Turning fixture for clutch hub in automatic transmission of automobile

An automatic transmission and clutch technology, applied in the direction of the chuck, etc., can solve the problems that the clamping force of the spring chuck is not easy to control, the clamping and unloading parts are inconvenient, and the positioning accuracy of the clamping body is not high, so as to improve the positioning accuracy and process stability. The effect of ensuring the stability of processing, convenient clamping and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

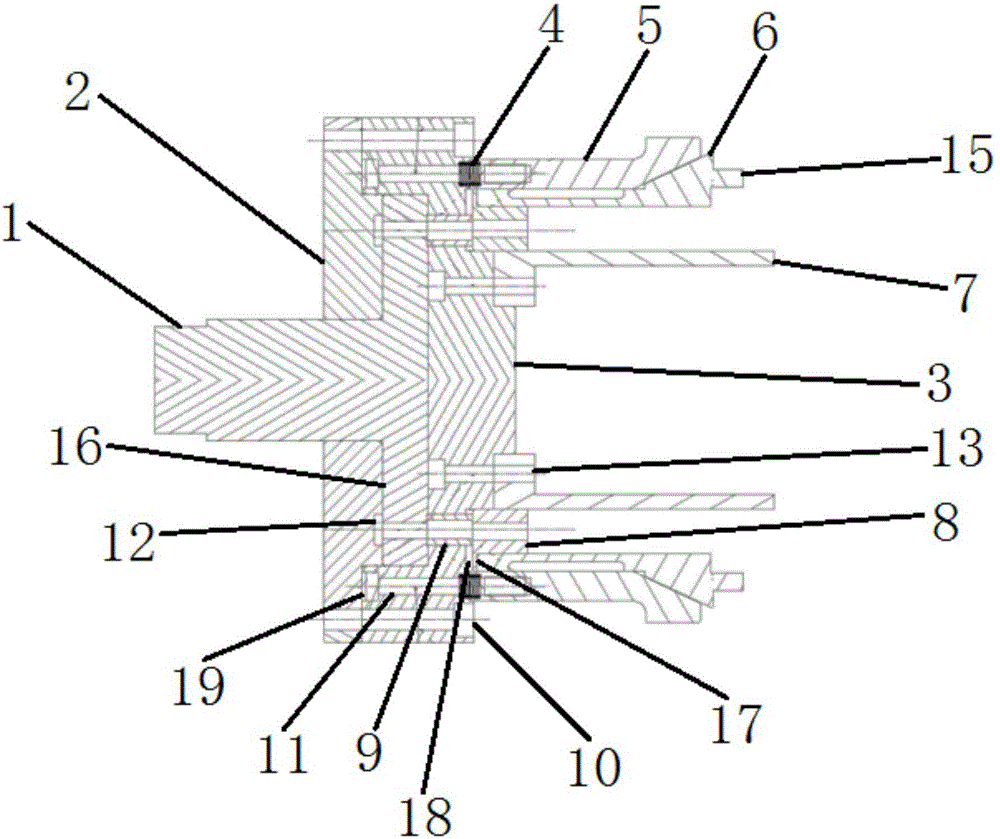

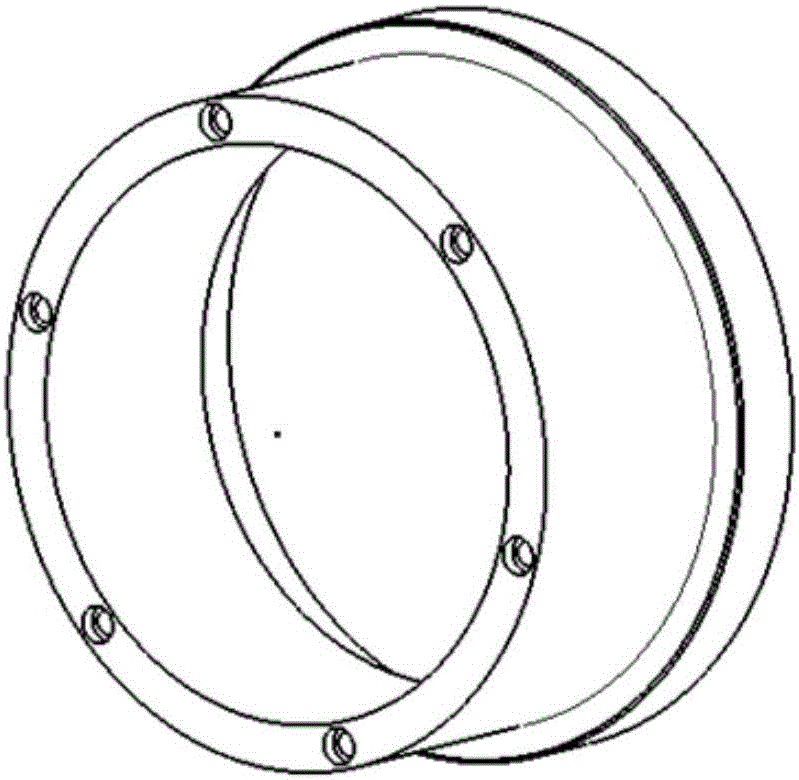

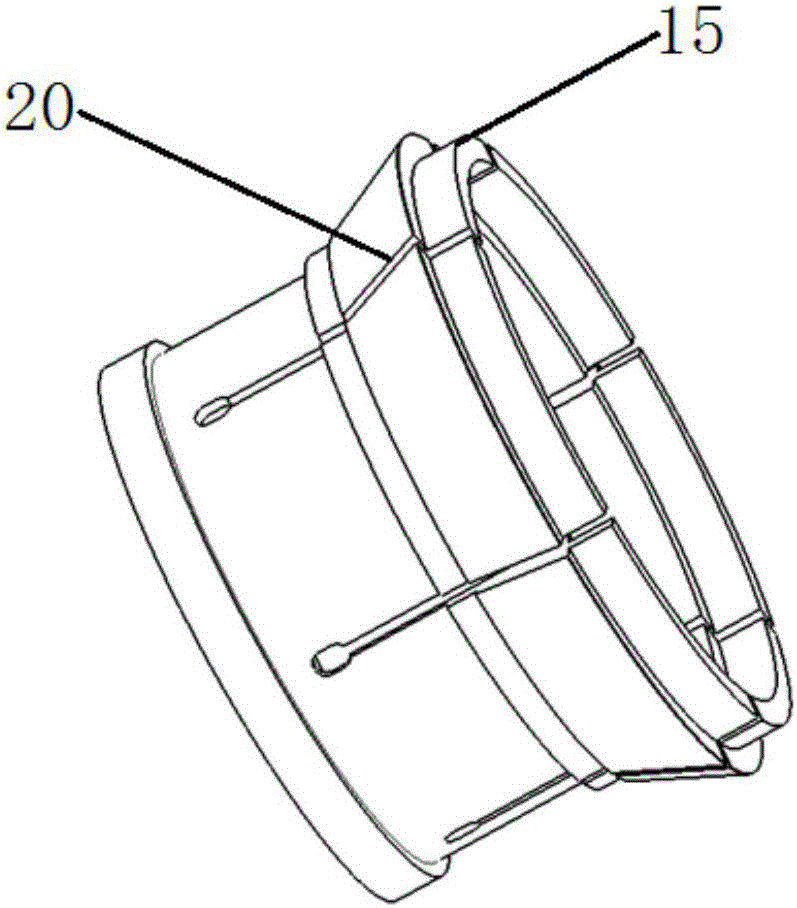

[0036] Such as figure 1 The clutch hub turning jig in the shown a kind of automobile automatic transmission comprises a jig support body, a positioning body 7 arranged at one end of the jig support body, and an elastic clamping mechanism arranged outside the positioning body 7. The elastic clamping mechanism includes a set The collet 6 outside the positioning body 7 and the housing 5 that is sleeved outside the collet 6 and adapted to the collet 6, a first elastic component is arranged between the collet 6 and the clamp support body, A second elastic assembly is provided between the housing 5 and the fixture support body, the clutch hub 14 is placed inside the collet 6, the positioning body 7 axially positions the clutch hub 14, and the housing 5 presses the collet 6 inwardly. , fix the clutch hub 14 on the fixture.

[0037] Wherein, the clamp supporting body includes a pull rod 1, a base 2 and a clip body 3, one end of the pull rod 1 is provided with a pull rod flange 16, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com