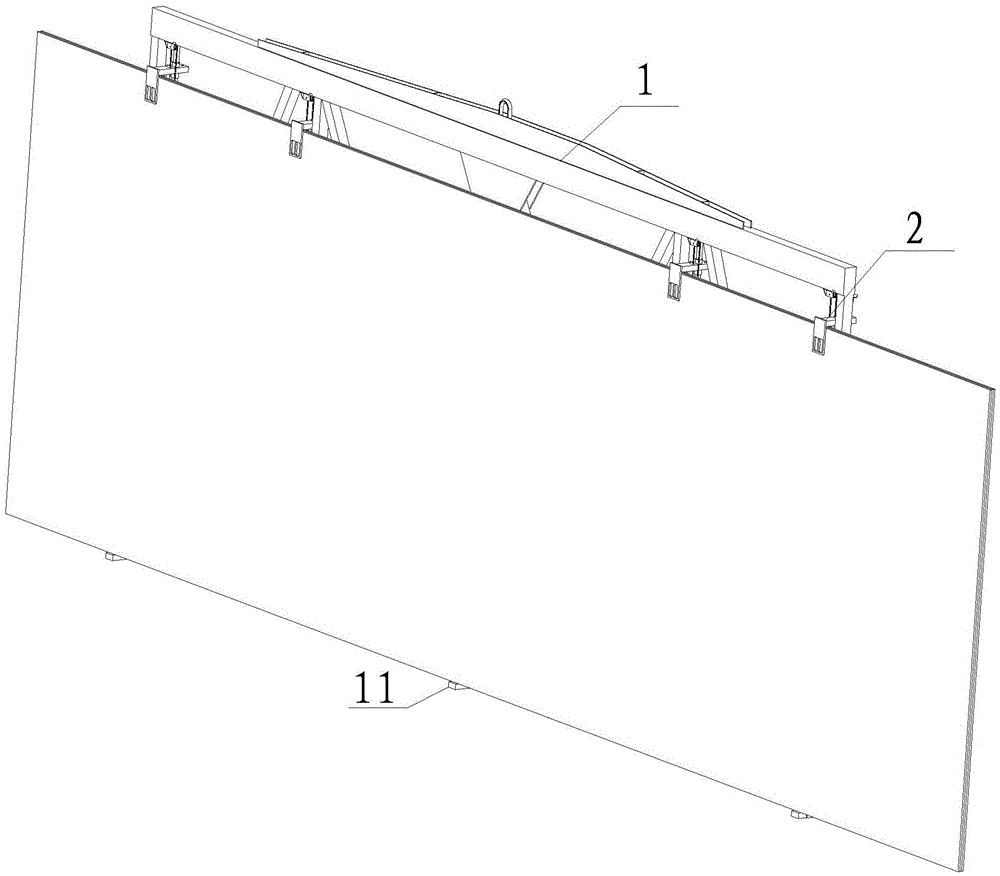

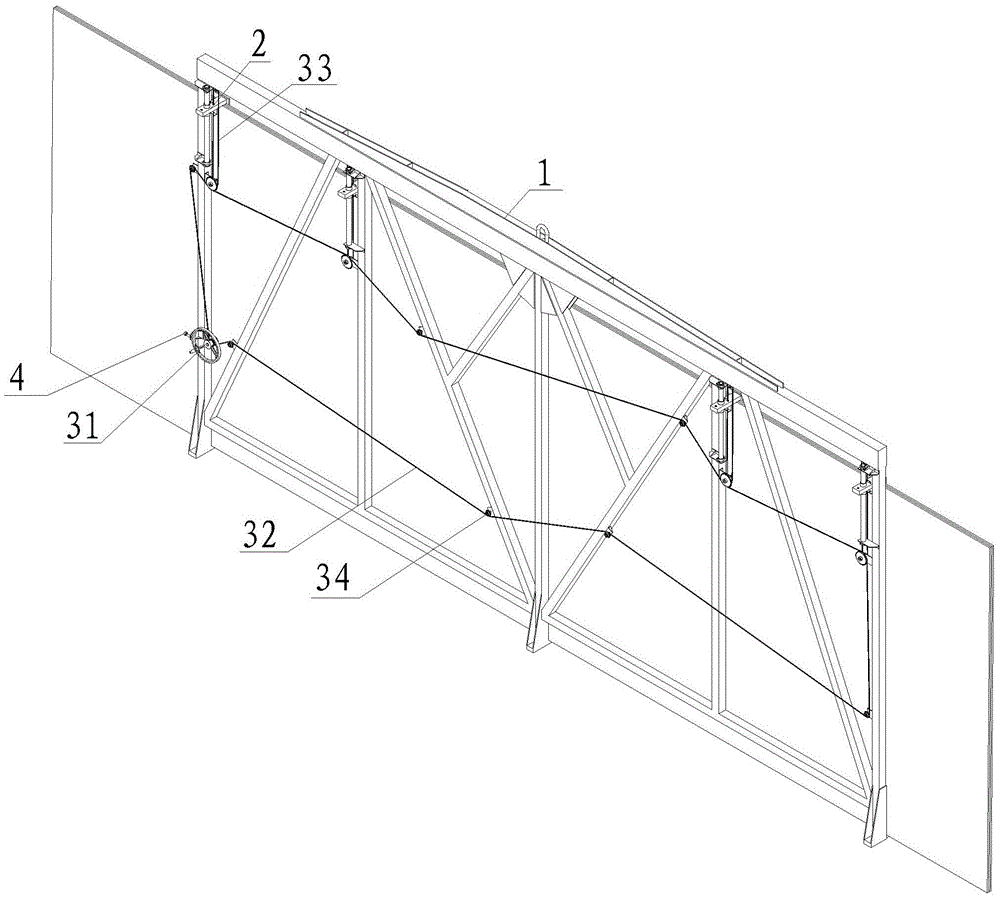

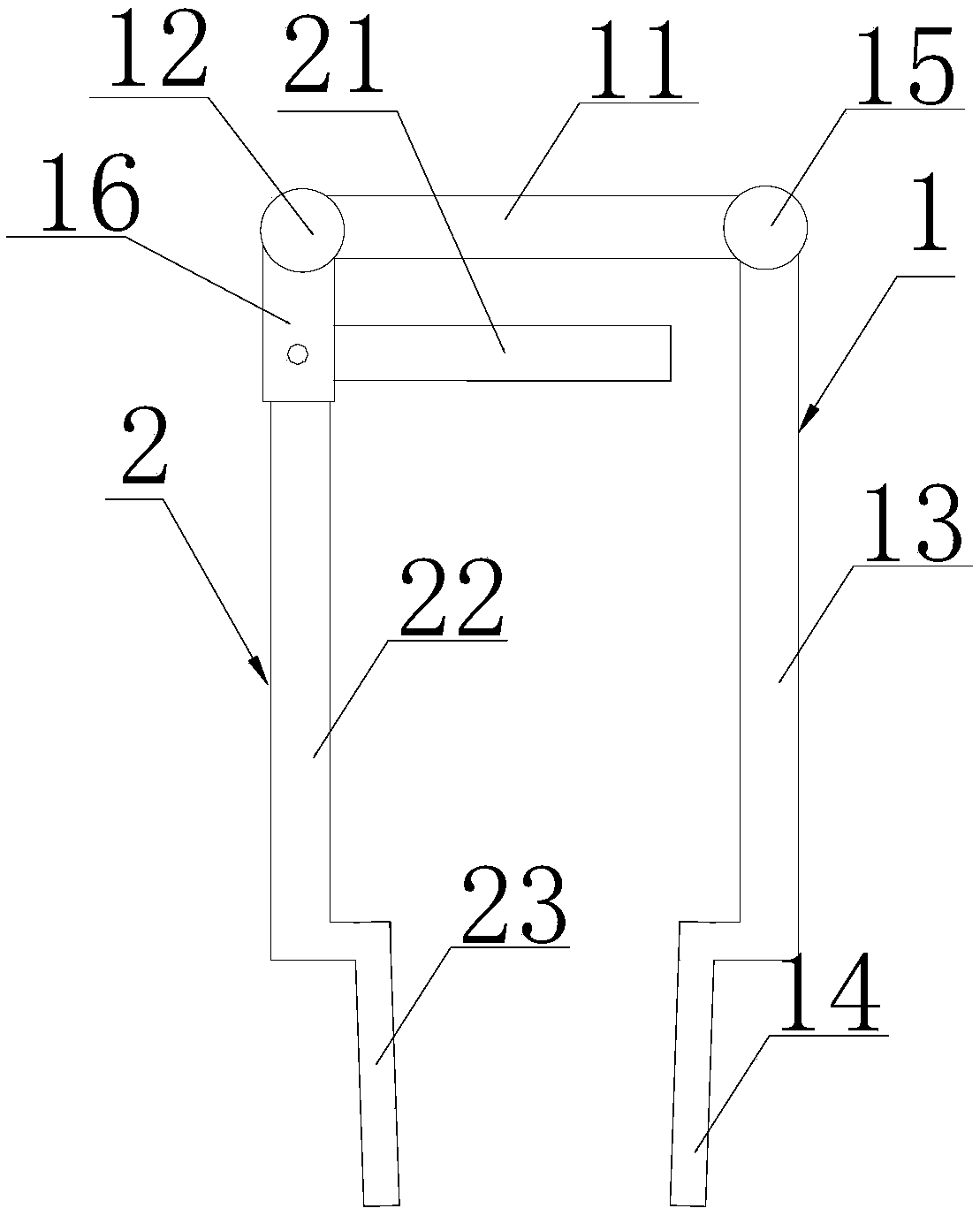

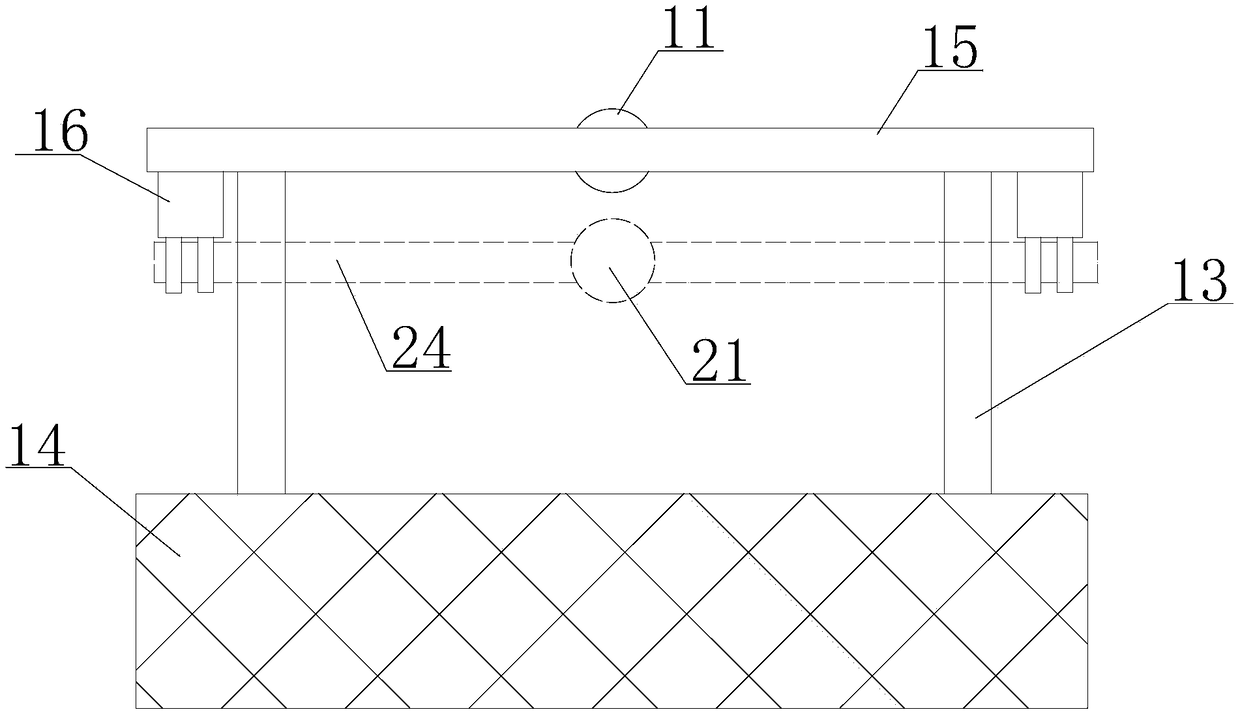

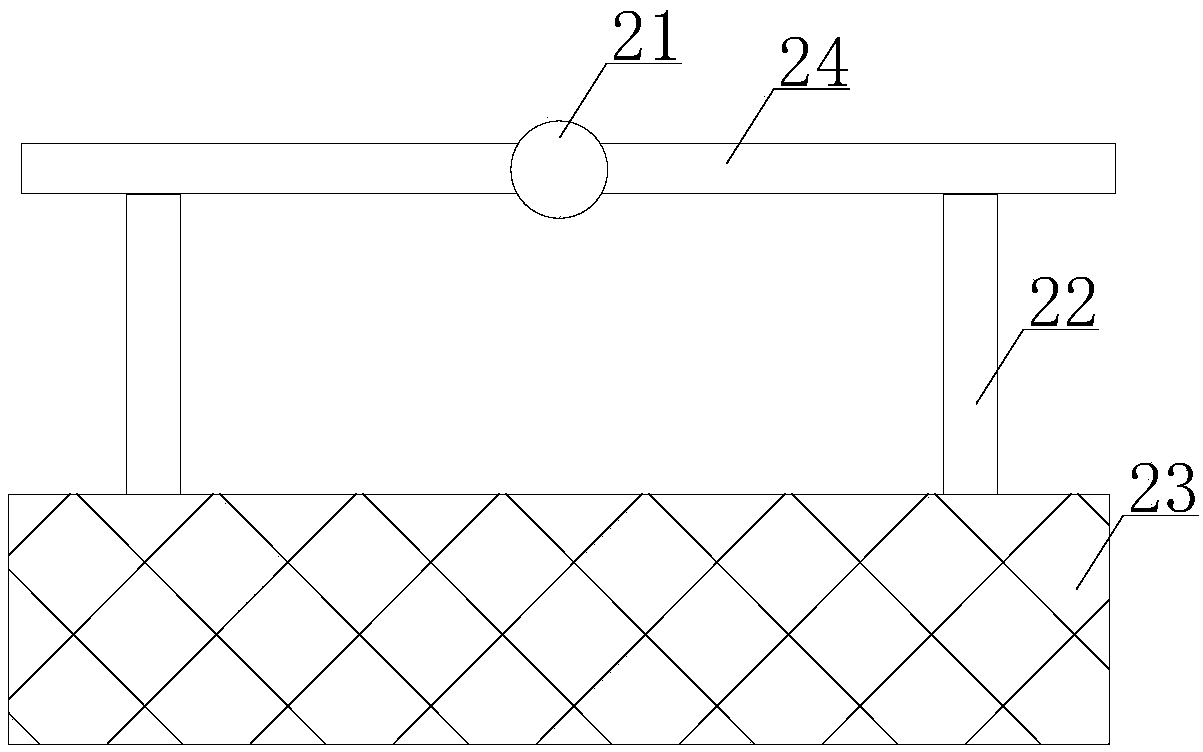

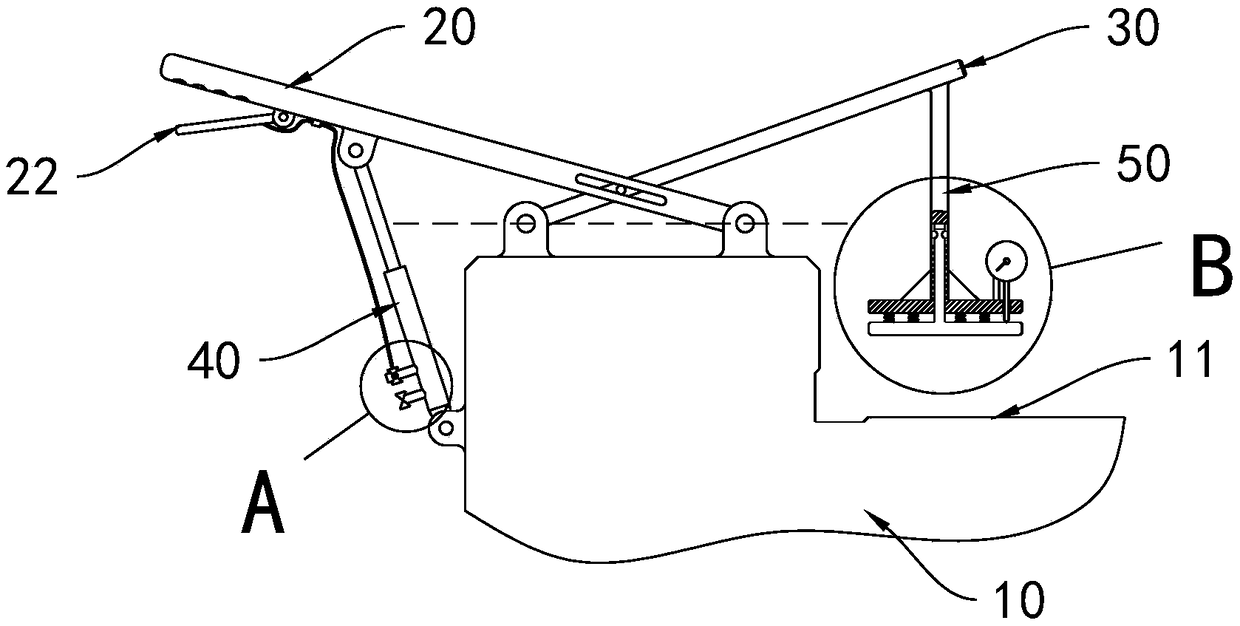

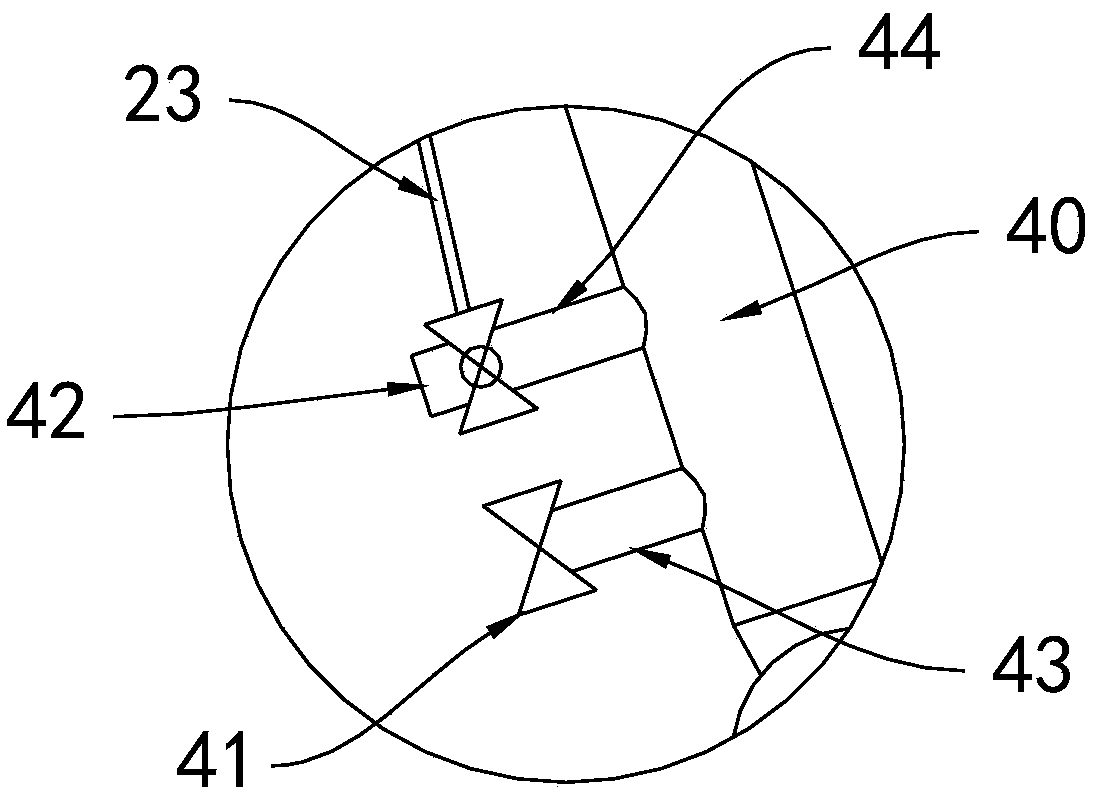

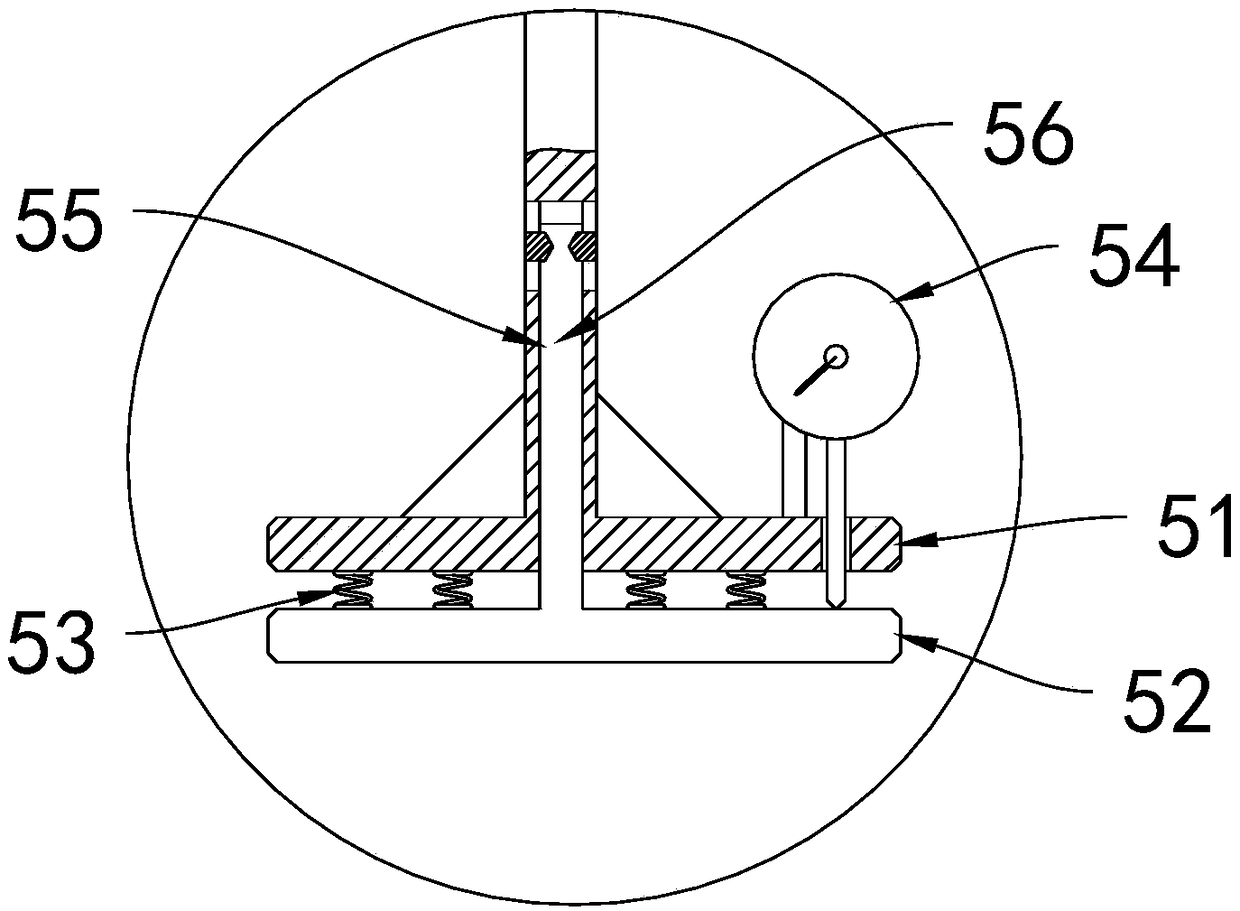

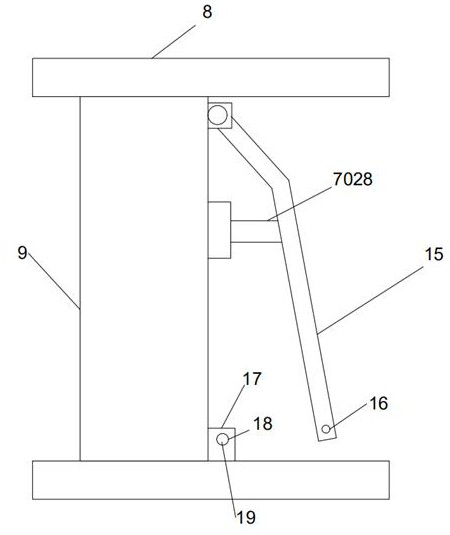

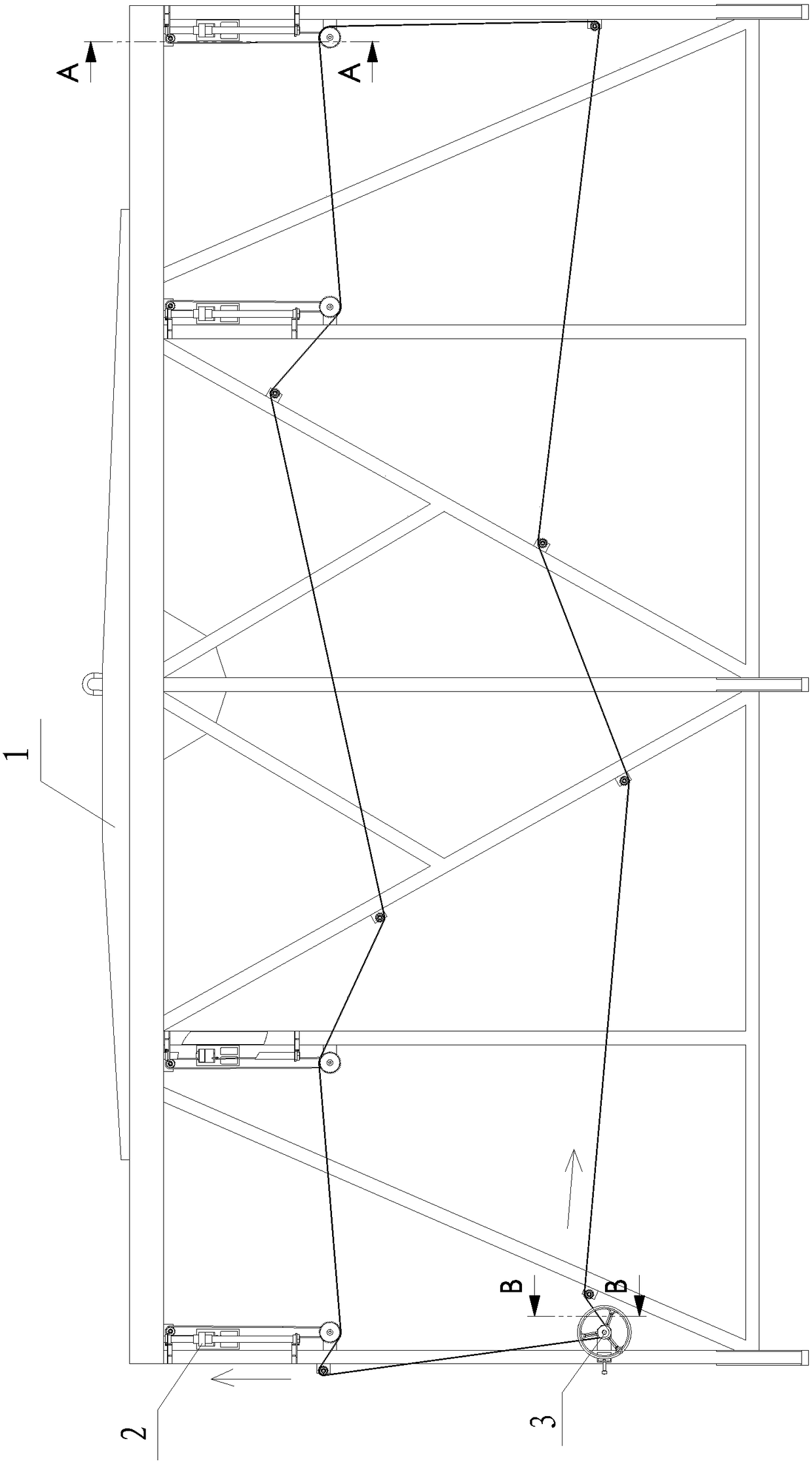

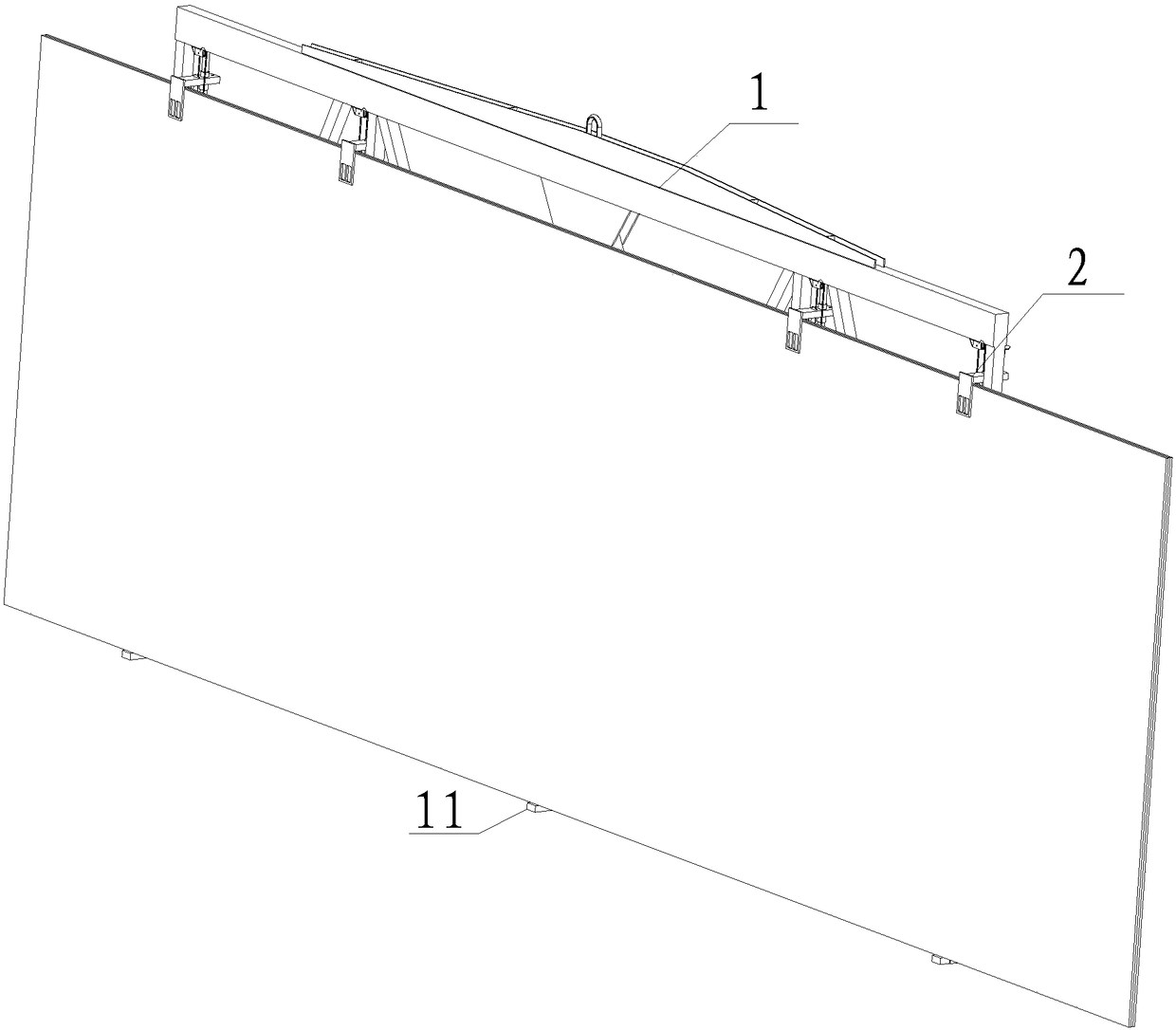

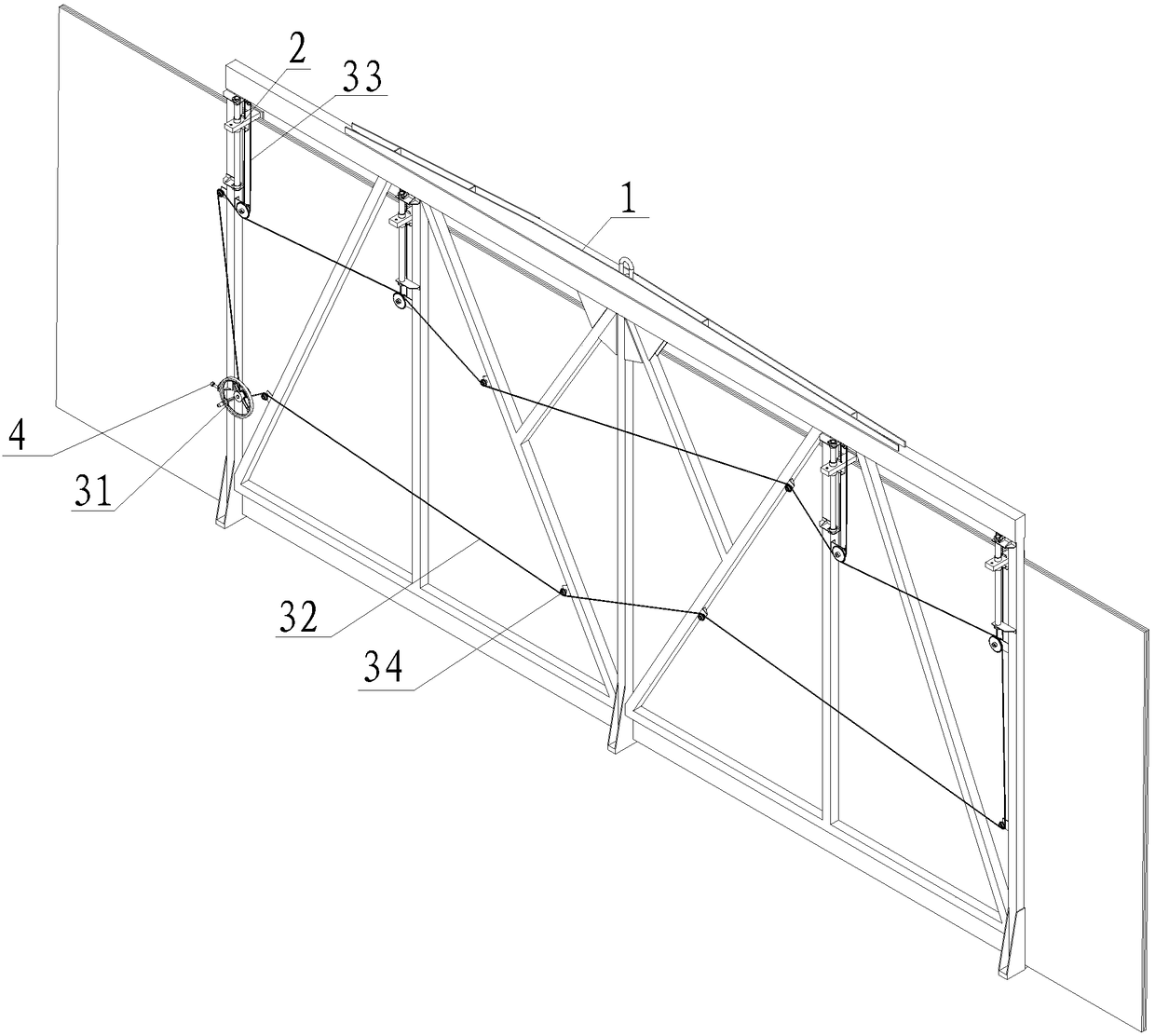

Large glass hanging bracket

The invention discloses a large glass hanging bracket. The large glass hanging bracket comprises a planar bracket, a plurality of hook assemblies and a drive assembly; a plurality of hanging legs perpendicular to the planar bracket are arranged at the lower end of the planar bracket; the hook assemblies comprise hooks and installation parts and are separatelyinstalled at the upper end of the planar bracket, and the hooks are movably installed at the upper end of the planar bracket through the installation parts; the drive assembly comprises a hand wheel, a large chain, a plurality of small chains and chain wheels; the hand wheel is fixed to the planar bracket in a rotating mode and is connected to the large chain through the chain wheels in a transmission mode, the large chain and the small chains are fixed to the planar bracket through the chain wheels, the large chain is connected to the small chains in a transmission mode through the chain wheels, and the hooks are fixedly connected to the small chains and correspond to the small chains in a one-to-one mode. Because the hand wheel can sequentially drive the large chain and the small chains and finally drive the hooks to clamp glass simultaneously, workers can fast clamp the large glass in a labor-saving mode.

Owner:XINYI ENVIRONMENTAL PROTECTION SPECIAL GLASS JIANGMEN

Turning fixture for clutch hub in automatic transmission of automobile

ActiveCN106141233AHigh positioning accuracyImprove processing stabilityChucksAutomatic transmissionEngineering

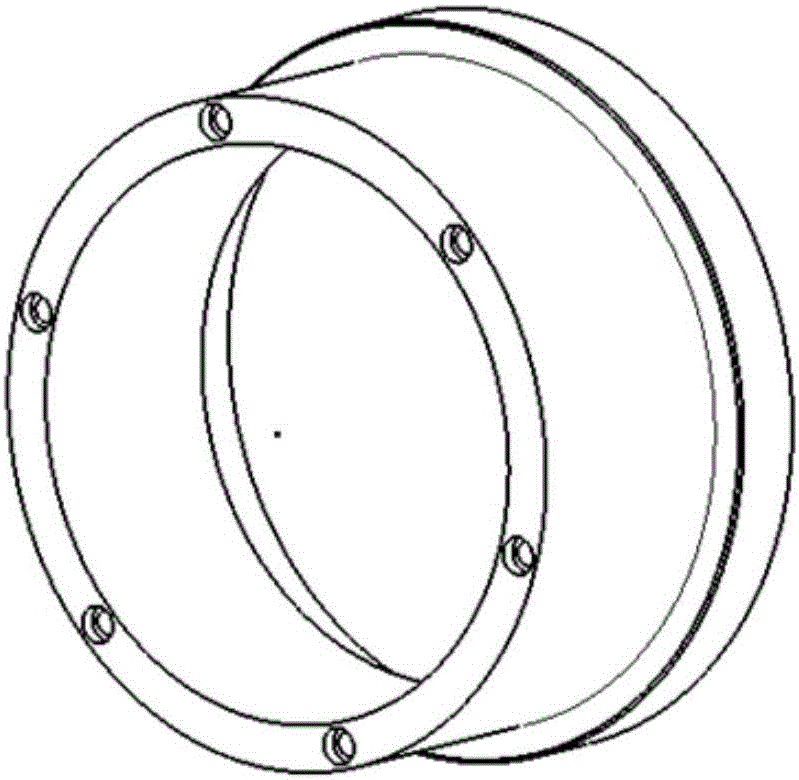

The invention relates to a turning fixture for a clutch hub in an automatic transmission of an automobile. The fixture comprises a fixture supporting body, a positioning body arranged at one end of the fixture supporting body and an elastic clamping mechanism arranged outside the positioning body, wherein the elastic clamping mechanism comprises a spring chuck arranged outside the positioning body as well as a casing which sleeves the outside of the spring chuck and is fit with the spring chuck, a first elastic assembly is arranged between the spring chuck and the fixture supporting body, a second elastic assembly is arranged between the casing and the fixture supporting body, the clutch hub is arranged on the inner side of the spring chuck, the positioning body axially positions the clutch hub, the casing presses the spring chuck inwards, and the clutch hub is fixed on the fixture. Compared with the prior art, the clutch hub is firmly fixed on the fixture by the aid of the elasticity of a compression spring, the self-locking effect of the spring chuck and the axial positioning of the positioning body, the positioning accuracy is high, clamping and dismounting are convenient and labor-saving, and the clamping efficiency of the clutch hub is greatly improved.

Owner:SHANGHAI UNIV OF ENG SCI

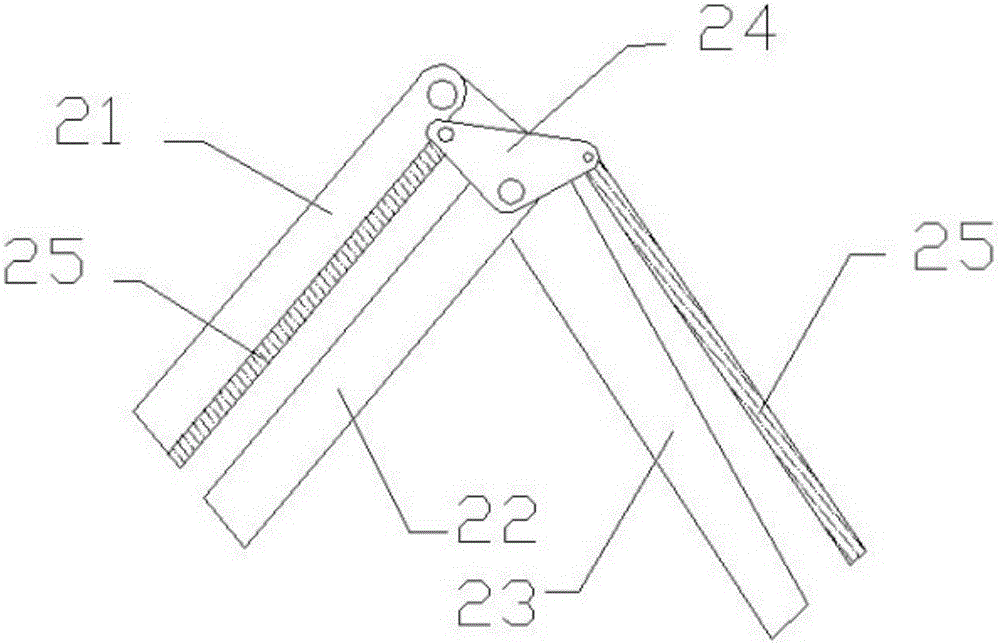

Seedling carrying clamp

InactiveCN108076909AImprove efficiencyLabor saving effectGrowth substratesCulture mediaTransportation FacilityEngineering

The invention relates to a seedling raising tool, and discloses a seedling carrying clamp. The seedling carrying clamp comprises a first clamping frame and a second clamping frame; the first clampingframe comprises a first handle, a first cross rod, a first connecting rod, a first clamping plate and a third cross rod; the second clamping frame comprises a second handle, a second cross rod, a second connecting rod and a second clamping plate; a clamping opening is formed between the first clamping plate and the second clamping plate; the first handle corresponds to the second handle to form agrip part; and the second handle is located between the first handle and the clamping opening. According to the seedling carrying clamp, the clamping plates are used for clamping seedling raising bagsfilled with the seedlings, and then the seedlings are carried out onto a transportation facility. A plurality of seedling raising bags can be clamped each time according to the length of the clampingplates, and compared with manual carrying efficiency, the efficiency of the seedling conveying clamp is higher. The second handle located below moves close to with the first handle part by itself under the gravity of the seedling raising bags, so that the force for clamping the seedling raising bags is generated, and thereby the effects of clamping and saving labor are achieved.

Owner:成都龙兴大地农业开发有限公司

Labor-saving slide table fixture

InactiveCN108655785ASimple structureReduce volumePositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a labor-saving slide table fixture. The essential is as follows: the labor-saving slide table fixture comprises a slide table assembly, a compression assembly, a drive assemblyand a limit assembly. The slide table assembly comprises a slide table and a linear guide rail. A lever hole penetrating through the top and bottom of the slide table is formed in the middle part inthe front-rear direction of the slide table. The slide table is fixedly arranged on a slide block of the linear guide rail. The stroke of the slide table is limited by the limit assembly. The compression assembly comprises a press rod, a press rod support seat, a press head, a lever, a lever support seat and a connection rod. The drive assembly comprises a power source, a drive seat, a drive seatend cover, a guide seat, a rod joint, a push rod, a guide flat key, a spring seat, a compression spring and an adjustment screw. The cylinder force needed during workpiece compression can be adjustedthrough the adjustment screw. After the slide table is driven to reach a limit part by the drive assembly, the lever of the compression assembly starts to be driven through the push rod, and the leveris enabled to rotate around the fulcrum of the lever support seat, so that the press head presses downwards the corresponding workpiece.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

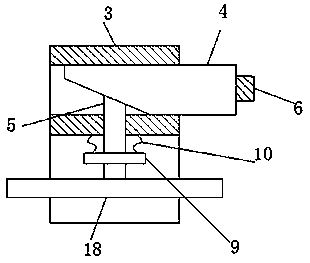

Sheet metal part punching die

InactiveCN111097832AQuick clampingEffort-saving clampingPerforating toolsMetal-working feeding devicesPunchingStructural engineering

The invention discloses a sheet metal part punching die. The sheet metal part punching die comprises an upper die plate and a lower die plate, wherein a positioning groove is formed in the center of the top of the lower die plate; a through hole is formed in the center of the bottom in the positioning groove; a clamping mechanism is arranged on the top of the lower die plate and comprises two L-shaped fixing blocks symmetrically arranged on the two sides of the positioning groove; square holes are formed in the side walls of the horizontal ends of the fixing blocks; first sliding blocks matched with the square holes are in sliding connection in the square holes; the ends, positioned in the square holes, of the first sliding blocks are arranged to be first slopes, and the other ends of thefirst sliding blocks extend to the outer parts of the square holes; clamping rods vertically arranged are arranged in the square holes; and the ends, away from the positioning groove, of the clampingrods are arranged to be second slopes matched with the first slopes, and the first slopes abut against the second slopes. By means of the sheet metal part punching die, sheet metal parts can be rapidly clamped in a labor-saving manner, and waste generated in the sheet metal part punching process can be conveniently collected.

Owner:扬州市祥跃泵业科技有限公司

More labor-saving slide fixture

InactiveCN108655785BSimple structureReduce volumePositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Wood door clamp with controllable down-pressing force

InactiveCN108748587ATo achieve the compaction effectTo achieve the purpose of lockingWood working apparatusEngineeringLever pressing

Owner:湖州欧贝得门业有限公司

Special machine tool for pattern roll lentil groove processing

InactiveCN106001723BRealize processingClamp firmlyMilling machinesMilling equipment detailsHydraulic cylinderEngineering

The invention discloses a special machine tool for machining a pattern roller lentil-shaped groove, and aims to provide a special machine tool in the field of metallurgical machining. The machine tool is provided with a frame module, a positioning and clamping device, a power head milling device and a feed indexing device; and the positioning and clamping device, the power head milling device and the feed indexing device are all arranged on the frame module. The whole structure of the machine tool adopts a gantry vertical milling machine layout; the rigidity of a machining process system is good; the workpiece positioning and clamping are realized by using a support roller and V-shaped block combined effect; a roller is fast in rotation and reliable in clamping; the workpiece maneuvering clamping and loosening are realized by using a hydraulic cylinder to achieve the effects of labor saving and fastness; a servo motor is adopted to provide power for peripheral indexing of the roller and positioning of a multi-station feeding position; the indexing and positioning precision is high; the automatic workpiece machining can be realized through electric control; and the machine tool is used for machining workpieces, low in vibration, few in surface vibration patterns, high in machining quality, simple in structure, convenient for maintenance and low in equipment investment.

Owner:KUNMING UNIV

Synchronous servo electric spindle of precision numerical control machine tool

PendingCN108788196ALow power consumption and heatingReduce thermal errorsLarge fixed membersMechanical energy handlingNumerical controlMagnetic tension force

The invention discloses a synchronous servo electric spindle of a precision numerical control machine tool. The synchronous servo electric spindle comprises a spindle, a sleeve casting, a stator and apermanent magnet rare-earth rotor, wherein a mounting chamber is arranged in the sleeve casting; the stator is mounted in the mounting chamber; the spindle is mounted in the stator in a sleeved manner; the permanent magnet rare-earth rotor is fixedly arranged at the spindle body of the spindle, and drives the spindle to rotate under magnetic force; a plurality of first cooling grooves are formedin the upper surface of the sleeve casting in the arrangement direction of the spindle; a plurality of second cooling grooves are formed in the lower surface of the sleeve casting in the arrangement direction of the spindle; and side cooling grooves used for communicating the first cooling grooves and the second cooling grooves are formed in the left side surface and the right side surface of thesleeve casting. The synchronous servo electric spindle disclosed by the invention has the advantages of being even in temperature drop, high in processing precision, long in service life, small in size, practical, low in speed, large in torque, and labor-saving in clamping.

Owner:广东中聪智能装备有限公司

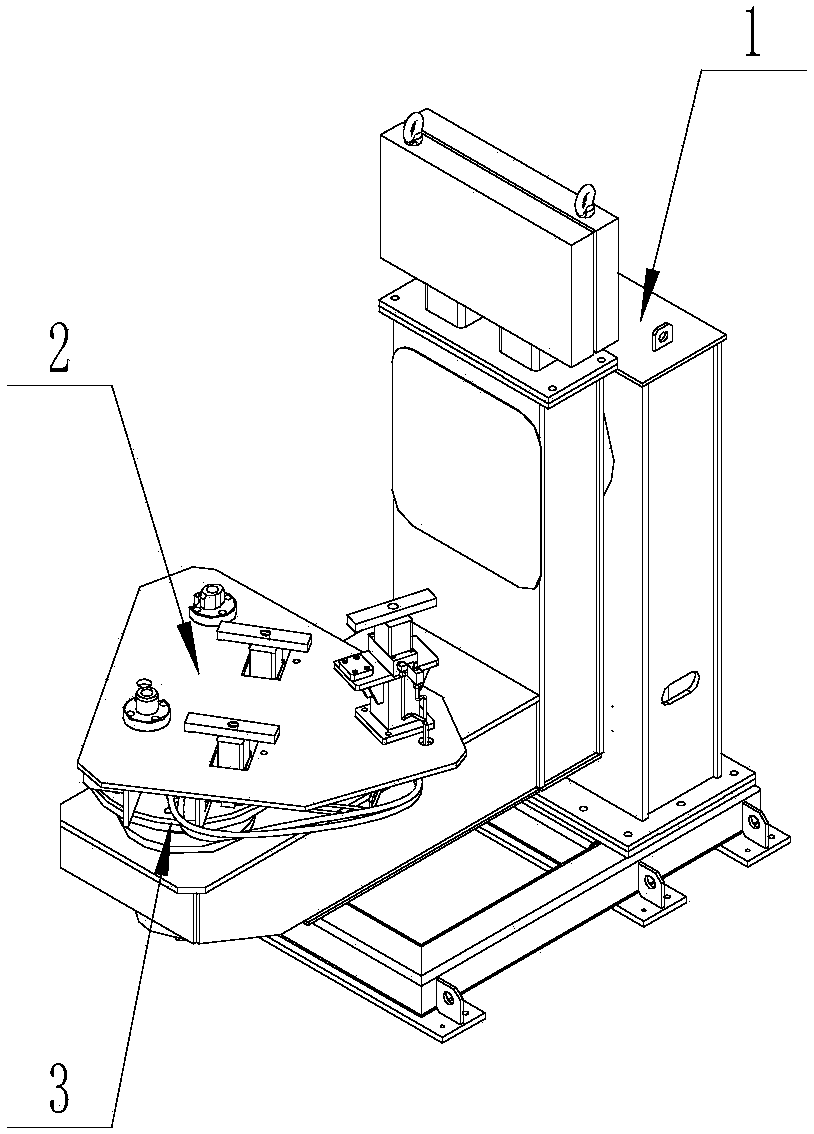

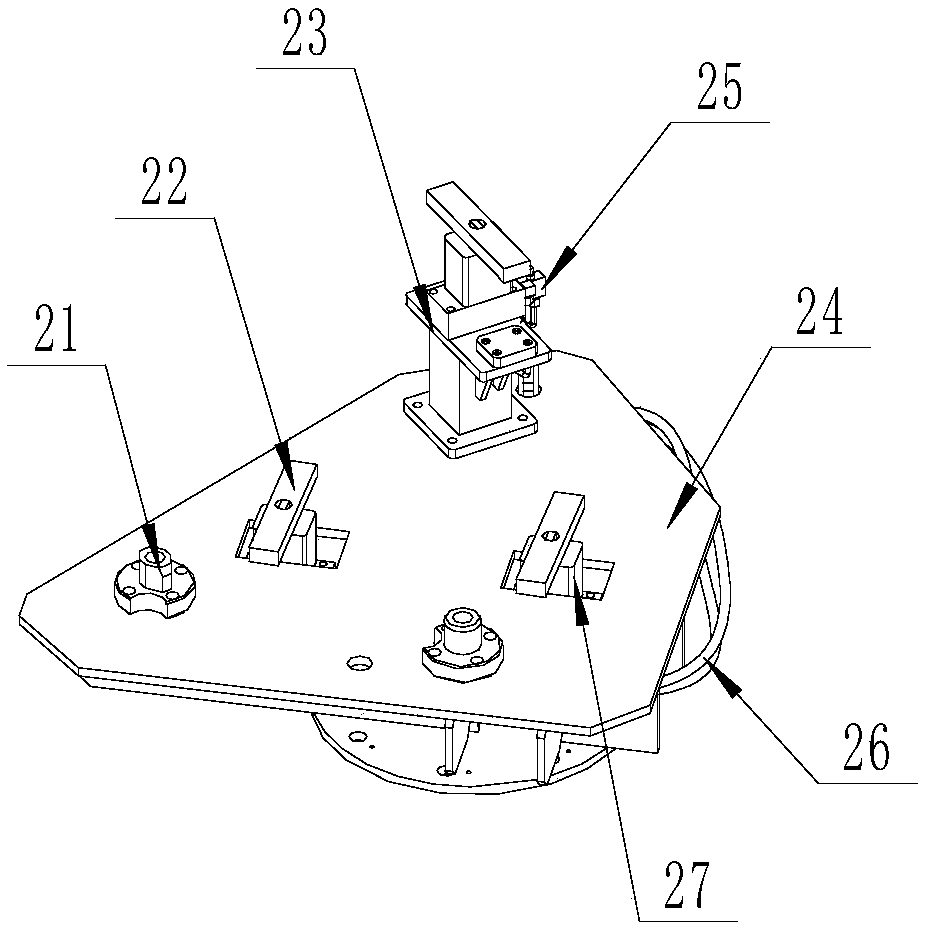

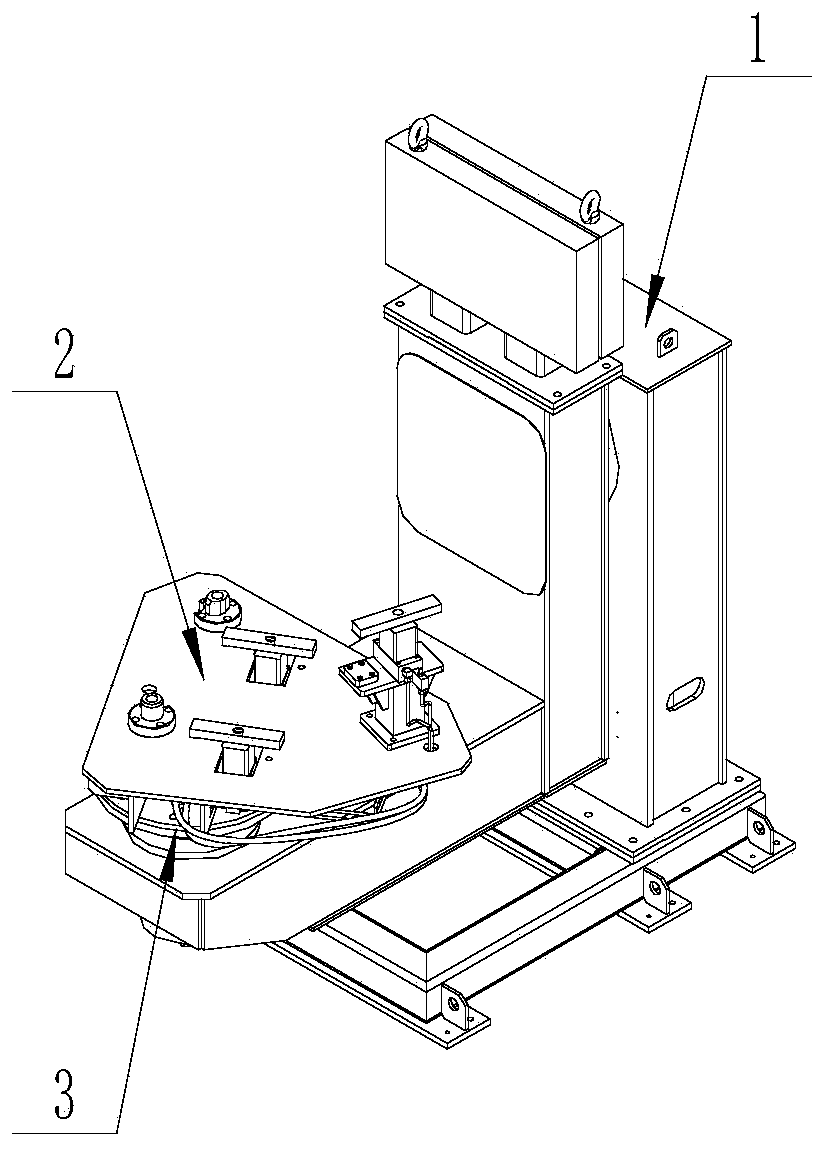

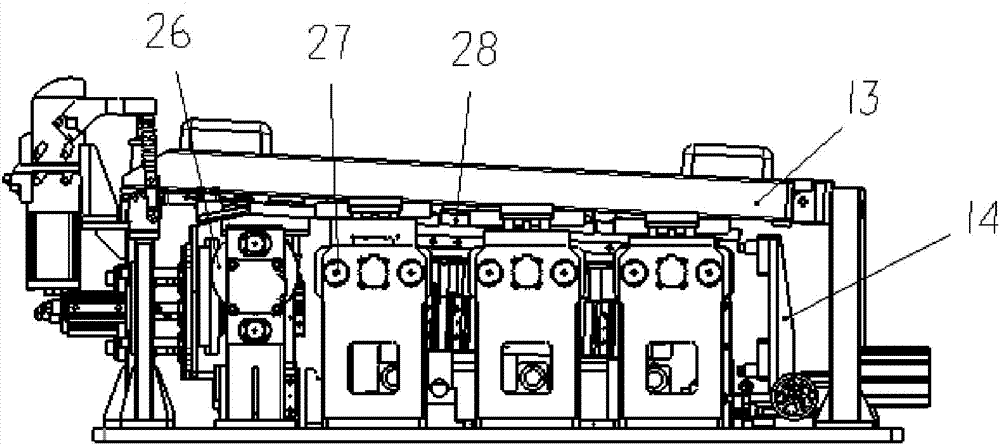

Heavy type part hydraulic clamping and welding positioner

ActiveCN107931918AQuick clampingImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesRotation functionTransmission function

The invention discloses a heavy type part hydraulic clamping and welding positioner, and belongs to the field of engineering machinery. The positioner comprises an L-shaped welding positioner main structure, a clamp body and a transmission mechanism. The clamp body comprises a positioning shaft, a pressing block, a positioning base, a clamp body base and a rotary hydraulic oil cylinder. The rotaryhydraulic oil cylinder is fixed to the clamp body base and fixedly connected with the pressing block. The positioning shaft and the positioning base are fixed to the clamp body base respectively, andthe clamp body base is fixed to the L-shaped welding positioner main structure. According to the heavy type part hydraulic clamping and welding positioner, it is ensured that clamping is rapid, efficient and accurate and saves labor in the large workpiece welding process, the product welding efficiency is improved, the transmission mechanism simultaneously achieves the transmission function and the rotation function, and the transmission mechanism has the double functions of load transferring and hydraulic fluid transferring.

Owner:SHANDONG LINGONG CONSTR MACHINERY

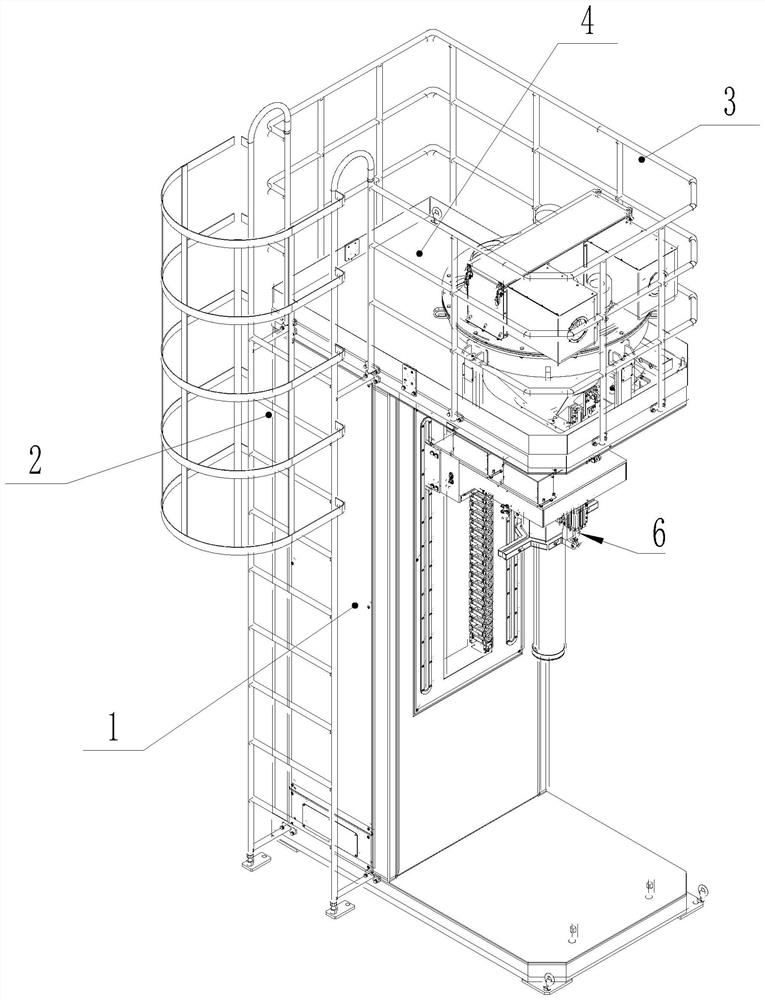

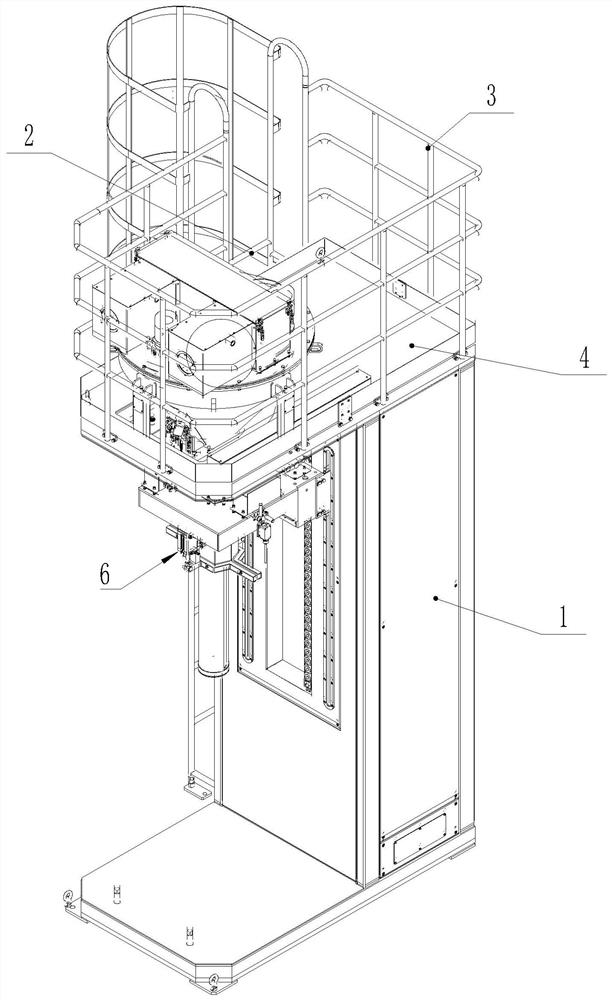

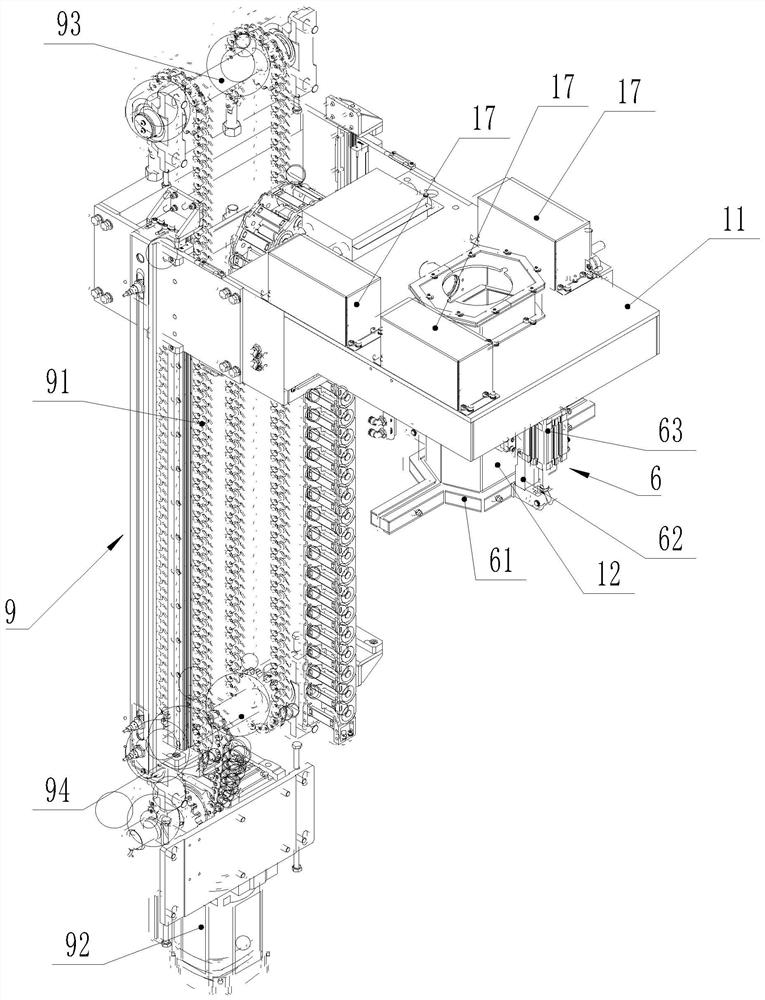

Semi-automatic powder packaging machine

The invention discloses a semi-automatic powder packaging machine, which comprises a machine base; a hopper is arranged on the upper portion of the machine base; discharging pipe is arranged at the bottom of the hopper; a material guiding mechanism used for sending out powder in the hopper is arranged in the hopper and / or the discharging pipe; a sliding base is installed on the machine base in the axis direction of the discharging pipe in a sliding mode; a mounting seat which is weighed by a weighing device is mounted on the sliding seat; a lining guide sleeve which is sleeved on the discharging pipe is mounted on the mounting seat; a bag clamping mechanism which is used for clamping a bag opening of a packaging bag in the lining guide sleeve is further mounted on the mounting seat; and an axial driving device for driving the sliding seat to axially slide is mounted on the machine base. According to the semi-automatic powder packaging machine provided by the invention, the dissipation of dust can be reduced while filling is very smooth, and the quality of the environment around the packaging machine is improved.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

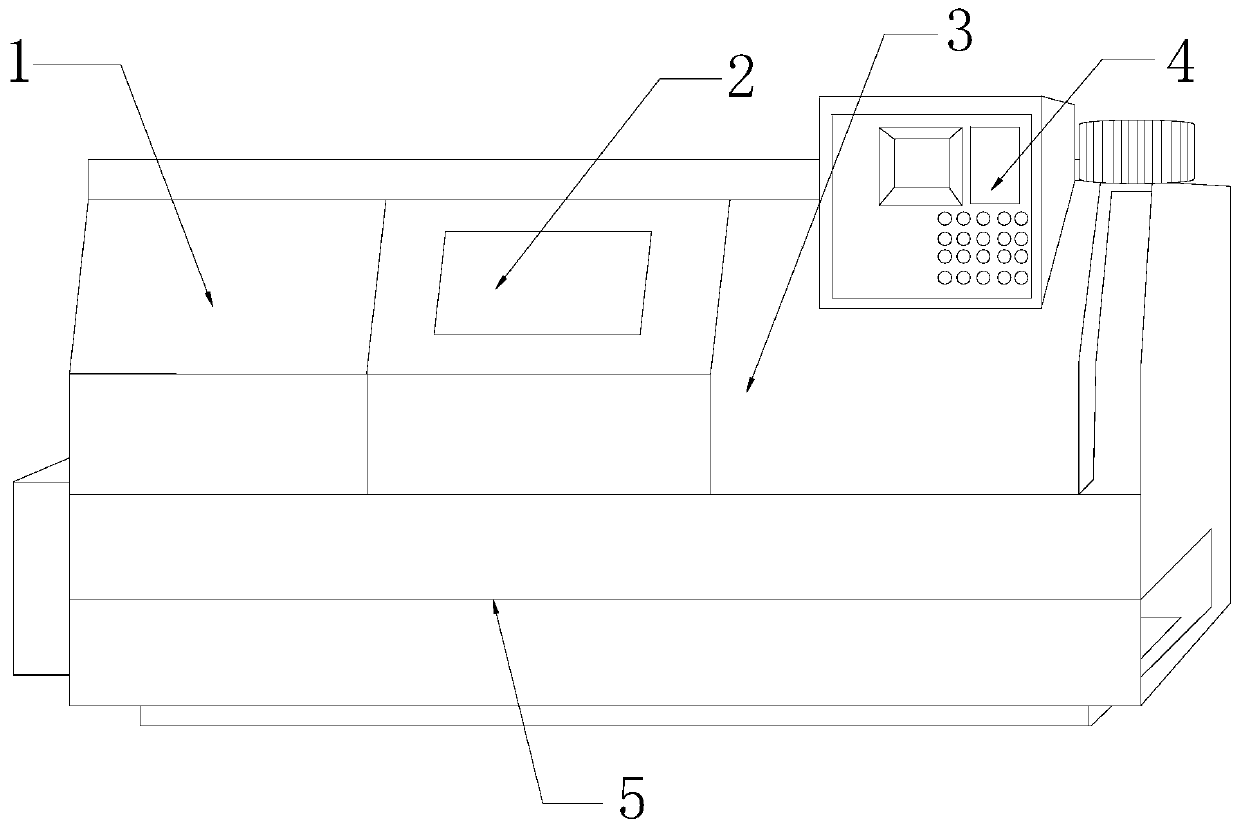

Anti-tool-collision digital controlled lathe

InactiveCN111571381AAvoid touchingEffort-saving clampingAutomatic grinding controlGrinding machinesStructural engineeringDigital control

Owner:周书全

A lampshade clamping device for landscape decorative street lamp installation

The invention discloses a lamp shade clamping device used for mounting a landscape decoration street lamp. The lamp shade clamping device used for mounting the landscape decoration street lamp comprises clamping boards, mounting seats, sliding devices, a handheld device and a pulling rope, and the clamping boards, the mounting seats, the sliding devices, the handheld device and the pulling rope are fixedly connected in sequence. Each clamping board comprises an arc board, a connecting pillar is fixed to one end of each arc board, and the two ends of each connecting pillar are provided with rotary blocks. A rotary shaft is fixed to the side surface of each connecting pillar, a bar-shaped sliding groove is formed in the side face of each rotary shaft, and each mounting seat comprises a connecting seat. A bar-shaped groove is formed in the top end of each connecting seat, and hinged seats are symmetrically arranged at the two ends of the side surface of each connecting seat. The hinged seats are connected to the clamping boards in a hinged mode, and a bar-shaped first through hole is formed in the surface where the hinged seats are located. According to the lamp shade clamping device used for mounting the landscape decoration street lamp, through the skillful structural combination of the clamping boards, the mounting seats, the sliding devices, the handheld device and the pulling rope, a street lamp shade can be effectively and fast clamped, and the working efficiency is improved since clamping operation is convenient and laborsaving. The handheld device directly controls the sliding devices to clamp the street lamp shade, so that the lamp shade clamping device used for mounting the landscape decoration street lamp has good practical value and high reliability.

Owner:华润建筑有限公司

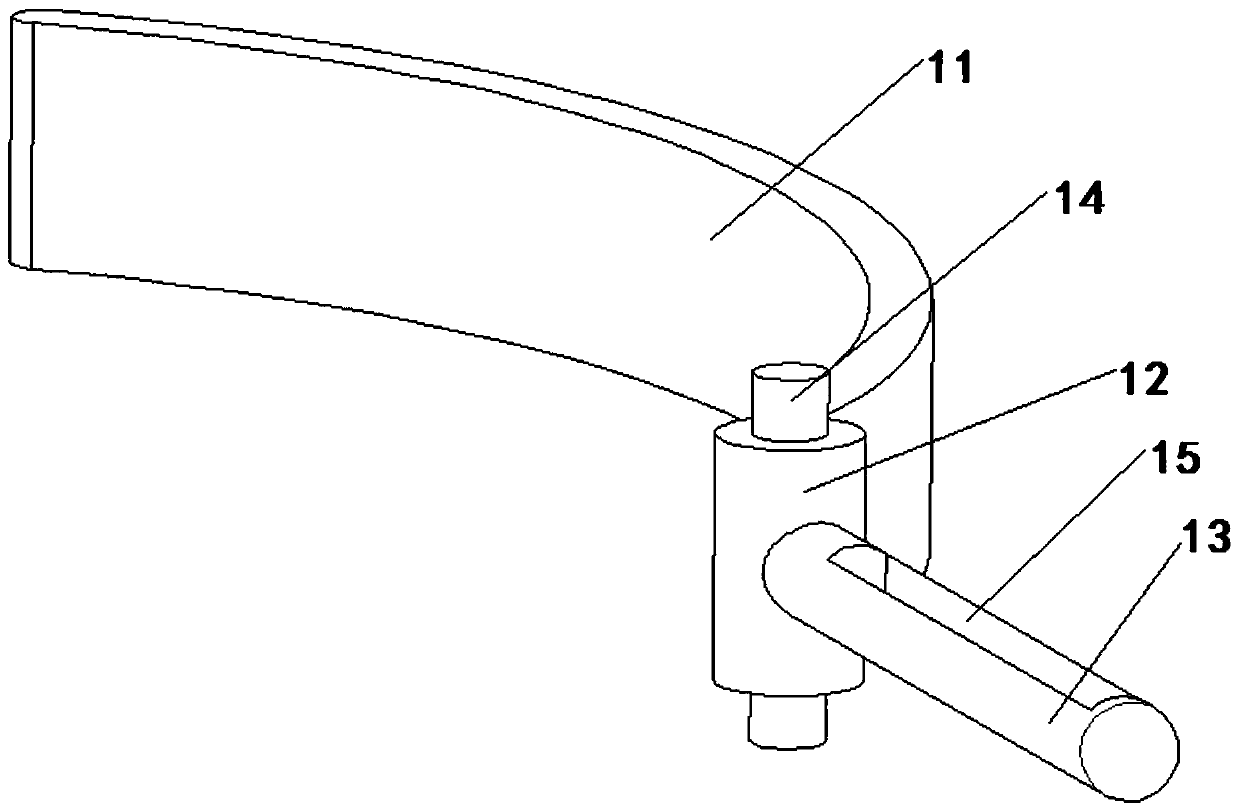

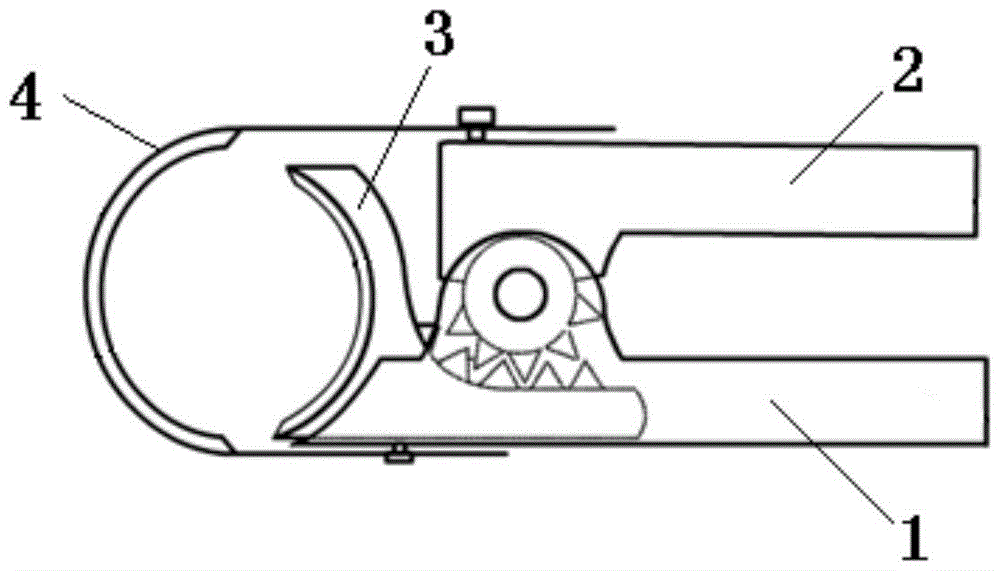

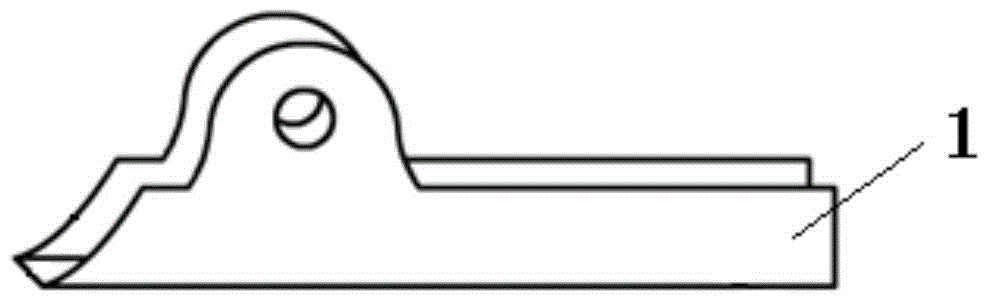

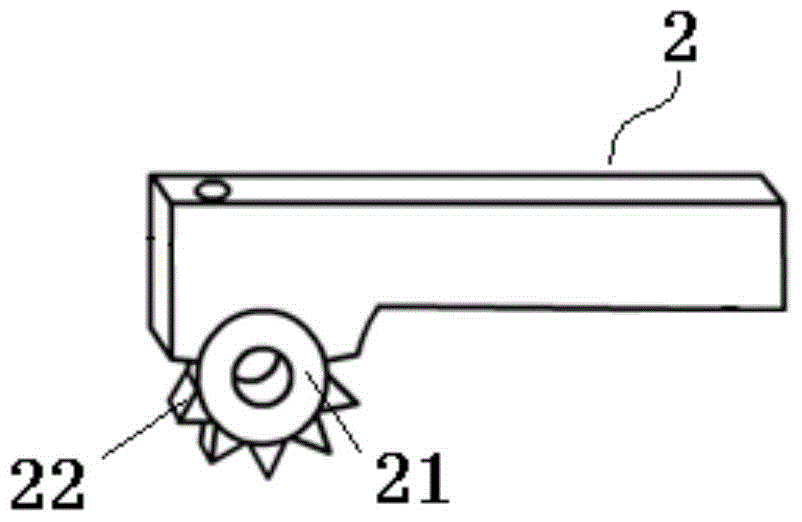

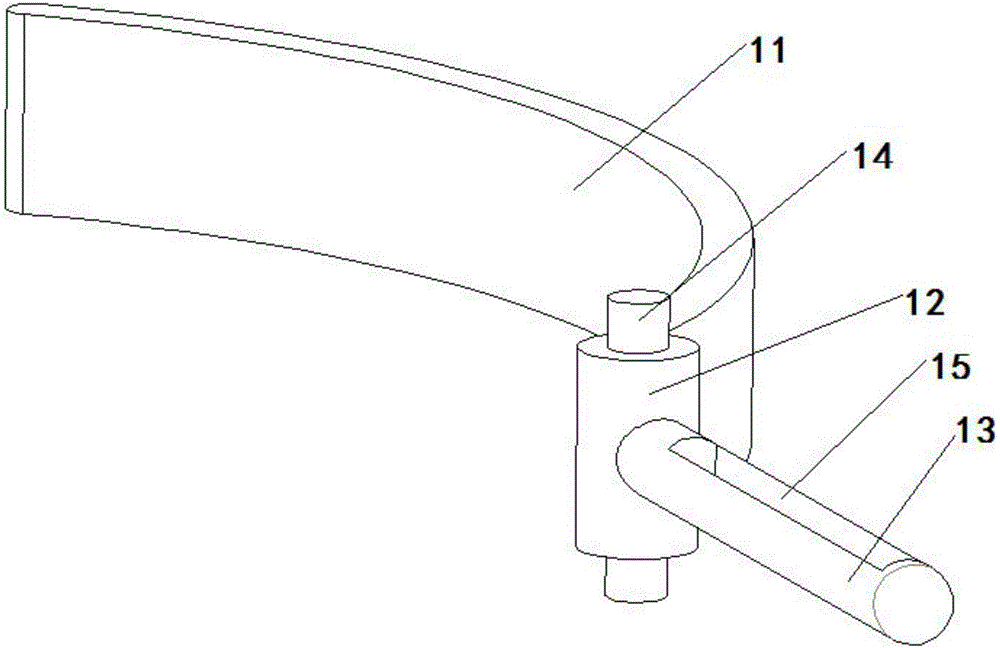

A cylinder valve wrench

The present invention relates to a steel cylinder valve wrench, and is characterized in that the steel cylinder valve wrench comprises a first handle and a second handle pivoted to the first handle; a pivot end of the second handle is provided with an annular part; an outer side of the annular part is uniformly provided with a plurality of first gear teeth along the circumferential direction; the first handle is provided with a chute for accommodating a clamping slide block; the clamping slide block comprises a straight segment and an arc segment integratedly disposed at one end of the straight segment; an opening direction of the arc segment departs from the pivot end; one side of the straight segment is provided with a plurality of gear teeth engaged with the first gear teeth; outer sides of the first handle and the second handle are commonly connected with a U-shaped clamping annular plate; and an opening of the clamping annular plate is arranged opposite to the opening of the arc segment of the clamping slide block. Due to the fact that the pivot end of the second handle is provided with the gear teeth, and the clamping slide block is provided with the gear teeth engaged with the gear teeth of the second handle, a steel cylinder valve can be clamped more firmly when the handles are held.

Owner:INST OF BOTANY CHINESE ACAD OF SCI

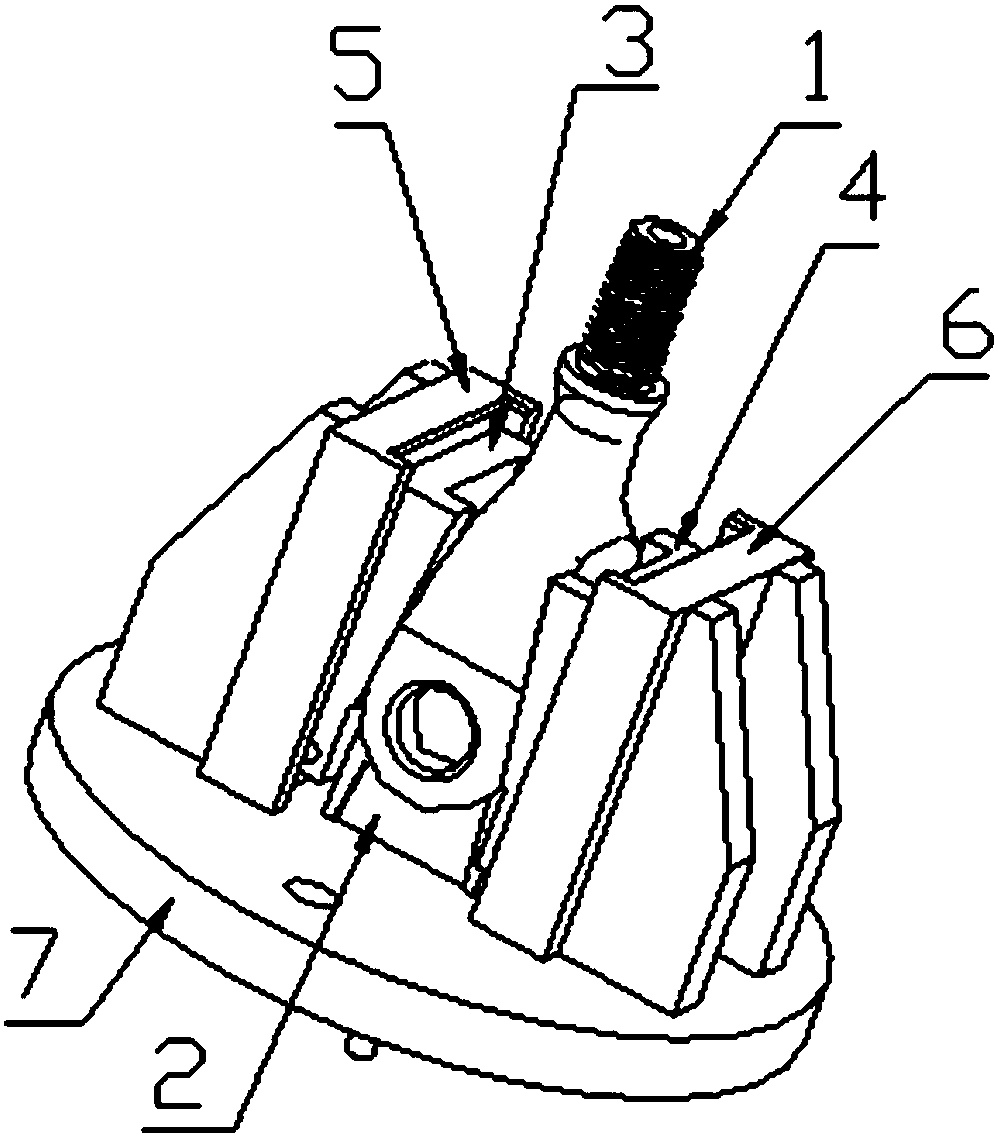

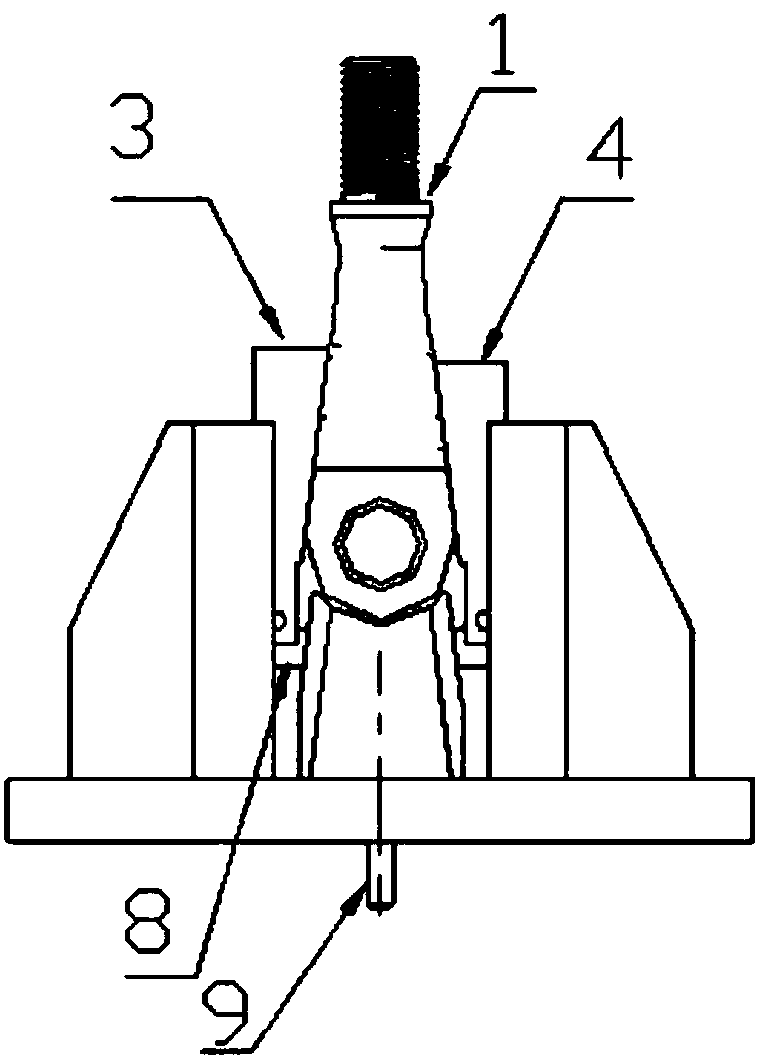

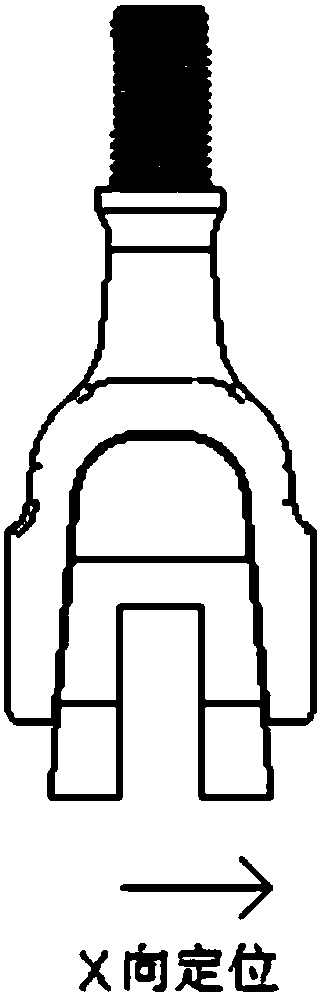

Automobile part turning tool

PendingCN108581573ALow costClamp firmlyPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention discloses an automobile part turning tool. The automobile part turning tool comprises a flange plate bottom plate, left and right slide blocks, a center automatic-aligning inclined supporting block, a slide block bracket, a slide supporting block, a pulling rod, a rotary shaft and a pin, wherein a screw hole is formed in a flange plate to lock with a numerical-control lathe main shaft; a hole for allowing the pulling rod to pass through is formed in the flange plate; the automatic-aligning inclined supporting block and the slide supporting block are fixedly arranged on the flangeplate; the slide block bracket is connected with a pulling rod movable joint; and the two ends of the bracket are connected with the left and right slide blocks through rotary shafts. The product appearance has symmetrical inclined surfaces, so that in the X direction, a product inner cavity has symmetrical inclined surfaces, and in a Y direction, the left and right slide blocks automatically align, position and clamp in the X direction; the center automatic-aligning inclined supporting block is automatically centered, aligned and positioned in the Y direction; and according to the back-off inclined surface in the X direction, a hydraulic pulling rod drives the left and right slide blocks to firmly lock the product on the Y-direction automatic aligning inclined support block through the slide block bracket, so that the automatic clamping purpose is realized.

Owner:SHIYAN HEJUN IND

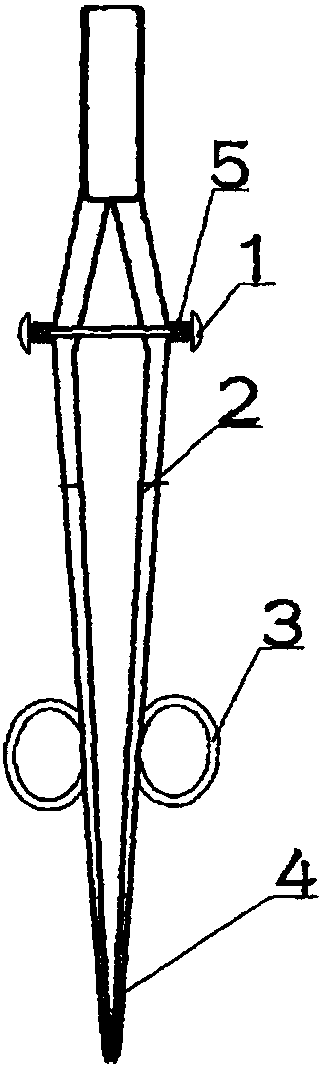

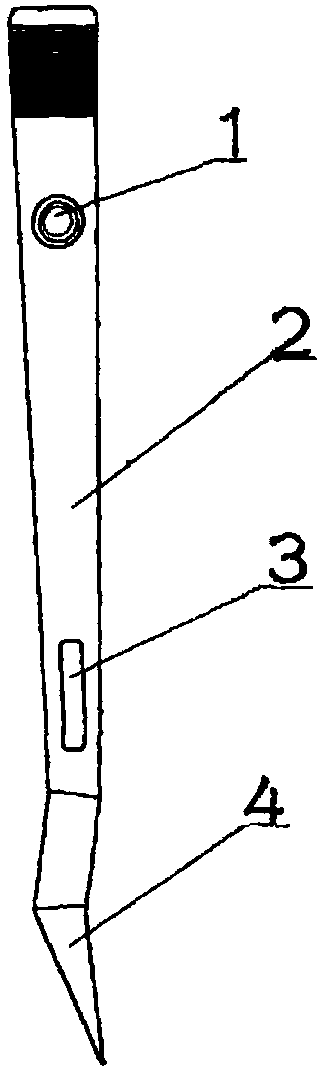

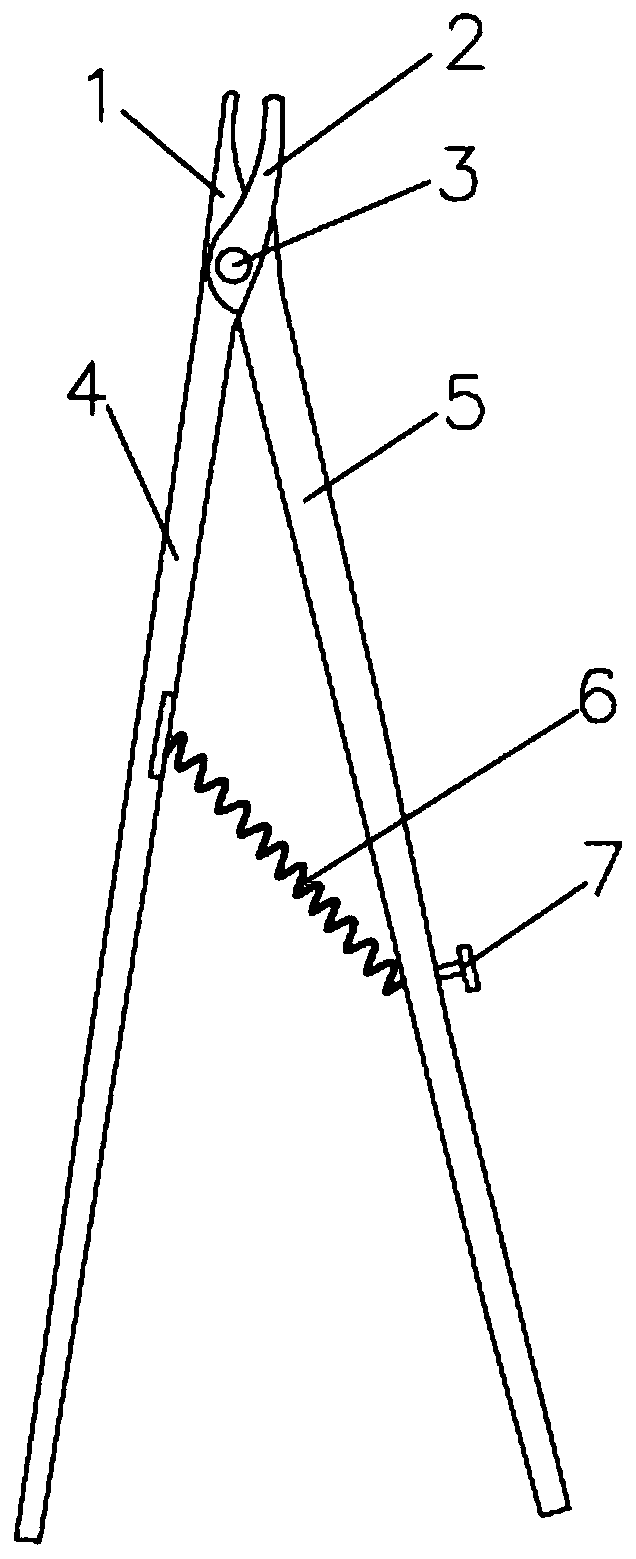

Dental tweezers

InactiveCN107714198ANo accidental injuryEffort-saving clampingTooth pincettesFinger flapDental forceps

The invention discloses a dental tweezers, comprising two tweezers flaps, the upper ends of the two tweezers flaps are connected as a whole, the upper part of the tweezers pierces the two tweezers flaps through a shaft pin, the two ends of the shaft pin are connected with nuts, and the connection between the nut and the tweezers flaps is Springs are arranged between them, and finger cots are respectively arranged at the lower parts of the two tweezers. The present invention is in a tightly closed state in a natural state, and will not accidentally injure patients. The two tweezers themselves have inward tension, which saves labor when clamping things. The structure is simple, easy to use, and easy to popularize.

Owner:黄杏玲

Lamp shade clamping device used for mounting landscape decoration street lamp

The invention discloses a lamp shade clamping device used for mounting a landscape decoration street lamp. The lamp shade clamping device used for mounting the landscape decoration street lamp comprises clamping boards, mounting seats, sliding devices, a handheld device and a pulling rope, and the clamping boards, the mounting seats, the sliding devices, the handheld device and the pulling rope are fixedly connected in sequence. Each clamping board comprises an arc board, a connecting pillar is fixed to one end of each arc board, and the two ends of each connecting pillar are provided with rotary blocks. A rotary shaft is fixed to the side surface of each connecting pillar, a bar-shaped sliding groove is formed in the side face of each rotary shaft, and each mounting seat comprises a connecting seat. A bar-shaped groove is formed in the top end of each connecting seat, and hinged seats are symmetrically arranged at the two ends of the side surface of each connecting seat. The hinged seats are connected to the clamping boards in a hinged mode, and a bar-shaped first through hole is formed in the surface where the hinged seats are located. According to the lamp shade clamping device used for mounting the landscape decoration street lamp, through the skillful structural combination of the clamping boards, the mounting seats, the sliding devices, the handheld device and the pulling rope, a street lamp shade can be effectively and fast clamped, and the working efficiency is improved since clamping operation is convenient and laborsaving. The handheld device directly controls the sliding devices to clamp the street lamp shade, so that the lamp shade clamping device used for mounting the landscape decoration street lamp has good practical value and high reliability.

Owner:华润建筑有限公司

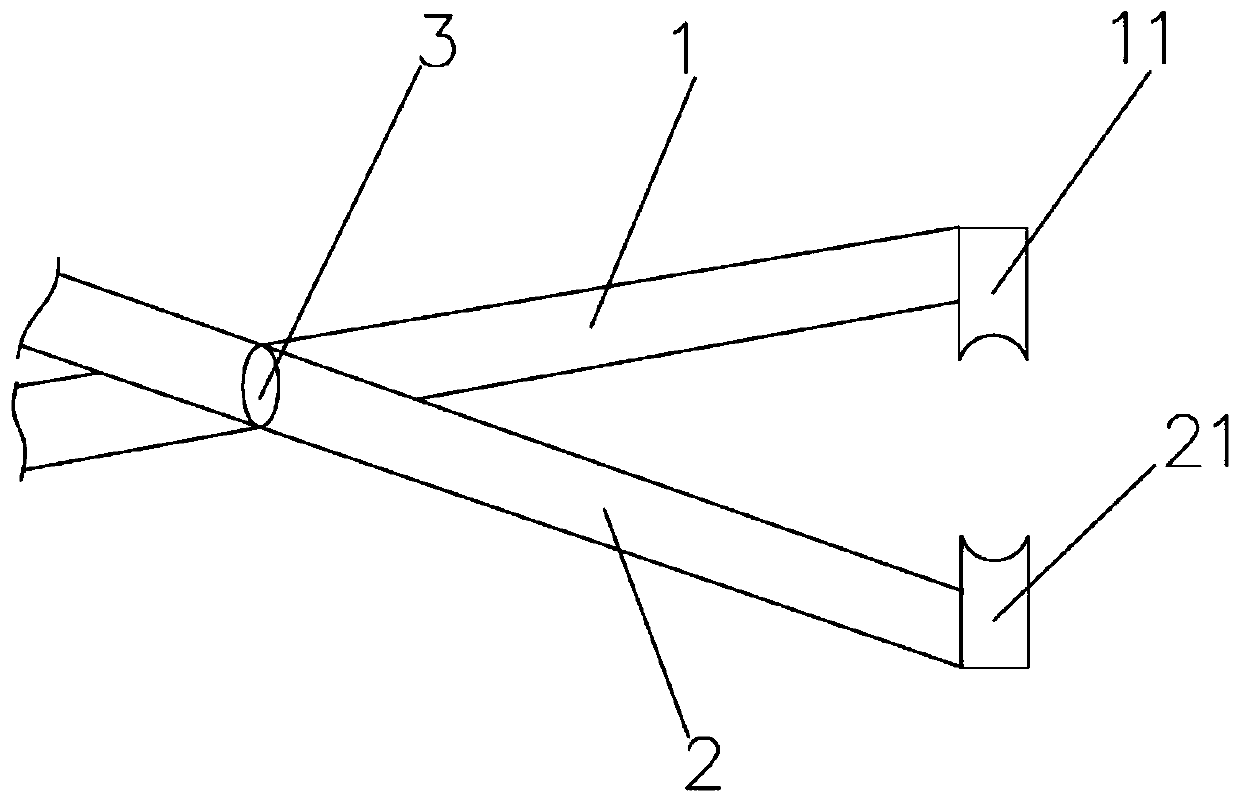

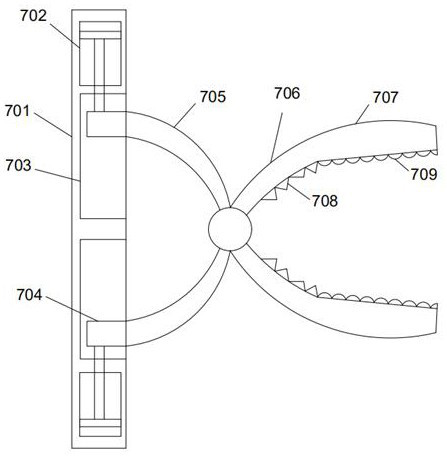

Peripheral iris microscopic nipper pliers for peripheral iridectomy of department of ophthalmology

PendingCN111249065AEffort-saving clampingConvenient operationEye surgerySurgical ManipulationEngineering

The invention provides peripheral iris microscopic nipper pliers for peripheral iridectomy of department of ophthalmology, and relates to the technical field of medical devices. The peripheral iris microscopic nipper pliers comprise a first tip end, a second tip end, a connecting part, a left handle, a right handle, a spring and a spring connecting part, wherein a first cutout is formed in the topend of the first tip end and is a curved sharp cutout, a second cutout is formed in the top end of the second tip end and is a curved shape cutout, the first tip end is connected with the upper end of the left handle, the second tip end is connected with the upper end of the right handle, the left handle and the right handle are hinged through the connecting part, one end of the spring is fixed to the right handle, the right handle is connected with the spring through the spring connecting part, and the other end of the spring is fixed to the left handle. After the technical scheme is adopted, the peripheral iris microscopic nipper pliers have the beneficial effects of being effortless in clamping, and convenient for surgery operations, and the peripheral iris microscopic nipper pliers have the advantages that the peripheral iris microscopic nipper pliers can be repeatedly used, and bleeding during pressurizing can be avoided.

Owner:XIAMEN EYE CENTER OF XIAMEN UNIVERSITY CO LTD

A universal multifunctional clamping device for digital products

ActiveCN109058732BEffort-saving clampingStand steadyFlexible article cleaningCleaning using toolsMechanical engineeringElectrical and Electronics engineering

Owner:束玲

Forging tool convenient for production and machining

InactiveCN111922277ARelieve fatigueEffort-saving clampingForging/hammering/pressing machinesEngineeringMachining

The invention discloses a forging tool convenient for production and machining, and belongs to the field of forging. The forging tool comprises a forging table and a sleeve, wherein a shielding plateis fixedly connected to the top of the left side of the forging table, a spherical cavity is formed in the middle of the left side of the shielding plate, the rod body of the sleeve is sleeved with aspherical hinge, and the spherical hinge is movably connected with the spherical cavity; and a movable rod is sleeved in the sleeve, a clamping device is fixedly connected to the right side of the movable rod, a connecting plate is fixedly connected to the left side of the movable rod, and a handle is fixedly connected to the left side of the connecting plate. By mounting the sleeve of a clampingdevice on the shielding plate, the high-temperature of a forging piece can be shielded, continuous lifting and clamping are not needed during use, the labor intensity of the arm is reduced, and the labor efficiency is indirectly improved; and moreover, the tool is flexible and convenient to use, clamping is labor-saving, the clamping effect is good, and the production efficiency and the forging quality are greatly improved.

Owner:孙金龙

Novel bench vice

InactiveCN104552046AImprove efficiencyEffort-saving clampingOther workshop equipmentVicesEngineeringMagnetism

The invention discloses a novel bench vice. The novel bench vice comprises a lead screw, a base, a switch, a separable nut, a scribing flat plate, a magnetic gauge stand, a bolt, a slide block and a movable handle. The novel bench vice is characterized in that the lead screw is connected with the separable nut through a thread; the separable nut is embedded into the slide block; the bolt is positioned at the elongation position of the separable nut; the magnetic gauge stand is arranged at a fixed jaw end; the switch is arranged at the top end of the magnetic gauge stand, and is used for controlling the magnetism of the magnetic gauge stand; the scribing flat plate is arranged at the extension positon of the bottom end of a movable jaw. By adopting the novel bench vice, the jaws can be opened and closed rapidly, the waste of labor force and time is reduced, workpieces are clamped more conveniently, the safety is enhance, the stability is high, the workpieces are fixed more firmly, the structure is simple, and the working efficiency is increased.

Owner:WUXI BODA ELECTRIC

large glass hanger

The invention discloses a large glass hanging bracket. The large glass hanging bracket comprises a planar bracket, a plurality of hook assemblies and a drive assembly; a plurality of hanging legs perpendicular to the planar bracket are arranged at the lower end of the planar bracket; the hook assemblies comprise hooks and installation parts and are separatelyinstalled at the upper end of the planar bracket, and the hooks are movably installed at the upper end of the planar bracket through the installation parts; the drive assembly comprises a hand wheel, a large chain, a plurality of small chains and chain wheels; the hand wheel is fixed to the planar bracket in a rotating mode and is connected to the large chain through the chain wheels in a transmission mode, the large chain and the small chains are fixed to the planar bracket through the chain wheels, the large chain is connected to the small chains in a transmission mode through the chain wheels, and the hooks are fixedly connected to the small chains and correspond to the small chains in a one-to-one mode. Because the hand wheel can sequentially drive the large chain and the small chains and finally drive the hooks to clamp glass simultaneously, workers can fast clamp the large glass in a labor-saving mode.

Owner:XINYI ENVIRONMENTAL PROTECTION SPECIAL GLASS JIANGMEN

Hydraulic clamping welding positioner for heavy parts

ActiveCN107931918BEasy to get on and offReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringProcess engineering

The invention discloses a heavy type part hydraulic clamping and welding positioner, and belongs to the field of engineering machinery. The positioner comprises an L-shaped welding positioner main structure, a clamp body and a transmission mechanism. The clamp body comprises a positioning shaft, a pressing block, a positioning base, a clamp body base and a rotary hydraulic oil cylinder. The rotaryhydraulic oil cylinder is fixed to the clamp body base and fixedly connected with the pressing block. The positioning shaft and the positioning base are fixed to the clamp body base respectively, andthe clamp body base is fixed to the L-shaped welding positioner main structure. According to the heavy type part hydraulic clamping and welding positioner, it is ensured that clamping is rapid, efficient and accurate and saves labor in the large workpiece welding process, the product welding efficiency is improved, the transmission mechanism simultaneously achieves the transmission function and the rotation function, and the transmission mechanism has the double functions of load transferring and hydraulic fluid transferring.

Owner:SHANDONG LINGONG CONSTR MACHINERY

A fixture for robot automatic welding

ActiveCN105598621BEasy to operateImprove welding qualityWelding/cutting auxillary devicesAuxillary welding devicesWall plateThin walled

The invention discloses a tool clamp used for robot automatic welding. The tool clamp comprises a separation plate tab positioning assembly (14), shaft hole positioning assemblies (6, 9), plane plate compression assemblies (2, 3, 5), curved plate compression assemblies (10, 11, 12), side wall plate compression assemblies (7, 8), a transverse beam assembly (13), back air protective jacking mechanisms (15, 16), jacking compression mechanisms (18, 19, 20), a middle separation frame assembling component (17) and auxiliary supports (1, 4), wherein the plane plate compression assemblies (2, 3, 5) and the curved plate compression assemblies (10, 11, 12) are located on the two sides of the middle part of the transverse beam assembly (13) respectively; the side wall plate compression assemblies (7, 8) are distributed on the two sides of the front end part of the transverse beam assembly (13); the shaft hole positioning assemblies (6, 9) are further distributed on the two sides of the front end part of the transverse beam assembly (13); and the separation plate tab positioning assembly (14) is distributed at the tail part of the transverse beam assembly (13). The invention provides an automatic welding tool which is simple to operate and efficient, aiming at certain complicated thin-wall welding parts; and the requirements on tool positioning precision and clamping efficiency by robot automatic welding are met.

Owner:JIANGXI HONGDU AVIATION IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com