A cylinder valve wrench

A cylinder valve, first-hand technology, applied in the field of cylinder valve wrench, can solve the problems of palm damage and difficult to twist, and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

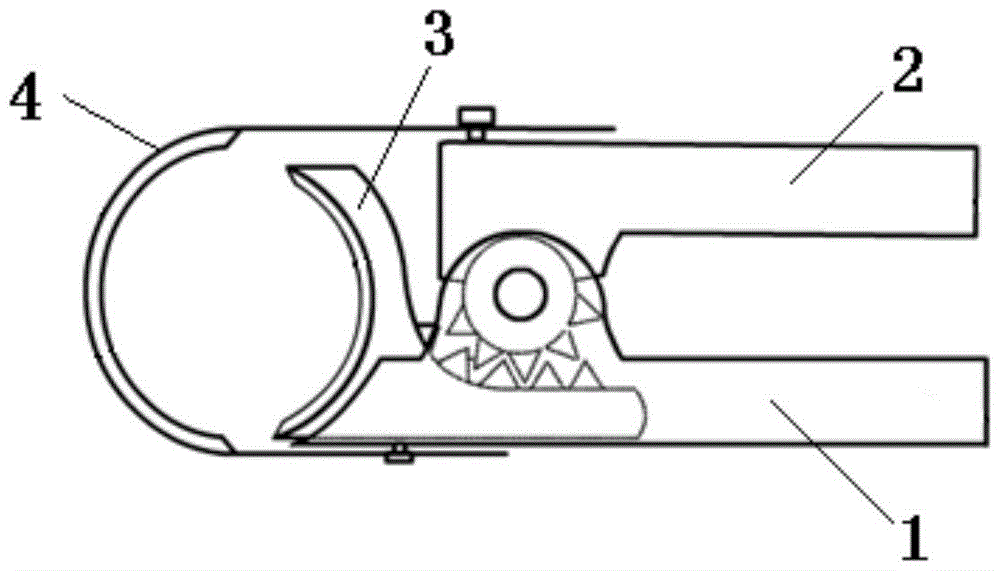

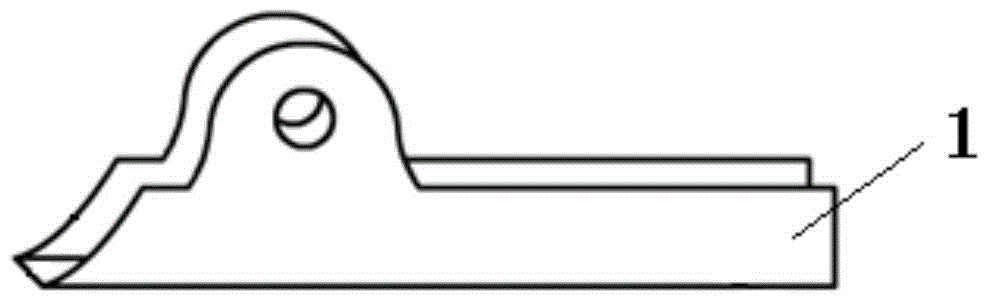

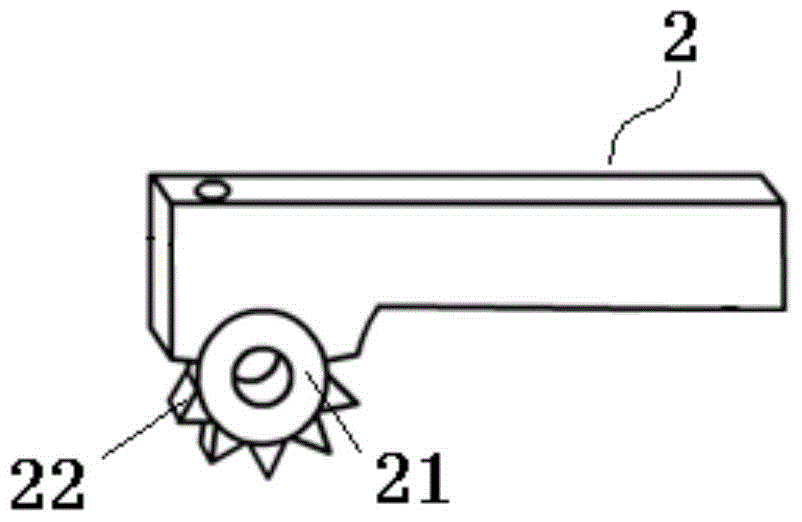

[0015] Such as figure 1 , figure 2 As shown, the present invention includes a first handle 1 and a second handle 2, and the first handle 1 and the second handle 2 are rotatably connected through a pivot shaft. At the pivotal end of the second handle 2, an annular part 21 (such as image 3 As shown), the outer side of the annular component 21 is evenly provided with a plurality of gear teeth 22 along the circumferential direction, and the inner hole of the annular component 21 is used for nesting the pivot shaft. A chute capable of accommodating the tightening slider 3 is provided on the first handle 1 .

[0016] Clamping slider 3 comprises a straight section 32 and an arc section 31 integrally arranged at one end of the straight section 32 (such as Figure 4 shown), wherein, the opening direction of the circular arc section 31 deviates from the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com